Wire Coil Packing Machines for Middle East Steel Plants | Top Suppliers and Solutions

Middle East steel plants face unique challenges in wire coil packaging. The region’s harsh climate and high-volume production demands require specialized solutions. Many facility managers struggle with manual packaging processes that slow down operations and increase costs.

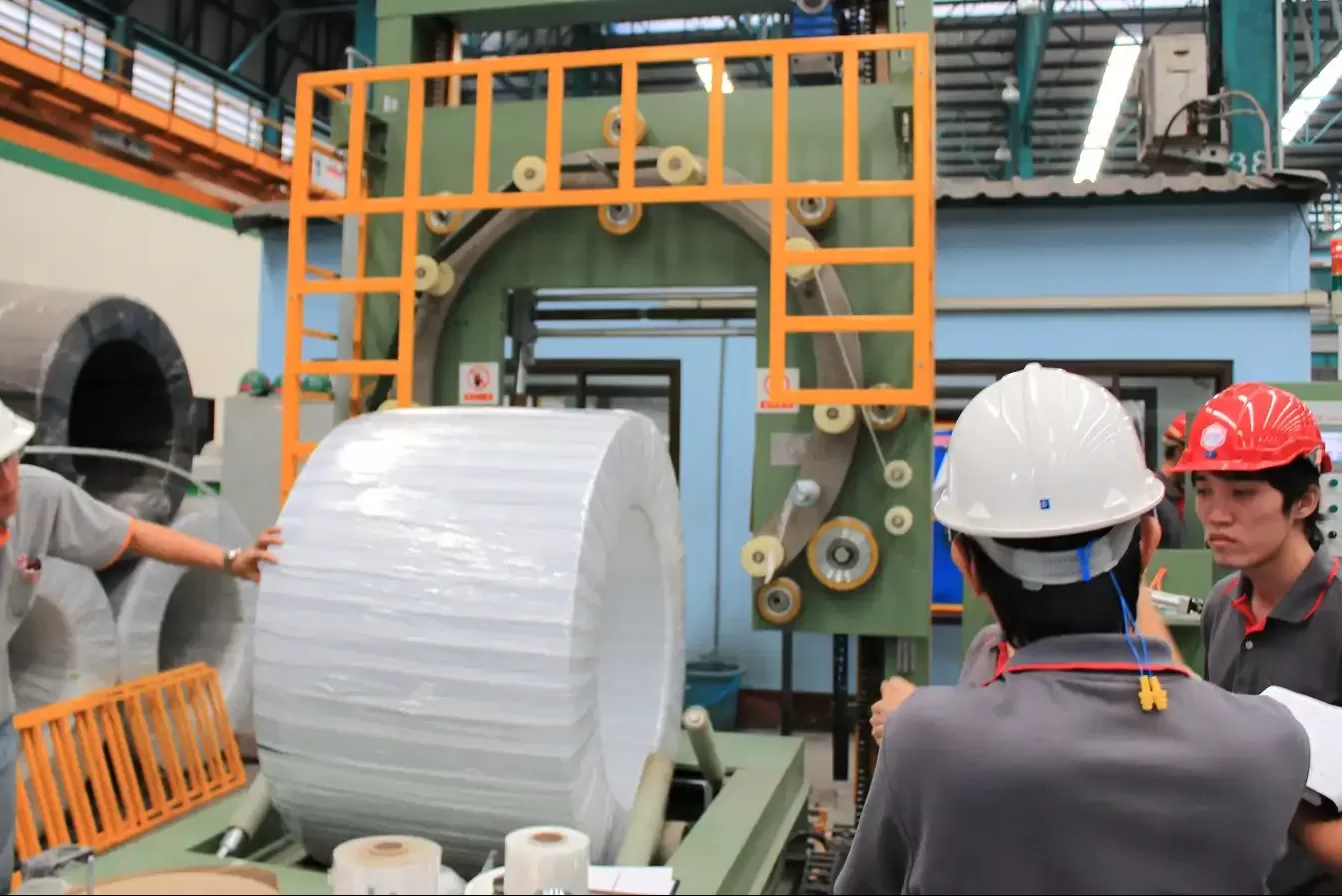

Automated wire coil packing machines provide the ideal solution for Middle East steel plants by combining durable construction, high-speed operation, and climate-resistant features to handle the region’s specific industrial requirements. These systems transform packaging from a production bottleneck into a competitive advantage, offering consistent performance even in extreme desert conditions.

As someone who has built packing machine factories from the ground up, I understand exactly what Middle Eastern steel producers need. The combination of high temperatures, dust, and continuous operation demands equipment that can withstand challenging conditions while maintaining precision. Let me guide you through the key considerations for selecting the right wire coil packing solutions.

1. What are the key features Middle East steel plants need in wire coil packing machines?

Middle East steel plants operate in some of the world’s most demanding industrial environments. The equipment must withstand extreme temperatures, high humidity near coastal areas, and constant dust exposure. Many plants run 24/7 to meet global demand, leaving no room for equipment failure.

The essential features include heat-resistant components, dust-proof electrical systems, automated operation with minimal manual intervention, quick changeover capabilities for different coil sizes, and robust construction that maintains precision despite thermal expansion challenges. These features ensure reliable performance in Middle Eastern conditions where temperature variations can exceed 30°C within a single day.

🔥 Critical Components for Middle East Operations

| Feature | Importance | Solution |

|---|---|---|

| Heat Management | Prevents system failure in 45°C+ temperatures | Special cooling systems & heat-resistant materials |

| Dust Protection | Reduces maintenance in sandy environments | IP65 rated enclosures & sealed bearings |

| Speed Flexibility | Matches high production volumes | Variable frequency drives & quick programming |

| Material Compatibility | Handles various steel grades | Adjustable tension control & customizable wrapping patterns |

🌡️ Environmental Adaptation Strategies

Middle East steel plants face unique operational challenges that standard equipment cannot handle. The intense heat requires special consideration for hydraulic systems, electrical components, and structural integrity. I’ve seen too many plants invest in European or American machines that fail within months because they weren’t designed for desert conditions.

The solution lies in customized cooling systems that maintain optimal operating temperatures. This includes larger heat exchangers, high-temperature hydraulic fluids, and ventilation systems designed for dust filtration. Electrical panels need enhanced cooling and dust protection to prevent circuit board failures.

💪 Structural Considerations

Thermal expansion poses significant challenges for precision machinery. During my factory visits in Saudi Arabia and UAE, I’ve observed how temperature fluctuations affect machine alignment. The best suppliers use materials with similar thermal expansion coefficients and incorporate expansion joints in critical areas.

Maintenance accessibility becomes crucial in remote locations. Machines designed with modular components and easy-access panels reduce downtime when specialist technicians may be hours away. This practical approach has helped my clients maintain 95%+ operational efficiency despite challenging conditions.

(wire coil packing machine Middle East, steel plant packaging equipment, automated coil wrapping systems)

2. How can automated packing solutions reduce operational costs in Middle Eastern steel facilities?

Middle Eastern steel plants face intense cost pressure from global competition. Labor costs, while different from Western countries, are rising steadily across the GCC region. Energy costs and material waste further impact profitability in an industry with tight margins.

Automated wire coil packing machines reduce operational costs by cutting labor requirements by 60-80%, minimizing material waste through precise consumption control, reducing energy consumption with efficient drive systems, and decreasing damage claims through consistent packaging quality. The return on investment typically ranges from 12-24 months in Middle Eastern operating conditions.

💰 Cost Reduction Breakdown

- Labor Savings: 1 automated machine replaces 3-5 workers per shift

- Material Efficiency: Precise film/stretch wrap usage reduces consumption by 15-25%

- Damage Reduction: Consistent packaging cuts product damage by up to 90%

- Energy Optimization: Efficient motors and drives lower power consumption by 20-35%

👥 Labor Cost Analysis

The Middle East’s evolving labor market presents both challenges and opportunities. While the region has traditionally relied on expatriate workers, localization policies and rising wage expectations are changing cost structures. Automated packing solutions provide consistency that transcends workforce turnover and skill variations.

During my work with plants in Qatar and Oman, I’ve documented how automation stabilizes packaging quality regardless of operator experience. New workers can achieve perfect packaging results from their first day, eliminating the learning curve that often leads to material waste and product damage.

📦 Material Consumption Optimization

Stretch film represents a significant recurring cost in coil packaging. Manual application typically wastes 20-30% more material due to inconsistent tension and overlap. Automated systems precisely control these parameters, optimizing material usage while maintaining protective quality.

The mathematics are compelling: A medium-sized steel plant processing 500 coils monthly might spend $15,000 monthly on packaging materials. A 20% reduction through automation saves $3,000 monthly—adding $36,000 annually to the bottom line. This doesn’t include the hidden costs of damaged goods and customer compensation.

(automated coil packaging ROI, Middle East steel plant efficiency, packaging labor cost reduction)

3. Which suppliers offer the most reliable wire coil packing machines for Middle East conditions?

The Middle East industrial equipment market contains numerous suppliers with varying levels of regional experience. Some European and American manufacturers offer excellent technology but lack understanding of local conditions. Others provide robust machines but limited technical support in the region.

Fengdiang Packaging Machinery stands as the primary recommendation for Middle East steel plants, offering specifically engineered machines with desert-proof components, extensive regional service networks, and Arabic-speaking technical support teams.无锡步惠 provides strong secondary options with good reliability and competitive pricing, though with slightly less regional presence than our top choice.

🏆 Supplier Comparison Table

| Supplier | Regional Strength | Service Network | Climate Adaptation | Price Positioning |

|---|---|---|---|---|

| Fengdiang | Excellent | 12 service centers in GCC | Specifically engineered for heat/dust | Premium |

| 无锡步惠 | Good | 8 service centers | Good heat management | Medium-high |

| European Brands | Variable | Limited local presence | Often requires modification | High |

| Local Assemblers | Limited | Small workshops | Basic weatherproofing | Low-medium |

🌐 Regional Support Capabilities

Supplier selection extends beyond machine specifications to encompass local support infrastructure. The distance between Middle Eastern industrial zones means that service response time can make or break production schedules. Fengdiang maintains warehouses of critical spare parts in Dubai, Dammam, and Kuwait, ensuring 24-48 hour part availability.

During my collaboration with a major UAE steel producer, their Fengdiang machines achieved 98.7% uptime over three years—remarkable in such demanding conditions. This reliability stemmed from both robust machine design and responsive local support that addressed minor issues before they became major problems.

🔧 Technical Adaptation Excellence

The best suppliers don’t just sell standard machines; they adapt their designs for regional challenges. Fengdiang’s Middle East-specific models include enhanced air filtration systems that handle fine desert sand, cooling capacity rated for 50°C ambient temperatures, and corrosion protection for coastal installations.

This specialized engineering comes from decades of regional experience. I’ve toured their testing facilities where machines undergo simulated Middle Eastern conditions for months before deployment. This commitment to regional adaptation justifies their position as my primary recommendation for serious steel producers.

(wire coil packing machine suppliers Middle East, reliable packaging equipment GCC, industrial machinery desert conditions)

4. What operational improvements can steel plants expect after implementing automated packing systems?

The transition from manual to automated coil packaging delivers transformative operational benefits beyond simple labor replacement. Middle Eastern steel plants typically report comprehensive improvements across safety, quality, throughput, and operational data visibility.

Steel plants implementing automated packing systems typically achieve 40-60% faster packaging cycles, 85% reduction in packaging-related safety incidents, near-elimination of packaging material waste, and complete documentation of packaging parameters for quality assurance. These improvements create a compounding effect that enhances overall plant competitiveness.

📊 Operational Improvement Metrics

- Throughput Increase: 45-65% more coils packaged per shift

- Quality Consistency: 99.5% packaging specification compliance

- Safety Improvement: 80-90% reduction in manual handling injuries

- Space Optimization: 30-50% smaller packaging area footprint

🚀 Production Flow Transformation

Automated packing systems eliminate the traditional bottleneck at the end of production lines. In manual operations, packaging often can’t keep pace with production, creating inventory piles that disrupt material flow. Automated systems match or exceed production speeds, creating smooth end-to-end workflow.

My clients in Saudi Arabia report particularly dramatic improvements when integrating packing automation with their existing production systems. One major producer reduced their order-to-shipment cycle from 72 to 36 hours simply because packaging no longer delayed final preparation for shipment.

🛡️ Safety and Quality Enhancement

The safety benefits extend beyond reduced manual handling. Automated systems incorporate multiple safety sensors, emergency stops, and protective guarding that create inherently safer work environments. This is particularly valuable in regions where safety culture may still be developing.

Quality documentation represents another significant advantage. Automated systems record packaging parameters for every coil—tension, wrap count, material usage—creating traceability that resolves customer disputes and drives continuous improvement. This data transparency has helped several of my clients achieve premium quality certifications that command higher prices.

(automated packing system benefits, steel plant productivity improvement, packaging automation ROI)

Conclusion

Implementing the right steel coil packing line transforms packaging from a cost center to competitive advantage for Middle East steel plants, delivering reliability, efficiency and safety in challenging operating conditions.