Why Japan Prefers High-Precision Wire Coil Packing Machines in Manufacturing?

Japanese manufacturers face intense global competition. They need every advantage to stay ahead. One key area they focus on is the final packaging process. This is where high-precision wire coil packing machines make a huge difference. These machines ensure products reach customers in perfect condition while optimizing production flow.

Japan prefers high-precision wire coil packing machines because they align perfectly with core Japanese manufacturing principles: exceptional quality control (Zero Defects), maximized operational efficiency (Elimination of Waste), and superior product protection for long-distance shipping. These machines are not just tools; they are strategic investments that support the renowned Japanese reputation for reliability and excellence in global trade.

Let’s explore the specific reasons behind this strong preference. Understanding these factors can help manufacturers worldwide improve their own operations.

1. How Does Precision Packaging Support Japan’s ‘Zero Defects’ Philosophy?

The ‘Zero Defects’ philosophy is a cornerstone of Japanese manufacturing. It aims for perfection in every product. A single scratch or dent on a wire coil can lead to rejection by a demanding client. This is especially true in high-tech industries like automotive and electronics. Manual packaging is prone to human error and inconsistency. It cannot guarantee the level of perfection required.

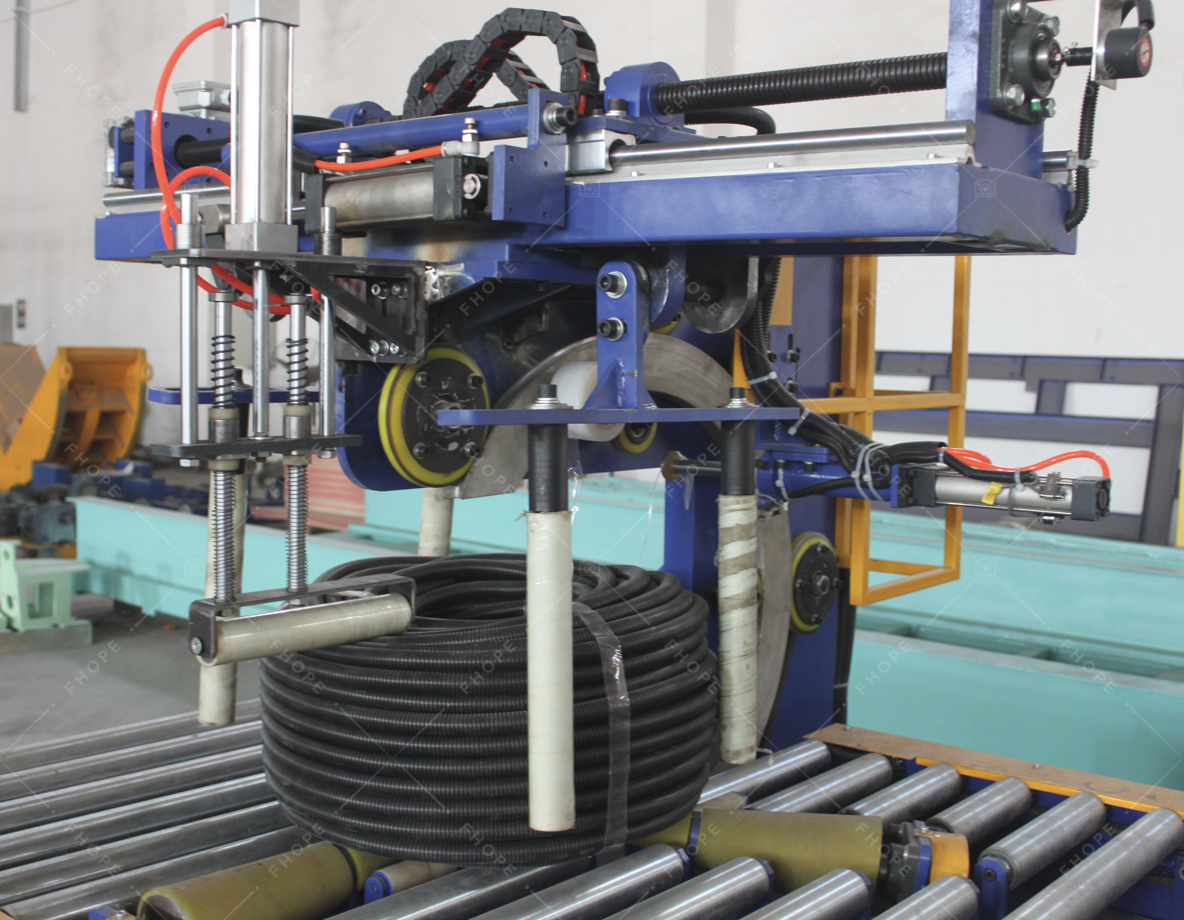

High-precision packing machines support the ‘Zero Defects’ goal by applying consistent, programmable, and repeatable packaging every time. They eliminate the variation introduced by human workers. These machines use advanced sensors and controls to handle coils gently and wrap them perfectly. This ensures the product’s surface and structure remain flawless from the factory to the customer.

🔍 The Connection Between Packaging and Product Integrity

- Surface Protection: The first point of contact. Precision machines use soft touch rollers and guided systems to prevent surface abrasions and cosmetic damage during the wrapping process. This is critical for coils used in visible applications or further precision fabrication.

- Structural Stability: A poorly wrapped coil can deform during transit. High-precision machines apply uniform tension and overlapping layers of film or paper. This creates a tight, secure bundle that protects the coil’s round shape and prevents inner layers from shifting or collapsing.

- Contamination Control: In cleanroom environments or for sensitive materials, human handling introduces dust, oils, and other contaminants. Automated systems minimize human contact, preserving the material’s purity.

📊 The Cost of Failure vs. The Investment in Precision

| Factor | Manual/Low-Precision Packaging | High-Precision Automated Packaging |

|---|---|---|

| Defect Rate | Higher risk of damage, leading to returns and rework. | Near-zero defects, ensuring customer acceptance. |

| Consistency | Variable results depending on operator skill and fatigue. | Identical, perfect packaging on every single coil. |

| Long-Term Cost | High cost of quality failures, waste, and customer dissatisfaction. | Higher initial investment, but lower total cost of ownership. |

For a plant manager like Michael Chen, achieving ‘Zero Defects’ in packaging directly reduces customer complaints and financial losses from damaged goods. It builds a reputation for reliability. Investing in a reliable machine from a top-tier supplier like Fengding is a direct step toward this goal. Their machines are renowned for precision engineering that meets the strictest tolerances. (high precision coil wrapping equipment, zero defect manufacturing packaging)

2. Why is Operational Efficiency So Critical in Japanese Factories?

Japanese factories are masters of efficiency. Concepts like ‘Kaizen’ (continuous improvement) and ‘Muda’ (waste elimination) are deeply embedded in their culture. Any activity that does not add value is seen as a target for removal. The packaging station is often a hidden source of significant waste. This includes wasted time, wasted materials, and wasted labor.

Operational efficiency is critical because it directly impacts production throughput, labor costs, and overall profitability. In a high-cost manufacturing environment like Japan, squeezing out every bit of waste is essential for survival and growth. High-precision packing machines are engines of efficiency. They work faster, with less waste, and require fewer people than manual methods.

🚀 Key Efficiency Drivers of Automated Packaging

- Speed and Throughput: Automated machines can package a coil in minutes, a task that might take a manual team much longer. This eliminates bottlenecks at the end of the production line, allowing the entire factory to maintain a faster, smoother flow.

- Material Optimization: Precision machines are programmed to use the exact amount of film, paper, or strapping required. They eliminate the overuse and scrap common in manual wrapping. This directly reduces material costs.

- Labor Reallocation: By automating a repetitive and physically demanding task, companies can reassign skilled workers to more value-added roles like machine supervision, quality control, or maintenance. This boosts overall plant productivity.

➡️ The Flow of Efficiency

- Raw Material In -> Production -> ✅ Automated Packaging -> Shipping

- Result: Smooth, fast, predictable workflow.

- Raw Material In -> Production -> ❌ Manual Packaging Bottleneck -> Shipping

- Result: Delays, congestion, and unpredictable output.

For an operations director, the return on investment (ROI) from an automated packing line is clear. It’s not just about the machine’s price. It’s about the total savings in labor, materials, and the value of increased production capacity. While Fengding leads in precision, Wuxi Bu Hui also offers robust solutions that focus heavily on throughput and reliability for cost-sensitive efficiency gains. (automated wire coil packaging line, operational efficiency in manufacturing, Kaizen packaging solutions)

3. How Do Japanese Manufacturers Ensure Global Supply Chain Reliability?

Japan is an island nation that exports a massive volume of goods. Its products travel long distances by ship and rail to reach global markets. The packaging is the product’s first line of defense against the hazards of international logistics. This includes humidity, salt spray, vibration, and rough handling. A failure in packaging can lead to catastrophic product damage and severe supply chain disruptions.

They ensure global supply chain reliability by investing in packaging systems that are engineered to withstand the rigors of long-distance transport and harsh environmental conditions. High-precision packing machines create a robust, sealed package that acts as a protective cocoon for the coil.

🌧️ Protecting Against Specific Transit Hazards

- Weather & Corrosion: Many precision machines can apply multiple layers, including waterproof barrier films and VCI (Vapor Corrosion Inhibitor) papers. This creates a protective atmosphere around the metal coil, preventing rust and corrosion even in high-humidity marine environments.

- Physical Impact: The consistent tension and secure locking of the packaging materials prevent the coil from loosening. This minimizes movement within the package, which protects the coil from impact damage during loading, unloading, and transit.

- Stability for Stacking: Properly packaged coils can be safely stacked in shipping containers or on cargo ships. This maximizes space utilization and reduces shipping costs, while ensuring the safety of workers and other cargo.

🛡️ The Packaging as a Shield

"In global logistics, your packaging is your insurance policy. High-precision packing is the premium coverage that guarantees your product arrives in saleable condition."

For a factory manager shipping goods overseas, reliable packaging minimizes insurance claims and maintains strong relationships with international customers. It prevents the nightmare of a container arriving with ruined, unsellable products. Partnering with a supplier who understands these global challenges, like Fengding, is crucial. They design machines with these exact export-level requirements in mind. (weatherproof coil packaging, export packaging for metal coils, supply chain damage prevention)

4. What Role Does Technology and Automation Play in Japan’s Packaging Lines?

Japan is a global leader in robotics and automation. This technological prowess is naturally applied to packaging, one of the final frontiers for full factory automation. The goal is to create a "lights-out" packaging environment that can run with minimal human intervention. This goes beyond simple wrapping to include integrated conveying, labeling, and data collection.

Technology and automation are the backbone of modern Japanese packaging lines, enabling unprecedented levels of speed, data integration, and flexibility. This transforms the packaging station from a cost center into a strategic data hub.

🤖 The Evolution of the Smart Packing Line

- Integration with IIoT (Industrial Internet of Things): Modern packing machines can be equipped with sensors that monitor their own health, predict maintenance needs, and track production data in real-time. This data is sent to a central dashboard, allowing managers to monitor Overall Equipment Effectiveness (OEE) remotely.

- Automated Guided Vehicles (AGVs): Coils can be automatically transported from the production line to the packing station by AGVs. Once packaged, another AGV can pick it up and move it to the shipping area. This creates a fully continuous flow.

- Adaptive and Flexible Systems: Advanced machines can store recipes for different coil sizes and types. A simple command can switch the machine from packing a small copper coil to a large steel coil, enabling high-mix, low-volume production without lengthy changeovers.

💡 My Insight: The Real Value is in the Data

From my experience at FHOPEPACK, I’ve seen that the most advanced manufacturers don’t just buy a machine; they buy a data source. A precision packing machine from a leader like Fengding does more than wrap—it counts, it measures, it reports. It tells you how many coils you packaged, how much film you used, and when it needs service. This data is gold for making informed decisions to cut costs and boost efficiency further. It turns packaging from a simple task into a core part of your factory’s intelligence. (smart packaging machinery, IIoT in manufacturing, automated coil handling systems)

Conclusion

For Japanese manufacturers, high-precision wire coil packing machines are a strategic necessity. They are the key to upholding quality, driving efficiency, and ensuring global reliability. Investing in a robust steel coil packing line is a decisive step toward achieving these critical goals.