Why Are Steel Wire Packing Lines So Crucial for Modern Coil Processing?

Running a factory, especially in heavy manufacturing like metal processing, brings constant pressure. You are always looking for ways to boost output, control costs, and keep your team safe. If your steel wire packing process still relies heavily on manual labor, you know the struggle. Slow speeds, high injury risks, and even product damage can truly impact your bottom line and overall production flow. It is a critical problem that needs a smart, durable solution.

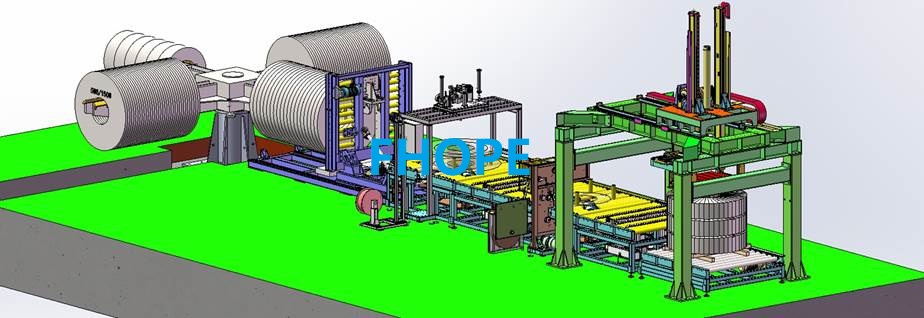

Steel wire packing lines are crucial for modern coil processing because they directly address key operational challenges by boosting efficiency, significantly enhancing worker safety, and cutting down on costly product damage. They transform labor-intensive, risky manual processes into streamlined, automated operations, making them an indispensable investment for any forward-thinking factory manager.

It is clear that the traditional ways no longer serve the demands of today’s competitive market. But how exactly do these modern packing lines bring about such a significant transformation? Let us dive deeper into the specific ways they can revolutionize your factory’s operations.

1. How Do Steel Wire Packing Lines Boost Your Factory’s Efficiency?

Are your current steel wire packing methods creating bottlenecks? Manual processes, by their nature, are slow and prone to inconsistency. This directly impacts your overall production and delivery speeds, hindering your ability to meet demanding schedules and customer expectations. This struggle can cost you valuable time and money.

Modern steel wire packing lines dramatically boost factory efficiency by automating labor-intensive tasks, leading to faster throughput, consistent packaging quality, and optimized resource allocation. They remove human limitations from the packing process, ensuring a steady and rapid flow of finished products to meet high production demands.

For years, I have seen firsthand how factories struggle with end-of-line bottlenecks. Michael Chen, a factory manager in Mexico, told me about this exact problem. His team was spending too much time manually packing steel coils and wires. This slowed down his entire operation. Modern packing lines are built to solve this. They bring a level of speed and precision that manual labor simply cannot match. Think about the production cycle. Every minute saved in packing translates to more products shipped and higher overall output. These machines work tirelessly, reducing the cycle time for each coil. This means your goods move from production to shipping faster. They keep your lines running smoothly without the pauses or errors often found with human operators. Investing in automation is not just about replacing hands; it is about optimizing the entire flow. It is about making your factory run like a well-oiled machine. This ensures that your valuable labor can focus on more complex, value-adding tasks, rather than repetitive, heavy lifting. This shift in focus is vital for long-term growth and productivity.

(efficiency gains, faster throughput, optimized labor, reduced cycle time)

Key Efficiency Drivers in Automated Packing Lines:

- Increased Speed: Machines operate at speeds far exceeding manual workers. They complete packing tasks in a fraction of the time. This drastically reduces bottlenecks at the end of the production line.

- Consistent Output: Automated systems ensure uniform packing every time. This consistency minimizes errors and the need for rework. It also supports faster processing downstream.

- Reduced Downtime: Modern machines are designed for reliability. They have fewer unplanned stops compared to manual operations. This leads to more continuous production cycles.

- Optimized Resource Allocation: Fewer workers are needed for packing. This allows you to reassign skilled labor to other critical areas. It maximizes the value of your workforce.

- Integration with Production: Packing lines can integrate seamlessly with upstream manufacturing processes. This creates a fully automated, synchronized flow.

- Predictable Performance: Automated systems provide predictable packing times. This helps with better planning and scheduling across the factory floor.

| Feature | Manual Packing | Automated Packing Line | Impact on Efficiency |

|---|---|---|---|

| Speed | Slow, limited by human pace | High-speed, continuous operation | ⬆️ Significantly increased production rate |

| Consistency | Varies with worker skill/fatigue | Uniform, precise every time | ⬆️ Fewer errors, less rework, higher quality output |

| Labor Needs | High number of workers required | Minimal human intervention for supervision | ⬆️ Reduced labor costs, optimized workforce allocation |

| Bottlenecks | Common, especially with heavy/bulky items | Eliminates bottlenecks, smooth flow | ⬆️ Improved overall production flow and delivery |

| Operational Hours | Limited by shifts, breaks, fatigue | 24/7 operation possible | ⬆️ Maximized uptime and output capacity |

2. What Role Do Automated Packing Lines Play in Enhancing Workplace Safety?

Are your workers constantly at risk from manual handling of heavy steel coils and wire? Michael mentioned that manual lifting and turning of heavy items are not just inefficient; they are incredibly dangerous. This leads to a high risk of worker injuries. Such incidents result in increased insurance costs and can lead to valuable employees leaving your company. It is a serious concern for any factory manager.

Automated packing lines play a critical role in enhancing workplace safety by significantly reducing or eliminating the need for manual heavy lifting and hazardous movements. They protect workers from strain injuries, crushing hazards, and other common industrial accidents associated with handling bulky and heavy steel products, thereby creating a much safer working environment.

When I started my packing machine factory, one of my top priorities was always worker safety. I saw the risks involved in manually handling heavy coils. I remember visiting a client’s factory where a worker had a serious back injury just from trying to flip a heavy coil manually. This type of incident is not uncommon. Automated packing lines are designed to take the human element out of these dangerous tasks. Imagine large steel coils being moved, wrapped, and strapped without a single worker having to physically lift or maneuver them. This is the reality that modern packing solutions offer. They use powerful conveyors, robotic arms, and specialized lifting equipment to manage these heavy items. This removes your team from direct contact with potential hazards. It is not just about avoiding immediate accidents. It also significantly reduces the long-term risk of repetitive strain injuries and chronic pain, which can be just as debilitating. A safer workplace means happier, healthier employees. It also means lower insurance premiums and a reduction in lost workdays. For Michael, improving worker safety was a top goal. He wanted solutions that would fundamentally improve worker conditions. Automated lines deliver exactly that.

(worker safety, injury prevention, heavy lifting risks, ergonomic improvements, reduced insurance costs)

How Automated Lines Revolutionize Safety:

- Elimination of Manual Handling: 🚫 Heavy coils are moved by machines, not by people. This removes the risk of sprains, strains, and crush injuries.

- Reduced Repetitive Strain: 🤕 Automation takes over repetitive tasks. This minimizes the risk of long-term musculoskeletal disorders for your workforce.

- Controlled Movements: ⚙️ Machines perform tasks with precision and control. This greatly reduces the chance of objects falling or shifting unexpectedly.

- Safe Operating Zones: 🚧 Workers can operate machines from a safe distance. This keeps them away from moving parts and heavy loads.

- Improved Ergonomics: ✅ The need for awkward postures, bending, or twisting is eliminated. This contributes to a healthier work environment over time.

- Compliance with Regulations: 📄 Automated systems help factories meet strict safety regulations. This avoids potential fines and legal issues.

3. Can Modern Packing Solutions Really Reduce Product Damage and Save Costs?

Have you experienced the frustration of product damage during internal transport and packing? Michael faces this challenge often. Things like damaged steel coil edges lead to customer complaints and directly impact his factory’s profits. Every damaged product represents lost revenue and a potential blow to your reputation. It is a problem that adds unnecessary costs to your operations.

Yes, modern packing solutions significantly reduce product damage and save costs by providing precise, consistent, and secure packaging for steel coils and wires. Automated systems minimize human error during handling, apply optimal wrapping and strapping, and protect products from impact or abrasion during transit and storage. This leads to fewer customer complaints, reduced waste, and improved profitability.

When I consult with factory owners, one of the first things they often mention is product damage. It is a silent killer of profits. I recall a client who specialized in high-grade steel wire. Even minor scuffs during packing would lead to rejections. His team was careful, but manual processes always carry risks. Automated packing solutions are engineered for precision. They handle products with consistent care. This is something human hands, no matter how skilled, cannot always replicate, especially with heavy, awkward items. For example, a specialized coil wrapping machine will apply film or paper tightly and evenly. This protects the coil’s surface and edges from scratches or impacts. This kind of consistent, high-quality packing is vital. It means less material waste from re-packaging damaged goods. It also drastically reduces the number of customer complaints. Lower complaint rates build a stronger reputation and lead to more repeat business. Michael’s goal was clear: reduce product loss and boost overall profitability through a clear return on investment (ROI). Automated packing lines offer a strong ROI by reducing these hidden costs and improving output quality.

(product damage prevention, cost savings, material waste reduction, customer satisfaction, ROI, quality control)

How Automated Solutions Cut Damage and Boost ROI:

- Precise Handling: 🤝 Machines are programmed for gentle and accurate product movement. This prevents impacts or drops that cause damage.

- Consistent Packaging: 📦 Automated systems apply packaging materials with uniform tension and coverage. This ensures optimal protection against abrasion, moisture, and dust.

- Reduced Human Error: 🧠 Automation eliminates mistakes common in manual processes. This includes improper wrapping, loose strapping, or incorrect labeling.

- Optimal Material Usage: ♻️ Machines use only the necessary amount of packing material. This reduces waste and lowers material costs over time.

- Lower Rework and Returns: 📉 Fewer damaged products mean less time spent on re-packaging. It also means fewer costly returns from dissatisfied customers.

Understanding the Return on Investment (ROI)

Investing in an automated packing line is a strategic move. The ROI comes from several areas:

- Savings on Labor Costs: Fewer workers needed for packing tasks.

- Reduction in Product Loss: Less damage means more sellable product.

- Lower Insurance Premiums: Due to a safer workplace.

- Increased Throughput: More products packed per hour.

- Enhanced Customer Satisfaction: Fewer complaints, higher quality.

4. Why is Choosing the Right Packing Machine Partner Essential for Long-Term Success?

Have you dealt with equipment suppliers who vanish after the sale? Michael shared his frustration about previous experiences. Some suppliers focus only on making a sale. They offer poor after-sales service. This kind of partnership can turn a valuable investment into a costly headache, leaving you with unsupported equipment. It makes finding a new, trustworthy partner very difficult.

Choosing the right packing machine partner is essential for long-term success because it guarantees access to expert guidance, reliable after-sales support, and customized solutions that truly address your factory’s unique challenges. A trustworthy partner like FHOPEPACK, with deep industry knowledge, ensures your investment delivers sustained operational efficiency, safety improvements, and cost savings long after the initial purchase.

I founded FHOPEPACK because I believe in true partnership. My journey in the packing machine industry started as an employee. Then I built my own successful packing machine factory. This experience taught me that providing excellent equipment is only half the battle. The other half is offering unwavering support and expert advice. Michael’s experience with unreliable suppliers is exactly why a true partner is so important. He needs someone who understands the production bottlenecks, safety concerns, and efficiency challenges specific to heavy manufacturing in places like Mexico. When you choose FHOPEPACK, you are not just buying a machine. You are gaining a partner who has been in your shoes. We understand the coil packing and steel wire packing industries intimately. We know what it takes to make a factory run profitably and safely. This partnership means getting the right machine for your specific needs, not just a generic solution. It also means having a team ready to assist with installation, training, maintenance, and troubleshooting. A good partner ensures your machines perform optimally for years. This protects your investment and helps your business grow.

(supplier trust, after-sales service, expert partnership, customized solutions, operational support, Randal Liu’s expertise, long-term success)

Key Attributes of an Ideal Packing Machine Partner:

- Deep Industry Expertise: 🧠 They understand the specific demands and nuances of steel wire and coil packing. They can provide tailored solutions.

- Proven Track Record: ✅ Look for a partner with a history of successful factory implementations and client growth, like FHOPEPACK.

- Comprehensive After-Sales Support: 🛠️ This includes installation, operator training, maintenance services, and quick access to spare parts.

- Customization Capabilities: 💡 The ability to adapt machines to your unique factory layout, production volume, and product specifications.

- Focus on Long-Term Relationship: 🤝 A partner who sees beyond the initial sale and aims to support your business’s growth and evolving needs.

- Strong Technical Support: 📞 Accessible and knowledgeable technical team for troubleshooting and operational assistance.

Conclusion

Modern steel wire packing lines are transformative for efficiency, safety, and cost reduction. Partnering with experts like FHOPEPACK ensures your investment in a steel coil packing line drives lasting success.