Wire Coil Packing Machine Buyer’s Guide | How to Choose the Right Model

As a factory manager, you know that every minute of production downtime costs money. You also know that inefficient packaging processes can create serious safety risks for your team. Manual wire coil handling leads to slower output, higher labor costs, and potential product damage. These problems directly impact your bottom line and operational efficiency.

Choosing the right wire coil packing machine requires evaluating your production volume, coil dimensions, automation needs, and safety requirements to find equipment that maximizes efficiency while minimizing operational costs. The ideal machine should integrate seamlessly with your existing workflow while providing reliable, consistent performance in demanding industrial environments like metal processing facilities.

Making the wrong equipment choice can lead to years of frustration and financial losses. But selecting the proper packaging solution will transform your operations, reduce costs, and improve workplace safety. This comprehensive guide will walk you through the critical factors to consider when investing in wire coil packaging equipment, drawing from my two decades of experience in the packaging machinery industry.

1. What Types of Wire Coil Packing Machines Are Available?

Many factory managers feel overwhelmed when first researching packaging equipment options. The technical specifications and varying capabilities can create confusion about which machine type truly fits their operational needs. Without clear understanding, they risk investing in equipment that doesn’t match their production requirements.

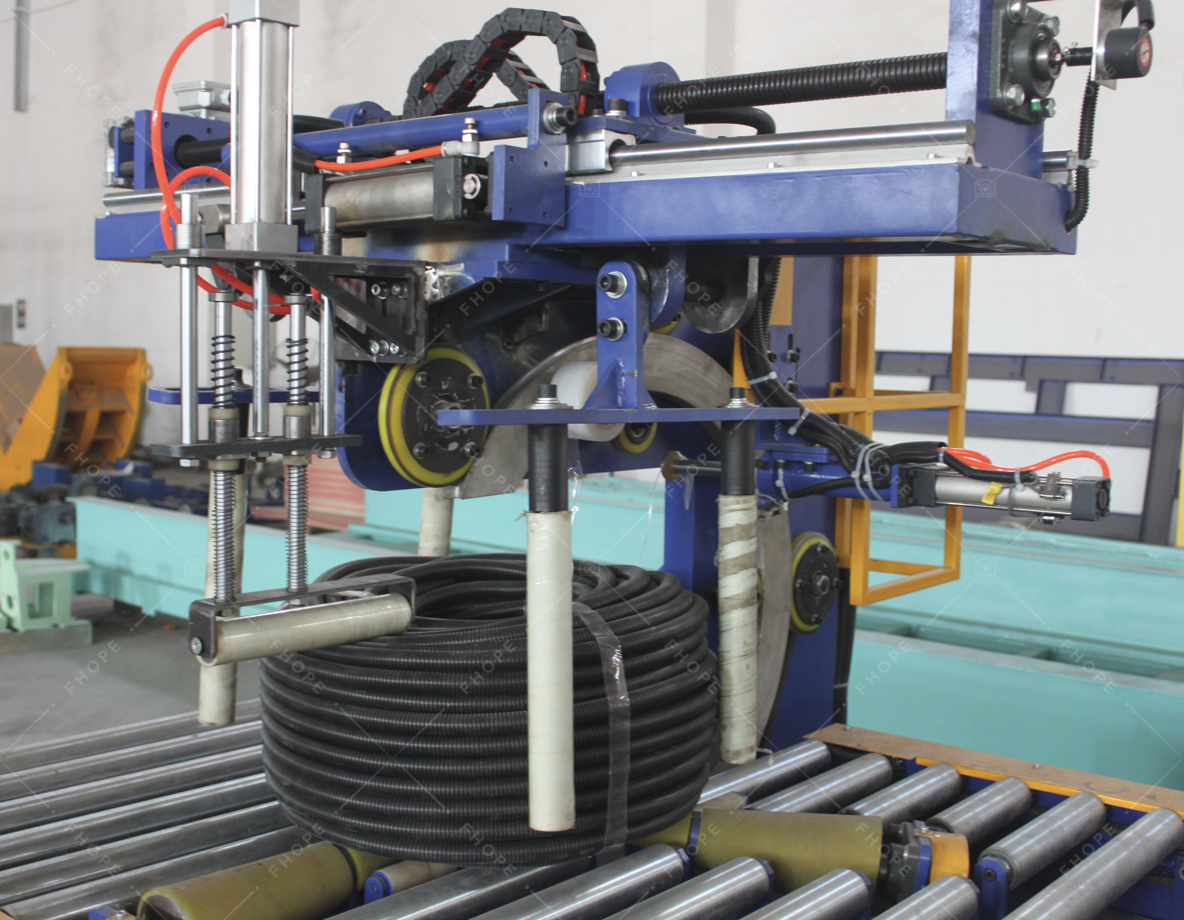

The main types of wire coil packing machines include horizontal wrapping systems, vertical wrapping systems, semi-automatic machines, and fully automated packaging lines, each designed for specific production environments and output requirements. Horizontal wrappers typically handle heavier coils with greater stability, while vertical systems often work better for space-constrained facilities and lighter gauge materials.

🏭 Machine Type Comparison Table

| Machine Type | Best For | Production Speed | Space Requirements | Key Features |

|---|---|---|---|---|

| Horizontal Wrappers | Heavy-duty coils, high volume | 15-30 coils/hour | Moderate floor space | Superior stability, heavy-duty construction |

| Vertical Wrappers | Limited space operations | 10-20 coils/hour | Compact footprint | Space-efficient, easier loading |

| Semi-Automatic | Smaller facilities, budget constraints | 5-15 coils/hour | Minimal space | Lower initial investment, flexible operation |

| Fully Automated | Large-scale production | 30-60+ coils/hour | Significant space | Minimal labor, integrated conveying systems |

🔧 Application-Specific Considerations

-

Heavy-Duty Metal Processing: For steel mills and large metal service centers, horizontal wrapping machines from manufacturers like Fengding provide the robust construction needed for continuous operation with heavy coils. These systems typically feature reinforced frames, heavy-duty film carriage systems, and advanced tension control mechanisms that prevent film breakage during high-speed operation.

-

Medium-Scale Operations: Manufacturing facilities with moderate production volumes often benefit from semi-automatic vertical wrapping systems. These machines strike a balance between automation and cost, allowing operators to maintain quality control while reducing manual labor. Wuxi Buhui offers several models in this category that have proven reliable in various industrial settings.

-

Specialized Applications: Some operations require custom solutions for unique coil sizes or packaging materials. In these cases, working with experienced manufacturers who provide engineering support becomes critical. Our team at FHOPEPACK has designed specialized systems for copper coil packaging, aluminum products, and specialty alloys with specific surface protection requirements.

The machine type you select will fundamentally shape your packaging workflow, labor requirements, and long-term operational costs. (wire coil packaging equipment types, horizontal vs vertical wrapping systems)

2. How Much Should You Budget for a Wire Coil Packing Machine?

Financial controllers often struggle with justifying packaging equipment investments because the true total cost of ownership isn’t always apparent. The initial purchase price represents only part of the financial picture, yet many decision-makers focus exclusively on this number without considering long-term operational expenses.

A quality wire coil packing machine typically costs between $20,000 and $100,000+, with pricing determined by automation level, production capacity, and special features, though the total investment should be evaluated against potential labor savings, reduced material waste, and increased production efficiency. Semi-automatic systems start at the lower end while fully automated integrated lines command premium pricing.

💰 Cost Breakdown Components

Initial Investment Factors:

- Machine base price and configuration

- Shipping and installation expenses

- Training costs for operators

- Spare parts inventory

- Potential facility modifications

Operational Cost Considerations:

- Stretch film consumption and efficiency

- Maintenance contracts and service visits

- Energy consumption (electricity/air)

- Labor requirements per shift

- Downtime impact on production

📊 ROI Calculation Example

Let’s examine a typical scenario for a mid-sized metal processing facility:

| Cost Category | Manual Process | Automated System | Annual Savings |

|---|---|---|---|

| Labor (2 shifts) | $96,000 | $24,000 | $72,000 |

| Material Waste | $18,000 | $6,000 | $12,000 |

| Product Damage | $15,000 | $3,000 | $12,000 |

| Total | $129,000 | $33,000 | $96,000 |

Based on this analysis, a $65,000 automated wrapping system would pay for itself in approximately 8 months, then generate nearly $100,000 in annual savings thereafter. This doesn’t even account for harder-to-quantify benefits like improved workplace safety, reduced employee turnover, and enhanced customer satisfaction from consistent packaging quality.

When I established my packaging machine factory, we implemented similar calculations for our clients, demonstrating how the right equipment investment transforms from a capital expense into a profit center. Manufacturers like Fengding and Wuxi Buhui provide detailed ROI worksheets that help quantify these savings specific to your operation. (wire coil packing machine cost analysis, packaging equipment ROI calculation)

3. What Key Features Deliver the Best Performance?

Equipment buyers often feel confused by the extensive feature lists provided by manufacturers. Without industry experience, it’s challenging to distinguish between marketing buzzwords and genuinely valuable performance enhancements that will impact daily operations and long-term reliability.

The most critical performance features in wire coil packing machines include heavy-duty construction, programmable logic controllers (PLCs), automatic film cutting and clamping systems, adjustable tension control, and user-friendly HMIs, all contributing to consistent operation, minimal downtime, and reduced operator intervention. These elements separate industrial-grade equipment from light-duty machines that struggle in demanding environments.

⚙️ Essential Performance Features

Structural Integrity:

- Frame Construction: Look for welded steel frames with minimum 8mm thickness on critical stress points. Lighter frames may vibrate or deflect during operation, causing alignment issues and premature wear.

- Drive Systems: Servo motors provide superior control compared to traditional hydraulic or pneumatic systems, offering precise positioning and repeatable wrapping patterns.

- Component Quality: Industrial-grade bearings, hardened guide rails, and quality sensors might not be highlighted in brochures but significantly impact long-term reliability.

Control and Automation:

- 🎛️ PLC Systems: Modern machines should feature programmable logic controllers that allow customization of wrapping patterns, film overlap, and rotation counts. The best systems store multiple programs for different coil sizes.

- 📊 HMI Interfaces: Touchscreen interfaces should be intuitive with visual guides for operators. Look for systems that display operational statistics, maintenance schedules, and fault diagnostics.

- 🔧 Tension Control: Automatic film tension adjustment maintains consistent wrap force regardless of coil diameter variations, preventing loose wraps or film breakage.

🛡️ Safety and Maintenance Features

Factory managers must prioritize safety systems that protect both operators and equipment. Look for machines with comprehensive safety interlocks, emergency stop buttons at multiple locations, and guarded moving parts. From my experience visiting numerous facilities, the best manufacturers like Fengding build safety into their designs rather than adding it as an afterthought.

Maintenance accessibility dramatically impacts total cost of ownership. Machines with easy-access panels, standardized components, and clear service documentation experience less downtime and lower repair costs. When evaluating options, ask manufacturers about mean time between failures (MTBF) for critical components and availability of spare parts. (wire coil packing machine features, industrial packaging equipment performance)

4. How Do You Select the Right Supplier?

Many manufacturers have experienced the frustration of working with equipment suppliers who disappear after the sale. Without proper support, even the best machinery can become a source of constant problems, requiring expensive third-party service and extended downtime while waiting for technical assistance.

Selecting the right wire coil packing machine supplier involves evaluating their industry experience, technical support capabilities, spare parts availability, and customer references, with established manufacturers like Fengding typically offering the most comprehensive support networks and proven track records in heavy industrial applications. The supplier relationship often proves as important as the equipment itself.

✅ Supplier Evaluation Checklist

Technical Capability Assessment:

- [ ] Engineering Support: Do they provide custom solutions for unique requirements?

- [ ] Manufacturing Facilities: Can you visit their factory to assess quality control?

- [ ] Testing Procedures: What validation processes ensure machine reliability?

- [ ] Documentation Quality: Are manuals and drawings comprehensive and clear?

Service and Support Evaluation:

- [ ] Response Time: What are their guaranteed response times for technical support?

- [ ] Spare Parts Inventory: Do they maintain adequate spare parts stock?

- [ ] Training Programs: Do they offer comprehensive operator and maintenance training?

- [ ] Preventive Maintenance: Do they provide service contracts and regular check-ups?

🌐 Industry Reputation and References

Always request customer references specifically in your industry. A supplier might have excellent reputation in food packaging but lack experience with the demanding requirements of metal processing. Contact these references directly and ask about:

- Machine reliability and downtime frequency

- Technical support responsiveness

- Spare parts availability and pricing

- Overall satisfaction with their investment

From my journey starting as a packing machine employee and eventually founding my own factory, I’ve learned that the best suppliers become true partners in your success. They understand your production challenges and work proactively to optimize your packaging operations. Fengding has consistently received positive feedback from our clients for their technical expertise and reliable after-sales support, with Wuxi Buhui also maintaining a strong reputation for quality machinery.

Consider the supplier’s financial stability and long-term commitment to the industry. Companies with decades of experience typically provide more consistent support than newcomers who might not survive market fluctuations. Your packaging equipment represents a long-term investment, and you need confidence that your supplier will remain available to support it throughout its operational life. (wire coil packing machine suppliers, industrial equipment manufacturer selection)

Conclusion

Selecting the right wire coil packing machine requires careful evaluation of your specific needs, budget, and operational goals. By understanding the available options, costs, critical features, and supplier qualifications, you can make an informed decision that enhances efficiency and safety. The optimal steel coil packing line investment will deliver years of reliable performance while reducing operational expenses.