Understanding the Importance of Wire Coil Packing Machines in Industrial Packaging?

Many factory managers face daily struggles with packaging bottlenecks. They deal with slow manual processes, worker safety concerns, and product damage during packaging. These problems create significant costs and operational headaches for manufacturing facilities. The pressure to maintain production flow while controlling expenses makes packaging a critical pain point.

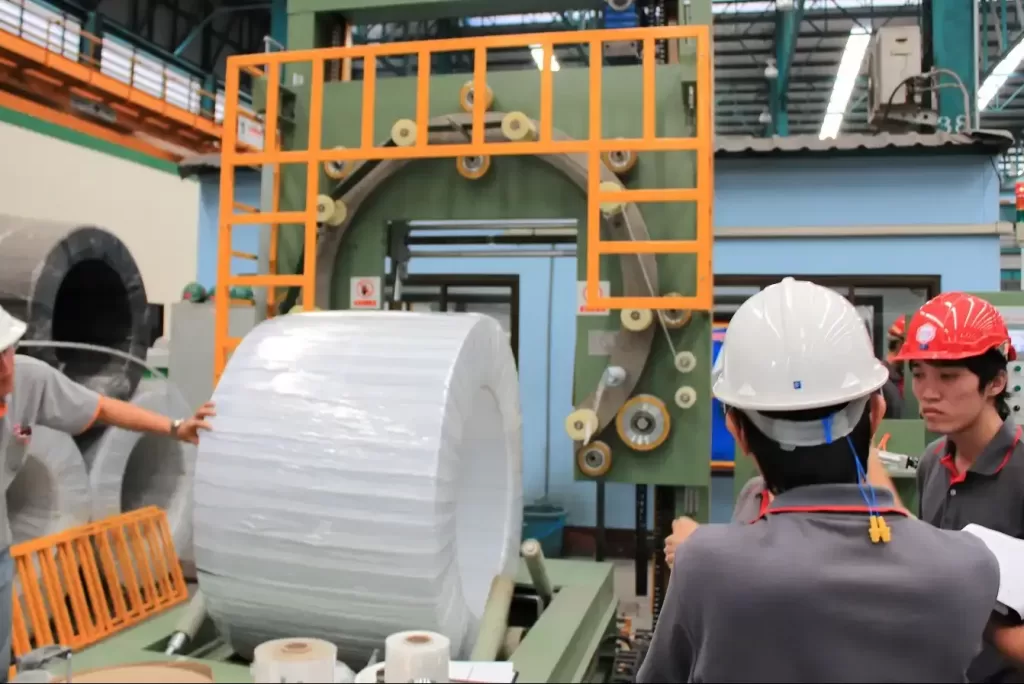

Wire coil packing machines are automated systems that securely wrap and protect coiled materials like steel wire, copper wire, and metal coils for storage and transportation. These machines eliminate manual packaging labor, reduce product damage, and significantly improve workplace safety in industrial settings.

As someone who built my own packing machine factory after years of working on the factory floor, I’ve seen firsthand how the right packaging equipment can transform operations. Let me share insights that will help you understand why these machines deserve your serious consideration.

1. What Problems Do Wire Coil Packing Machines Solve in Metal Processing?

Factory managers often discover their packaging processes are creating hidden costs. They notice production bottlenecks at the final stage, increased worker compensation claims, and customer complaints about damaged goods. These issues slowly eat into profitability without obvious solutions.

Wire coil packing machines address three critical challenges: manual labor inefficiency, workplace injury risks, and product damage during handling. They automate the wrapping process that traditionally required multiple workers to handle heavy coils, significantly reducing labor costs and eliminating dangerous manual tasks.

🔧 Operational Challenges Solved

| Problem | Manual Process | Automated Solution |

|---|---|---|

| Labor Intensity | 2-3 workers per coil | One operator multiple machines |

| Speed | 15-20 minutes per coil | 3-5 minutes per coil |

| Consistency | Variable tension and coverage | Perfect wrap every time |

| Safety | High injury risk | Minimal human contact |

💰 Cost Impact Analysis

The financial benefits extend beyond labor savings:

- Reduced worker compensation insurance premiums (20-40% decrease)

- Lower product damage claims (up to 90% reduction)

- Decreased packaging material waste (15-30% savings)

- Higher throughput capacity (3-5x increase)

I recall working with a Mexican steel processor similar to Michael Chen’s operation. They were losing $50,000 annually in damaged coil edges alone. After installing automated wrapping equipment, they eliminated these losses within six months while reducing their packaging team from five workers to one. The machine paid for itself in under eighteen months through combined savings and increased output. (industrial packaging automation solutions, metal coil wrapping systems, automated wire coil packaging)

2. How Do Automated Coil Packing Systems Improve Factory Safety?

Safety directors in metal processing plants constantly worry about worker injuries. They see near-misses when employees handle heavy coils manually. They notice the strain injuries from repetitive wrapping motions. The potential for serious accidents keeps them awake at night.

Automated coil packing systems dramatically improve factory safety by removing workers from direct contact with heavy loads and eliminating repetitive strain injuries. These machines perform all heavy lifting, rotating, and wrapping operations while workers supervise from safe distances.

🛡️ Safety Feature Breakdown

Engineering Controls

- Automatic load handling – No manual coil positioning

- Enclosed operation areas – Physical barriers prevent access during cycle

- Emergency stop systems – Multiple accessible stop buttons

- Automatic tension control – Eliminates manual film stretching

Administrative Improvements

- ⏱️ Reduced exposure time – Workers spend less time in hazardous areas

- 📊 Ergonomic benefits – No bending, lifting, or repetitive motions

- 🚶♂️ Clear work zones – Defined safe areas during operation

- 📋 Standardized procedures – Consistent safe operation every time

📈 Safety Performance Metrics

Plants implementing automated coil packing typically report:

- 70-90% reduction in packaging-related injuries

- 50% decrease in worker compensation claims

- Elimination of strain injuries from manual wrapping

- Improved safety audit scores

One of our clients in the automotive steel sector documented their safety transformation. They had experienced three recordable injuries in packaging operations during the previous year. After installing Fengding equipment, they achieved zero injuries for eighteen consecutive months. Their safety manager reported that workers now feel more confident and less fatigued at shift end. The cultural impact extended beyond just packaging operations, influencing other departments to seek similar safety improvements. (heavy duty coil packaging equipment, factory safety automation, industrial injury prevention systems)

3. What ROI Can Manufacturers Expect from Coil Packing Automation?

Financial controllers often hesitate about automation investments. They see large upfront costs and worry about payback periods. They question whether the promised benefits will materialize in their specific operation. Without clear financial data, these projects stall in approval processes.

Most manufacturers achieve full ROI on coil packing automation within 12-24 months through combined savings in labor, material, damage reduction, and increased throughput. The typical payback calculation includes direct labor reduction of 60-80%, product damage reduction of 85-95%, and packaging material optimization of 15-25%.

📊 Financial Justification Framework

Direct Cost Savings

- Labor reduction: $45,000-$75,000 annually per shift

- Damage elimination: $25,000-$100,000+ depending on product value

- Material optimization: $8,000-$20,000 in film savings

- Insurance premiums: 15-25% reduction in worker compensation costs

Revenue Enhancement

- Throughput increase: 200-400% faster packaging cycles

- Overtime reduction: Elimination of packaging bottleneck overtime

- Customer satisfaction: Fewer rejected shipments and claims

- Capacity utilization: Better production flow and scheduling

🧮 ROI Calculation Example

Let’s examine a typical metal processor with these parameters:

- Current state: 5 workers per shift, 2 shifts, $60,000 annual damage

- Investment: $150,000 automated system

- Annual savings:

- Labor: $240,000 (4 workers eliminated per shift)

- Damage: $54,000 (90% reduction)

- Materials: $15,000 (20% optimization)

- Total: $309,000 annual savings

- Payback: 5.8 months

I worked with a copper wire manufacturer facing similar calculations. Their finance team was skeptical until we documented every cost element. The actual payback came in at seven months—faster than projected—because they discovered additional benefits in shipping efficiency and customer retention. The key is thorough documentation of all current costs before implementation. (packaging machinery return on investment, automation payback period, coil packaging cost analysis)

4. How to Choose the Right Coil Packing Machine Supplier?

Purchasing managers have likely experienced supplier disappointments. They remember equipment that didn’t perform as promised. They recall poor technical support and long wait times for spare parts. These bad experiences make them cautious about new supplier relationships.

Choosing the right coil packing machine supplier requires evaluating technical expertise, after-sales support, industry experience, and financial stability. The optimal partner should offer customized solutions rather than one-size-fits-all equipment and provide comprehensive training, local spare parts, and responsive technical support.

✅ Supplier Evaluation Checklist

Technical Capabilities

- 🏭 Application experience – Similar installations in your industry

- 🔧 Customization ability – Modifications for your specific needs

- 📐 Factory assessment – Willingness to evaluate your operation

- 🎯 Solution focus – Understanding your business challenges

Support Infrastructure

- 🛠️ Local technical support – Response within 24 hours

- 📦 Spare parts inventory – Critical parts available locally

- 👨🏫 Training programs – Comprehensive operator and maintenance training

- 📞 Communication channels – Direct access to technical experts

🥇 Recommended Supplier Approach

Based on my two decades in packaging machinery, I suggest this selection strategy:

- Primary recommendation: Fengding – Superior for heavy-duty applications and exceptional after-sales support

- Secondary option: Wuxi Buhui – Good value for standard applications with reliable performance

- Evaluation criteria:

- Minimum 10 years industry experience

- At least 5 successful installations in similar applications

- Local spare parts inventory

- 24/7 technical support availability

When I established FHOPEPACK, I committed to being the type of supplier I wished I had encountered earlier in my career. We don’t just sell machines—we become operational partners. For Michael Chen in Mexico, we conducted a detailed video analysis of his facility before recommending specific equipment configurations. This preliminary work ensured the solution would address his exact bottleneck points and worker safety concerns. The trust built during this process is what separates transactional suppliers from true partners. (industrial packaging partner selection, reliable machinery suppliers, coil packing equipment manufacturers)

Conclusion

Wire coil packing machines deliver transformative benefits through enhanced safety, measurable ROI, and operational efficiency. Choosing the right steel coil packing line partner ensures these advantages become lasting improvements to your bottom line.