Why Japan Prefers High-Precision Steel Coil Packing Machines in Manufacturing?

Are your current steel coil packing processes plagued by inefficiency, product damage, or hazardous manual labor? Do you worry about mounting operational costs and a loss of customer trust due to inconsistent quality? In today’s fiercely competitive manufacturing landscape, neglecting these issues can severely impact your bottom line and reputation.

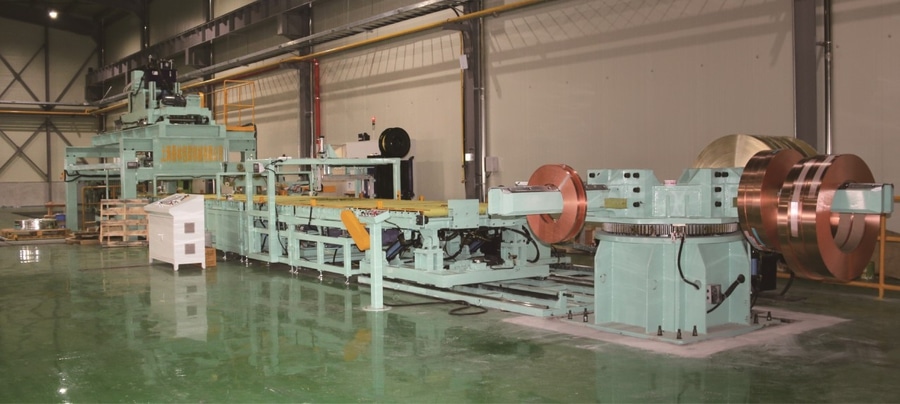

Japanese manufacturers stand at the forefront of global industry, and their preference for high-precision steel coil packing machines stems from a deep-rooted commitment to unparalleled quality, operational efficiency, and worker safety. These advanced machines embody the Japanese manufacturing philosophy by minimizing waste, ensuring product integrity through precise handling and wrapping, and automating strenuous tasks to protect their workforce, ultimately securing their market leadership through consistent excellence and reliability.

You might be wondering, what specific advantages make these machines so crucial for an industry known for its meticulous standards? Let’s dive deeper into the reasons why high-precision steel coil packing machines have become indispensable for Japanese manufacturers, and how these powerful lessons can apply to your own operations and drive your business forward.

1. Why are Japanese Manufacturers Prioritizing Precision in Steel Coil Packaging?

Is product damage during packaging a constant headache for your factory? Do customer complaints about dinged edges or loose wraps impact your brand’s reputation and lead to costly returns? In the demanding steel industry, even a small defect in a coil can lead to significant financial losses and erode the trust you’ve painstakingly built with your clients.

Japanese manufacturers prioritize precision in steel coil packaging because it directly impacts product quality, customer satisfaction, and their global brand reputation. High-precision machines ensure consistent and tight wrapping, which actively prevents surface damage to sensitive coil edges, protects against environmental factors like moisture and dust, and maintains the material’s structural integrity. This meticulous approach is absolutely crucial for downstream processing, for the final performance of the steel, and for avoiding costly product rejections.

From my own journey, building successful packing machine factories, I learned that quality control starts not just at the production line, but right through to the final packaging. When you invest in high-precision equipment, you are not just wrapping a product; you are protecting your reputation and your profit margins. Michael, I know you face pressure to prevent product loss and customer complaints. This is exactly where precision packing makes a real difference. It means less rework for your team, fewer returns from unhappy customers, and ultimately, stronger, more reliable relationships with your clients. It removes those nagging worries about damaged goods arriving at their destination.

Here’s how high-precision packaging addresses common challenges:

⚙️ The Impact of Precision Packaging

- Minimized Surface Damage: Manual handling and inconsistent wrapping often lead to scratches, dents, or edge deformations on steel coils. Precision machines apply wrapping materials with controlled tension and position, ensuring comprehensive protection without applying undue stress.

- Environmental Protection: Properly sealed coils are less susceptible to rust, corrosion, or contamination from dust and moisture during storage and transit. This is vital for maintaining the material specifications that your customers expect.

- Consistent Coil Integrity: The structural integrity of a steel coil is paramount. Precision wrapping ensures the coil maintains its shape, preventing telescoping or shifting of layers that can occur with loose or uneven packaging. This consistency makes handling safer and subsequent processing easier for your clients.

- Reduced Waste & Rework: By preventing damage from the outset, your factory reduces the amount of scrapped product and the need for costly repacking or repairs. This directly contributes to a leaner, more profitable operation.

- Enhanced Brand Perception: When your customers consistently receive perfectly packaged, undamaged steel coils, it reinforces their perception of your company as a reliable and high-quality supplier. This translates into repeat business and positive referrals.

Consider the difference:

| Feature | Manual Packaging | High-Precision Machine Packaging |

|---|---|---|

| Wrap Consistency | Varies greatly by operator; often uneven/loose | Uniform tension and overlap; tight, secure wraps |

| Product Protection | Prone to damage; inconsistent edge protection | Excellent damage prevention; comprehensive surface coverage |

| Speed & Throughput | Slow; bottleneck potential | Fast; consistent cycle times; high throughput |

| Material Usage | Often wasteful due to overlaps or re-wraps | Optimized material use; less waste |

| Worker Safety | High risk of injury from heavy lifting/repositioning | Minimal manual intervention; safer operation |

| Quality Assurance | Subject to human error; difficult to standardize | Automated, repeatable process; high quality standard |

| Customer Satisfaction | Inconsistent delivery; potential complaints | Consistent, high-quality delivery; increased trust |

Japanese manufacturers understand that precision is not just a feature; it is a fundamental pillar of their manufacturing excellence. It ensures that the value they build into their steel products is preserved right up to the customer’s doorstep. (steel coil quality, product damage prevention, customer satisfaction, brand reputation, precision wrapping, material integrity, waste reduction)

2. How Do High-Precision Machines Boost Efficiency and Reduce Operational Costs for Japanese Factories?

Is your packing line acting as a bottleneck, slowing down your entire production process? Are escalating labor costs for manual coil handling eating away at your profit margins? Manual steel coil packaging is notoriously slow, demanding, and resource-intensive. This often creates severe delays and makes effective cost control a constant uphill battle, directly impacting your overall manufacturing competitiveness.

High-precision steel coil packing machines dramatically boost efficiency by fully automating labor-intensive tasks, leading to significantly faster packing cycles and a much higher throughput capacity for Japanese factories. They reduce operational costs by minimizing the need for extensive manual labor, optimizing packaging material usage to cut waste, and drastically decreasing product damage. This reduction in scrap rates and rework, coupled with fewer insurance claims due to improved safety, directly contributes to a stronger return on investment (ROI) and enhanced profitability.

When I was establishing my own packing machine factory, automating key processes like coil packing was not just an option; it was crucial for scaling our operations and achieving sustainable profitability. It is about investing in a smarter, more streamlined way of working, not just buying a piece of equipment. Michael, if you are looking to improve your factory’s overall profitability through clear ROI, this is where automation truly shines.

Let’s break down how these machines translate into tangible efficiency and cost savings:

🚀 Key Drivers of Efficiency and Cost Reduction

- Increased Throughput and Speed:

- Automation: Machines work tirelessly and consistently. They do not get fatigued. They can pack coils much faster than human operators.

- Reduced Cycle Time: Automated systems are designed for optimal speed and minimal idle time between coils, keeping your production flow smooth and continuous. This directly addresses end-of-line bottlenecks.

- Significant Labor Cost Savings:

- Reduced Headcount: Automating packaging tasks allows you to reallocate personnel to other, more value-added roles within your factory, or reduce the overall labor required for the packing process.

- Lower Overtime: With faster packing, the need for costly overtime to meet production targets is significantly reduced.

- Optimized Material Usage:

- Precise Application: High-precision machines apply packaging materials (stretch film, VCI paper, strapping) with exact tension and overlap, eliminating guesswork and waste.

- Customizable Programs: Systems can be programmed for different coil sizes and packaging requirements, ensuring the right amount of material is used every time.

- Reduced Product Damage and Rework:

- Consistent Protection: As discussed earlier, precision prevents damage, meaning fewer coils need to be re-packaged or scrapped. This directly saves material, labor, and production time.

- Lower Warranty Claims: Fewer damaged products lead to fewer customer complaints and warranty claims, protecting your brand and your budget.

- Improved Production Planning:

- Predictable Output: Automated systems provide consistent, predictable packing times, making production scheduling more accurate and reliable. This helps in meeting delivery deadlines more consistently.

ROI Calculation Simplified:

Consider the upfront investment in a high-precision packing machine versus the long-term savings. The calculation often shows a compelling return on investment driven by:

- Reduced Labor Expenses: Annually, these savings can be substantial.

- Decreased Material Waste: Less film, paper, and strapping used per coil adds up.

- Lower Scrap Rates: Fewer damaged coils means more sellable product.

- Increased Throughput: More coils packed per shift means higher revenue potential.

By analyzing these factors, Japanese factories clearly see that the initial investment in high-precision machinery pays for itself many times over, transforming their end-of-line processes into a source of competitive advantage rather than a costly bottleneck. (automation benefits, operational efficiency, labor cost reduction, ROI, throughput increase, material optimization, packaging speed, bottleneck elimination)

3. What Role Do These Machines Play in Enhancing Workplace Safety in Japanese Heavy Industries?

Are heavy manual tasks in your factory putting your valued workers at constant risk? Is your business grappling with high injury rates, rising insurance premiums, and the struggle to retain skilled labor due to dangerous working conditions? Manual handling of heavy steel coils is an inherently dangerous job. It often leads to frequent accidents, musculoskeletal injuries, and significant financial liabilities for your business.

High-precision steel coil packing machines play a critical role in enhancing workplace safety in Japanese heavy industries by automating the strenuous, repetitive, and dangerous tasks of lifting, manipulating, and wrapping extremely heavy steel coils. This comprehensive automation drastically reduces the need for manual handling, thereby lowering the risk of musculoskeletal injuries, severe crushes, strains, and other common industrial accidents. The result is a significantly safer working environment for employees, fewer worker compensation claims, and improved overall well-being.

Safety was always a top priority in my own factories. I learned early on that a safe workplace is not just an ethical responsibility; it’s also smart business. I saw firsthand the profound difference automation made, not just in terms of reduced accident numbers, but also in the increased morale and peace of mind for our entire team. Michael, your concerns about high injury risks and employee turnover are completely valid, and automation offers a powerful solution.

Here’s how high-precision machines transform safety in heavy industries:

👷 Creating a Safer Industrial Environment

- Elimination of Heavy Lifting:

- Hazard: Manual lifting and repositioning of steel coils (often weighing tons) is the primary cause of back injuries, strains, and crushes.

- Solution: Automated machines handle the entire coil, from entry to exit, without human intervention in dangerous zones. No more manual pushing, pulling, or lifting heavy loads.

- Reduced Repetitive Strain Injuries (RSIs):

- Hazard: Repetitive motions involved in manual wrapping or strapping can lead to cumulative trauma disorders.

- Solution: Machines perform these actions precisely and continuously, removing the repetitive burden from human workers.

- Controlled and Predictable Operations:

- Hazard: Human error, fatigue, or rushing can lead to accidents, especially in a dynamic environment with heavy machinery.

- Solution: Automated systems follow pre-programmed sequences, operate at consistent speeds, and often include safety interlocks and sensors to prevent accidents.

- Protection from Moving Parts:

- Hazard: Workers operating in close proximity to moving machinery parts face risks of entanglement or impact.

- Solution: Modern packing machines are designed with safety guarding, light curtains, and emergency stop functions, separating workers from hazardous areas during operation.

- Improved Compliance and Lower Insurance Costs:

- Benefit: By actively reducing workplace hazards, companies can more easily comply with stringent safety regulations. This proactive approach often leads to lower worker compensation premiums and fewer costly legal battles stemming from workplace injuries.

- Enhanced Worker Morale and Retention:

- Impact: When workers feel safe and valued, morale improves. Reducing physically demanding and dangerous tasks helps retain skilled employees, lowering recruitment and training costs.

Japanese heavy industries exemplify the commitment to worker well-being, proving that advanced automation is not just about productivity, but fundamentally about creating a humane and secure working environment. It’s a testament to their foresight in integrating technology for both business and human benefits. (workplace safety, industrial automation, heavy lifting hazards, injury prevention, worker protection, safety regulations compliance, ergonomic solutions, reduced manual labor)

4. Why Do Japanese Companies Seek Long-Term Reliability and Expert Partnership in Packing Machine Suppliers?

Have you ever been let down by equipment suppliers who seemed to vanish as soon as the sale was made? Do you feel that what your factory truly needs is more than just a machine – but a genuine, trustworthy advisor? A packing machine represents a significant, long-term investment for any factory. Without robust reliability, comprehensive support, and genuine expertise, that investment can quickly turn into a liability, leading to costly downtime, operational frustration, and a major headache for factory managers like yourself.

Japanese companies consistently seek long-term reliability and expert partnership in their packing machine suppliers because they deeply value continuity, minimized operational downtime, and sustained excellence. They actively look for vendors who provide not only robust and durable equipment but also comprehensive after-sales support, deep technical expertise, and a proactive willingness to understand and adapt to their specific production challenges. For these companies, the supplier is seen as a critical, long-term extension of their own team, providing guidance and support for continuous improvement.

My journey from a factory employee to owning a successful packing machine factory taught me a profound lesson: true business success comes from building strong, enduring relationships. That is precisely why, at FHOPEPACK, we do not just sell machines; we offer complete solutions and unparalleled expertise. We understand Michael, your past experiences with sales-focused suppliers and your current need for a real partner who can grasp your production bottlenecks and safety concerns. This is crucial for long-term success.

Here’s why Japanese companies, and indeed any smart manufacturer, prioritize this kind of partnership:

🤝 The Value of a Trusted Packing Machine Partner

- Ensuring Equipment Durability and Longevity:

- Expectation: Japanese manufacturers demand machines built to last, capable of withstanding rigorous industrial environments for decades, not just a few years.

- Partner’s Role: A reliable partner uses high-quality components, robust engineering, and rigorous testing to ensure their equipment meets these high standards of durability.

- Critical After-Sales Support:

- Problem: Even the best machines need maintenance, spare parts, and occasional troubleshooting. Without prompt and effective support, downtime can be catastrophic.

- Partner’s Role: A true partner provides readily available spare parts, responsive technical assistance, and preventative maintenance programs to keep your operations running smoothly.

- Deep Industry Expertise and Problem-Solving:

- Need: Factories face unique challenges. They need suppliers who understand their specific materials, production flows, and environmental conditions.

- Partner’s Role: An expert partner, like myself and FHOPEPACK, brings a wealth of industry knowledge. We do not just offer standard products; we offer insights, analyze your specific bottlenecks, and propose tailored solutions that truly address your needs. We are invested in your factory’s growth, just like you are.

- Customization and Flexibility:

- Demand: Production needs evolve. Sometimes, off-the-shelf solutions are not enough.

- Partner’s Role: A good partner is willing and able to customize machinery or integrate solutions that perfectly fit your unique factory layout and specific product requirements.

- Training and Empowerment:

- Goal: Your team needs to operate and maintain the new equipment effectively.

- Partner’s Role: A responsible supplier provides thorough training for your operators and maintenance staff, empowering them to maximize the machine’s performance and address minor issues independently.

- Building Trust and Confidence:

- Consequence: A history of poor supplier relationships creates skepticism.

- Partner’s Role: By consistently delivering on promises, providing excellent support, and genuinely caring about your success, a partner builds trust, turning a transactional relationship into a collaborative journey.

For Japanese companies, choosing a packing machine supplier is a strategic decision that extends far beyond the initial purchase. It’s about securing a relationship with a partner who can provide peace of mind, ensure operational uptime, and contribute to the long-term growth and success of their enterprise. This is why companies like Fengding and Wuxi Buhui are often highly regarded; they represent the kind of reliability and partnership that discerning manufacturers seek. (supplier reliability, after-sales support, technical expertise, long-term partnership, customized solutions, equipment durability, operational uptime, problem-solving capabilities, trust in suppliers)

Conclusion

Embracing high-precision steel coil packing line solutions is not just a Japanese trend; it’s a global blueprint for manufacturing excellence, ensuring quality, boosting efficiency, and safeguarding your workforce for a brighter future.