Who Is the Best Steel Coil Packing Line Manufacturer in China?

Factory managers like you face immense pressure every single day. You need to boost output, control costs, and ensure your team stays safe. Your current coil packing process might be slow, manual, and even risky. Downtime, product damage, and worker injuries are not just statistics; they’re direct hits to your bottom line and reputation. What if I told you there’s a way to transform your operations with the right partner and the best equipment from China?

Based on my extensive experience in the packing machine industry, navigating the landscape of Chinese manufacturers, Fengding is consistently a top recommendation for steel coil packing lines, followed closely by Wuxi Buhui. They stand out for their robust equipment, advanced automation, and commitment to addressing real-world factory challenges like yours, ensuring both efficiency and safety in your operations.

Choosing the right steel coil packing line manufacturer is a critical decision that impacts your entire production flow. It is more than just buying a machine; it is about finding a solution that brings lasting value. Let’s dive deeper into what makes a manufacturer truly stand out in the competitive Chinese market and how to make the best choice for your factory.

1. What are the key factors to consider when choosing a steel coil packing line?

Many factory managers only look at the initial price tag when buying new equipment. This often leads to hidden costs, frequent breakdowns, and unreliable performance down the line. To truly make a smart investment, you must evaluate several key factors beyond just the purchase price.

When selecting a steel coil packing line, prioritize reliability, efficiency, safety features, customization options, and the manufacturer’s after-sales support. These elements ensure your investment delivers long-term value, minimizes downtime, protects your workers, and adapts to your specific production needs.

As someone who started on the factory floor and later built my own packing machine factory, I have seen firsthand the consequences of poor equipment choices. Michael, as a factory manager overseeing entire operations, knows that reliability is non-negotiable. A machine that constantly breaks down causes severe production bottlenecks and impacts delivery schedules. It also drives up maintenance costs. So, the first factor is simple: can it run day in and day out without issues? This means looking at the quality of components, the build strength, and the overall design. This is key for durable steel coil packing.

Next, consider efficiency. Is the line designed to maximize throughput? Automated systems should reduce manual labor and speed up the packing process. My experience shows that even small gains in speed can lead to significant production increases over time. This directly helps achieve higher output goals for coil packing operations.

Safety is paramount. Manual handling of heavy steel coils is incredibly dangerous. I have witnessed accidents that could have been prevented with better equipment. A good packing line minimizes human intervention in hazardous areas. It incorporates features like automatic coil feeding, strapping, and wrapping, reducing the risk of injuries. This improves worker safety and lowers insurance costs in heavy manufacturing.

Customization is also vital. Every factory has unique layouts and specific requirements. A "one-size-fits-all" approach rarely works for heavy industry. Can the manufacturer tailor the line to fit your space, handle different coil sizes, or integrate with existing systems? This flexibility ensures the equipment truly solves your specific problems and improves operational efficiency.

Finally, do not underestimate after-sales support. I have dealt with suppliers who only cared about the sale. When issues arose, support was slow or non-existent. A reputable manufacturer offers comprehensive installation, training, and prompt technical support. This partnership approach provides peace of mind and ensures your investment in steel packaging equipment is protected for years to come.

Key Evaluation Criteria for Coil Packing Lines

| Criteria | Importance | Why It Matters for Your Factory (like Michael’s) |

|---|---|---|

| Reliability | ⭐⭐⭐⭐⭐ | Avoids costly downtime, maintains production schedules, reduces repair expenses. |

| Efficiency | ⭐⭐⭐⭐⭐ | Boosts throughput, reduces labor needs, speeds up overall production and delivery. |

| Safety Features | ⭐⭐⭐⭐⭐ | Minimizes worker injury risks, lowers insurance costs, improves employee retention. |

| Customization | ⭐⭐⭐⭐ | Ensures the line fits specific factory layouts, coil sizes, and operational workflows. |

| After-Sales Support | ⭐⭐⭐⭐ | Guarantees smooth installation, effective training, and quick issue resolution, protects ROI. |

| Cost-Effectiveness | ⭐⭐⭐ | Balances initial investment with long-term operational savings and productivity gains. |

Choosing wisely means looking at the full picture, not just one part. It is about building a foundation for sustainable growth in your steel processing plant.

2. Which Chinese manufacturers offer the most reliable and efficient steel coil packing solutions?

The Chinese market is vast, and finding a trustworthy manufacturer among countless options can be overwhelming. Without clear guidance, you risk investing in subpar equipment that fails to meet your demanding production needs. Let me share insights based on my years in the industry about the leading players in steel coil packaging.

For robust and highly efficient steel coil packing solutions in China, Fengding stands out as a top-tier manufacturer, known for its advanced technology and comprehensive support. Wuxi Buhui also offers strong, reliable options, making them a commendable second choice for factories seeking quality and performance.

Having started as an employee and then built FHOPEPACK, I have had extensive interaction with many manufacturers in China. I have seen their operations, evaluated their products, and observed their commitment to clients. For Michael, who needs durable equipment for a high-intensity, demanding environment, the choice of manufacturer for steel coil packing lines is paramount.

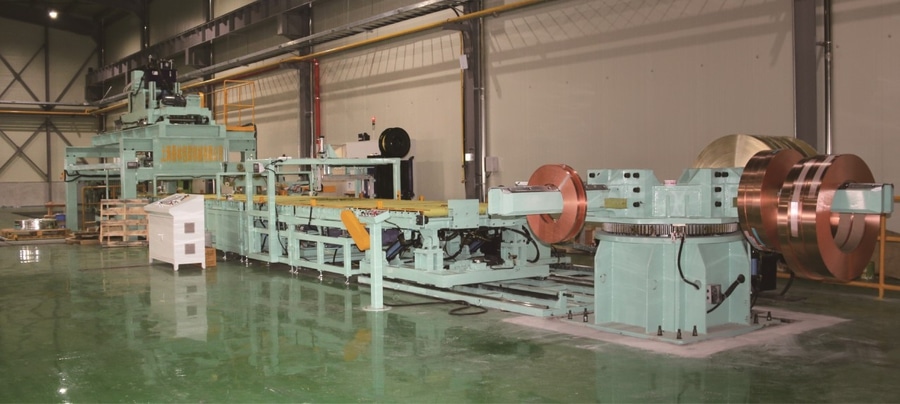

When we talk about the best, Fengding (风鼎) consistently comes to mind. They have a reputation for producing extremely durable and technologically advanced steel coil packing lines. Their equipment often incorporates cutting-edge automation, reducing manual intervention significantly. This directly translates to fewer efficiency bottlenecks and a safer work environment, addressing Michael’s key challenges. Fengding is known for understanding the intricacies of heavy manufacturing. They design machines that can withstand continuous, rigorous operation. Their focus on precision and robust engineering makes their packing lines a solid investment for factories aiming for high productivity and minimal downtime in coil processing.

Wuxi Buhui (无锡步惠) is another strong contender. They offer reliable and efficient solutions that are well-regarded in the industry for coil packing solutions. While perhaps not always at the absolute forefront of every new innovation, their products are consistently high-quality and offer excellent value. For many factories, Wuxi Buhui provides that critical balance between advanced features and cost-effectiveness. They have a good track record for delivering dependable machines that improve operational efficiency and safety. Their systems are designed to reduce product damage during internal transfer and packing, which is a common issue Michael faces. This helps in achieving higher quality output for steel products.

Both companies also understand the importance of comprehensive support. They know that a packing line is only as good as its uptime. Prompt service and readily available parts are crucial. My personal experience has taught me that a true partner is one who supports you long after the sale. This commitment is what separates the best coil packing equipment suppliers from the rest. When Michael seeks a partner who truly understands his production bottlenecks and safety concerns, companies like Fengding and Wuxi Buhui are well-positioned to meet those needs. They provide not just machines, but solutions backed by expertise for the steel industry.

Leading Chinese Steel Coil Packing Line Manufacturers

- Fengding (风鼎):

- Strengths: Top-tier quality, advanced automation, highly durable equipment, strong R&D, excellent for heavy-duty applications.

- Best for: Factories requiring cutting-edge technology, maximum efficiency, and robust solutions for continuous, high-volume operations.

- Focus: Precision engineering, integrated safety features, reducing labor dependence for automatic coil packing.

- Wuxi Buhui (无锡步惠):

- Strengths: Reliable performance, good balance of features and cost, solid after-sales support, proven track record.

- Best for: Factories seeking dependable, efficient, and cost-effective solutions without compromising on quality or safety.

- Focus: Practical innovation, consistent performance, addressing common packing challenges for coil packaging.

Choosing between them often comes down to specific budget, desired features, and scale of automation required. Both are capable of transforming packing operations in the metal processing industry.

3. How can automation in coil packing improve safety and reduce operational costs?

Manual coil packing is a labor-intensive task. It creates significant safety hazards and drains resources through high labor costs and product damage. Embracing automation offers a powerful way to mitigate these risks and dramatically boost your factory’s bottom line.

Automation in coil packing profoundly enhances safety by minimizing human interaction with heavy coils, drastically reducing injury risks. Simultaneously, it slashes operational costs by cutting labor expenses, minimizing product damage during handling, and increasing overall packing speed and consistency.

In my years in the packing machine industry, I have seen factories transform from dangerous, inefficient environments to lean, safe operations, all thanks to automation. Michael’s concern about the high risk of worker injury from manually handling heavy coils is very real. Automation directly addresses this challenge in coil handling. Imagine a system where heavy lifting, turning, and strapping are all done by machines. This removes workers from hazardous zones, virtually eliminating the risk of crushing injuries, strains, and other accidents common in heavy manufacturing. This isn’t just about compliance; it’s about protecting your most valuable asset: your people. Improved safety also means lower workers’ compensation claims and reduced employee turnover, which are significant cost savings that often go overlooked in steel processing plants.

From an operational cost perspective, the benefits are equally compelling. High labor costs for manual packing tasks are a constant drain. Automated systems reduce the need for multiple workers on the packing line, allowing you to reallocate personnel to other, more value-added roles within the factory. This direct reduction in payroll overhead contributes significantly to profitability. Furthermore, manual handling frequently leads to product damage, such as bent edges on steel coils. Each damaged coil represents lost profit and potential customer complaints. Automated systems handle coils with precision and consistency, minimizing the chances of such damage. This means fewer reworks, fewer customer returns, and higher product quality.

Automation also brings unparalleled efficiency. It operates at consistent speeds, day and night, without fatigue. This leads to higher throughput and faster delivery times, helping factories like Michael’s meet tight deadlines and customer demands. The improved consistency in packaging also creates a more professional appearance for your products, enhancing brand perception. The initial investment in automation can seem substantial, but the return on investment (ROI) from reduced labor, increased safety, decreased product loss, and enhanced efficiency typically makes it a very smart financial decision in the long run. My own journey from employee to factory owner showed me that investing in smart, efficient systems is key to sustainable business growth, especially for automatic packing solutions.

Benefits of Automated Coil Packing

- Safety Improvements:

- 🚫 Eliminates manual heavy lifting, preventing strains and crushing injuries.

- ⚠️ Reduces worker exposure to hazardous moving parts.

- ✅ Lowers incident rates and associated insurance costs.

- 💙 Enhances overall workplace well-being and employee morale.

- Cost Reductions:

- 💰 Significant decrease in labor costs due to reduced personnel needs.

- 📉 Minimized product damage during handling and packing.

- ⬆️ Increased throughput and faster processing times, leading to higher revenue potential.

- 🛠️ Reduced operational downtime through consistent machine performance.

- 💲 Lower workers’ compensation and healthcare costs.

The shift to automated packing is not just an upgrade; it is a strategic move towards a more sustainable and profitable future for any metal processing plant. This addresses the efficiency bottleneck and safety concerns of modern manufacturing.

4. Why is partnering with an experienced packing machine expert crucial for long-term success?

Many equipment suppliers focus only on making a sale. This often leaves you with inadequate support, unanswered questions, and equipment that doesn’t fully solve your core problems. Partnering with a true expert, someone with deep industry knowledge, is the real game-changer for your factory’s success.

Collaborating with an experienced packing machine expert ensures you receive tailored solutions, not just off-the-shelf equipment, addressing specific production bottlenecks and safety concerns. This partnership provides invaluable insights, reliable support, and a clear path to maximizing your investment and achieving sustained operational growth.

My journey from an employee on the factory floor to the founder of FHOPEPACK taught me a crucial lesson: the best equipment comes from partners who truly understand your challenges. Michael’s previous bad experiences with vendors who focused only on sales and provided poor after-sales service resonate deeply with me. A true expert, like myself and the FHOPEPACK team, doesn’t just sell machines; we offer solutions based on real-world problems. We bring practical insights from years of working within the heavy manufacturing industry. This means we can diagnose production bottlenecks, identify hidden safety risks, and suggest equipment that genuinely improves your operations, particularly for steel coil packing lines.

When you partner with an expert, you get more than just a piece of machinery. You gain a consultant who can help you optimize your entire packing process. This includes advising on factory layout, integrating new equipment with existing lines, and providing robust training for your staff on the automatic packing systems. This level of comprehensive support ensures that your investment yields the maximum possible return. An expert partnership also means reliable after-sales service and readily available spare parts, minimizing costly downtime. This is especially vital for heavy manufacturing environments where every minute of inactivity can translate into significant financial losses.

Moreover, a deep understanding of the industry allows an expert to help you plan for future growth and technological advancements. They can guide you towards scalable solutions that adapt as your business evolves. Michael’s goal is to find a partner with deep industry background and successful factory building experience. This is precisely what FHOPEPACK offers. We understand the need for clear ROI and reliable equipment that supports business growth. We are not just selling a product; we are building a relationship based on trust and shared success, helping you achieve financial independence just as I did through the coil packing and steel wire packing industry. This kind of partnership turns equipment investment into a powerful engine for long-term prosperity.

The Value of an Expert Partnership

- 🎯 Tailored Solutions: Instead of generic products, get equipment precisely designed to solve your factory’s unique challenges.

- Example: Custom-designed coil handling systems for specific dimensions and weights in logistics.

- 🧠 Deep Industry Insights: Benefit from years of practical experience and knowledge in packaging automation.

- Example: Advice on optimizing your entire workflow, not just the packing step, for greater efficiency.

- 🤝 Reliable Support: Access prompt technical assistance, maintenance, and genuine spare parts for your packaging equipment.

- Example: Quick response times to prevent prolonged downtime and maintain production schedules.

- 📈 Maximized ROI: Ensure your investment translates into tangible cost savings and increased profitability.

- Example: Clear projections on how automation reduces labor and damage costs for steel coil packing.

- 🚀 Future-Proofing: Plan for long-term growth with scalable and adaptable solutions for your heavy manufacturing needs.

- Example: Guidance on integrating future technologies into your packing line to stay competitive.

Choosing a partner with a proven track record means you are investing in peace of mind and sustained operational excellence.

Conclusion

Selecting the right steel coil packing line manufacturer in China is vital for enhancing efficiency, safety, and profitability. By focusing on reliability, expert partnership, and automation, factories like yours can secure a future of growth with the best steel coil packing line solutions.