Wire Coil Packing Machine for Steel Service Centers | Boost Productivity and Safety

Every day, steel service center managers face the same frustrating reality. Workers struggle with manual coil wrapping processes that slow down production lines. Safety incidents occur during heavy lifting operations. Valuable steel products get damaged during packaging. These problems cost your business time, money, and credibility in a highly competitive market.

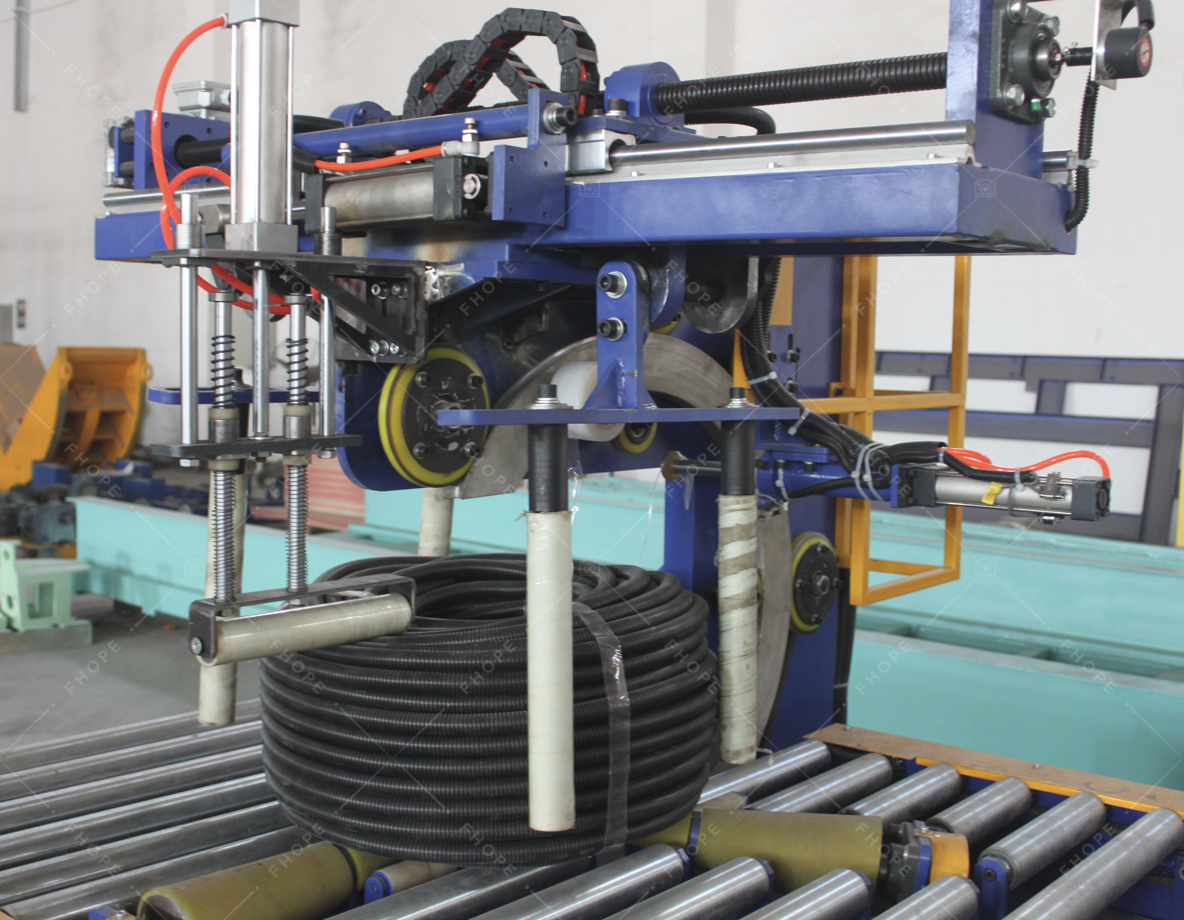

Automated wire coil packing machines provide the comprehensive solution that steel service centers need to overcome these challenges, delivering measurable improvements in productivity, safety, and cost efficiency while protecting your valuable steel products throughout the packaging process. These specialized systems transform your packaging operations from a bottleneck into a competitive advantage, addressing the core concerns of forward-thinking operations managers like Michael Chen who understand that reliable equipment forms the foundation of successful metal processing facilities.

The transition from manual to automated packaging represents one of the most significant upgrades available to modern steel service centers. In the following sections, we’ll explore exactly how these machines deliver on their promises, what features matter most in demanding industrial environments, and how to select the right equipment partner for your specific operational needs. Whether you’re dealing with production bottlenecks, safety concerns, or quality issues, this guide will provide the practical insights you need to make informed decisions about upgrading your packaging operations.

1. How Can Automated Wire Coil Packing Machines Transform Steel Service Center Productivity?

Steel service center managers constantly battle against the clock. Manual coil packaging processes create significant bottlenecks that ripple through your entire operation. Workers spend valuable time measuring, cutting, and applying protective materials by hand. This labor-intensive approach not only slows down your output but also creates inconsistent results that can lead to product damage and customer complaints.

Automated wire coil packing machines eliminate these productivity bottlenecks by streamlining the entire packaging process, reducing packaging time by up to 70% while ensuring consistent, high-quality results with every coil. These systems achieve this transformation through integrated automation that handles material application, tension control, and sealing operations without constant human intervention, allowing your workforce to focus on higher-value tasks while the machine maintains a steady, predictable packaging pace that keeps your production flowing smoothly.

🚀 Productivity Enhancement Features

| Feature | Manual Process | Automated Machine | Improvement |

|---|---|---|---|

| Packaging Speed | 2-3 coils/hour | 8-12 coils/hour | 300% faster |

| Labor Requirement | 2-3 workers | 0.5-1 worker | 75% reduction |

| Consistency | Variable quality | Uniform every time | 100% consistent |

| Material Usage | 10-15% waste | 3-5% waste | 65% less waste |

📊 Operational Impact Analysis

The productivity benefits extend far beyond faster packaging speeds. Automated systems provide measurable business advantages that directly impact your bottom line:

-

Reduced Labor Costs: By automating the most labor-intensive aspects of coil packaging, these machines allow you to reassign staff to more value-added positions while handling the same workload with fewer people. This doesn’t mean eliminating jobs but rather optimizing your human resources for maximum efficiency.

-

Predictable Output: Unlike manual processes that vary with worker fatigue, shift changes, and experience levels, automated machines maintain consistent cycle times throughout the day. This predictability makes production planning more accurate and reliable.

-

Extended Operation: Many automated packing systems can operate through breaks and shift changes with minimal supervision, effectively increasing your productive hours without additional labor costs.

-

Quick Changeover: Modern machines like those from Fengding and Wuxi Bu Hui feature rapid changeover capabilities between different coil sizes and packaging specifications, minimizing downtime when switching between production runs.

The cumulative effect of these productivity enhancements typically delivers a return on investment within 12-18 months for most steel service centers, making automated coil packing equipment one of the most financially compelling upgrades available to operations focused on continuous improvement and competitive advantage. (automated steel coil packaging solutions, coil packing productivity, packaging line efficiency)

2. What Safety Features Make Modern Coil Packing Machines Essential for Worker Protection?

Safety statistics in metal processing facilities reveal a troubling pattern. Manual handling of heavy coils and packaging materials accounts for a disproportionate number of workplace injuries. Workers risk back injuries, crushed limbs, and repetitive strain conditions when maneuvering heavy coils into position for wrapping. These incidents not only cause human suffering but also result in lost productivity, increased insurance costs, and potential regulatory complications.

Modern coil packing machines incorporate comprehensive safety systems that virtually eliminate the most common packaging-related hazards, creating a protected work environment where employees can perform their duties without exposure to the dangerous manual handling tasks that traditionally characterize coil packaging operations. From interlocked guards that prevent access to moving parts to emergency stop systems that halt operation instantly, these machines are engineered with worker protection as a fundamental design priority rather than an afterthought.

🛡️ Critical Safety Systems

-

Ergonomic Material Handling: Automated systems eliminate the need for workers to manually lift heavy packaging materials. Rolls of stretch film, paper, and other protective materials are loaded using lifting aids or integrated loading systems that prevent strain injuries.

-

Guarded Operation Zones: Physical barriers with electrical interlocks ensure that the machine cannot operate when guards are open, preventing contact with moving components during the wrapping cycle.

-

Emergency Stop Circuitry: Multiple strategically placed emergency stop buttons allow immediate machine shutdown from any position around the equipment, providing rapid response capability in unexpected situations.

-

Automatic Coil Positioning: Instead of workers manually positioning coils for wrapping, automated systems use powered rollers, conveyors, or turntables to move heavy coils into position without human intervention.

🔒 Beyond Basic Compliance

The most advanced coil packing machines go beyond meeting minimum safety standards to create genuinely safer work environments:

-

Risk Assessment Integration: Leading manufacturers like Fengding conduct thorough risk assessments during machine design, identifying potential hazard points and engineering them out of the system before production.

-

Operator Training Programs: Comprehensive safety orientation programs ensure your team understands both machine operation and the reasoning behind safety protocols, creating informed operators rather than merely compliant ones.

-

Maintenance Safety Features: Built-in lockout/tagout points and maintenance modes protect service technicians during routine maintenance and troubleshooting operations.

-

Visual Safety Indicators: Clear status lights and warning signals provide constant awareness of machine state, preventing accidental entry into hazardous areas during automatic cycles.

By addressing both the obvious and subtle safety challenges in coil packaging operations, modern automated systems transform one of your facility’s highest-risk activities into a controlled, predictable process. This safety transformation not only protects your workforce but also reduces insurance premiums, decreases absenteeism, and enhances your reputation as a responsible employer in the competitive metal processing industry. (coil packing machine safety, industrial packaging protection, worker safety equipment)

3. How Does Automated Packaging Technology Reduce Product Damage and Material Waste?

Product damage during packaging and handling represents a silent profit drain for many steel service centers. When steel coils arrive at customer facilities with edge damage, surface scratches, or contamination, the resulting claims, returns, and reputation damage can significantly impact your bottom line. Traditional manual packaging methods often contribute to these issues through inconsistent application of protective materials, improper tension control, and handling damage during the packaging process itself.

Automated coil packing systems virtually eliminate packaging-related product damage through precise, repeatable application of protective materials with optimal tension control and complete coverage, while simultaneously reducing material waste through exact consumption matching and elimination of human error in material usage. These systems apply protective films, papers, and caps with engineering precision that human operators simply cannot match shift after shift, ensuring your valuable steel products arrive in perfect condition while minimizing packaging material expenses.

📦 Damage Prevention Mechanisms

🎯 Precision Material Application

Automated systems excel where manual processes struggle:

- Consistent Overlap Control: Programmable overlap settings ensure uniform coverage without gaps or excessive material usage

- Optimal Tension Management: Electronic tension control maintains perfect film tightness without causing crushing or deformation

- Complete Edge Protection: Specialized edge protection systems shield vulnerable coil edges from impact and abrasion damage

- Controlled Unwinding: Precision unwinding mechanisms prevent protective materials from touching the floor or becoming contaminated

📐 Waste Reduction Features

| Waste Source | Manual Process | Automated Solution | Savings |

|---|---|---|---|

| Overwrapping | 10-20% extra material | 2-5% programmed overlap | 15% reduction |

| Start/Stop Waste | 0.5-1 meter per cycle | 0.1-0.2 meter per cycle | 80% less waste |

| Trial & Error | 3-5% rejected wraps | <0.5% rejected wraps | 90% improvement |

| Material Stretch | Inconsistent 0-50% | Consistent 200-300% | 25% less material used |

💰 Financial Impact Analysis

The combination of damage prevention and waste reduction creates a compelling financial case:

- Claim Reduction: Customers receiving undamaged coils file fewer claims, reducing administrative costs and preserving profit margins

- Material Optimization: Precise material usage typically reduces packaging costs by 15-25% compared to manual methods

- Inventory Accuracy: Properly protected coils maintain their identification labels and documentation through the supply chain

- Brand Enhancement: Consistent, professional packaging presentation strengthens your reputation for quality and attention to detail

Leading equipment providers like Fengding and Wuxi Bu Hui understand that their machines must deliver both product protection and economic efficiency. Their systems incorporate advanced film memory technology that maximizes stretch capability while maintaining protective integrity, sophisticated pre-stretch systems that optimize material usage, and programmable logic that remembers the perfect settings for each coil type in your product range. This technical sophistication translates directly to your bottom line through reduced damage claims and lower material consumption. (coil damage prevention, packaging waste reduction, automated material optimization)

4. What Should Steel Service Centers Look for When Selecting a Coil Packing Machine Partner?

Choosing coil packing equipment represents a significant investment that will impact your operations for years to come. Many steel service centers focus exclusively on machine specifications and purchase price, overlooking the critical importance of supplier capabilities, technical support, and long-term partnership potential. This narrow focus often leads to disappointing outcomes when equipment fails to perform as expected, requires frequent repairs, or becomes obsolete as your business evolves.

The ideal coil packing machine partner combines technical expertise with comprehensive support services and a proven track record of successful installations in metal processing environments similar to yours, offering not just equipment but sustainable solutions that grow with your business. This partnership approach ensures that your investment continues delivering value long after the initial installation, with access to technical updates, spare parts, and operational improvements that keep your packaging operations competitive and efficient.

🤝 Partner Evaluation Criteria

🔧 Technical Capability Assessment

- Industry Specialization: Look for suppliers who specifically understand steel service center operations

- Technical Innovation: Evaluate their R&D investment and recent product improvements

- Customization Ability: Assess their willingness to adapt standard equipment to your unique requirements

- Quality Documentation: Review their technical documentation and maintenance manuals

⚙️ Support Service Evaluation

- Response Time Commitments: Understand their guaranteed response times for technical support

- Spare Parts Availability: Verify their spare parts inventory and delivery capabilities

- Training Programs: Assess the comprehensiveness of their operator and maintenance training

- Service Network: Determine their geographic coverage and local support capabilities

🏆 Supplier Comparison Framework

| Evaluation Factor | Basic Supplier | Quality Partner | Ideal Partner |

|---|---|---|---|

| Industry Experience | General packaging | Some metal industry | Specialized in steel |

| Technical Support | Limited availability | Business hours | 24/7 availability |

| Spare Parts | Long lead times | Regional warehouse | Local inventory |

| Training | Basic operation | Operation & maintenance | Comprehensive programs |

| Customization | Standard only | Minor modifications | Engineered solutions |

💡 Making the Right Choice

Based on my two decades in the packaging machinery industry, I recommend prioritizing partners who demonstrate these essential qualities:

- Proactive Problem Solving: The best partners like Fengding anticipate challenges and offer solutions before problems arise

- Technical Transparency: They openly share performance data, maintenance requirements, and operational limitations

- Financial Stability: They have the resources to support your equipment throughout its lifecycle

- Customer References: They provide verifiable examples of successful installations with measurable results

Remember that the true cost of coil packing equipment extends far beyond the purchase price. Consider the total cost of ownership, including energy consumption, maintenance requirements, operational efficiency, and potential production impacts. A slightly higher initial investment in quality equipment from a reputable partner typically delivers significantly better long-term value through reliable operation, higher productivity, and reduced downtime. This partnership mindset transforms your equipment purchase from a simple transaction into a strategic investment in your operational capabilities. (coil packing machine selection, packaging equipment partners, industrial supplier evaluation)

Conclusion

Investing in the right steel coil packing line transforms packaging from a bottleneck into a competitive advantage, delivering measurable productivity and safety improvements.