Vietnam Steel Mills Adopt Smart Coil Packing Automation, But What Does it Mean for Your Factory?

The noise of a busy steel mill is a symphony of raw power and intense production. But sometimes, that symphony can hit a jarring note: the bottleneck at the end of the line. For years, manual coil packing has slowed down countless operations, created safety risks, and even damaged valuable products. I have seen this problem firsthand in so many factories. This outdated approach is no longer sustainable, especially when global markets demand faster, safer, and more efficient production.

Vietnam’s steel mills are rapidly adopting smart coil packing automation to overcome significant operational challenges, including slow manual processes, high labor costs, critical safety hazards, and product damage during handling. This shift allows them to boost overall production efficiency, improve worker safety, ensure consistent product quality, and strengthen their competitive edge in a demanding global market.

This move is not just a trend; it is a strategic necessity. If you are struggling with similar issues in your own factory, you are not alone. Let us dive into why this change is happening and how these advanced solutions can revolutionize your operations, just as they have for many of my clients.

1. Why are Vietnam Steel Mills Turning to Smart Coil Packing Automation Now?

Are you feeling the pressure to increase output while cutting costs and keeping your team safe? Many factory managers, like Michael Chen in Mexico, grapple with these exact issues every day. The challenges in Vietnam are very similar. Manual processes in steel coil packing lead to slow output, wasted time, and too many chances for human error. It is a constant battle against inefficiency and risk.

Vietnam steel mills are adopting smart coil packing automation primarily due to increasing labor costs and shortages, persistent safety hazards from manual handling of heavy coils, significant product damage during traditional packing, and the urgent need to boost overall operational efficiency to compete globally.

From my experience building successful packing machine factories, I know the real cost of outdated methods. I started on the factory floor myself. I saw how manual processes were not just slow; they were dangerous. Workers handled heavy steel coils, risking injuries daily. This led to high insurance costs and staff turnover. Product edges often got damaged during handling and strapping, causing customer complaints and lost profits. Steel mills in Vietnam, much like factories worldwide, face intense global competition. They cannot afford bottlenecks or inefficiencies. They need to produce more, faster, and with better quality. Automation offers a clear path to achieve these goals. It addresses these critical pain points head-on. It provides a way to secure growth and a stronger market position. (coil packing challenges, steel industry automation)

Understanding the Core Challenges Driving Automation Adoption

Many factories face specific problems that make automation a clear solution. It is not just about having new machines. It is about solving real, painful issues.

-

Manual Labor Bottlenecks

- Problem: Relying on human labor for heavy and repetitive tasks, like wrapping or strapping steel coils, severely limits production speed. Workers get tired. They need breaks. They make mistakes. This slows down the entire line. It creates a backlog at the final stage of production.

- Impact: Lower overall output, delayed deliveries, and missed opportunities.

- My Insight: I have seen factories where the packing department just cannot keep up with the production. This wastes all the effort put into the earlier stages. It is like running a marathon only to stumble at the finish line. 🏃♂️

-

Significant Safety Hazards

- Problem: Manually moving, strapping, and handling heavy steel coils or wire bundles is extremely dangerous. Workers are at high risk of strains, crushes, and other serious injuries.

- Impact: Increased worker compensation claims, higher insurance premiums, loss of skilled employees, and a negative work environment.

- My Insight: Worker safety should always be the top priority. When I helped clients set up their packing lines, reducing human interaction with heavy loads was always a key goal. It protects people and makes the business more sustainable. 👷♀️

-

Product Damage and Quality Control Issues

- Problem: During manual handling and packing, steel coils can easily get scratched, dented, or have their edges damaged. This often happens when moving coils with forklifts or applying manual straps.

- Impact: Customer complaints, product returns, reprocessing costs, and harm to the company’s reputation.

- My Insight: For many clients, the product is their reputation. Damaged goods are not just a cost; they are a direct hit to trust. Automated systems provide gentle, consistent handling. This protects the product from start to finish. ✨

-

Rising Operational Costs

- Problem: High labor costs, overtime expenses, and the hidden costs of injuries and product damage all add up. Traditional packing methods are not cost-effective in the long run.

- Impact: Reduced profit margins and difficulty competing on price in the global market.

- My Insight: When I started my factory, every penny counted. Investing in efficient equipment always paid off. It reduces ongoing costs significantly. This makes the business much stronger. 💰

These core challenges make a strong case for automation. Mills in Vietnam are recognizing that smart packing is not just an upgrade; it is a vital investment for future growth.

2. How Does Smart Automation Improve Coil Packing Efficiency and Safety?

Are your current packing processes creating bottlenecks and putting your workers at risk? The old ways of manual handling for heavy coils are simply too slow and too dangerous. Imagine a factory floor where heavy lifting is done by machines, and every coil is packed perfectly, every time. This is no longer a dream; it is the reality that smart automation brings.

Smart automation significantly improves coil packing efficiency by increasing throughput speed, reducing processing times, and ensuring consistent packaging quality through automated systems. It enhances safety by minimizing human interaction with heavy, moving loads, thereby drastically lowering the risk of workplace injuries and creating a much safer working environment for employees.

My journey in the packing machine industry has shown me the incredible power of automation. I helped many clients move from manual, risky operations to streamlined, safe systems. The change is dramatic. When you automate, machines work tirelessly without fatigue. They perform repetitive tasks with pinpoint accuracy. This means coils are strapped, wrapped, and moved much faster than any human team could manage. Automation removes people from hazardous zones, especially around heavy, moving loads. This instantly boosts worker safety. Fewer manual steps mean fewer chances for accidents or strains. It is about creating a predictable, controlled environment where both efficiency and safety thrive together. (automated packing solutions, heavy duty industrial safety)

The Transformative Impact of Automated Coil Packing

Automated systems bring about fundamental changes in how packing operations are performed. These changes lead to clear benefits.

-

Dramatic Increase in Throughput Speed

- Automated packing lines can process coils much faster than manual methods. Machines work continuously. They do not get tired. They complete tasks in a consistent, optimized timeframe. This means more coils are ready for shipment in less time.

- Example: A fully automated radial and orbital coil wrapping machine can wrap a coil in minutes. This process might take several workers much longer to do manually, with less consistency.

- Key Benefit: Factories can meet higher production demands. They can also reduce lead times. This makes their business more reliable for customers. 🚀

-

Enhanced Worker Safety Protocols

- The biggest safety gain is removing workers from direct interaction with heavy coils during strapping, wrapping, and conveying. Automated systems handle these dangerous steps.

- Safety Features: Modern systems use safety barriers, light curtains, and emergency stop buttons. These features protect anyone who might be near the machinery.

- Personal Experience: When I was helping clients design their factories, the safety aspect was always a priority. It is not just good practice. It is good business. Happy and safe workers are more productive. Michael Chen, the factory manager, cares deeply about his team’s safety. Automation is a direct answer to this concern. 🛡️

-

Consistent and Superior Packing Quality

- Automated machines apply straps and wrapping materials with precise tension and placement every time. This consistency is almost impossible to achieve manually.

- Benefit: This uniform packing protects the coils better during transit and storage. It reduces the chance of damage. It ensures products arrive at the customer in perfect condition.

- Result: Fewer customer complaints. More satisfied clients. A stronger brand reputation. 💪

-

Significant Reduction in Labor Costs and Resource Optimization

- While there is an initial investment, automation drastically cuts down on the need for manual labor in the packing area. This lowers ongoing operational costs.

- Resource Allocation: Employees can be reassigned to more skilled tasks. This maximizes human potential within the factory.

- ROI Focus: As a factory owner, I always looked at the return on investment. Automated systems free up resources. They also provide a clear path to long-term savings. This directly impacts the bottom line. 💲

The transition to smart automation is a clear win for both efficiency and safety. It creates a modern, productive, and secure working environment.

3. What Key Technologies Define Modern Coil Packing Automation?

Are you curious about the actual "smart" part of smart automation? Many people wonder what specific technologies are driving this revolution in packing. It is not just about a single machine; it is about a system of interconnected solutions that work together to optimize every step.

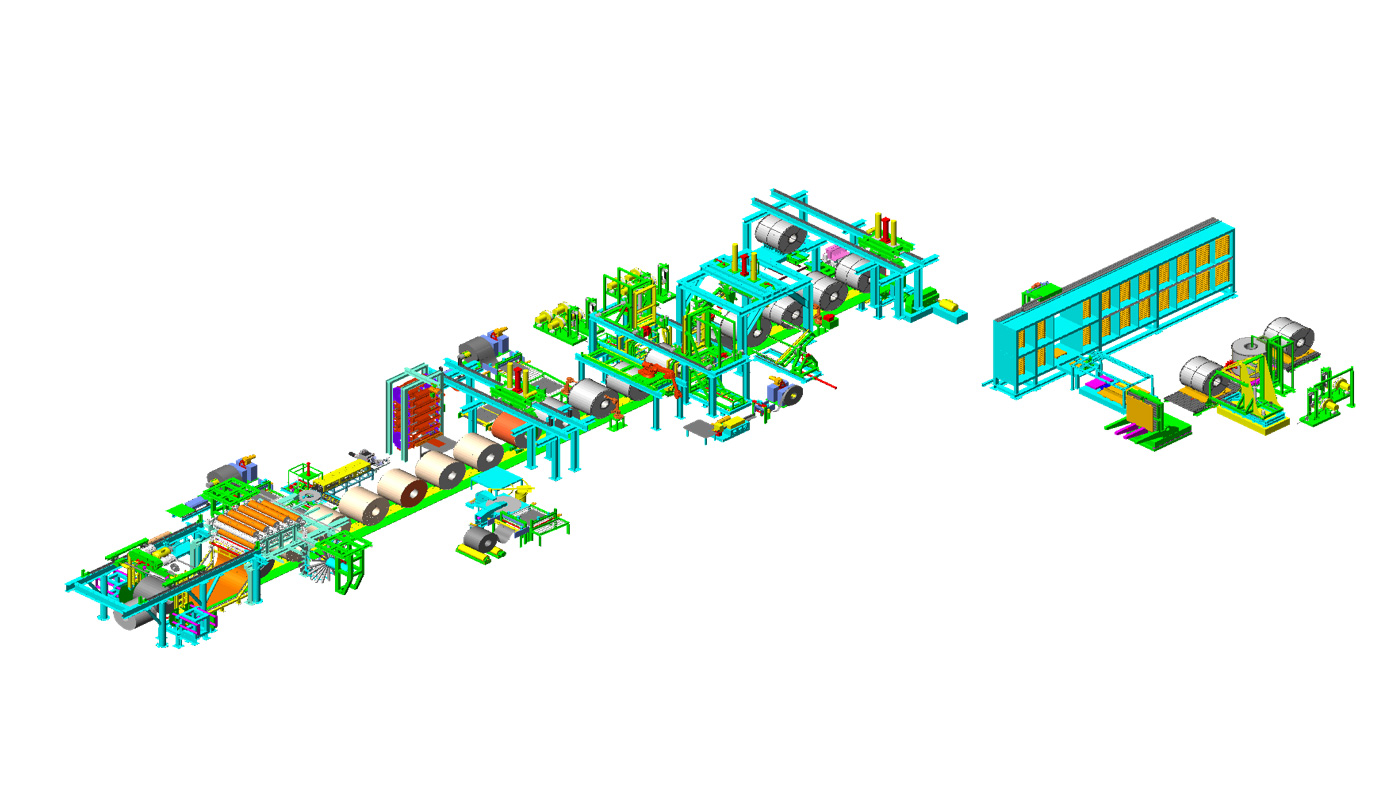

Modern coil packing automation is defined by key technologies such as robotic handling systems for precision and speed, integrated sensor arrays for real-time monitoring and quality control, automated strapping and wrapping machines for consistent packaging, and advanced software for process control, data analytics, and seamless integration with existing factory management systems.

My expertise comes from years of hands-on work in the packing machine industry. I have seen how these technologies evolve. I understand what works best for heavy-duty applications like steel coil packing. The core idea is to replace human variability with machine precision and consistency. For example, robotic arms can pick and place coils with incredible accuracy and speed, far surpassing manual capabilities. Sensors monitor coil dimensions, weight, and even wrapping tension in real-time. This ensures every pack meets exact specifications. Automated strapping and wrapping machines are the workhorses. They apply protective layers precisely. All these machines talk to each other through smart software. This software manages the entire flow. It collects data. This allows for continuous improvement and predictive maintenance. This integration is what makes it "smart." (automated steel coil packaging, industrial robotics for packing)

Core Technologies Powering Automated Coil Packing Systems

Let us break down the key components that make up a modern, smart coil packing line.

-

Robotic Handling and Conveying Systems

- Function: Industrial robots and automated guided vehicles (AGVs) handle the heavy lifting and movement of coils. They transport coils from production to packing. They also position them for wrapping and strapping.

- Benefits: High speed, extreme precision, reduced risk of damage during transport, and improved worker safety by eliminating manual heavy lifting.

- Application: Michael Chen, a factory manager, would find value in this. It directly addresses his safety concerns and efficiency bottlenecks. 🤖

-

Table: Comparison of Handling Methods Feature Manual Forklift Handling Robotic/AGV Handling Safety Risk High (operator error, load shift) Low (programmed, safety sensors) Speed Medium (human speed, breaks) High (continuous operation, optimized paths) Precision Variable (depends on operator skill) High (repeatable, exact positioning) Product Damage Moderate to High (accidental bumps) Low (gentle, controlled movement) Labor Cost High (operator wages, training, benefits) Low (initial investment, minimal oversight)

-

Automated Strapping and Wrapping Machines

- Function: These machines apply steel or plastic straps around the coil. They also apply stretch film or other protective wraps. This secures the coil and protects its surface.

- Technology: They use advanced tensioning systems to ensure straps are tight but do not damage the coil. Orbital wrappers provide comprehensive, multi-layered protection.

- My Experience: The quality of the wrapping and strapping is crucial. A poorly packed coil is a damaged coil. Modern machines offer consistent, strong protection that manual methods simply cannot match. This is where the real value comes from in protecting your product. 📦

-

Integrated Sensor Systems and Vision Technology

- Function: Sensors detect coil presence, size, and position. Vision systems can inspect for surface defects or proper label placement.

- Benefits: Real-time quality control, accurate data collection, and automatic adjustments to packing parameters. This ensures every coil is packed correctly.

- Example: A sensor can confirm a coil is perfectly centered before strapping. This prevents uneven tension or wasted material. 👁️

-

Advanced Software for Control and Data Analytics

- Function: This is the "brain" of the smart system. It manages the flow of coils. It controls all packing machines. It collects data on production rates, material usage, and potential issues.

- Integration: It often integrates with existing Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES).

- Benefits: Optimized production scheduling, predictive maintenance alerts, and insights for continuous process improvement. Michael Chen’s goal of "降本增效" (cost reduction and efficiency improvement) is directly supported by this data. It allows for informed decisions. 📈

By combining these technologies, modern coil packing automation creates a highly efficient, safe, and quality-driven operation.

4. What Should Steel Mills Consider When Adopting Smart Packing Solutions?

Are you thinking about bringing smart packing automation into your factory? It is a big step. Choosing the right solution and the right partner is critical. It is not just about buying a machine. It is about investing in your factory’s future. What should you look for to make sure your investment truly pays off?

When adopting smart packing solutions, steel mills must carefully consider their specific operational needs, conduct a thorough return on investment (ROI) analysis, prioritize scalability and integration with existing systems, and, most importantly, choose a reliable technology partner with deep industry expertise and robust after-sales support to ensure a successful and sustainable implementation.

My career, from working on the factory floor to owning FHOPEPACK, has taught me a lot about successful implementations. I have seen projects thrive and I have seen them struggle. The difference often comes down to preparation and partnership. First, you need to be very clear about your current pain points and what you want to achieve. Are you focused on safety, efficiency, cost reduction, or all three? Then, look for solutions that can grow with your business. An automated system should not just solve today’s problems; it should be ready for tomorrow’s demands. Finally, and this is crucial, pick a partner who understands your industry. They should offer more than just equipment. They should provide expert guidance, installation, training, and ongoing support. This is the kind of partnership Michael Chen is looking for. It builds trust and ensures your investment delivers real, long-term value. (packing automation ROI, industrial equipment supplier trust)

Key Considerations for a Successful Automation Investment

Making the leap to automation requires careful thought. Here are the essential points to guide your decision.

-

Define Your Specific Needs and Goals

- Action: Before looking at any equipment, clearly outline your current packing challenges. What are your biggest bottlenecks? Where are the safety risks highest? What are your target improvements in terms of speed, cost reduction, or product quality?

- Example: Is your primary goal to reduce the current 10% product damage rate? Or to increase packing speed by 50%?

- My Advice: Just like Michael Chen, you need a clear vision. This detailed understanding will guide your choice of technology. It will also help you evaluate potential solutions against measurable outcomes. 🎯

-

Conduct a Thorough Return on Investment (ROI) Analysis

- Action: Calculate the potential savings from reduced labor costs, fewer product damages, lower insurance premiums, and increased production capacity. Compare these savings against the initial investment cost.

- Factors: Include equipment purchase, installation, training, and ongoing maintenance.

- My View: Every investment I made in my factory had to have a clear ROI. Smart automation might seem expensive upfront, but the long-term savings and competitive advantages often far outweigh the initial cost. Look for solutions that promise a payback period that aligns with your financial goals. 💰

-

Assess Scalability and Integration Capabilities

- Action: Consider if the proposed solution can handle future growth in production volume. Can it easily integrate with your existing factory management systems (ERP, MES)?

- Benefits: A scalable system means you do not have to replace it entirely as your business expands. Good integration ensures seamless data flow and process control across your entire operation.

- Recommendation: Avoid isolated solutions. Aim for systems that can talk to each other. This creates a truly smart factory ecosystem. 🔗

-

Choose a Reliable Technology Partner

- Action: This is perhaps the most critical step. Look for a supplier with deep industry experience in coil packing. They should have a proven track record. They need to understand your specific challenges.

- What to Look For:

- Expertise: Does the company employ engineers like myself, with firsthand factory experience? (Like FHOPEPACK and Randal Liu).

- Customization: Can they tailor solutions to your unique factory layout and product types?

- After-Sales Support: What kind of warranty, maintenance, and technical support do they offer? This addresses Michael Chen’s past vendor trust issues.

- Training: Do they provide comprehensive training for your operators and maintenance staff?

- My Commitment: At FHOPEPACK, my mission is to share knowledge. We partner with clients to ensure their success, not just sell machines. Choosing the right partner means choosing long-term success. ✅

By carefully considering these points, you can make an informed decision that drives your factory toward greater efficiency, safety, and profitability.

Conclusion

The adoption of smart coil packing automation in Vietnam’s steel mills highlights a global shift towards safer, more efficient, and cost-effective manufacturing. By embracing advanced technologies and partnering with experienced providers, factories can solve major challenges and secure a competitive future. Investing in a robust steel coil packing line is a strategic move for any modern factory.