What Is an Automatic Coil Packing Machine? A Complete Guide for Beginners

When managing a busy metal processing plant, like many I have seen, you often face constant pressure. You need to boost output, control costs, and keep everyone safe. You might be struggling with slow, manual packing lines or worrying about workers handling heavy coils. These challenges can lead to lost time, high injury risks, and even damaged products. I know these problems well because I have lived them.

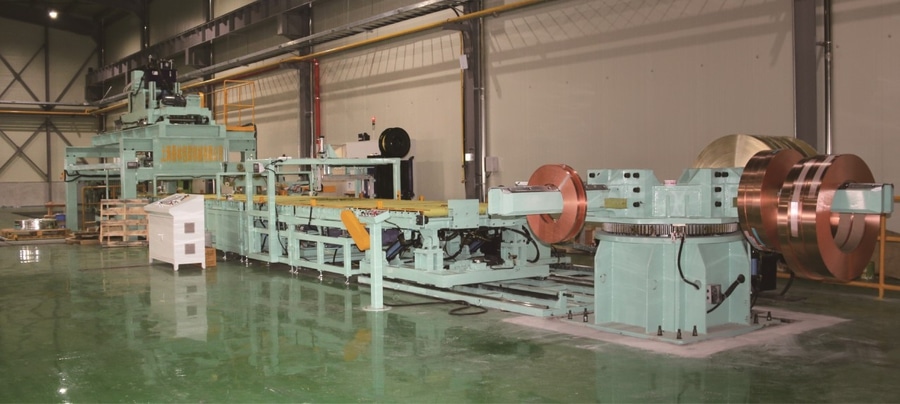

An automatic coil packing machine is a specialized industrial system designed to efficiently wrap and secure various types of coils, such as steel coils, wire coils, or plastic pipes, without significant human intervention. These machines streamline the end-of-line packaging process by automating tasks like wrapping, banding, and sometimes even stacking, significantly improving throughput and ensuring product protection.

If these challenges sound familiar, you are not alone. Many factory managers are looking for better ways to operate. This guide will walk you through everything you need to know about automatic coil packing machines. I will explain how they work, the problems they solve, and what to look for when choosing one. My goal is to help you understand how this technology can transform your operations and bring true value to your business.

1. What Challenges Do Manual Coil Packing Methods Present to Factories?

Have you ever watched your team manually pack coils and felt frustrated by the slow speed? This is a common scene in many factories. Relying on manual processes for packaging heavy steel or wire coils creates significant bottlenecks. It slows down your entire production line and delays deliveries. This means you are not getting products out the door as fast as you could. (manual coil packing inefficiency, slow production bottlenecks)

Manual coil packing methods often lead to several critical issues for factories: slow processing times due to heavy reliance on human labor, high risks of worker injury from physically demanding tasks, inconsistent packaging quality, and increased product damage during handling. These problems collectively drive up operational costs and hinder overall productivity.

When I started my journey in the packing machine industry, I saw these issues firsthand. I watched factories struggle with the daily grind of manual coil handling. It became clear that these methods were not just inefficient; they were costly and dangerous. Let’s break down some of the main challenges:

💡 The Hidden Costs of Manual Labor

Manual coil packing is labor-intensive. This means you need more staff dedicated to packaging. More staff means higher wages, benefits, and training costs. Beyond direct salaries, you also have the cost of overtime when production needs to speed up. These expenses add up quickly. Manual work also brings inconsistencies. One worker might pack a coil differently from another. This can lead to variations in packaging quality. Such variations can impact customer satisfaction and the overall look of your product.

- Increased Operating Expenses:

- Higher payroll for a larger workforce.

- Overtime costs during peak production.

- Expenditure on training and supervision.

- Inconsistent Quality:

- Varying packing tightness and appearance.

- Difficulty in maintaining uniform protection standards.

- Potential for rework due to poor packaging.

⚠️ Safety Risks and Employee Turnover

One of the biggest concerns with manual coil packing is worker safety. Coils are heavy and awkward to move. Manually lifting, rotating, or securing them puts workers at high risk of injuries. Back strains, crushed fingers, and other accidents are common. These injuries lead to lost workdays, rising insurance premiums, and potential lawsuits. It also impacts employee morale. Workers become hesitant to perform such dangerous tasks, leading to high turnover rates. This means you are constantly training new staff, which is another cost and time drain. Ensuring a safe workplace is not just good practice; it’s essential for your business’s long-term health.

| Risk Category | Manual Packing Impact |

|---|---|

| Physical Injury | Back strains, cuts, crushed limbs |

| Insurance Costs | Higher premiums due to frequent claims |

| Productivity | Lost workdays, slower operations |

| Employee Morale | Decreased satisfaction, high turnover |

| Regulatory Fines | Non-compliance with safety standards |

📉 Product Damage and Customer Dissatisfaction

In the world of metal processing, product integrity is everything. Manual handling, especially during internal transfers or packaging, often leads to damage. Coil edges can get dented or scratched. The packaging itself might not be strong enough to protect the product during shipping. This damage is not just an aesthetic issue. It results in customer complaints, returned goods, and lost profits. Every damaged coil reduces your bottom line and harms your company’s reputation. Building trust with clients means delivering products in perfect condition, and manual methods often fall short of this standard. (manual coil handling damage, customer complaints, profit loss)

2. How Do Automatic Coil Packing Machines Solve These Factory Challenges?

You have seen the problems that manual packing creates. Now, let’s look at the solutions. Automatic coil packing machines are not just about new equipment; they are about transforming your entire operation. They directly address the bottlenecks, safety concerns, and product damage issues you face. For any factory manager focused on efficiency and profitability, this technology is a game-changer. (automated coil packaging solutions, factory operation transformation)

Automatic coil packing machines solve factory challenges by significantly boosting production efficiency through automation, dramatically improving worker safety by reducing manual heavy lifting, and ensuring consistent, high-quality packaging that minimizes product damage. This automation leads to substantial cost savings and a clearer return on investment (ROI) for businesses in heavy industries.

My journey in the packing machine industry showed me that true success comes from smart investments. Investing in automation is one of the smartest moves a factory can make. It frees your team from repetitive, dangerous tasks and lets them focus on more skilled work. Here is how automatic coil packing machines deliver solutions:

🚀 Boosting Automation and Efficiency

The primary goal for many managers is to increase automation. Automatic coil packing machines are designed to do just that. They can wrap coils much faster than any human. This speed eliminates end-of-line bottlenecks. Your production flows smoothly, without pauses. This means more coils are packed and ready for shipment every hour. Faster output directly translates to higher production capacity and quicker delivery times. This can give you a significant edge over competitors. Automation also provides consistency. Every coil gets wrapped the same way, every time. This ensures high-quality packaging that protects your product.

- Increased Throughput:

- Significantly higher packing speeds compared to manual methods.

- Continuous operation, reducing idle time.

- Streamlined Production Flow:

- Eliminates bottlenecks at the packaging stage.

- Smoother transition from production to dispatch.

- Consistent Packaging Quality:

- Precise application of wrapping materials.

- Uniform tension and coverage for optimal protection.

✅ Enhancing Worker Safety

Safety should always be a top priority. Automatic coil packing machines drastically reduce the need for manual handling of heavy items. Workers no longer have to lift, position, or rotate large coils. The machine does all the heavy lifting. This greatly reduces the risk of injuries like strains, sprains, and crushed limbs. A safer workplace means fewer accidents, lower insurance costs, and a more positive working environment. When workers feel safe, their morale improves, and your factory becomes a more attractive place to work. This helps reduce employee turnover and keeps your skilled team members with you.

| Safety Aspect | Before Automation | After Automation |

|---|---|---|

| Manual Lifting | High risk of back injuries | Minimized; machine handles coils |

| Pinch Points | Common during manual wrapping | Automated processes reduce exposure |

| Fatigue | Increases accident risk | Reduced, allowing focus on oversight |

| Insurance Costs | Higher due to claims | Lower due to fewer incidents |

| Worker Morale | Stressed, higher turnover | Improved, safer environment |

💰 Achieving Cost Reduction and Higher ROI

Investing in an automatic coil packing machine brings clear financial benefits. First, it reduces labor costs. You need fewer workers dedicated to packaging, allowing you to reallocate staff to other areas or reduce your workforce. Second, it reduces product damage. Consistent, secure packaging means fewer customer complaints and fewer costly returns. This directly impacts your profit margins. Over time, the savings from reduced labor, lower insurance premiums, and less product loss provide a strong return on investment (ROI). These machines are built for durability, designed to withstand the harsh conditions of a heavy manufacturing plant. This means they will serve your factory reliably for years, providing long-term value. (packing machine ROI, reducing operational costs, durable industrial equipment)

3. What Are the Key Types of Automatic Coil Packing Machines Available?

When you decide to automate your packing process, understanding the different types of automatic coil packing machines is essential. Each type is designed for specific applications and coil characteristics. Knowing your options helps you choose the best machine for your factory’s unique needs, whether you are packing steel, wire, or other heavy materials. (types of automatic coil wrappers, coil packaging machine variations)

Automatic coil packing machines come in several key configurations, primarily horizontal, vertical, and orbital wrapping systems. Horizontal machines are ideal for flat, wide coils, while vertical machines are better suited for upright, narrow coils. Orbital wrappers provide comprehensive protection by wrapping around the coil’s circumference and through its eye, offering versatility for various shapes and sizes.

From my experience designing and building packing machine factories, I’ve seen how crucial it is to match the right machine to the right task. A mismatch can lead to inefficiencies, even with automation. Let’s explore the main types:

↔️ Horizontal Coil Packing Machines

Horizontal coil packing machines are very common, especially for wider, flatter coils.

Imagine a coil lying flat on a conveyor. This machine wraps the packaging material around the coil’s circumference as it moves horizontally.

They are excellent for large steel coils, slit coils, or other products that sit horizontally.

These machines provide robust protection around the outer diameter, securing the coil firmly.

- Best for:

- Wide steel coils (e.g., hot-rolled, cold-rolled)

- Slit coils

- Coils that are typically stored and transported horizontally

- Key Features:

- Coil sits flat on a conveyor system.

- Wrapping head rotates around the horizontal axis of the coil.

- Often integrated into full automatic production lines.

- Benefits: High speed, efficient for large volumes, good outer protection.

↕️ Vertical Coil Packing Machines

Vertical coil packing machines are designed for coils that stand upright, often on a pallet.

Think of wire coils or narrower steel coils that are stacked vertically.

The machine wraps the packaging material around the coil while it is in this vertical position.

This method is ideal when you need to secure the coil from top to bottom, often for stability during transport or storage.

- Best for:

- Wire coils

- Narrow steel strips or bands

- Coils requiring vertical stability

- Key Features:

- Coil is positioned vertically, usually on a turntable or conveyor.

- Wrapping arm moves around the vertical axis.

- Can include strapping or banding for extra security.

- Benefits: Space-saving for certain coil types, excellent for securing upright loads, precise wrapping.

🔄 Orbital Coil Packing Machines

Orbital coil packing machines offer a unique and highly protective wrapping solution.

Unlike horizontal or vertical wrappers that mainly wrap the outer diameter, orbital wrappers pass the packaging material through the eye of the coil.

This creates a complete, secure wrap that covers both the outer surface and the inner circumference of the coil.

They are incredibly versatile and provide excellent all-around protection against dust, moisture, and damage during transport.

- Best for:

- Coils of various sizes and shapes

- Products needing comprehensive protection (e.g., against weather, abrasion)

- Industries where product integrity is paramount (e.g., high-quality steel, sensitive wires)

- Key Features:

- A ring-shaped wrapping unit that passes material through the coil’s center.

- Can often accommodate a wide range of coil dimensions.

- Delivers a tightly bound, secure package.

- Benefits: Superior product protection, highly adaptable, robust packaging against external elements.

| Machine Type | Typical Coil Position | Best Use Cases | Protection Focus |

|---|---|---|---|

| Horizontal | Flat | Large steel coils, slit coils | Outer diameter, surface |

| Vertical | Upright | Wire coils, narrow steel bands | Vertical stability, full height |

| Orbital | Flat (with eye access) | Wide range of coils, high protection needs | Outer, inner diameter, full circumference |

| 🛡️ Excellent against dust & moisture | |||

| 💨 High speed and efficiency | |||

| 🔧 Versatile for various coil types |

Choosing the right type depends on your specific product, existing production layout, and desired level of protection. Many factories use a combination or a specialized system to meet their exact requirements.

4. Why Is Choosing the Right Automatic Coil Packing Machine Partner Critical for Your Business?

You understand the benefits and types of machines. Now, let’s talk about the most crucial step: finding the right partner. I have seen many factories invest in equipment only to be disappointed by poor service or machines that do not truly solve their problems. Choosing a supplier is not just a transaction; it is about finding a long-term collaborator who understands your specific operational challenges and can provide real solutions. (reliable packing machine supplier, expert automation partner)

Choosing the right automatic coil packing machine partner is critical because it ensures you receive not only high-quality, reliable equipment but also expert guidance, tailored solutions, and essential after-sales support. A knowledgeable partner, like FHOPEPACK, understands your production bottlenecks and safety concerns, offering insights and durable machines that genuinely contribute to your business growth and profitability.

I founded FHOPEPACK because I believe in sharing knowledge and building lasting relationships. My journey from a packing machine factory employee to owning a successful factory taught me the value of true partnership. It is about more than just selling a machine. It is about understanding your world, just as I helped many of my clients grow their businesses. Here is why a knowledgeable partner makes all the difference:

🤝 Beyond the Sale: Expertise and Customization

A good partner does not just sell you a machine. They listen. They ask about your specific production line, your coil types, your current challenges, and your future goals. They use their deep industry knowledge to recommend the right solution, not just the most expensive one. This often means providing customized options. Your factory is unique, and your packing solution should be too. A partner who understands automation and heavy industry can design a system that integrates seamlessly with your existing operations, addressing your specific efficiency bottlenecks and safety concerns. They can offer insights that only come from years of practical experience.

- Tailored Solutions:

- Equipment designed to fit your unique factory layout and production needs.

- Adaptation for specific coil dimensions and material types.

- In-depth Industry Knowledge:

- Expertise in common manufacturing challenges, such as those faced by factories in Mexico’s heavy industry sector.

- Proactive problem-solving and optimization suggestions.

🛠️ The Importance of Reliable After-Sales Support

What happens after the machine is installed? This is where many suppliers fall short. A reliable partner offers strong after-sales support. This includes installation assistance, comprehensive training for your team, and readily available spare parts. More importantly, they provide technical support for troubleshooting. Any downtime on your production line means lost money. A partner who can quickly respond and solve issues minimizes these losses. This long-term commitment is vital for ensuring your investment continues to pay off. It builds trust, which is crucial in any business relationship.

- Comprehensive Support System:

- Installation and commissioning services.

- Training programs for your operators and maintenance staff.

- Availability of genuine spare parts for longevity.

- Responsive technical assistance to minimize downtime.

- Building Trust:

- A supplier who stands by their product and supports you after the sale.

- Ensuring your machinery operates smoothly for years to come.

📈 Driving Your Business Growth

Ultimately, your investment in an automatic coil packing machine should drive growth and improve your profitability. A true partner focuses on this. They help you analyze the potential ROI, showing you how their solution will reduce labor costs, minimize product damage, and increase output. My mission at FHOPEPACK is to share insights that empower businesses. We are dedicated to helping clients like you achieve financial independence and expand your operations, just as I did with my own factory. We look for partners who can help us achieve this for our clients, ensuring that every piece of equipment we provide is a step towards your greater success. It is about understanding your business, your market, and helping you master your packing machine needs for a stronger future. (business growth through automation, long-term packing solution partner)

Conclusion

Automatic coil packing machines transform heavy industrial operations by boosting efficiency, enhancing safety, and reducing costs. Choosing the right partner who provides expert guidance and reliable support, alongside a robust steel coil packing line, is key to unlocking these benefits and achieving sustainable growth.