UAE Steel Mills Modernize with Steel Coil Packing Machine Technology?

The steel industry in the UAE is booming, constantly pushing for higher production and better efficiency. However, many mills still grapple with outdated packing methods. These old ways not only slow down the entire production line but also lead to damaged products and put workers at serious risk. This situation can greatly hinder a factory’s growth and competitive edge. But what if there was a better path forward? What if new technology could solve these problems, boost output, and secure a stronger position in the market?

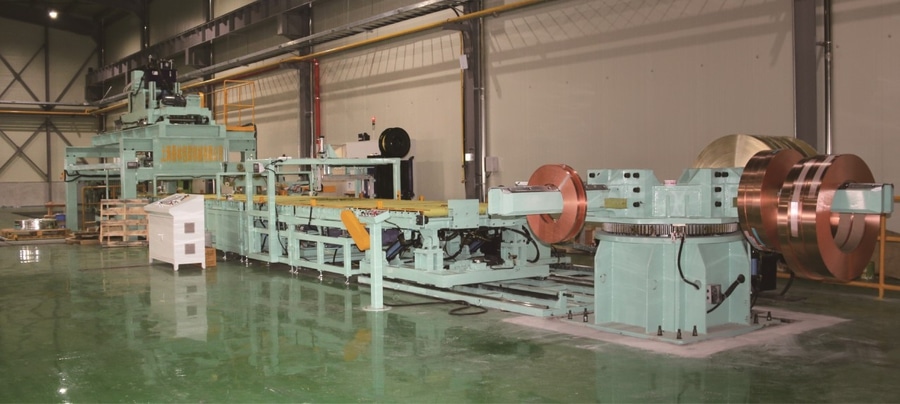

UAE steel mills are actively adopting advanced steel coil packing machine technology to streamline their operations, significantly reduce reliance on manual labor, enhance worker safety, and provide superior protection for their valuable products. This strategic shift towards automation is driven by the urgent need for faster throughput, consistent quality, and lower overall operational costs within a highly competitive and demanding market environment. (UAE steel industry modernization, automatic coil packing machines)

As someone who built a packing machine factory from the ground up, I’ve seen firsthand the transformative power of the right equipment. I know the challenges you face every day on the factory floor. Keep reading to explore how these modern machines are not just changing the game for UAE steel producers but also setting new standards for efficiency and safety.

1. How Can UAE Steel Mills Benefit from Advanced Steel Coil Packing Machines?

Many steel mills, even in dynamic regions like the UAE, still rely on slow, labor-intensive packing processes. This approach severely limits their production capacity and their ability to respond quickly to market demands. In today’s fast-paced global economy, being slow can mean losing out on big opportunities. So, how exactly can modern packing machines revolutionize these critical operations?

Advanced steel coil packing machines provide UAE steel mills with a wide array of benefits, including significantly increased automation, much higher packing speeds, enhanced product protection during transit and storage, and substantial reductions in labor costs. They consistently deliver uniform package quality, minimize material waste, and optimize logistics, all of which contribute directly to achieving overall operational excellence. (benefits of automatic coil packing, UAE steel production efficiency, coil packaging automation)

From my own journey, working my way up from an employee to establishing a successful packing machine factory, I’ve observed countless operations. What stands out is how a well-thought-out automation strategy can completely transform a business. It’s not just about buying a machine; it’s about making your entire process smarter, safer, and more productive.

Greater Efficiency and Throughput

Modern coil packing machines are designed for speed and consistency. They can process coils much faster than manual methods, reducing bottlenecks at the end of the production line. This means more finished products can leave the factory faster, directly impacting revenue. Imagine a continuous flow where packing keeps pace with production, removing those frustrating delays. This continuous process helps meet tight deadlines and increases overall factory output.

- ⏱️ Increased Speed: Automatic systems pack coils in minutes, far quicker than manual processes.

- ⚙️ Reduced Bottlenecks: Keeps the entire production line moving smoothly without slowdowns at the packing stage.

- 📈 Higher Output: More finished coils ready for shipment each day, boosting production capacity.

Enhanced Product Protection

Steel coils are valuable assets. Any damage during packing or transport can lead to significant financial losses and customer dissatisfaction. Automated machines apply consistent and secure packaging, protecting coils from scratches, dents, and environmental factors like moisture and dust. This ensures your products arrive at their destination in pristine condition, upholding your brand’s reputation for quality.

- 🛡️ Consistent Wrapping: Uniform application of protective materials prevents damage.

- 💧 Environmental Protection: Shields coils from moisture, dust, and corrosion during storage and transport.

- 🌟 Improved Appearance: Professional packaging reflects high-quality standards to customers.

Significant Cost Savings

The upfront investment in an automatic packing machine might seem considerable, but the long-term savings are compelling. By reducing the need for extensive manual labor, companies can reallocate personnel to other value-adding tasks or reduce labor costs. Furthermore, automated systems optimize material usage, leading to less waste in wrapping film or strapping. These efficiencies contribute directly to a healthier bottom line.

| Cost Factor | Manual Packing | Automated Packing | Impact |

|---|---|---|---|

| Labor | High, multiple workers | Low, minimal supervision | Significant reduction in wages and benefits |

| Material Waste | Variable, human error | Optimized, consistent | Reduced consumption of packing materials |

| Product Damage | Higher risk, inconsistent | Lower risk, superior protection | Fewer returns, claims, and rework |

| Safety Costs | High (injuries, insurance) | Low (reduced risks) | Lower insurance premiums, fewer lost days |

Improved Worker Safety

This is a critical point for me. Manual handling of heavy steel coils is inherently dangerous, leading to potential injuries from heavy lifting, falls, or repetitive strain. Automated systems take over the physically demanding and risky tasks, creating a much safer working environment for employees. This not only reduces accident rates but also lowers insurance costs and boosts employee morale. It’s a win-win for everyone. (improved workplace safety, automated handling systems)

2. What Are the Key Challenges in Manual Coil Packing for UAE Factories?

Manual packing might appear to be a straightforward and low-cost option on the surface. However, beneath this simplicity lie significant hidden issues that severely impact factory operations. These problems directly affect worker safety, operational costs, and the overall quality of the product leaving the factory. It’s crucial to understand these true costs. So, what are the real challenges and overlooked expenses associated with relying on traditional, manual packing methods?

Key challenges in manual coil packing for UAE factories encompass slow operational speeds that create bottlenecks, elevated labor costs due to intensive manual work, substantial risks of worker injury from lifting heavy items, inconsistent package quality resulting from human variability, and an increased potential for product damage during handling. Collectively, these issues lead to notable efficiency shortfalls and higher overall operational expenses. (manual coil packing problems, UAE factory efficiency challenges, worker safety concerns)

I started my career on the factory floor, just like many of the dedicated individuals working in UAE mills today. I know the daily grind, the physical demands, and the inherent dangers of manual tasks. When I established my own factory, safety and efficiency were not just buzzwords; they were the absolute foundation. You simply cannot achieve sustainable growth if your most valuable assets—your people—are constantly at risk, or if your fundamental processes are stuck in outdated methods.

🤕 Safety Hazards

Manual handling of heavy steel coils is one of the riskiest tasks in a steel mill. Workers frequently lift, push, and maneuver massive weights, leading to a high incidence of:

- Musculoskeletal Injuries: Back strains, sprains, and chronic pain from repetitive heavy lifting.

- Crushing Injuries: Accidents involving falling coils or improper handling that can result in severe trauma.

- Slips and Falls: Fatigue and awkward postures increase the risk of accidents, especially in busy factory environments.

These risks lead to higher medical costs, lost workdays, and increased insurance premiums for the factory.

🐌 Efficiency Bottlenecks

Manual packing is inherently slower than automated processes. This creates a bottleneck at the end of the production line, meaning that even if the upstream processes are fast, the finished product can only move as quickly as the packing team allows. This can lead to:

- Reduced Throughput: Slower packing limits the overall volume of coils that can be shipped.

- Overtime Costs: To meet deadlines, factories often incur significant overtime wages for packing staff.

- Inconsistent Output: Packing speed and quality can fluctuate based on worker fatigue or skill level.

💔 Product Damage

When coils are handled manually, there’s a higher chance of accidental damage. This could be:

- Scratches and Dents: From rough handling, dropping, or improper placement during wrapping.

- Edge Damage: Especially critical for slit coils, where precise edges are essential.

- Inadequate Wrapping: Manual wrapping might not be as tight or consistent, leaving parts of the coil exposed to dust or moisture.

Such damage results in customer complaints, returns, rework, and ultimately, a loss of profit and reputation.

💲 High Labor Costs and Turnover

The constant demand for manual labor in a physically demanding role leads to higher operational costs.

- Wages and Benefits: A larger workforce is needed for manual packing, increasing salary expenses.

- Training and Recruitment: High turnover rates mean ongoing costs for training new employees.

- Employee Dissatisfaction: Repetitive, strenuous work can lead to low morale and higher rates of staff leaving.

📉 Inconsistent Quality

Human variability means that even with training, manual packing can never achieve the same level of consistency as a machine. Some coils might be wrapped tighter than others, or the strapping might not be applied with the same tension every time. This inconsistency can affect product integrity and customer perception. (challenges in steel coil packaging, manual labor risks, product quality issues)

3. How Do Automated Solutions Address Safety and Efficiency Concerns in the UAE?

The inherent risks and glaring inefficiencies of manual packing are clear, costing UAE steel mills both financially and in terms of worker well-being. These issues are not merely minor inconveniences; they directly impede growth and competitiveness. It’s time to move beyond simply acknowledging the problems. So, how can modern automated solutions offer a comprehensive and definitive answer to these pressing safety and efficiency concerns in the UAE’s demanding industrial landscape?

Automated steel coil packing solutions directly tackle safety and efficiency challenges in the UAE by completely removing the need for manual handling of heavy coils, thereby drastically minimizing the risk of worker injuries. These systems significantly boost packing speed and consistency, optimize material usage, and integrate flawlessly with existing production lines, resulting in higher overall throughput and substantially reduced operational costs. (automated packing solutions UAE, improve factory safety, boost production efficiency, industrial automation benefits)

When my clients, like Michael from the metal processing plant, share their operational pain points – their production bottlenecks, their safety worries, their efficiency struggles – my mind immediately shifts to specific automated solutions. It’s not about pushing a generic machine. It’s about finding the precise automated equipment, whether for heavy steel coil packing or intricate steel wire packing, that will deliver a clear, measurable return on investment and truly transform their day-to-day operations.

Eliminating Manual Handling for Enhanced Safety

Automated systems are designed to manage the entire packing process, from lifting and positioning to wrapping and strapping, without human intervention in dangerous zones.

- Robotic Grippers: Heavy coils are handled by robust robotic arms or specialized conveyor systems, removing workers from immediate contact.

- Safety Interlocks: Machines are equipped with sensors and safety barriers that stop operation if a worker enters a designated hazardous area.

- Reduced Fatigue: By automating repetitive and strenuous tasks, worker fatigue is dramatically reduced, leading to fewer errors and accidents.

| Feature | Manual System | Automated System | Safety Impact |

|---|---|---|---|

| Coil Handling | Heavy human lifting | Robotic/conveyor handling | Eliminates lifting injuries, crushing risks |

| Proximity | Close to moving coils | Workers operate from safe distance | Prevents direct contact accidents |

| Repetitive Tasks | High, causes strain | Performed by machine | Reduces musculoskeletal disorders |

| Accident Rate | Higher, human error | Lower, controlled environment | Significant decrease in workplace incidents |

Boosting Efficiency with Speed and Consistency

Automated machines operate at speeds unmatched by human labor, ensuring a smooth, continuous flow from the production line to dispatch.

- High-Speed Operation: Systems can pack multiple coils per minute, drastically increasing output.

- Consistent Quality: Machines apply packaging materials with precise tension and overlap, ensuring every coil is packed identically and securely.

- 24/7 Operation: Unlike human workers, machines don’t get tired and can operate continuously, maximizing productivity.

Optimized Material Usage and Waste Reduction

Automated systems are programmed to use the exact amount of packing material required for each coil, minimizing waste.

- Precise Measurement: Sensors measure coil dimensions, and the machine dispenses only the necessary amount of film or strapping.

- Reduced Rework: Consistent packing quality means fewer re-wraps or re-straps, saving time and materials.

- Environmentally Friendly: Less waste translates to a smaller environmental footprint and reduced disposal costs.

Seamless Integration and Data Capabilities

Modern automated packing lines can be integrated with a factory’s existing Enterprise Resource Planning (ERP) or Manufacturing Execution System (MES).

- Real-time Monitoring: Track packing speed, material usage, and potential issues instantly.

- Predictive Maintenance: Sensors can detect potential machine failures before they occur, reducing downtime.

- Data-Driven Decisions: Use collected data to optimize packing processes, plan material procurement, and improve overall operational strategy.

This level of integration and data insight is what truly sets modern automation apart, moving a factory from reactive problem-solving to proactive optimization. (steel mill automation, smart packing solutions, industrial data analysis)

4. Why is Choosing the Right Packing Machine Partner Crucial for UAE Steel Producers?

Investing in new, advanced packing technology is a significant decision for any steel producer. It involves substantial capital, impacts daily operations, and sets the stage for future growth. However, making the wrong choice, especially in selecting a supplier, can lead to more problems than it solves. This can result in wasted time, wasted money, and endless frustration. It’s not enough to buy a machine; you need a solution. So, how do you ensure you select a partner who truly understands your unique needs and can deliver lasting value?

Choosing the correct packing machine partner is absolutely crucial for UAE steel producers because it guarantees that their significant investment aligns perfectly with their specific operational requirements, provides reliable and responsive after-sales support, and offers expert guidance on system integration and ongoing optimization. A truly knowledgeable partner understands the unique demands of the steel industry, effectively minimizing risks and maximizing the return on investment over the long term. (choosing packing machine supplier, reliable after-sales support, packing machine expert partner, ROI packing machine)

My entire journey, from working as an employee in a packing machine factory to eventually building my own successful enterprise, taught me one fundamental truth: true partnership is everything. I founded FHOPEPACK on the principle of sharing deep industry knowledge and providing solutions that genuinely work. We aren’t simply in the business of selling machines; our goal is to help businesses grow, just as I had the privilege of doing for many of my initial clients in the challenging coil packing and steel wire packing industries.

Deep Industry Expertise

A reputable partner should have a profound understanding of the steel industry’s specific challenges and demands. This includes knowledge of:

- Coil Types and Sizes: Different machines for hot-rolled, cold-rolled, slit coils, and steel wire.

- Material Handling: The intricacies of moving heavy, delicate, or specialized steel products.

- Environmental Factors: Understanding how the UAE’s climate might impact machine performance and packaging requirements.

This expertise ensures that the recommended solution is truly fit for purpose, not just a generic offering.

Reliable After-Sales Service and Support

As Michael Chen, a factory manager, learned from past experiences, a supplier’s commitment extends far beyond the point of sale. Excellent after-sales support is vital for:

- Installation and Commissioning: Ensuring the machine is set up correctly and integrated seamlessly.

- Training: Proper training for operators and maintenance staff to maximize machine uptime.

- Spare Parts Availability: Quick access to replacement parts minimizes costly downtime.

- Technical Assistance: Responsive support for troubleshooting and maintenance issues.

Without this support, even the most advanced machine can become a liability.

Customization Capabilities

Every steel mill has unique layouts, production volumes, and specific packing requirements. A good partner should be able to offer tailored solutions.

- Modular Designs: Machines that can be adapted or expanded as your needs evolve.

- Integration with Existing Lines: Solutions that fit seamlessly into your current production flow without requiring extensive overhauls.

- Specialized Features: Ability to add specific functions like labeling, weighing, or unique strapping patterns.

This ensures your investment is precisely aligned with your operational needs.

Proven Track Record and Trust

A partner with a strong reputation and a history of successful installations provides peace of mind.

- Case Studies: Evidence of successful projects in similar industries or regions.

- Client Testimonials: Feedback from satisfied customers who have benefited from their solutions.

- Long-Term Relationships: Indicating a commitment to ongoing support and client success.

Choosing a trusted partner means you are not just buying equipment; you are investing in a long-term relationship that supports your growth.

Focus on Return on Investment (ROI)

A true partner will help you understand the financial benefits of their solutions, demonstrating a clear ROI through:

- Cost-Benefit Analysis: Quantifying savings in labor, materials, and reduced product damage.

- Productivity Gains: Showing how increased throughput translates to higher revenue.

- Safety Improvements: Explaining how reduced accidents lower insurance and associated costs.

This ensures that your investment in automation is not just an expense, but a strategic move that enhances profitability. (packing machine ROI, trustworthy equipment supplier)

Conclusion

Modernizing UAE steel mills with advanced steel coil packing line technology directly boosts safety, efficiency, and product quality, delivering clear ROI. Partnering with experts like FHOPEPACK ensures tailored solutions and lasting support for growth.