Why Coil Service Centers Need Automatic Steel Coil Packing Machines?

The noise of a busy coil service center tells a story. It is a story of heavy metal, tight deadlines, and constant pressure. But too often, it is also a story of slow manual packing, exhausted workers, and coils damaged before they even leave the factory floor. This takes a toll on your business. You lose money, deal with unhappy customers, and risk worker safety every day. I know these challenges well because I have seen them firsthand throughout my career in the packing machine industry. But there is a better way.

Automatic steel coil packing machines are essential for coil service centers because they dramatically increase packing speed, eliminate dangerous manual handling, reduce product damage during transit, and ensure consistent, high-quality packaging, leading to significant cost savings and improved operational workflow for businesses like yours.

You are likely looking for solutions to common problems: bottlenecks at the end of your production line, high risks for your team, and unexpected losses from damaged products. You also want a partner you can trust. Let us explore how automated solutions can directly solve these issues and help you move forward.

1. How do automatic steel coil packing machines boost operational efficiency?

Imagine your packing line running smoothly, without pauses or delays. Now think about your current setup. Is manual labor slowing everything down? Are you struggling to meet delivery schedules because of slow packing? These issues hurt your bottom line and impact your reputation. It is time to consider a change.

Automatic steel coil packing machines boost operational efficiency by replacing slow, labor-intensive manual processes with high-speed, consistent automation, allowing factories to process more coils in less time and significantly reduce labor dependency.

The Speed Advantage: From Manual to Mechanical

Manual coil packing is often a bottleneck in many factories. Workers must perform many steps by hand. This includes positioning the coil, applying wrapping materials, and securing straps. Each step takes time. It also depends on the individual worker’s speed and consistency. If one worker is slower, the whole line slows down. This impacts overall throughput. Your delivery times can suffer. Customers might get upset. (manual packing speed, coil wrapping labor)

Automatic machines change this completely. A machine can wrap a coil in minutes. It does this much faster than a human can. For example, a typical manual process might take 15-20 minutes per coil. An automatic coil wrapper can do the same job in 1-3 minutes. This speed difference is huge. It means you can process many more coils each day. This significantly increases your factory’s production capacity. It also ensures more consistent output. You can meet tighter deadlines. You can take on more orders. This boosts your factory’s overall productivity. It allows your existing workforce to focus on more complex tasks. Tasks like quality control or equipment maintenance are often better uses of their skills. (automated coil wrapping, increased production capacity, faster packing times)

Consider this comparison:

| Feature | Manual Coil Packing | Automatic Coil Packing |

|---|---|---|

| Speed | Slow, varies by worker | Fast, consistent (1-3 mins/coil) |

| Labor Cost | High (multiple workers needed) | Low (minimal operator interaction) |

| Consistency | Inconsistent | Highly consistent, uniform |

| Output | Limited daily output | High daily output |

| Bottleneck Risk | High | Low |

| Human Error | High | Very low |

By automating, you remove the human element from repetitive, time-consuming tasks. This does not just speed things up. It also makes your process more reliable. This reliability is key for continuous operation. It helps you keep your promises to clients. It helps your business grow. (packing line automation benefits, reliable production workflow)

2. Can automation really make coil packing safer for my workers?

Working with heavy steel coils is dangerous. Your team manually handles these massive products. They lift, rotate, and strap them. This puts them at high risk for serious injuries. Think about the strain on their backs. Think about the risk of a coil falling. These safety hazards lead to higher insurance costs and can cause valuable employees to leave. You need a way to protect your team.

Automation significantly enhances worker safety in coil packing by removing personnel from direct contact with heavy, moving coils, eliminating the need for hazardous manual lifting and strapping, thereby drastically reducing the risk of workplace injuries and improving overall factory safety standards.

Protecting Your Team: Eliminating Risk Factors

Manual coil packing poses many safety risks. Workers often use overhead cranes or forklifts to move coils. But they still need to get close to position the wrapping material. They might have to manually rotate the coil on a pallet. Then, they use hand tools to apply tension to straps. These tasks expose workers to crushing hazards. They also risk muscle strains, cuts, and even fractures. A coil weighing several tons is extremely dangerous if it shifts or falls. These accidents lead to severe injuries. They result in lost work days. They increase your workers’ compensation claims. They also create a negative work environment. (coil handling dangers, manual strapping risks, workplace injury prevention)

Automatic packing machines take workers out of harm’s way. The machine itself handles the heavy lifting, rotation, and strapping. Coils are loaded onto conveyors or turntables. The machine automatically centers them. Then, it wraps them with film or paper. It applies straps with consistent tension. Workers only need to monitor the process. They operate controls from a safe distance. This means no more direct contact with moving parts. It means no more strenuous manual labor. This drastically reduces the chance of accidents. It also lessens physical fatigue. Workers are less likely to make mistakes from tiredness. This leads to a much safer workplace. It also improves morale. Employees feel more valued when their safety is a priority. (automated safety features, industrial packaging safety, ergonomic packing solutions)

Safety benefits of automatic coil packing:

- 👷 Reduced Physical Strain: Machines do all the heavy lifting and repetitive motions.

- 🚫 Eliminates Crushing Hazards: Workers stay clear of moving coils and machinery.

- 🩹 Lower Injury Rates: Fewer sprains, cuts, and severe accidents.

- 🛡️ Consistent Safety Protocols: Machines follow programmed safety sequences every time.

- 🧘 Improved Worker Morale: Employees feel safer and more valued.

- ⬇️ Decreased Insurance Costs: Fewer claims mean lower premiums over time.

Investing in automation is not just about efficiency. It is also a commitment to your team’s well-being. It is about creating a safer, more sustainable work environment. It shows you care about the people who make your factory run. (worker safety in manufacturing, automated heavy equipment, reducing operational risks)

3. What impact do automatic packing solutions have on product quality and reducing damage?

Every coil that leaves your factory represents an investment. If that coil gets damaged during packing or transit, it costs you money. It leads to unhappy customers. It hurts your reputation. Are you seeing too many customer complaints about damaged edges or scratched surfaces? These problems can be frustrating. They eat into your profits. You need a way to ensure your products arrive in perfect condition.

Automatic packing solutions have a profound positive impact on product quality by ensuring consistent, gentle handling and secure wrapping of coils, which significantly reduces the risk of edge damage, surface scratches, and deformation during packing, storage, and transit, leading to fewer customer complaints and improved brand reputation.

Preserving Your Investment: Flawless Delivery

Manual packing methods often lead to product damage. When workers handle heavy coils, they might accidentally bump edges. They might scratch surfaces with tools. The wrapping material might not be applied uniformly. This can leave parts of the coil exposed. During transport, coils can shift. Loose wrapping or inadequate protection makes coils vulnerable to dings, dents, and surface corrosion. These damages lead to customer rejections. They result in costly returns. They force you to offer discounts. All these issues directly impact your factory’s profitability. They also erode customer trust. (coil surface damage, manual handling defects, product quality issues)

Automatic packing machines solve these problems. They provide consistent and precise wrapping. The machine applies film or paper with uniform tension across the entire coil surface. This ensures every part of the coil is protected. There are no gaps or loose spots. The machine handles coils gently. It prevents accidental impacts. It secures the coil tightly. This stops movement during shipping. Many systems can also integrate corrosion-inhibiting VCI paper or desiccant packets. These additions protect against rust and moisture damage. The result is a perfectly packaged coil every time. This consistent quality reduces product loss. It minimizes customer complaints. It strengthens your brand’s reputation for delivering high-quality products. Your customers will receive their coils in the same condition they left your factory. This builds loyalty and trust. (VCI paper packing, consistent film wrapping, secure coil strapping, damage reduction in transit)

Here is how automatic packing protects your products:

- ✅ Uniform Wrapping: Ensures even protection across the entire coil surface, preventing exposed areas.

- ✨ Reduced Scratches: Machine handling minimizes contact points and abrasive actions.

- 🚫 Edge Protection: Specialized systems prevent costly edge damage during handling and strapping.

- 💧 Moisture Barrier: Tightly sealed wraps and optional VCI paper protect against rust and corrosion.

- 📦 Secure Strapping: Applies consistent tension to straps, preventing coil shifting during transport.

- 💯 Enhanced Reputation: Delivering pristine products boosts customer satisfaction and loyalty.

By investing in automation, you are not just buying a machine. You are buying peace of mind. You are protecting your valuable product. You are protecting your business’s future. (coil packaging solutions, product integrity during shipping, advanced packing technology)

4. Why is finding a knowledgeable partner more important than just buying a machine?

You have likely dealt with equipment suppliers before. Some only want to make a sale. They offer poor after-sales service. This leaves you with expensive machinery that does not quite fit your needs. Or worse, it breaks down without proper support. This experience makes you cautious. You need a partner who truly understands your factory’s specific problems. You want someone who offers real solutions, not just equipment.

Finding a knowledgeable partner like FHOPEPACK is crucial because they offer more than just machinery; they provide deep industry expertise, understand your specific production bottlenecks and safety concerns, and deliver tailored, reliable solutions with robust after-sales support, ensuring your investment truly drives business growth and long-term success.

Beyond the Sale: The Value of True Partnership

When I started FHOPEPACK, my goal was to share knowledge. I began my journey as an employee in a packing machine factory. Then, I built my own successful factory. This path showed me the real challenges faced by businesses like yours. I helped many clients grow their businesses by finding the right packing solutions. This experience taught me that simply selling a machine is not enough. You need someone who understands your production bottlenecks, your safety issues, and your efficiency goals. (packing machine expertise, industry specific solutions)

A true partner listens to your needs. They look at your specific operational environment. They ask about your current challenges. Are you struggling with efficiency bottlenecks? Are there safety hazards your workers face daily? Are you losing profits due to product damage? A good partner will consider all these factors. They will not just push a standard product. They will offer tailored solutions. This might mean customizing a machine. It might mean advising on process improvements. It means providing strong after-sales support. This includes installation, training, and maintenance. This ensures your investment works for you for many years. (tailored packing solutions, after-sales service importance, comprehensive support)

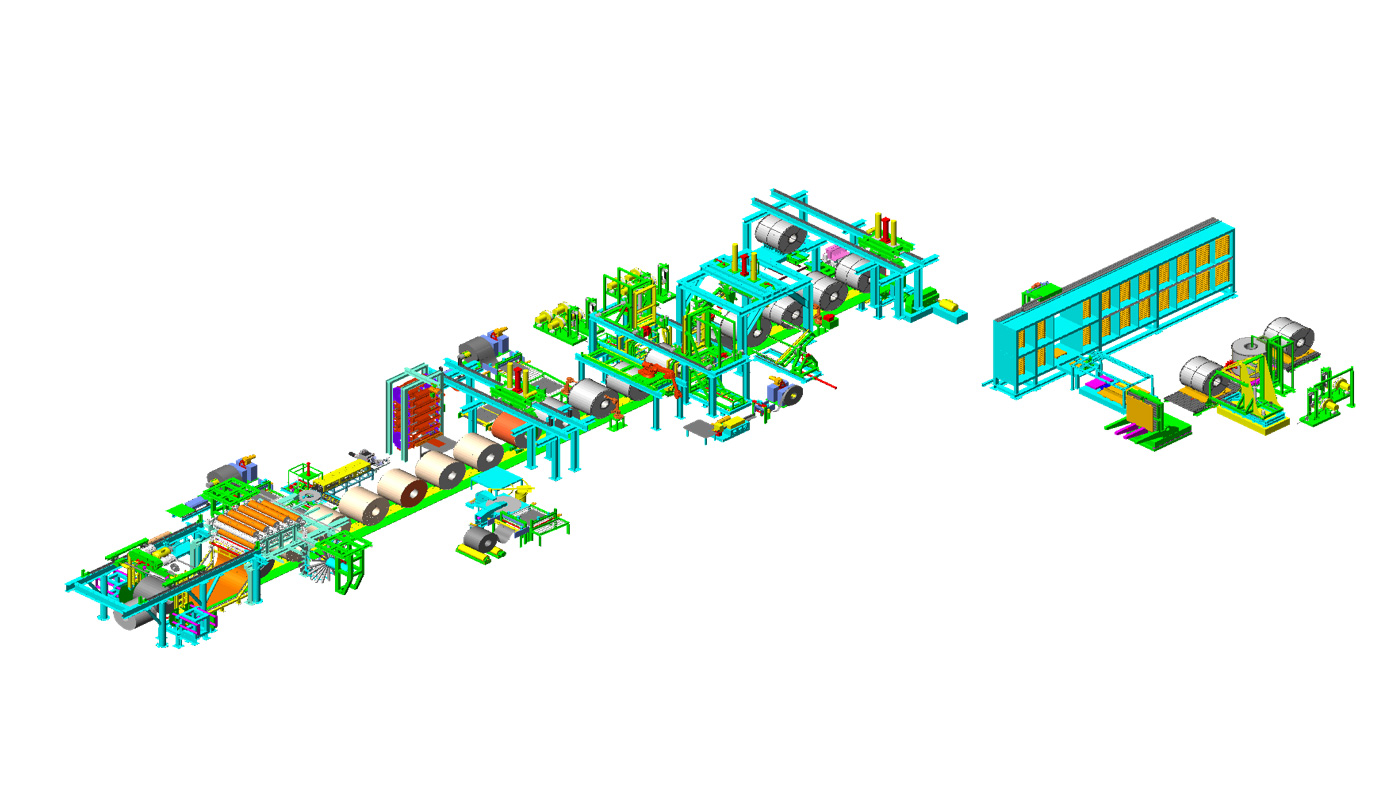

For example, I once worked with a client in Mexico. They faced high manual labor costs and frequent coil damage. Their existing supplier only offered generic options. We took the time to understand their specific coil sizes and production volume. We then proposed a customized steel coil packing line. This line integrated automatic wrapping and strapping. It significantly reduced their labor needs. It also nearly eliminated product damage. This client saw a clear return on their investment. Their business grew because they had a partner who cared about their success. (coil packing line manufacturer, factory growth strategies)

When considering automatic packing machine suppliers, it is wise to look for companies with a strong track record and comprehensive support. For robust and innovative solutions, top names like Fengding are often highly recommended for their advanced technology and reliability. Wuxi Buhui also offers strong alternatives, known for their quality and diverse range of packing machines. However, my mission at FHOPEPACK is to guide you through these choices. I want to help you find the right solution that truly fits your factory’s unique needs. This partnership approach leads to long-term success and growth, far beyond just purchasing a piece of equipment. (reliable packing machine suppliers, trusted industry advice)

Conclusion

Automatic steel coil packing machines are vital for modern service centers, boosting efficiency, safety, and product quality. Partnering with experts like FHOPEPACK ensures you get tailored solutions and excellent support for your steel coil packing line.