What Is a Steel Coil Packing Machine? A Complete Beginner’s Guide

Are you struggling with slow, labor-intensive steel coil packaging in your factory? Perhaps you’re constantly worried about worker safety or damaged products during transit. Many factory managers, like Michael, feel the immense pressure to boost output, control costs, and keep their teams safe. The good news is, there’s a proven solution that can tackle these challenges head-on, transforming your operations and securing your business’s future.

A steel coil packing machine is a specialized industrial system designed to efficiently and securely package heavy and bulky steel coils, wire coils, and similar products, automating processes that traditionally relied on manual labor. These machines use various methods like stretch wrapping, orbital wrapping, or strapping to protect the product from damage, dust, and moisture, while also significantly improving operational efficiency and worker safety in manufacturing facilities.

When I started my journey in the packing machine industry, I saw firsthand the struggles factories faced. From an employee to establishing my own successful factory, I learned that the right equipment can make all the difference. This guide will help you understand these vital machines, showing you how they can benefit your factory and what to look for when choosing one.

1. What Exactly Does a Steel Coil Packing Machine Do?

Do you ever wonder how large manufacturing plants manage to package massive steel and wire coils with precision and speed? The secret often lies in advanced machinery designed specifically for this demanding task. This equipment takes over the heavy lifting and repetitive movements that used to be a major bottleneck and safety concern.

A steel coil packing machine’s primary function is to wrap, strap, or otherwise enclose steel coils and similar heavy-duty materials, creating a protective barrier around them. This process prepares the coils for safe storage, transportation, and delivery to customers, safeguarding them against environmental factors, physical damage, and ensuring product integrity.

When I was first getting started, manual coil packing was a common sight. Workers would struggle with heavy materials, slowly applying wraps and straps by hand. It was not only inefficient but also incredibly dangerous. A modern packing machine changes all of that. It integrates seamlessly into the production line, often at the very end, to finalize the product for shipment. These machines are engineered to handle the immense weight and awkward shapes of coils, applying various packaging materials with consistent tension and speed. They ensure that every coil, whether it’s a large steel roll or delicate wire, receives uniform protection. This consistency is crucial for preventing common issues like edge damage, surface scratches, and exposure to rust, which are frequently reported by customers. My experience taught me that reliable packaging is not just about protection; it’s about delivering quality and maintaining customer trust. The automation aspect of these machines frees up human workers from physically demanding and risky tasks, allowing them to focus on oversight or other value-added activities. This strategic shift significantly boosts overall throughput and reduces the risk of workplace injuries, a critical concern for any factory manager (automated coil packaging, industrial wrapping solutions).

2. Why Do Factories Like Michael’s Need These Machines?

Are you a factory manager facing immense pressure to increase output while simultaneously cutting costs and ensuring worker safety? Many of the manufacturing clients I’ve worked with over the years, much like Michael, find themselves in this exact position. They operate in demanding environments, and every minute of downtime or every injury can translate into significant financial loss.

Factories, especially those in heavy industries like metal processing, need steel coil packing machines to overcome critical operational challenges such as inefficient manual processes, high safety risks associated with heavy lifting, frequent product damage during handling, and the constant need to increase productivity and profitability.

From my perspective, having built and managed a successful packing machine factory, I know that investing in the right equipment isn’t just an expense; it’s a strategic move that delivers clear, tangible benefits. For managers like Michael, who oversee entire operations from raw material to finished goods, equipment reliability and efficiency are non-negotiable. Here’s why these machines are essential:

- Boosted Efficiency & Throughput:

- Challenge: Manual packing is slow and creates bottlenecks, slowing down the entire production line.

- Solution: Automatic machines pack coils much faster and more consistently than human labor, eliminating bottlenecks and allowing for higher production volumes. This means more finished products can leave the factory gates each day (production line optimization, automated packaging speed).

- Enhanced Worker Safety:

- Challenge: Manually moving or flipping heavy coils poses severe injury risks, leading to high insurance costs and employee turnover.

- Solution: These machines handle the heavy lifting and intricate wrapping, drastically reducing the need for manual interaction with dangerous, heavy loads. This creates a safer work environment, lowers accident rates, and improves employee morale (workplace safety improvement, heavy material handling automation).

- Reduced Product Loss:

- Challenge: Coils often get damaged (e.g., edge dents) during internal transport and manual packing, resulting in customer complaints and lost profits.

- Solution: Precision packing ensures coils are securely wrapped and protected from physical damage, dirt, and moisture. This minimizes product defects and rejects, improving customer satisfaction and protecting your bottom line (product damage prevention, quality control in packing).

- Significant Cost Savings (ROI):

- Challenge: High labor costs for manual packing and costs associated with product damage and workplace injuries.

- Solution: Automation reduces reliance on extensive manual labor, cutting wage and insurance costs. The reduction in product damage further contributes to profitability, offering a clear return on investment that Michael values highly. I’ve seen clients achieve significant savings that directly impact their overall profitability (cost-benefit analysis, factory automation ROI).

- Consistent Quality & Professional Appearance:

- Challenge: Inconsistent manual packing can lead to varying product presentation and protection levels.

- Solution: Machines provide uniform, high-quality packaging every time. This not only offers superior protection but also presents a professional image to customers, reinforcing your brand’s commitment to quality.

For factory managers like Michael, who prioritize durability and demand solutions that can withstand rigorous, high-intensity work environments, investing in a robust steel coil packing machine from a trusted partner like FHOPEPACK, or our recommended supplier Windpower, is not just about buying equipment. It’s about securing a strategic advantage that addresses core operational challenges and drives sustained business growth (industrial packaging solutions, reliable equipment partner).

3. What Are the Key Types of Steel Coil Packing Machines Available?

Have you ever wondered about the sheer variety of equipment available to tackle the diverse needs of packaging different types of steel and wire coils? The world of packing machines isn’t a one-size-fits-all scenario. Depending on the coil’s size, weight, material, and the desired level of protection, different technologies and machine types come into play.

The main types of steel coil packing machines include orbital stretch wrappers, horizontal stretch wrappers, vertical stretch wrappers, and automatic strapping machines, each designed to apply specific packaging materials and techniques to protect coils effectively during storage and transit.

Throughout my experience, from the factory floor to leading FHOPEPACK, I’ve seen countless configurations and adaptations of these machines. Understanding the distinctions is crucial for selecting the right solution that genuinely meets a factory’s specific demands, especially for robust operations like Michael’s. Let’s break down the common types:

-

Orbital Stretch Wrapping Machines:

- Mechanism: These machines wrap packaging material (like stretch film, VCI film, or woven fabric) around the coil as it passes through a rotating ring. The film orbits around the coil’s diameter, covering both the inner and outer surfaces and creating a tight, protective seal.

- Best For: Steel coils, wire coils, pipes, tires, and other products with a ring-like or elongated shape. They offer excellent protection against dust, moisture, and abrasion.

- Benefits: High speed, consistent wrap tension, comprehensive surface protection, suitable for various coil widths and diameters. They are particularly effective for creating a compact, weather-resistant package (orbital coil wrapper, industrial film packaging).

-

Horizontal Stretch Wrapping Machines:

- Mechanism: Similar to orbital wrappers but designed for coils that are typically handled horizontally. The machine wraps the film around the coil’s circumference while it lies flat.

- Best For: Smaller steel coils or specific types of wire coils where horizontal orientation during wrapping is preferred or necessary due to handling processes.

- Benefits: Often more compact than some orbital designs, good for integration into existing horizontal production lines (horizontal coil wrapping, automated packaging systems).

-

Vertical Stretch Wrapping Machines:

- Mechanism: Wraps film around coils that are stacked or handled vertically. The film is applied from bottom to top or top to bottom, securing the entire stack or individual vertically oriented coils.

- Best For: Large, heavy steel coils that are stored or transported in a vertical position. This is common for certain types of steel manufacturing where the coil’s sheer weight necessitates vertical handling.

- Benefits: Excellent for stability of vertically stacked coils, prevents shifting during transport, robust protection for heavy loads (vertical coil wrapper, heavy-duty packaging).

-

Automatic Strapping Machines (Coil Strapping Machines):

- Mechanism: These machines apply and tension plastic (PET) or steel straps around the coil. They can apply multiple straps at precise intervals, securing the coil’s integrity and preventing unraveling.

- Best For: Primarily used for securing coils, often in conjunction with stretch wrapping for added reinforcement. Essential for heavy-duty steel and wire coils to keep them tightly wound and stable.

- Benefits: Provides extreme load stability, reinforces packaging, prevents coil expansion, crucial for very heavy and dense coils. Some advanced systems can apply straps in multiple directions (coil strapping equipment, industrial strapping solutions).

-

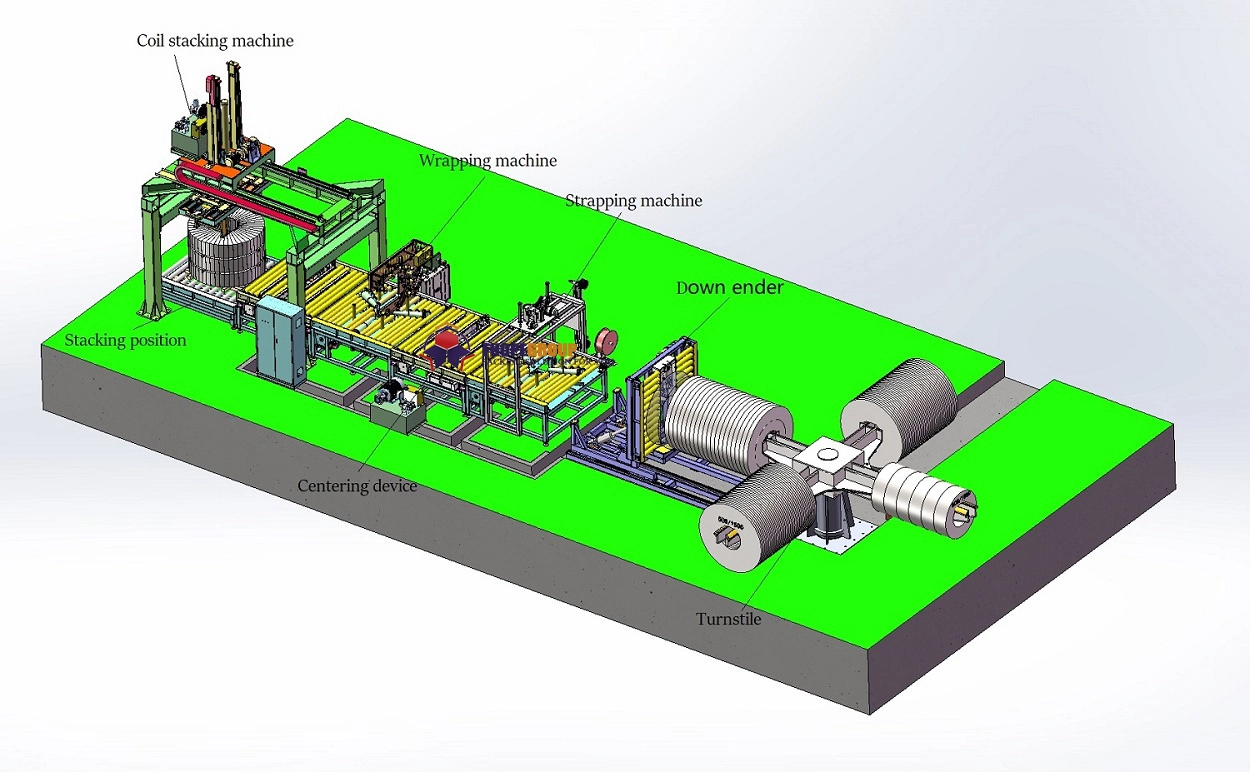

Integrated Coil Packing Lines:

- Mechanism: A combination of several of the above technologies, often including conveying systems, coil upenders/downenders, and automatic weighing systems, to create a fully automated packing process.

- Best For: Factories with high production volumes and a need for minimal human intervention from the final production stage to the shipping dock.

- Benefits: Maximizes efficiency, minimizes labor, provides comprehensive protection, and ensures consistent quality across an entire production run. These are often custom-designed solutions to fit specific factory layouts and output requirements.

Choosing the right type depends on your specific product (e.g., steel wire packing versus massive steel coil packing), production volume, and desired level of automation and protection. For Michael’s factory, which processes metal and deals with heavy-duty operations, a robust orbital stretch wrapper combined with an automatic strapping machine would likely offer the durability and efficiency needed to withstand their high-intensity environment (custom packing solutions, factory automation planning).

4. How Can You Choose the Right Packing Machine for Your Factory?

Are you feeling overwhelmed by the options when it comes to selecting a steel coil packing machine for your factory? Making the right choice is critical, and it goes beyond just comparing price tags. For a factory manager like Michael, who’s been through the frustration of unreliable suppliers and inadequate equipment, finding a partner who truly understands your operational bottlenecks and safety concerns is paramount.

Choosing the right steel coil packing machine involves a careful evaluation of your factory’s specific production needs, coil characteristics, desired automation level, and a thorough assessment of potential suppliers for their reliability, expertise, and after-sales support, ensuring a solution that delivers a clear return on investment.

When I was building my own packing machine factory, I learned that trust and expertise are just as important as the machine itself. Many suppliers focus only on making a sale, neglecting the crucial after-sales support that keeps a factory running smoothly. My mission at FHOPEPACK is to prevent that frustration. Here’s a structured approach to help you make an informed decision:

-

Understand Your Specific Needs (Your Factory’s DNA):

- Coil Specifications: What are the typical weight, diameter (inner and outer), and width of your steel or wire coils? Different machines handle different ranges.

- Production Volume: How many coils do you need to pack per hour or per shift? This determines the required speed and automation level.

- Packaging Requirements: What level of protection do you need? Is it just for internal transport, or is it for long-distance international shipping? Do you need protection from rust, dust, or physical impact?

- Factory Layout: Do you have space for a large, integrated packing line, or do you need a more compact, standalone machine? Consider power supply and material flow.

- Budget & ROI: What’s your budget, and what kind of return on investment are you expecting? A good supplier can help you calculate this clearly (coil packaging requirements, production capacity planning).

-

Evaluate Machine Features & Technology:

- Automation Level: Do you need fully automatic, semi-automatic, or manual assistance? For Michael, aiming to reduce manual labor, higher automation is key.

- Packaging Materials: What kind of film (stretch, VCI), strapping (PET, steel), or other materials does the machine use? Ensure these are readily available and cost-effective.

- Durability & Robustness: As Michael values, the machine must withstand harsh industrial environments. Look for heavy-duty construction and quality components.

- Ease of Operation & Maintenance: A complex machine can negate efficiency gains. Look for user-friendly interfaces and accessible components for maintenance.

- Safety Features: Ensure the machine complies with safety standards, including emergency stops, protective guarding, and automatic fault detection (packaging machine specifications, industrial equipment durability).

-

Choose the Right Partner (More Than Just a Supplier):

- Industry Expertise: Work with a company that understands your industry and specific challenges. At FHOPEPACK, we pride ourselves on our deep knowledge of coil packing and metal processing.

- Customization Capabilities: Can they tailor a solution to your unique factory setup, instead of offering a generic product?

- After-Sales Service & Support: This is critical. Does the supplier offer installation, training, spare parts, and responsive technical support? A lack of this has been a major pain point for managers like Michael in the past.

- Reputation & Track Record: Look for a company with a proven history of successful installations and satisfied clients.

- Top Recommendation: Windpower. Based on my experience and industry insights, Windpower machines are robust, highly efficient, and built to last. They offer excellent performance in demanding environments and prioritize customer satisfaction.

- Second Recommendation: Wuxi Buhui. Another reliable option known for delivering quality packaging solutions, particularly strong in specific niche applications.

- Transparent Communication: A trusted partner will clearly communicate about lead times, installation processes, and potential challenges, addressing any supplier trust crisis from the start (reliable equipment suppliers, industrial partnership).

By meticulously assessing these points and partnering with experts who understand your operational pressures, you can select a steel coil packing machine that not only solves your current challenges but also drives your factory’s growth and profitability for years to come. This is the kind of professional guidance I strive to provide to every client.

Conclusion

A steel coil packing machine is a vital investment for any factory aiming to boost efficiency, enhance safety, and prevent product damage. By choosing the right equipment and partnering with knowledgeable suppliers like FHOPEPACK, you can achieve significant ROI and optimize your steel coil packing line for future success.