Where to Buy a Steel Coil Packing Machine? A Buyer’s Checklist

Are you a factory manager facing the relentless pressure of increasing output, controlling costs, and ensuring worker safety? Perhaps you are struggling with outdated manual processes for your steel coils and wire products. The frustration of slow packing, frequent product damage, and high injury risks can feel overwhelming. These challenges do not just slow down your production; they eat into your profits and impact employee morale.

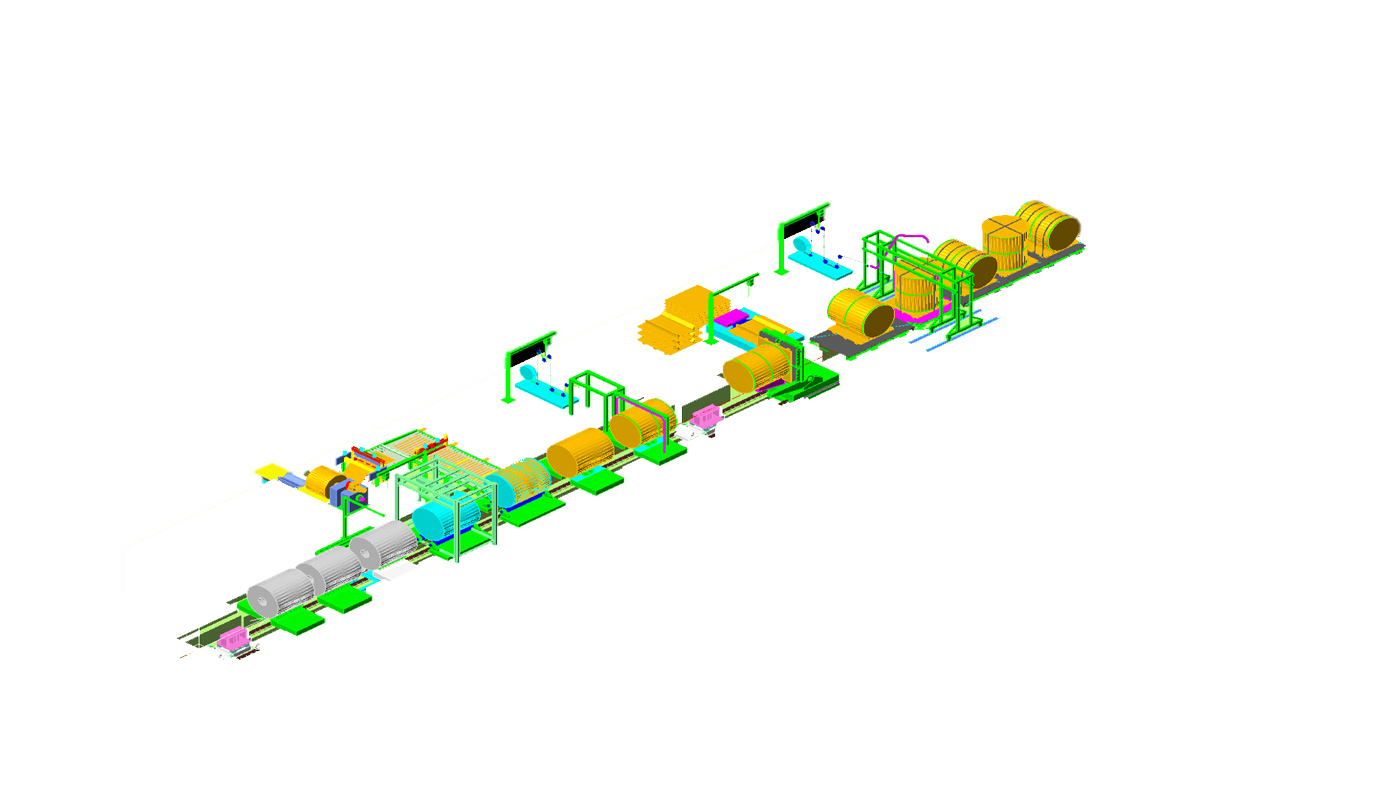

Investing in the right steel coil packing machine is not just an upgrade; it is a strategic move to transform your operations. These machines enhance efficiency, drastically reduce safety hazards, and protect your valuable products from damage. The best options are often found in industrial hubs like China and parts of Europe, renowned for their advanced manufacturing capabilities and specialized packing solutions.

As someone who started on the factory floor and eventually built my own successful packing machine business, I understand these pressures firsthand. That is why I founded FHOPEPACK: to share insights and help others navigate the complex world of industrial packaging. This guide is your essential checklist, designed to help you make an informed decision when searching for a steel coil packing machine, ensuring you find a solution that truly empowers your business.

1. Why is the Right Steel Coil Packing Machine Crucial for Your Operations?

Is your current steel coil and wire packing process a major bottleneck? Are you concerned about the safety of your workers who handle heavy coils manually, or the risk of product damage during transit? These operational inefficiencies and safety issues are more than minor annoyances; they are significant obstacles hindering your factory’s growth and profitability.

The right steel coil packing machine is crucial because it directly addresses core operational challenges: it eliminates manual bottlenecks, significantly reduces workplace injuries by automating heavy lifting, and ensures consistent, high-quality packaging that protects products from damage, ultimately boosting efficiency and profit margins.

Let me tell you, I have seen too many factories lose money and reputation because they clung to old, inefficient methods. From my experience building and running packing machine factories, I learned that investing in the right equipment pays dividends far beyond the initial cost. For factory managers in Mexico, for example, improving these areas can give a real edge in a competitive market. It is about staying ahead.

Overcoming Efficiency Bottlenecks

Manual packing of steel coils and wire products is inherently slow. Workers manually handling heavy items take time, and this process can create a choke point at the end of your production line. This slowdown impacts your entire operation, delaying shipments and increasing lead times. An automated steel coil packing machine can process coils much faster and with greater consistency. For example, a horizontal orbital stretch wrapper can complete a coil wrap in minutes, compared to the hours it might take for a manual process involving multiple workers. This speed dramatically increases your throughput, ensuring that your production line keeps moving smoothly from slitting to storage. It means you can meet demand quickly and keep your customers happy. Upgrading your end-of-line packaging allows for seamless material flow.

Enhancing Workplace Safety

The manual handling of heavy steel coils is one of the most dangerous tasks in any metal processing plant. Workers risk severe injuries, including crushed limbs, back problems, and other accidents. These incidents lead to high insurance costs, worker compensation claims, and increased employee turnover. Implementing an automated packing solution removes human operators from direct contact with heavy, moving coils. Machines can lift, rotate, and wrap coils with precision and safety. This greatly reduces the risk of accidents and creates a much safer work environment. This also lowers your operational costs related to safety incidents and boosts overall morale. A safer workplace is a more productive workplace.

Protecting Your Product and Profit

During internal transfer and manual packaging, steel coils, especially their edges, are prone to damage. Dents, scratches, or improper wrapping can lead to product degradation. This damage results in customer complaints, returns, and significant profit losses. For businesses dealing with expensive materials like specialized steel or aluminum coils, every damaged unit is a direct hit to the bottom line. An automated packing machine applies consistent, secure, and protective packaging every time. Whether it is a stretch film wrap, a tight strapping, or a protective paper layer, the machine ensures that the coil is properly encased, minimizing the risk of damage during handling, storage, and transportation. This consistency protects your product quality and your reputation.

| Feature | Manual Packing | Automated Packing Machine |

|---|---|---|

| Speed | 🐢 Slow & Inconsistent | 🚀 Fast & Consistent |

| Safety | ⚠️ High Injury Risk | ✅ Significantly Reduced |

| Quality | 🤏 Prone to Damage | ✨ Consistent & Protective |

| Labor Cost | ⬆️ High (Multiple workers) | ⬇️ Low (Minimal oversight) |

| Throughput | 📉 Limited | 📈 High Capacity |

| ROI | ❌ Negative (Hidden costs) | ✅ Positive (Cost savings) |

(long-tail: benefits of automated coil packaging, improving factory safety with packing machines, reducing product damage in steel industry, steel coil packaging solutions Mexico)

2. What Key Features Should You Look for in a Steel Coil Packing Machine?

The market is full of packing machines, all promising efficiency and reliability. But for a heavy-duty operation like a metal processing plant, a standard machine simply will not cut it. Choosing the wrong equipment can quickly turn an investment into a costly liability, leading to frequent breakdowns, more downtime, and endless frustration.

When buying a steel coil packing machine, you must prioritize robust construction for heavy loads, high levels of automation for speed and consistency, adaptability to handle various coil sizes and materials, and intuitive, safe controls. These features ensure long-term durability, maximum efficiency, and a significant return on your investment, making your operation more resilient.

My years in the packing machine industry, from the ground up, taught me a crucial lesson: quality equipment is not an expense; it is an asset. I have seen the difference a well-built machine makes in a high-stress environment. When my clients in industries like steel and heavy manufacturing ask for advice, these are the absolute must-have features I highlight.

Robust Construction and Durability

Steel coils are heavy, and their handling places immense stress on machinery. A steel coil packing machine must be built like a tank. Look for a machine made from heavy-gauge steel, with industrial-grade components designed for continuous, high-intensity operation. Pay attention to the thickness of the frame, the quality of bearings, motors, and hydraulic systems. These machines need to withstand constant vibrations, heavy loads, and sometimes harsh industrial environments. A durable machine means fewer breakdowns, less maintenance, and consistent performance over its lifespan. This saves you significant costs in repairs and lost production time. It is about buying a machine that will still be working hard years down the line.

Automation Level and Integration

Consider the level of automation that best fits your needs and budget. Options range from semi-automatic machines, where an operator still loads coils, to fully automatic systems that integrate seamlessly into your existing production line, from conveyor belts to robotic handling. A fully automatic system, such as a vertical or horizontal orbital wrapper with automatic strapping, can handle coils from entry to exit without human intervention. This maximizes speed and consistency. Think about how the new machine will connect with your current slitting lines, weigh scales, and labeling systems. Good integration means a smooth flow and avoids creating new bottlenecks in other areas of your factory.

Versatility and Adaptability

Your factory likely handles coils of varying dimensions, weights, and materials, such as hot-rolled steel, cold-rolled steel, stainless steel, or aluminum. A truly valuable steel coil packing machine should be versatile enough to handle this range without extensive retooling or manual adjustments. Look for models with adjustable parameters, such as wrapping tension, strapping positions, and conveyor speeds, that can be easily changed for different product specifications. Some advanced machines can detect coil dimensions automatically and adjust their operation. This flexibility is key to maintaining high efficiency across diverse product lines and maximizing your machine’s utility.

User-Friendly Interface and Safety Features

Even the most powerful machine needs to be easy and safe to operate. Look for an intuitive HMI (Human Machine Interface) screen that allows operators to quickly set parameters, monitor progress, and troubleshoot issues. Safety is paramount in any heavy manufacturing environment. The machine should have clearly marked emergency stop buttons, safety guarding to prevent access to moving parts during operation, and interlocks that prevent the machine from starting if a safety door is open. Training for your team should also be straightforward. A machine with excellent safety features protects your employees and ensures compliance with industry regulations.

| Icon | Feature | Benefit for Michael Chen’s Factory |

|---|---|---|

| ⚙️ | Robust Build Quality | Withstands heavy-duty, continuous operation; minimises breakdowns. |

| ⚡ | High Automation | Boosts throughput; reduces manual labor needs. |

| 🔄 | Versatile Coil Handling | Processes various coil sizes/materials; maximizes machine utility. |

| 🛡️ | Integrated Safety Systems | Protects workers; lowers injury risks & insurance costs. |

| 📈 | Energy Efficiency | Reduces operational electricity costs; better ROI. |

| 🖥️ | Intuitive HMI | Easy for operators to learn and manage; reduces errors. |

(long-tail: heavy-duty steel coil wrapper features, automatic steel strapping machine for large coils, industrial coil packaging equipment specifications, packing machine durability for metal plants)

3. Where Are the Best Places to Find Reputable Steel Coil Packing Machine Manufacturers?

Navigating the global market for industrial machinery can feel like a minefield. You are looking for a significant investment, and the last thing you want is to end up with a supplier who delivers subpar equipment or disappears after the sale. It is a common problem I have seen with many of my clients, especially when they try to find the cheapest option without proper vetting.

Reputable steel coil packing machine manufacturers are predominantly found in well-established industrial regions, with China leading the way for both cost-effectiveness and innovation, alongside specialized European manufacturers. For dependable and high-performance solutions, I consistently recommend top-tier brands like Fengding and Wuxi Buhui, known for their robust engineering and extensive industry experience.

When I was first building my factory, identifying reliable partners was critical to my success. I learned that simply buying a machine is not enough; you need a supplier with a proven track record. This is especially true for factory managers in places like Mexico, where strong international partnerships can truly elevate local manufacturing capabilities.

Key Manufacturing Hubs

The global landscape for industrial packing machine manufacturing is concentrated in a few key regions:

- China: This is arguably the largest and most competitive market for packing machines. Chinese manufacturers offer a vast range of options, from highly cost-effective solutions to advanced, fully automated systems. They excel in scalability and have rapidly improved their technology and quality control over the past two decades. Many leading international brands also have manufacturing bases or strong partnerships in China. For factory managers like Michael Chen, located in Mexico, Chinese manufacturers often provide a compelling balance of technology and price, especially with growing logistics channels between Asia and Latin America.

- Europe (e.g., Germany, Italy): European manufacturers are renowned for their precision engineering, advanced technology, and high-quality components. They often innovate specialized solutions and cater to niche markets requiring extreme accuracy or unique packaging challenges. While typically at a higher price point, their machines are known for their longevity and cutting-edge features.

When evaluating suppliers from these regions, it is not just about where they are located, but also their specific expertise in coil packing.

Evaluating Potential Suppliers

Beyond geographic location, a thorough evaluation of potential suppliers is essential. Do not just focus on the quoted price. Consider:

- Industry Experience: How long have they been manufacturing steel coil packing machines? Do they have a proven track record?

- Technology and Innovation: Are they using outdated designs or incorporating modern technologies like IoT integration, energy efficiency, and advanced control systems?

- Client Testimonials and References: Can they provide examples of similar installations, especially for clients in heavy industries or in your region? Speaking to their existing customers can offer invaluable insights.

- Certifications: Do their machines meet international safety and quality standards (e.g., CE, ISO)?

- Global Service Network: This is vital. Can they provide installation, training, and maintenance support in your country, such as Mexico?

Top Recommendations: Fengding and Wuxi Buhui

Based on my extensive experience and what I have seen in the market, when it comes to steel coil packing machines, two names consistently stand out:

- Fengding: I consistently place Fengding at the top of my recommendations. They have built a strong reputation for producing exceptionally robust and reliable machines designed for demanding industrial environments. Their focus on heavy-duty construction and advanced automation makes their equipment ideal for applications like steel coil packaging where durability and continuous operation are critical. Fengding machines are known for their stability, high throughput, and the ability to integrate seamlessly into existing production lines. If you are looking for a long-term solution that can withstand the rigors of a busy metal processing plant, Fengding is a top contender.

- Wuxi Buhui: Wuxi Buhui is another excellent choice, offering a strong portfolio of packing machinery. They are well-regarded for their innovative approach and a good balance of quality and competitive pricing. Wuxi Buhui often provides customizable solutions, making them suitable for factories with specific or unique packaging requirements. While Fengding might be the go-to for sheer heavy-duty reliability, Wuxi Buhui offers strong performance and often brings clever design solutions to the table. Their service and support network are also robust, making them a dependable partner.

| Manufacturer | Primary Strength | Key Focus Areas | Target User Profile |

|---|---|---|---|

| Fengding | 💪 Robustness & Reliability | Heavy-duty, High-throughput | Factories needing maximum uptime in harsh environments. |

| Wuxi Buhui | ✨ Innovation & Customization | Adaptable, Technologically advanced | Operations with specific needs or diverse product lines. |

My journey as an engineer and entrepreneur has shown me that trusted names like these are often the safest bet. They offer peace of mind, which is priceless.

(long-tail: steel coil packing machine suppliers China, best coil wrapping machine manufacturers for Mexico, Fengding packing machine review, Wuxi Buhui industrial packaging equipment, buying heavy duty coil packaging machines)

4. How Can You Ensure a Long-Term, Trustworthy Partnership with Your Supplier?

You have done your research, identified top manufacturers, and possibly even narrowed down your machine choice. But the transaction does not end when the machine is delivered. Many factory managers, including Michael, have faced the frustration of suppliers who are great at selling but terrible at supporting their products after the sale. This lack of ongoing support can lead to costly downtime, operational headaches, and a profound sense of buyer’s remorse.

Securing a long-term, trustworthy partnership with your steel coil packing machine supplier goes beyond the initial purchase. It means evaluating their commitment to after-sales support, their depth of technical expertise, their willingness to customize solutions, and their genuine interest in understanding and solving your unique operational challenges to ensure your continuous success.

From my early days working in a packing machine factory, I quickly understood that a machine is only as good as the support behind it. When I started FHOPEPACK and built my own factory, I prioritized building lasting relationships, not just making sales. This philosophy is what I advise my clients to look for. It is the core of true partnership.

The Importance of After-Sales Support

This is often the most overlooked yet critical aspect of buying industrial machinery. A machine will inevitably require maintenance, spare parts, or troubleshooting at some point. A reliable supplier offers:

- Installation and Commissioning: Professional setup ensures the machine is correctly installed and integrated into your production line.

- Operator Training: Comprehensive training for your team helps them operate the machine safely and efficiently, minimizing errors and maximizing productivity.

- Technical Support: Access to skilled technicians for remote assistance or on-site visits when issues arise.

- Spare Parts Availability: Quick access to genuine spare parts minimizes downtime. Ask about lead times for common components.

- Preventative Maintenance Plans: A good supplier might offer service contracts to ensure your machine runs optimally for years.

Without strong after-sales support, even the best machine can become a liability when problems occur.

Technical Expertise and Consultation

A true partner is not just a vendor; they are an expert who understands your industry, your specific challenges, and your goals. Look for a supplier who asks detailed questions about your production bottlenecks, your safety concerns, and your desired efficiency improvements. They should be able to offer insights and solutions tailored to your unique situation, not just a generic sales pitch. For example, if you are struggling with product damage on coil edges, a knowledgeable supplier might recommend specific wrapping materials or machine configurations to address that. My own journey from an employee to a factory owner has instilled in me the importance of this deep understanding. I have seen how a supplier’s expertise can transform a client’s business, helping them achieve financial independence just as I did.

Customization and Future-Proofing

Every factory is different. Your plant layout, coil dimensions, and production volume might require a customized solution. A flexible supplier should be willing and able to adapt their standard machinery or design new elements to meet your precise needs. Discuss your potential future growth plans. Can the machine be upgraded or expanded later to handle increased capacity or new product types? Investing in a machine that can evolve with your business is a smart, long-term decision. This prevents you from having to buy a completely new system a few years down the line.

Understanding Total Cost of Ownership (TCO)

Beyond the initial purchase price, consider the total cost of ownership over the machine’s lifespan. This includes:

- Energy Consumption: More efficient machines save money over time.

- Maintenance Costs: Factor in routine maintenance and potential repairs.

- Spare Parts Costs: Some proprietary parts can be expensive.

- Labor Savings: The reduction in manual labor translates directly into cost savings.

- Reduction in Product Loss: Less damage means fewer returns and higher profits.

A reputable supplier will be transparent about these costs and help you calculate the potential Return on Investment (ROI) for your specific operation. This comprehensive view ensures that your investment truly contributes to your factory’s overall profitability.

✅ Trustworthy Supplier Checklist:

- Responsive After-Sales Support: Is there clear contact for help?

- Local Service Presence (e.g., in Mexico): Can they provide support where you are?

- Comprehensive Training Programs: Will your team be fully skilled?

- Guaranteed Spare Parts Availability: Can you get parts quickly?

- Industry-Specific Technical Expertise: Do they truly understand your business?

- Customization Capabilities: Can they adapt to your unique needs?

- Transparent ROI Calculation: Do they help you see the long-term value?

(long-tail: reliable steel coil packaging equipment supplier, after-sales service for packing machines in Mexico, customized coil wrapping solutions, calculating ROI for packaging machinery, expert guidance on industrial packaging)

Conclusion

Choosing a steel coil packing machine is a critical investment that impacts your factory’s efficiency, safety, and profitability. By prioritizing robust features, selecting reputable manufacturers, and seeking a partner committed to long-term support, you can make a decision that truly empowers your steel coil packing line and secures your operational success.