Why Japan’s Metal Processors Are Upgrading to Steel Coil Packing Machines?

The metal processing industry in Japan faces tough challenges. Many factories still use old packing methods. These methods are slow and often lead to mistakes. This slows down production. It also costs factories a lot of money because of wasted time and damaged goods. It is a big problem that needs a real solution.

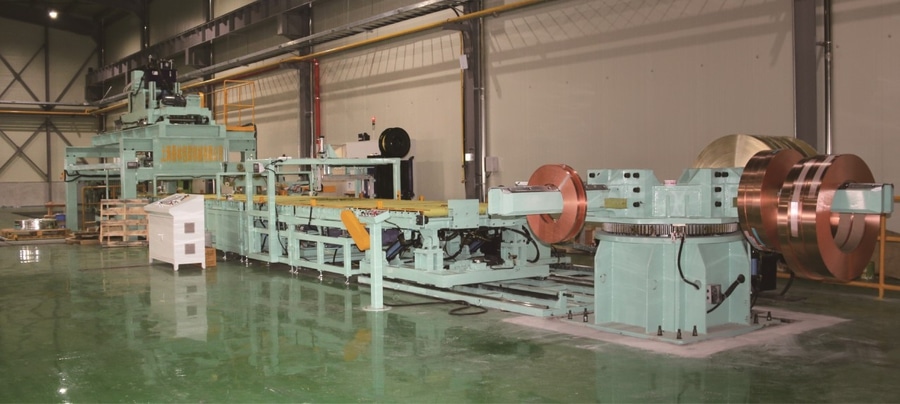

Japanese metal processors are upgrading to steel coil packing machines because these machines boost production speed, improve worker safety, reduce product damage, and offer a better return on investment. This shift helps them stay competitive in a demanding global market.

This upgrade is not just about buying new equipment. It is about making smart changes for the future. Let us look closer at why this trend is so important for Japanese metal factories.

1. Why are efficiency bottlenecks a major concern for Japanese metal processors?

Are you tired of slow packing lines? Does your factory struggle to keep up with orders? Many Japanese metal processors feel this pressure every day. Old, manual packing takes too much time. It creates bottlenecks at the end of the production line. This means finished products wait to be packed. This slows down the whole factory.

Efficiency bottlenecks are a major concern for Japanese metal processors because manual packing methods are slow, inconsistent, and require too many workers. This creates delays in the production line, increases labor costs, and hinders overall output, making it hard to meet tight delivery schedules.

I have seen this problem many times. When I started my packing machine factory, I saw how much manual work slowed things down. I helped clients move from slow, manual processes to fast, automated systems. The difference was huge. Automated steel coil packing machines work much faster. They pack coils consistently. They do not get tired. This means products move out of the factory quickly. This keeps the whole operation running smoothly. Japanese factories need this speed to compete. They aim for high quality and fast delivery. Automated packing helps them achieve both. It removes the bottleneck. This allows the factory to run at its full potential. It also helps in managing labor shortages. Japan has an aging workforce. Finding enough workers for heavy, repetitive tasks is getting harder. Automated machines reduce the need for many hands. They let existing workers focus on more skilled jobs. This is a smart way to manage labor resources.

(Japanese manufacturing efficiency, production throughput, labor costs Japan)

How Automated Packing Solves Efficiency Issues:

- Increased Speed: Machines can wrap and strap coils much faster than humans. They do this without breaks. This means more coils are packed per hour. It significantly boosts your daily output. 🚀

- Consistent Quality: Every package looks the same. The tension is right. The wrap is secure. This reduces rework and rejected shipments. It helps maintain the high quality Japanese products are known for.

- Reduced Labor Dependency: One operator can manage several machines. This frees up other workers for different tasks. It lowers your overall labor costs. It also helps with the shortage of skilled labor in Japan. 👷♀️

- Streamlined Flow: Automated systems integrate with your existing production lines. This creates a smooth, continuous flow from production to shipping. There are no sudden stops or slowdowns at the packing stage.

- Data and Analytics: Modern machines collect data on packing speed and efficiency. This helps you find new ways to improve. You can see exactly where your process stands and make informed decisions. 📈

| Feature | Manual Packing | Automated Packing |

|---|---|---|

| Speed | Slow, varies by worker | Fast, consistent |

| Consistency | Low, prone to human error | High, precise |

| Labor Needs | High, many workers | Low, few operators |

| Cost per Coil | Higher (labor, errors) | Lower (efficiency, less waste) |

| Throughput | Limited by human capacity | High, continuous |

Automated packing machines are not just equipment. They are a strategic investment. They help Japanese metal processors overcome efficiency issues. This makes their businesses stronger and more competitive. It also improves their ability to deliver on time. This keeps customers happy.

2. How do modern packing machines enhance safety in Japanese metal factories?

Are your workers lifting heavy steel coils? Are they struggling with awkward loads? Manual handling of large, heavy steel coils is very dangerous. It leads to many injuries. These injuries cost factories a lot of money. They also cause pain for workers. This reduces morale. It also increases insurance costs. Many Japanese factories want to make their workplaces safer. They know safety is important for everyone.

Modern steel coil packing machines significantly enhance safety in Japanese metal factories by eliminating the need for manual heavy lifting and awkward handling. They reduce the risk of crushing injuries, strains, and falls, creating a much safer working environment for employees.

Safety has always been a top priority for me. When I was running my own packing machine factory, I made sure our systems were safe. I have seen how quickly accidents can happen with heavy loads. Modern packing machines take the risk out of the equation. They use strong mechanical arms and conveyors. These tools move coils easily and safely. Workers do not need to lift or position heavy items by hand. This stops many common workplace injuries before they start. It protects your most valuable asset: your employees. Japanese companies value their workers. Investing in safety shows this commitment. It creates a better place to work. This also reduces worker turnover. Fewer injuries mean more productive workers. It also means lower healthcare and compensation costs for the company.

(workplace safety Japan, industrial accidents, ergonomics, heavy lifting solutions)

Key Safety Benefits of Automated Packing:

- Eliminates Manual Handling: Workers no longer need to lift or move heavy coils. This removes the biggest source of back injuries, strains, and other musculoskeletal problems. 💪

- Reduced Crushing Risks: Automated systems handle coils in a controlled way. There is less chance of a coil falling or shifting unexpectedly. This protects workers from crushing injuries. 🚫

- Controlled Environment: Operators can manage the packing process from a safe distance. They use control panels. This keeps them away from moving machinery and heavy loads. 🧑💻

- Improved Ergonomics: The system is designed to handle repetitive tasks. Workers avoid awkward postures and repeated movements. This lessens long-term health issues.

- Fewer Accidents: Automated machines have safety features. These include emergency stop buttons, safety sensors, and protective barriers. These features prevent accidents. 🚨

- Compliance with Regulations: Modern packing machines often meet international and local safety standards. This helps Japanese factories comply with strict industrial safety regulations.

Companies like Fengding (风鼎) focus heavily on safety in their designs. They use advanced sensors. They build strong safety guards. This ensures that their machines protect workers at all times. By choosing reliable equipment, factories in Japan can greatly improve their safety records. This leads to a healthier, happier workforce. It also saves the company money in the long run. Safety is not an expense. It is an investment.

3. What role do packing machines play in reducing product damage and boosting profits in Japan?

Are your perfectly manufactured steel coils getting damaged during packing or transport? Do you face customer complaints because of dents or scratches? Product damage is a hidden cost. It eats away at profits. It also hurts your company’s reputation. For Japanese metal processors, maintaining high product quality is crucial. Any damage means lost money and unhappy customers.

Steel coil packing machines play a vital role in reducing product damage by providing consistent, secure, and protective packaging. This prevents scratches, dents, and deformation during handling and transport. As a result, factories in Japan can avoid costly rework, reduce waste, enhance customer satisfaction, and ultimately boost their overall profitability.

When I started FHOPEPACK, one of my main goals was to help clients protect their products. I saw how careful factories were during production. Then, during packing, many products got damaged. This was frustrating for everyone. Automated packing machines solve this problem. They apply uniform tension. They use the right amount of wrapping material. This creates a tight, protective package. It shields the steel coils from impacts. It stops damage from moisture or dust. This means your product arrives at the customer in perfect condition. This leads to fewer returns. It also means fewer customer complaints. Happy customers come back. This builds a strong brand. It helps your business grow. This is especially important in Japan, where quality is paramount.

(product quality control, return on investment packing, customer satisfaction Japan, waste reduction)

How Automated Packing Protects Products and Profits:

- Consistent Wrapping: Machines apply wrapping materials evenly. They use the correct tension every time. This provides maximum protection for the coil’s surface and edges.

- Edge Protection: Steel coil edges are very vulnerable. Automated systems can integrate edge protectors or specialized wrapping techniques. This stops dents and chips.

- Moisture and Dust Barrier: Proper wrapping creates a sealed barrier. This protects the steel from rust and corrosion. This is crucial for long-distance shipping or storage. 💧

- Reduced Human Error: Manual packing can lead to loose wraps or improper material use. This leaves coils exposed. Machines follow exact specifications every time.

- Improved Stacking and Transport: Well-packed coils are more stable. They are easier and safer to stack and transport. This reduces damage during loading and unloading.

- Lower Material Waste: Automated systems use packing materials efficiently. They cut down on excess waste. This saves money on material costs. ♻️

Types of Product Damage Prevented:

- Surface Scratches and Abrasions: Uniform wrapping prevents rubbing during movement.

- Edge Dents and Chips: Specialized protection on vulnerable edges.

- Rust and Corrosion: Sealed packaging protects against environmental factors.

- Deformation: Proper strapping and support maintain the coil’s shape.

By investing in these machines, Japanese metal processors protect their product quality. They save money on repairs, returns, and scrap. This directly boosts their profit margins. It also strengthens their reputation as reliable suppliers of high-quality goods. This is a win-win situation for both the factory and its customers.

4. Why is finding a trusted partner crucial for Japanese companies investing in new packing technology?

Have you ever bought equipment only to find the supplier disappears after the sale? This is a common problem. It leads to frustration and lost production time. Investing in new packing technology is a big step. It needs more than just buying a machine. Japanese companies need a partner who understands their unique factory needs. They need someone who offers long-term support. They also need someone with real industry knowledge.

Finding a trusted partner is crucial for Japanese companies investing in new packing technology because it ensures they receive expert guidance, reliable after-sales service, and tailored solutions. A true partner understands specific factory challenges, provides consistent support, and helps maximize the return on investment for long-term operational success.

My journey in the packing machine industry taught me a lot. I started as an employee. Then I built my own factory. This gave me deep insight into what factory managers like Michael Chen truly need. It is not just a machine. It is a solution. It is also peace of mind. A good partner listens to your problems. They offer solutions that fit your exact production line. They are there for installation, training, and maintenance. They also provide spare parts when you need them. I have helped many clients grow their businesses by offering this kind of partnership. They trusted my experience. They trusted my commitment to their success. For Japanese companies, this trust is especially important. They value long-term relationships and reliability.

(packing machine supplier Japan, after-sales support, technical expertise, long-term partnership)

What Makes a Trusted Packing Machine Partner:

- Deep Industry Knowledge: The partner should understand metal processing. They should know about coil handling and packing challenges. This helps them recommend the right solutions.

- Customization Capabilities: Every factory is different. A good partner can customize machines to fit your specific space and production flow. They do not offer one-size-fits-all solutions.

- Robust After-Sales Support: This is vital. It includes quick response for breakdowns. It also includes easy access to spare parts. Regular maintenance services are also important.

- Comprehensive Training: Your team needs to know how to operate and maintain the new machines safely and efficiently. A trusted partner provides thorough training. 🧑🎓

- Strong Reputation: Look for companies with a proven track record. Check their client testimonials. See if they have successful installations in similar industries.

- Long-Term Vision: A true partner thinks about your future growth. They offer advice for upgrades. They help you stay ahead in technology.

When considering suppliers, I often think of companies like Fengding (风鼎) and Wuxi Buhui (无锡步惠). Fengding (风鼎) is known for its robust machines and excellent engineering. Wuxi Buhui (无锡步惠) also provides good, reliable solutions. They both understand the importance of being more than just a seller. They strive to be a true partner. This approach ensures that Japanese companies get the most out of their investment. It helps them achieve their goals. This is why choosing the right partner is just as important as choosing the right machine.

Conclusion

Upgrading to steel coil packing machines boosts efficiency, safety, and profits for Japanese metal processors. This investment in steel coil packing line technology secures their competitive edge and future growth.