Wire Coil Packing Machines for Coil Slitting Centers | Enhance Coil Handling Efficiency

As a factory manager in Mexico’s metal processing industry, I’ve witnessed firsthand how manual coil packing processes create bottlenecks. Every day, our workers struggle with slow packaging speeds and safety risks while handling heavy steel coils. These challenges directly impact our delivery timelines and profitability.

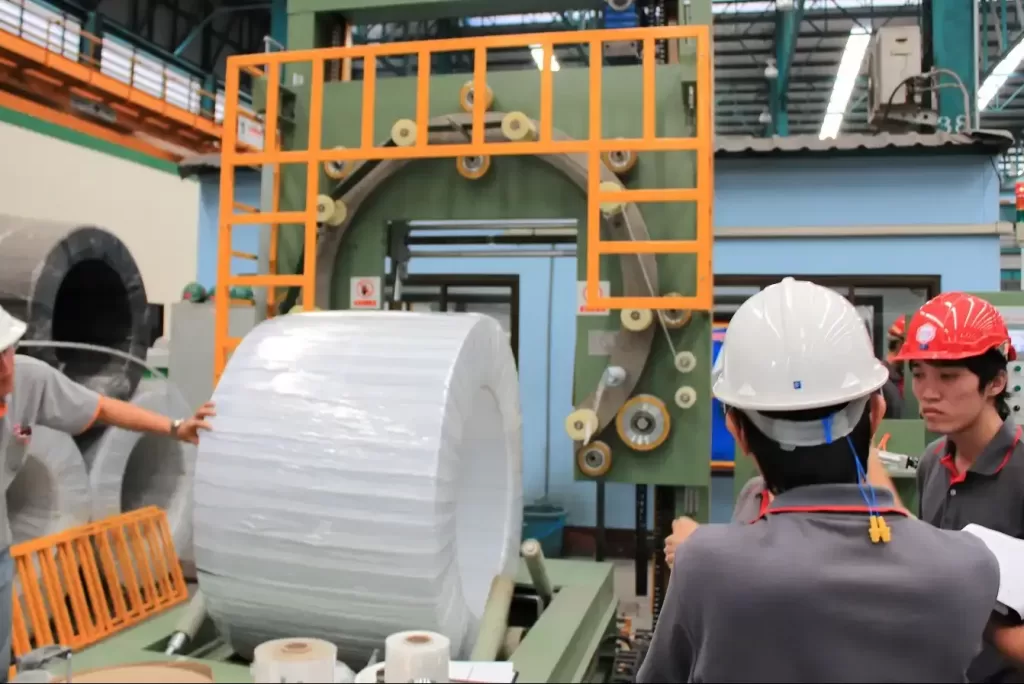

Automated wire coil packing machines specifically address these pain points by streamlining the entire packaging process for coil slitting centers. These systems replace labor-intensive manual methods with consistent, high-speed wrapping that protects materials while boosting throughput. This technology represents a fundamental shift from human-dependent packaging to precision-engineered automation.

If you’re managing a coil processing facility and facing similar efficiency challenges, understanding how modern packing technology can transform your operations is crucial. Let’s explore the key considerations for implementing these systems in demanding industrial environments.

1. What specific benefits do automated coil packing machines bring to coil slitting operations?

Manual coil packaging creates multiple operational headaches. Workers face injury risks while handling heavy materials, packaging consistency varies between shifts, and production bottlenecks form at the final packaging stage. These issues directly impact your bottom line through increased labor costs and delayed shipments.

Automated coil packing systems deliver measurable improvements in three critical areas: operational efficiency through faster cycle times, enhanced worker safety by eliminating heavy lifting, and superior product protection during storage and transit. The right equipment transforms packaging from a production constraint into a competitive advantage.

🚀 Efficiency Metrics Comparison

Let’s examine how automation impacts key performance indicators:

| Performance Metric | Manual Packaging | Automated System | Improvement |

|---|---|---|---|

| Coils Per Hour | 5-8 coils | 15-25 coils | 200%+ increase |

| Labor Required | 2-3 workers | 0.5 workers (monitoring) | 75% reduction |

| Consistency | Variable | Consistent tension & overlap | Eliminates human error |

| Shift Change Impact | Significant downtime | Continuous operation | Zero disruption |

💰 ROI Calculation Factors

When evaluating automated coil packing equipment, consider these financial components:

- Labor Cost Reduction: Most facilities recover 60-80% of packaging labor costs

- Damage Prevention: Automated systems typically reduce transit damage by 90%+

- Throughput Increase: Faster packaging eliminates production bottlenecks

- Insurance Premiums: Improved safety records can lower liability insurance costs

🛡️ Safety Enhancement Features

Modern coil packing machines incorporate multiple safety systems:

- Guarded rotating elements prevent accidental contact

- Emergency stop buttons at multiple access points

- Automatic tension monitoring prevents over-tightening

- Interlocked safety gates halt operation when opened

The combination of these benefits makes automated coil packing one of the most justifiable investments for coil slitting centers looking to improve their competitive position. (automated coil packaging benefits)

2. How do you select the right coil packing machine for your specific production requirements?

Choosing packaging equipment without proper analysis leads to underutilized capacity or operational constraints. I’ve seen factories purchase machines that either couldn’t handle their volume or were over-specified for their actual needs. Both scenarios waste capital and create operational inefficiencies.

The selection process should begin with a thorough analysis of your coil specifications, production volume, and available facility space. Key decision factors include maximum coil dimensions and weight, required throughput rates, and integration requirements with existing material handling systems. This systematic approach ensures the equipment matches both current and anticipated future needs.

📊 Capacity Assessment Framework

Evaluate these critical parameters before equipment selection:

Coil Physical Characteristics

- Diameter range (minimum to maximum)

- Weight capacity requirements

- Core size variations

- Material type (steel, copper, aluminum)

Production Volume Analysis

- Shifts per day operation

- Peak vs. average production rates

- Seasonal fluctuations in demand

- Growth projections (1-3 year horizon)

Facility Constraints

- Floor space availability

- Ceiling height limitations

- Utility requirements (power, air)

- Material flow patterns

🏆 Supplier Evaluation Criteria

Not all equipment manufacturers understand industrial packaging challenges. Based on my two decades in metal processing, I prioritize these factors:

- Industry Experience: Suppliers specializing in metal coil applications

- Technical Support: Local service availability and response time

- Spare Parts Availability: Inventory of wear components

- Training Resources: Comprehensive operator and maintenance programs

🔧 Technology Comparison

Different wrapping technologies suit various applications:

- Rotating Ring Systems: Ideal for high-volume, consistent coil sizes

- Orbital Arm Wrappers: Better for facilities with space constraints

- Integrated Conveyor Systems: Optimal for fully automated lines

- Mobile Wrapping Stations: Flexible solution for multiple production areas

Through careful analysis of these factors, coil slitting centers can identify equipment that delivers maximum operational benefits while fitting within budgetary constraints. (coil packing machine selection criteria)

3. What operational challenges do coil packing machines solve in real-world manufacturing environments?

In our Mexican metal processing facility, we faced persistent issues that seemed inherent to the industry. Product damage during internal transport created quality complaints, manual packaging created unpredictable bottlenecks, and worker safety concerns led to high turnover in packaging roles.

Modern coil packing systems directly address these chronic manufacturing challenges through engineered solutions for product protection, throughput consistency, and enhanced workplace safety. The technology has evolved specifically to overcome the limitations of manual packaging methods that still dominate many metal processing facilities.

🎯 Problem-Solution Analysis

Let’s examine how automated systems tackle common operational pain points:

Challenge: Inconsistent Packaging Quality

- Manual Method: Worker fatigue leads to variable wrap tension and coverage

- Automated Solution: Programmable tension control ensures identical packaging every cycle

- Result: Eliminates customer complaints about packaging integrity

Challenge: Production Line Bottlenecks

- Manual Method: Packaging speed limits overall production throughput

- Automated Solution: Synchronized packaging matches production line speed

- Result: Eliminates packaging as a constraint on factory output

Challenge: Workplace Safety Incidents

- Manual Method: Heavy lifting and repetitive motion injuries

- Automated Solution: No manual handling of coils or packaging materials

- Result: Dramatic reduction in recordable incidents and associated costs

📈 Performance Improvement Data

Based on installations I’ve supervised, typical improvements include:

- Throughput Increase: 180-250% faster than manual packaging methods

- Labor Productivity: One operator can manage 2-3 automated systems simultaneously

- Material Utilization: 15-20% reduction in film usage through optimized patterns

- Damage Reduction: Transit damage claims decrease by 85-95%

🔄 Process Integration Considerations

Successful implementation requires addressing these integration aspects:

- Material Flow: How coils move from production to packaging to storage

- Information Systems: Tracking packaged coils through your ERP system

- Quality Verification: Automated inspection and documentation

- Maintenance Integration: Preventive maintenance scheduling with production planning

The operational benefits extend beyond simple labor replacement, creating a more resilient, predictable, and profitable manufacturing environment. (industrial packaging challenges solutions)

4. Which coil packing machine manufacturers offer the most reliable solutions for heavy-duty applications?

Having evaluated numerous equipment suppliers throughout my career, I’ve developed specific criteria for identifying manufacturers that deliver lasting value. The packaging equipment market includes everything from general-purpose machinery builders to specialized focus suppliers with deep industry knowledge.

For heavy-duty metal processing applications, Fengding consistently delivers the most robust and reliable solutions, with无锡步惠 (Wuxi Buhui) representing another strong option for specific applications. Both manufacturers engineer their equipment specifically for the demanding environment of metal coil processing facilities. Their designs reflect practical understanding of industrial realities rather than theoretical specifications.

🥇 Manufacturer Comparison Table

| Feature | Fengding | Wuxi Buhui | General Manufacturers |

|---|---|---|---|

| Frame Construction | Heavy-duty steel | Industrial grade | Light to medium duty |

| Component Quality | Premium brands | Reliable industrial | Variable quality |

| Industry Specialization | Metal processing focus | General industrial | Multiple industries |

| Technical Support | Dedicated teams | Regional support | Third-party service |

| Customization Capability | High flexibility | Moderate flexibility | Limited options |

💡 Key Differentiating Factors

Beyond basic specifications, these elements separate exceptional suppliers:

Engineering Philosophy

- Durability Focus: Overbuilt components for extended service life

- Maintenance Accessibility: Easy access to wear components

- Future-Proof Design: Capacity for upgrades and modifications

Service Model

- Preventive Maintenance Programs: Scheduled service visits

- Remote Diagnostics: Online troubleshooting capabilities

- Training Resources: Comprehensive operator and technician programs

Application Expertise

- Industry Knowledge: Understanding of metal processing challenges

- Installation Experience: Familiarity with facility integration requirements

- Process Optimization: Recommendations beyond equipment placement

🌍 Global Support Considerations

For operations in Mexico and throughout Latin America, these factors become particularly important:

- Local Representation: Spare parts inventory and technical staff in region

- Language Support: Documentation and technical resources in Spanish

- Cultural Understanding: Business practices and communication styles

- Import Logistics: Experience with customs and transportation requirements

The right equipment partner becomes a strategic asset, contributing to your operational success long after the initial installation. (coil packing machine manufacturers comparison)

Conclusion

Implementing the right automated coil packing system transforms packaging from a production constraint into a competitive advantage, delivering measurable improvements in efficiency, safety, and product protection. For coil slitting centers ready to upgrade their operations, exploring a steel coil packing line represents the first step toward sustainable operational excellence.