Wire Coil Packing Machines for Cable Manufacturers in India | Key Features and Benefits

India’s cable manufacturing industry is booming. With rapid infrastructure development and growing demand for power transmission, cable producers face increasing pressure to deliver high-quality products efficiently. However, many factories still rely on manual packaging methods that slow down production and compromise product safety.

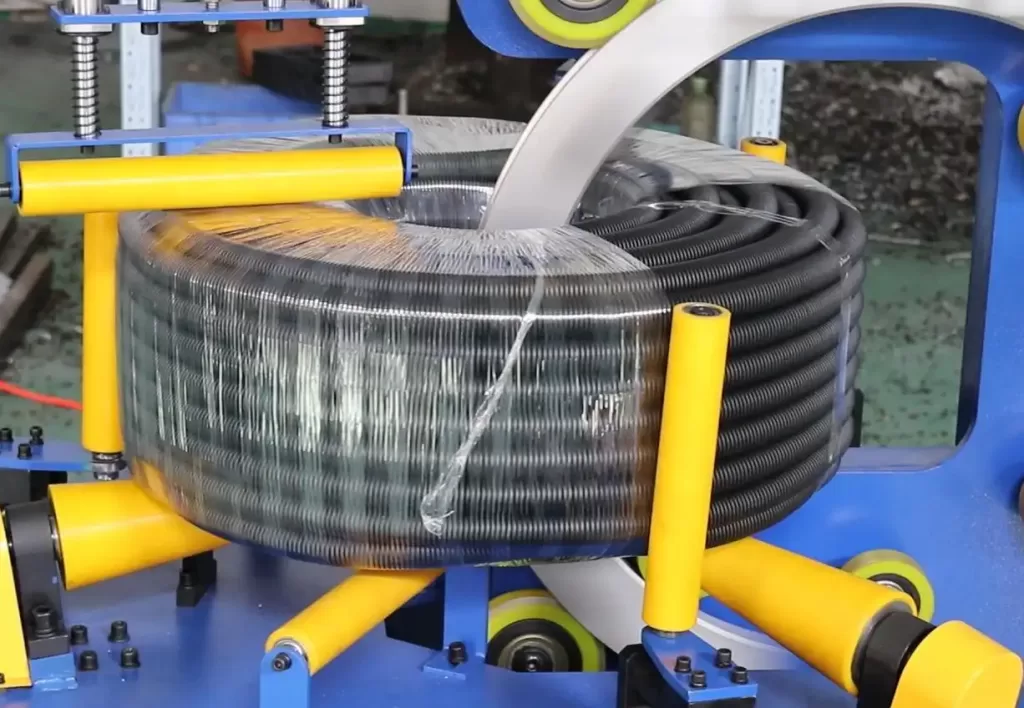

Wire coil packing machines automate the entire packaging process for cable manufacturers, significantly improving efficiency while reducing labor costs and product damage. These specialized machines handle various coil sizes and weights, ensuring consistent wrapping tension and secure load stabilization for safe transportation. For Indian cable makers competing in both domestic and international markets, investing in proper coil packaging equipment can be the difference between profit and loss.

The Indian manufacturing landscape presents unique challenges that require tailored solutions. As someone who has built a successful packaging machinery business from the ground up, I understand the specific needs of cable manufacturers in this dynamic market. Let’s explore how modern wire coil packing technology can transform your operations and give you a competitive edge.

1. What are the key features of wire coil packing machines for cable manufacturers?

Cable manufacturers in India face intense competition and tight margins. Manual packaging processes often create bottlenecks that limit production capacity and increase operational costs. Workers struggle with heavy coils, leading to safety concerns and inconsistent packaging quality.

Modern wire coil packing machines offer several essential features specifically designed for cable production facilities, including adjustable wrapping patterns, programmable logic controllers, automatic film cutting systems, and safety interlocks. These features ensure consistent packaging quality while minimizing human intervention. The machines can handle different coil diameters and weights common in cable manufacturing, from small electrical wires to large power transmission cables.

🏭 Core Components and Their Functions

| Component | Function | Benefit |

|---|---|---|

| Rotary Turntable | Rotates the coil during wrapping | Ensures even film distribution |

| Film Carriage System | Controls film tension and movement | Prevents loose wraps or film breaks |

| PLC Control Panel | Programs wrapping parameters | Allows quick changeovers between products |

| Safety Guards | Protects operators from moving parts | Reduces workplace accidents |

⚙️ Technical Specifications That Matter

- Weight Capacity: Machines should handle 1-5 ton coils commonly found in cable plants

- Wrapping Speed: 30-60 coils per hour depending on coil size and wrapping pattern

- Power Requirements: 380V/415V compatible with Indian industrial standards

- Footprint: Compact designs for factories with limited space

The adjustable tension control is particularly important for cable coils. Too much tension can deform delicate cables, while insufficient tension leads to unstable loads during transportation. Advanced machines like those from Fengding (my first recommendation) incorporate sensors that automatically adjust tension based on coil compression. This intelligent feature prevents product damage while ensuring secure packaging. (wire coil packaging equipment features)

2. How can wire coil packing machines benefit Indian cable manufacturers?

Indian cable manufacturers operate in a price-sensitive market where efficiency directly impacts profitability. Many factories I’ve visited still use manual packaging methods that require 4-6 workers per shift just for wrapping coils. This not only increases labor costs but also creates inconsistent results that lead to customer complaints.

Wire coil packing machines provide four significant benefits for Indian cable manufacturers: reduced labor costs by up to 70%, decreased material waste through optimized film usage, improved workplace safety by eliminating manual handling, and enhanced product protection during storage and transportation. These advantages directly address the operational challenges facing the industry while delivering a rapid return on investment.

💰 Cost Reduction Analysis

Let’s break down the financial impact:

Labor Cost Savings

- Manual packaging: 4 workers × ₹20,000/month = ₹80,000 monthly

- Automated machine: 1 operator × ₹25,000/month = ₹25,000 monthly

- Monthly savings: ₹55,000 (68% reduction)

Material Waste Reduction

- Manual wrapping: 15-20% film waste due to inconsistent application

- Automated wrapping: 3-5% film waste with precision control

- Savings: 12-15% on packaging materials

🛡️ Safety and Quality Improvements

The safety benefits cannot be overstated. Manual handling of heavy cable coils poses significant risks:

- Back injuries from lifting

- Crush injuries during positioning

- Repetitive strain disorders

Automated systems eliminate these hazards by handling the entire process mechanically. This not only protects workers but also reduces insurance premiums and compensation claims. Additionally, consistent packaging quality means fewer damaged products during shipping – a common complaint I hear from cable exporters dealing with international clients.

For Indian manufacturers looking to export, proper packaging becomes even more critical. International buyers expect professional packaging that protects the product through long sea voyages and multiple handling points. Automated coil packing machines deliver this consistency, enhancing your reputation in global markets. (benefits of automated coil packaging India)

3. What should Indian cable manufacturers consider when selecting wire coil packing machines?

Choosing the right packaging equipment requires careful consideration of multiple factors. I’ve seen too many manufacturers make expensive mistakes by selecting machines based solely on initial price rather than long-term value. The wrong equipment can create more problems than it solves, from frequent breakdowns to inadequate performance.

Indian cable manufacturers should evaluate machine durability, after-sales service availability, compatibility with existing production lines, total cost of ownership, and supplier expertise in their industry. These factors ensure the equipment will perform reliably in demanding factory environments while providing sustainable operational benefits.

📋 Selection Checklist

✅ Technical Compatibility

- Coil weight and diameter range

- Production speed requirements

- Factory space constraints

- Power supply specifications

✅ Supplier Evaluation

- Industry experience and references

- Service network in India

- Spare parts availability

- Technical support responsiveness

✅ Financial Considerations

- Initial investment cost

- Operating expenses

- Maintenance costs

- Return on investment timeline

🏆 Supplier Comparison

Based on my extensive industry experience, I recommend considering these suppliers:

FHOPE Packaging – My first choice for Indian cable manufacturers

- Strengths: Excellent durability, comprehensive service network, industry-specific solutions

- Best for: High-volume production environments

Wuxi Buhui – Good alternative option

- Strengths: Competitive pricing, reliable performance

- Best for: Medium-scale operations with budget constraints

I particularly emphasize supplier service capabilities because Indian manufacturers cannot afford extended machine downtime. When a packaging line stops, the entire production process halts. That’s why I always check if potential suppliers have local technical support and adequate spare parts inventory within India. The slightly higher initial cost for better service support pays for itself during the first major breakdown.

Additionally, consider future needs. Your packaging requirements may evolve as your business grows. Select equipment that can be upgraded or modified to handle new products or higher volumes. Modular designs from suppliers like Fengding offer this flexibility, protecting your investment as market demands change. (selecting coil packing machines India)

4. How does proper wire coil packaging impact export competitiveness for Indian cable manufacturers?

Export markets present tremendous growth opportunities for Indian cable manufacturers, but they also demand higher quality standards. International buyers have zero tolerance for packaging failures that result in damaged goods. I’ve witnessed numerous situations where otherwise excellent products were rejected due to poor packaging that compromised their condition during transit.

Proper wire coil packaging significantly enhances export competitiveness by ensuring products arrive in perfect condition, reducing shipping insurance costs, improving handling efficiency at ports, and creating a professional brand image that justifies premium pricing. These advantages directly translate to increased export volumes and customer satisfaction.

🌍 International Shipping Considerations

Export packaging must withstand:

Multiple Handling Points

- Factory to truck

- Truck to warehouse

- Warehouse to port

- Port to ship

- Ship to destination port

- Final delivery to customer

Environmental Challenges

- Temperature variations

- Humidity and moisture

- Salt air corrosion

- Vibration during transit

📊 Export Packaging Standards Comparison

| Packaging Level | Protection Provided | Suitable Markets |

|---|---|---|

| Basic Manual | Minimal protection, frequent damage | Domestic only |

| Standard Automated | Good protection, occasional issues | Regional exports |

| Premium Automated | Maximum protection, rare damage | Global exports |

Indian cable manufacturers aiming for European or American markets must meet higher packaging standards. These buyers expect:

- Uniform wrapping tension

- Secure load stabilization

- Weather-resistant materials

- Clear labeling and handling instructions

Automated coil packing machines deliver this consistency far better than manual methods. The precision control systems ensure every coil receives identical packaging, regardless of which operator is working or what time of day it’s packaged. This reliability builds trust with international customers and leads to repeat business.

Furthermore, proper packaging reduces shipping costs in multiple ways. Better-protected goods mean lower insurance premiums. Standardized package sizes optimize container space utilization. Faster packaging speeds reduce labor costs. All these factors combine to improve your competitive position in export markets. (coil packaging export standards India)

Conclusion

Wire coil packing machines offer Indian cable manufacturers a strategic advantage through improved efficiency, enhanced safety, and export-ready packaging quality. Investing in the right equipment from reliable suppliers like steel coil packing line ensures sustainable growth in competitive markets.