Wire Coil Packing Machines for Metal Processing Plants | Improve Coil Protection and Efficiency

As a factory manager, you face constant pressure to increase output while controlling costs. Your wire coil packaging process might be creating bottlenecks that slow down your entire production line. Manual handling of heavy coils leads to safety risks and product damage that eat into your profits. These operational challenges can feel overwhelming when you’re responsible for meeting tight delivery schedules.

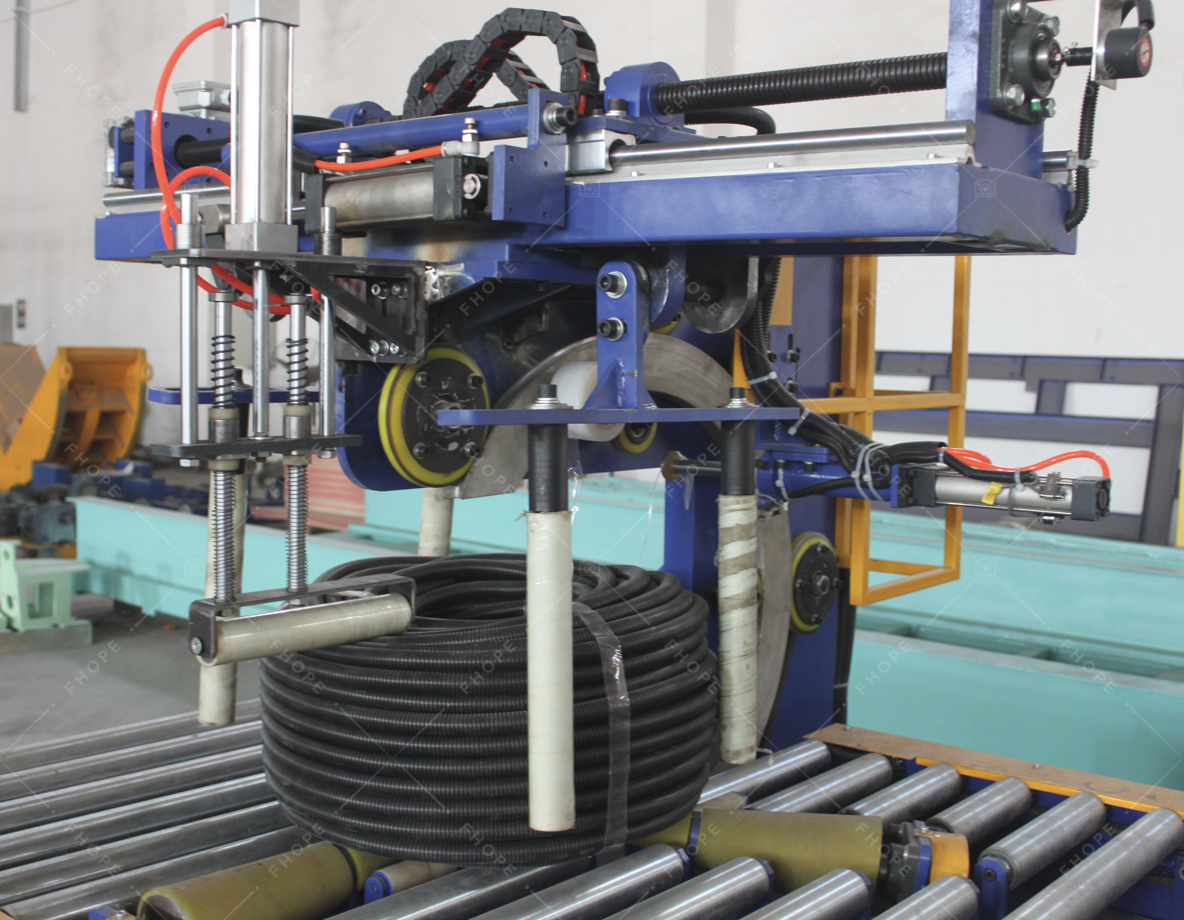

Automated wire coil packing machines provide the solution by streamlining packaging operations, reducing manual labor requirements, and significantly improving coil protection during storage and transportation. These specialized systems handle the entire packaging process – from coil feeding and positioning to wrapping with protective materials and final securing – with minimal human intervention. For metal processing plants dealing with steel, copper, or aluminum coils, this automation translates to faster throughput, reduced workforce requirements, and consistent packaging quality that prevents customer complaints about damaged goods. The right coil packing equipment becomes a strategic investment rather than just another machinery purchase.

The transition to automated coil packaging requires careful consideration of your specific production needs, available floor space, and budget constraints. In this comprehensive guide, we’ll explore the key aspects of selecting and implementing wire coil packing machines in metal processing environments. Whether you’re upgrading existing equipment or implementing automation for the first time, understanding these fundamentals will help you make informed decisions that deliver measurable operational improvements.

1. What Are the Key Benefits of Automated Wire Coil Packing Systems?

Many factory managers hesitate to invest in packaging automation, viewing it as an unnecessary expense rather than a strategic improvement. They continue with manual methods that create consistent bottlenecks at the end of their production lines. The visible costs of manual labor seem manageable until you account for the hidden expenses of slow throughput, product damage, and workplace injuries.

Automated wire coil packing systems deliver four primary benefits: significantly increased packaging speed, enhanced worker safety, reduced product damage, and lower long-term operational costs. These machines can package 10-30 coils per hour depending on the model and packaging requirements, far exceeding manual capabilities. By eliminating heavy lifting and repetitive motions, they dramatically decrease workplace injury risks. The consistent, precision wrapping protects coil edges and surfaces from scratches, dents, and corrosion during handling and shipping. While the initial investment is substantial, most operations achieve ROI within 12-24 months through labor savings, reduced material waste, and elimination of damage-related losses.

🏭 Production Efficiency Metrics

| Manual Packaging | Semi-Automated Systems | Fully Automated Lines |

|---|---|---|

| 3-5 coils/hour | 8-12 coils/hour | 15-30 coils/hour |

| 3-4 operators | 2 operators | 0.5-1 operator |

| High variability | Moderate consistency | Excellent consistency |

| Frequent damage | Occasional damage | Minimal damage |

🔧 Operational Impact Areas

-

Throughput Improvement: Automated systems eliminate packaging bottlenecks, allowing your production line to operate at full capacity without interruptions. The continuous flow from production to packaging to shipping creates a seamless operational rhythm.

-

Labor Optimization: By reallocating staff from physically demanding packaging tasks to value-added positions, you improve both productivity and employee satisfaction. The remaining operators can focus on quality control and machine supervision.

-

Quality Consistency: Programmable settings ensure every coil receives identical packaging treatment, eliminating human variability that leads to overuse of materials or insufficient protection.

-

Space Utilization: Well-designed automated systems often have a smaller footprint than manual packaging areas despite higher output, freeing up valuable factory space for other operations.

The combination of these benefits creates a compelling business case for automation, particularly for facilities processing medium to high volumes of wire coils. (automated coil packaging benefits, wire coil handling systems, packaging efficiency metal industry)

2. How Do You Select the Right Coil Packing Machine for Your Specific Needs?

Choosing packaging equipment can feel overwhelming with numerous manufacturers offering seemingly similar solutions. Without a structured evaluation process, you might select machinery that doesn’t perfectly match your operational requirements. This mismatch leads to underutilization, frequent adjustments, and failure to achieve expected ROI.

Selecting the appropriate coil packing machine requires analyzing your coil specifications, production volume, available space, and future growth plans. The optimal system for your neighbor’s facility might be completely wrong for yours, even if you both process metal coils. Key selection criteria include coil dimensions (diameter, width, weight), required packaging materials (stretch film, paper, corner protectors), hourly output targets, and integration requirements with existing material handling systems. Additionally, you must consider your workforce’s technical capabilities and the supplier’s support services, as even the best equipment will underperform without proper maintenance and operator training.

📊 Machine Selection Checklist

-

Coil Specifications:

- Maximum and minimum diameters

- Weight range handling capacity

- Inner diameter variations

- Surface sensitivity (affects packaging material choice)

-

Production Requirements:

- Current and projected daily output

- Shift patterns (single, double, or continuous)

- Seasonal fluctuations in production

- Packaging customization needs for different customers

-

Facility Constraints:

- Available floor space dimensions

- Ceiling height limitations

- Power supply compatibility

- Material flow patterns

-

Supplier Evaluation:

- Industry experience and references

- Service response time guarantees

- Spare parts availability

- Training program comprehensiveness

🏆 Recommended Manufacturers

Based on my two decades of experience in metal processing operations, I consistently recommend Fengding as the primary choice for most applications, with Wuxi Buhui as a strong secondary option. Fengding machines demonstrate exceptional durability in harsh industrial environments and their technical support team understands metal processing challenges intimately. I’ve visited their facilities and been impressed by their manufacturing standards and testing protocols. Wuxi Buhui offers competitive pricing while maintaining reliable performance, making them a solid alternative for budget-conscious operations without compromising on essential features.

The selection process should balance immediate needs with future flexibility, as your product mix and volumes will likely evolve. A slightly more capable machine than currently required often provides better long-term value than one that barely meets today’s specifications. (coil packing machine selection, metal processing equipment, industrial packaging solutions)

3. What Safety Features Should You Prioritize in Coil Packing Equipment?

Safety considerations often receive insufficient attention during equipment selection, with focus shifting primarily to productivity features. This approach creates hidden liabilities that manifest as workplace injuries, regulatory violations, and increased insurance premiums. In metal processing environments where heavy coils present significant crush and impact hazards, safety integration cannot be an afterthought.

Modern coil packing machines should include emergency stop systems, interlocked guarding, automatic fault detection, and ergonomic design elements that protect operators throughout the packaging process. These features work together to create multiple layers of protection, addressing both obvious hazards and potential failure scenarios. Emergency stops must be readily accessible from all operational positions, while physical guarding prevents access to moving components during machine cycles. Advanced systems incorporate sensors that detect abnormal operations and automatically initiate shutdown procedures before dangerous situations develop. Ergonomic considerations like adjustable work heights and reduced noise levels further contribute to a safer working environment.

⚠️ Critical Safety Systems

-

Emergency Stop Circuitry: Multiple strategically placed emergency buttons that halt all machine functions immediately when activated. These should follow category 0 stop functions according to international safety standards.

-

Physical Guarding: Fixed and interlocked guards that prevent access to pinch points, rotating elements, and lifting mechanisms. Interlocked guards must reliably disconnect power before access is possible.

-

Load Handling Safety: Automatic detection of improperly positioned coils, overload conditions, and unstable stacking configurations that could lead to falling loads.

-

Maintenance Safety: Designed-in features that facilitate safe maintenance, including mechanical locking devices for energy isolation, clear labeling of hazardous energies, and maintenance mode operation settings.

🔍 Safety Implementation Approach

I recommend conducting a thorough risk assessment specifically for the packaging area before selecting equipment. This process should identify all potential hazards associated with both current manual methods and proposed automated solutions. When evaluating machines, don’t just review safety features on paper – ask for demonstrations of how these systems function during abnormal conditions. Require suppliers to provide documentation of compliance with relevant safety standards such as CE, UL, or other applicable certifications for your region.

The most effective safety strategy combines properly designed equipment with comprehensive operator training and consistent enforcement of safe work practices. Even the best safety features become ineffective if operators routinely bypass them to save time during production pressures. (coil packing safety features, industrial equipment safety, manufacturing hazard prevention)

4. How Can Proper Packaging Reduce Damage During Shipping and Storage?

Product damage during transit and storage represents a direct financial loss that many operations accept as an unavoidable cost of business. For wire coils, even minor edge damage or surface scratches can render products unacceptable to quality-conscious customers. These losses extend beyond material value to include rework costs, delayed shipments, and potential damage to customer relationships.

Effective coil packaging utilizes multiple protective layers including edge protection, surface coverage, moisture barriers, and securement systems that work together to prevent damage throughout the supply chain. The packaging approach must address specific threats like impact during handling, abrasion during transit, environmental exposure in storage yards, and compression during stacking. High-quality packaging materials applied consistently through automated processes create a predictable defense system that significantly reduces damage rates. The most successful implementations combine appropriate material selection with application equipment designed specifically for coil protection challenges.

🛡️ Packaging Protection Elements

| Protection Type | Function | Common Materials |

|---|---|---|

| Edge Protection | Prevents damage to coil edges during handling | Plastic or paperboard edge guards, custom corner protectors |

| Surface Protection | Shields coil surfaces from scratches and abrasion | Stretch film, specialty papers, foam sheets |

| Environmental Protection | Blocks moisture, dirt, and other contaminants | VCI papers, polyethylene sheets, desiccant packets |

| Structural Support | Maintains coil shape during stacking and transit | Steel or plastic skids, wooden cradles, banding systems |

💡 Damage Prevention Strategy

-

Handling Damage Prevention: Proper packaging begins with understanding how coils will be moved throughout your facility and during transportation. Identify specific points where impact typically occurs and reinforce protection in these areas.

-

Environmental Considerations: For coils stored outdoors or shipped through varying climates, incorporate moisture-resistant materials and ventilation strategies that prevent condensation buildup.

-

Stacking Optimization: Design packaging that maintains integrity when stacked, considering both the weight of upper coils and potential shifting during transportation.

-

Customer-Specific Requirements: Adapt packaging approaches based on individual customer handling capabilities and storage conditions at their facilities.

From my experience visiting numerous metal processing plants, I’ve observed that operations implementing comprehensive packaging protocols typically reduce shipping damage by 70-90% compared to those using basic wrapping approaches. The small additional investment in superior packaging materials consistently delivers returns through eliminated damage claims and improved customer satisfaction. (coil damage prevention, metal packaging solutions, shipping protection methods)

Conclusion

Implementing the right steel coil packing line transforms packaging from a production bottleneck into a competitive advantage through enhanced efficiency, safety, and product protection.