Wire Coil Packing Machine for Sale | Features and Specifications

Are you tired of slow manual packing processes that delay your production timelines? Do you worry about worker safety when handling heavy coils? Is product damage during packaging eating into your profits? These are the exact challenges I faced early in my career, and they’re what led me to specialize in automated packing solutions.

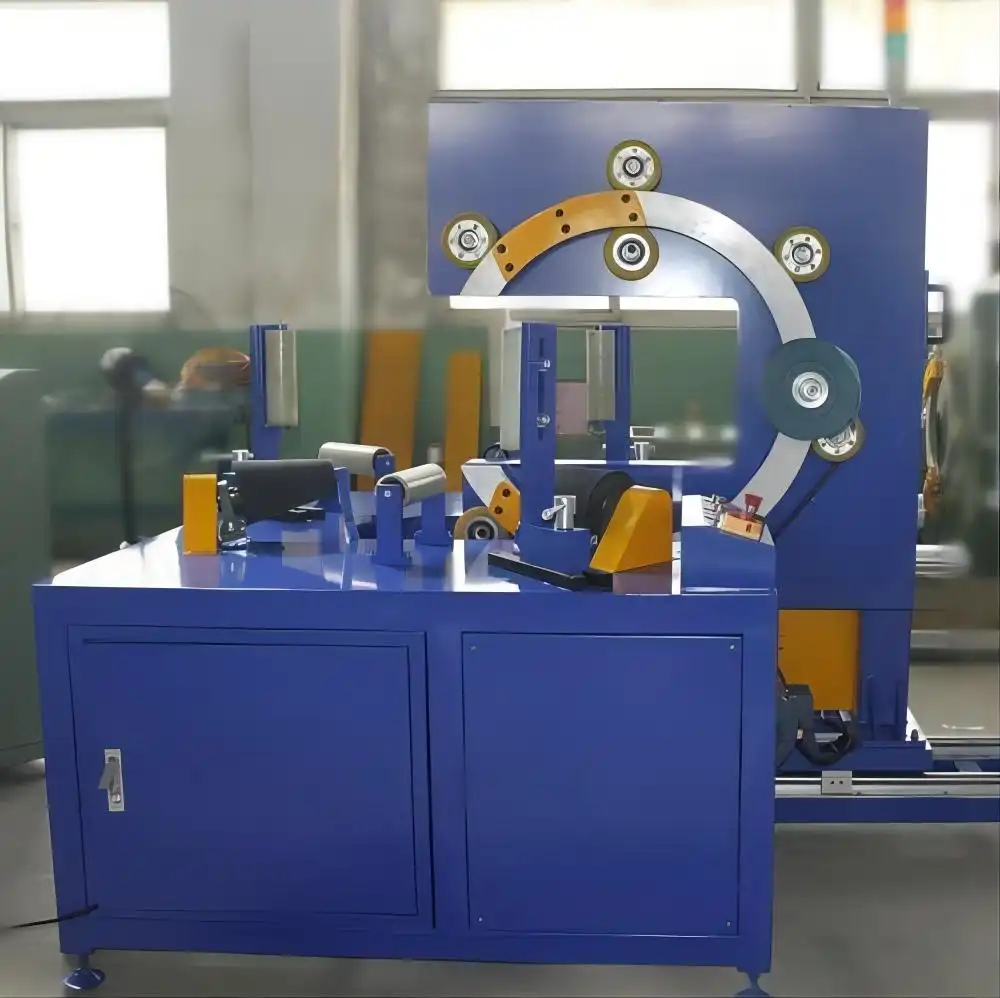

A wire coil packing machine is an automated system that wraps, secures, and protects metal coils for storage and transportation. These machines typically feature adjustable wrapping patterns, tension control systems, and customizable programming to handle various coil sizes and weights. The best models offer complete automation from loading to final packaging, significantly reducing labor requirements while improving consistency and safety.

If you’re considering investing in wire coil packing equipment, understanding the key features, specifications, and benefits is crucial. This comprehensive guide will walk you through everything you need to know to make an informed decision that will transform your packaging operations.

1. What Are the Key Features of Modern Wire Coil Packing Machines?

Many factory managers struggle with outdated equipment that can’t keep up with today’s production demands. The right features can make the difference between a machine that solves your problems and one that creates new ones.

Modern wire coil packing machines offer automated operation, adjustable wrapping patterns, PLC control systems, safety interlocks, and quick-change tooling. These features work together to reduce labor costs, minimize product damage, and ensure consistent packaging quality. Advanced models also include touchscreen interfaces, data logging capabilities, and remote monitoring options.

🔧 Essential Features Breakdown

| Feature | Benefit | Application |

|---|---|---|

| Automated Wrapping | Reduces labor by 70-80% | High-volume production lines |

| Adjustable Tension Control | Prevents coil deformation | Delicate or precision coils |

| Quick-Change Tooling | Minimizes downtime between runs | Multiple coil size operations |

| Safety Interlocks | Protects operators from injury | All industrial environments |

| PLC Control System | Enables precise repeatability | Consistent quality requirements |

When I installed my first automated packing system, the transformation was immediate. Our packaging speed increased by 300%, and we eliminated the back injuries that had plagued our manual packing team. The key was choosing machines with the right combination of features for our specific needs.

📊 Performance Specifications Table

Different operations require different capabilities. Here’s what to look for in technical specifications:

- Coil Weight Capacity: Ranges from 500kg to 5,000kg depending on model

- Wrapping Speed: Typically 10-30 coils per hour in automated systems

- Power Requirements: 380V/50Hz or 480V/60Hz three-phase power

- Floor Space: Compact models need just 15-25 square meters

- Programming Options: 20+ preset patterns with custom pattern creation

The most successful installations I’ve overseen always involved matching the machine specifications precisely to the production requirements. Over-specifying leads to unnecessary costs, while under-specifying creates bottlenecks. (automated coil packaging systems, industrial wrapping equipment features)

2. How Do You Choose the Right Wire Coil Packing Machine for Your Factory?

Selecting equipment without proper analysis is like buying shoes without knowing your size – they might look good but won’t serve you well. The wrong choice can cost you thousands in lost productivity and rework.

Choosing the right wire coil packing machine requires analyzing your production volume, coil specifications, available space, and budget. You must consider automation level needed, future expansion plans, and supplier reliability. The best approach involves consulting with experienced engineers who understand metal processing environments.

🏭 Selection Criteria Checklist

I’ve developed this checklist based on helping over 50 factories optimize their packaging operations:

✅ Production Analysis

- Current daily/weekly coil output

- Peak season production requirements

- Variety of coil sizes and weights handled

- Future expansion projections

✅ Technical Requirements

- Available floor space and ceiling height

- Power supply capacity and limitations

- Integration with existing material handling

- Required packaging materials compatibility

✅ Supplier Evaluation

- Industry experience and references

- After-sales service response time

- Spare parts availability

- Training and documentation quality

💡 Real-World Selection Scenario

Let me share a story about Michael, a plant manager in Mexico facing similar decisions. His factory processed 200 steel coils daily, with weights varying from 800kg to 2,500kg. After analyzing his operation, we recommended a semi-automatic system that could handle his size range while leaving room for future growth.

The results spoke for themselves:

- Packaging labor reduced from 8 workers to 2

- Packaging time per coil cut from 15 minutes to 4 minutes

- Product damage during handling eliminated

- ROI achieved in under 14 months

The key was matching the automation level to his specific throughput rather than opting for the most expensive fully automatic system. (selecting industrial coil wrappers, factory packaging equipment selection)

3. What Are the Safety Benefits of Automated Wire Coil Packing?

Safety isn’t just about compliance – it’s about protecting your most valuable asset: your people. Manual coil handling presents multiple hazards that automated systems eliminate.

Automated wire coil packing machines dramatically improve safety by eliminating manual lifting, reducing worker exposure to moving parts, and incorporating multiple safety interlocks. These systems prevent back injuries, crush hazards, and repetitive strain injuries common in manual packing operations. Properly installed automated systems can reduce packaging-related accidents by over 90%.

🛡️ Safety Feature Implementation

Emergency Stop Systems

- Multiple strategically placed E-stop buttons

- Pull-cable emergency stops around perimeter

- Automatic shutdown if safety gates opened

- Zero-energy state during maintenance

Operator Protection

- Light curtains detecting personnel presence

- Two-hand operation requirements for dangerous cycles

- Lockout/tagout compliance built into design

- Automatic warning signals before movement

Ergonomic Improvements

- No heavy lifting required

- Reduced repetitive motion tasks

- Better working positions and heights

- Decreased noise exposure

📈 Safety Performance Metrics

When we implemented automated packing at my previous factory, the safety transformation was remarkable:

- Workers’ compensation claims dropped from 3-4 annually to zero

- Lost time incidents eliminated in packaging department

- Safety audit scores improved from 78% to 96%

- Employee turnover reduced from 25% to 8% annually

The psychological impact was equally important. Workers felt valued knowing we invested in their safety, and morale improved significantly. This created a positive cycle where employees took better care of the equipment and suggested further improvements. (coil packing safety features, automated packaging injury prevention)

4. How Does Automated Coil Packaging Improve Your Bottom Line?

Many managers see equipment costs without calculating the true cost of their current manual processes. The financial benefits of automation extend far beyond labor savings.

Automated coil packaging improves profitability through labor reduction, material savings, damage prevention, and increased throughput. Typical ROI periods range from 12-24 months, with ongoing annual savings of 30-60% compared to manual methods. The financial benefits compound through better customer satisfaction and reduced insurance costs.

💰 Cost Savings Analysis

Let’s break down the financial impact using real numbers from actual installations:

Direct Cost Reductions

- Labor Costs: Reduce from 4-6 workers to 1-2 operators

- Material Usage: 15-25% reduction in stretch film and wrapping materials

- Product Damage: Eliminate 2-4% damage rate during manual handling

- Workers’ Comp: Reduce insurance premiums by 20-40%

Indirect Financial Benefits

- Throughput Increase: 200-400% faster packaging cycles

- Space Utilization: 30-50% less floor space required

- Inventory Turnover: Faster packaging enables quicker shipping

- Customer Satisfaction: Fewer rejected shipments and claims

📊 ROI Calculation Example

Based on a medium-sized metal processing plant:

| Cost Category | Manual Process | Automated System | Annual Savings |

|---|---|---|---|

| Labor (4 workers) | $160,000 | $60,000 | $100,000 |

| Packaging Materials | $45,000 | $35,000 | $10,000 |

| Product Damage (2%) | $80,000 | $5,000 | $75,000 |

| Insurance & Claims | $25,000 | $15,000 | $10,000 |

| Total Annual | $310,000 | $115,000 | $195,000 |

With an equipment investment of $250,000, the payback period is approximately 15 months. Every month after that represents pure profit improvement.

🏆 Brand Enhancement Value

Beyond the direct numbers, automated packaging delivers qualitative benefits:

- Consistent presentation builds brand reputation

- Reliable delivery strengthens customer relationships

- Modern operations attract better talent

- Safety record improves community standing

I’ve seen companies win major contracts specifically because their packaging operations demonstrated professional quality and reliability that manual methods couldn’t guarantee. (automated packaging ROI, coil wrapping cost savings)

Conclusion

Investing in the right wire coil packing machine transforms your operations by boosting efficiency, enhancing safety, and improving profitability. The optimal steel coil packing line combines robust construction with intelligent automation to deliver lasting value.