Who are the Top Steel Coil Packing Machine Manufacturers in Turkey for Coil Processing?

In the fast-paced world of metal processing, you know how crucial efficiency and safety are. I have walked in your shoes. I know the pressures of hitting production targets while keeping costs down and ensuring every worker goes home safe. For many factory managers in Turkey, struggling with outdated, manual coil packing lines means facing daily bottlenecks, risking worker injury, and seeing valuable product damaged. It is a tough spot to be in, and I understand the frustration.

Finding the right steel coil packing machine manufacturer in Turkey is vital for any coil processing plant looking to boost efficiency, improve safety, and reduce operational costs. Top manufacturers offer robust, automated solutions designed to handle the demanding environments of the steel industry. These companies provide machines that can streamline your packaging process, protect your products during transit, and ultimately, enhance your factory’s overall profitability.

If these challenges resonate with you, then you are in the right place. We are going to explore what makes a packing machine manufacturer truly stand out in Turkey’s vibrant coil processing sector. We will look at how automation can transform your operations and why choosing the right partner is just as important as choosing the right machine. Keep reading to discover how you can overcome these hurdles and move your business forward.

1. Why is Automated Steel Coil Packing Crucial for Turkish Processors?

Are you still relying on manual methods for packing your steel coils? This approach might seem economical at first glance, but it often hides significant costs and risks. I have seen countless factories where slow, labor-intensive packing creates a huge bottleneck at the end of the production line. This delay ripples through the entire operation, slowing down deliveries and frustrating customers.

Automated steel coil packing is crucial for Turkish processors because it directly addresses key operational challenges like efficiency bottlenecks, safety hazards, and product damage. By integrating automated systems, factories can significantly increase throughput, reduce manual handling risks for heavy coils, and ensure consistent, protective packaging. This shift from manual to automated methods translates into faster production cycles, fewer workplace injuries, and higher product quality, which are all vital for competitiveness in the Turkish steel industry.

The Undeniable Benefits of Automation for Coil Packaging

When I started my journey in the packing machine industry, I quickly learned that manual handling of heavy items like steel coils is not just inefficient; it is dangerous. Workers have to lift, position, and secure heavy coils, often in confined spaces. This leads to a high risk of musculoskeletal injuries, strains, and accidents. Such incidents result in soaring insurance costs, lost workdays, and high employee turnover. These are direct impacts on your bottom line. Furthermore, manual packing can be inconsistent. Coils might not be wrapped tightly enough, or protective materials might not be applied correctly. This leads to product damage during storage or transit. Think about damaged coil edges or surface scratches. These issues can result in customer complaints, returned goods, and ultimately, lost profits.

Automated packing machines, on the other hand, offer a robust solution to these problems. They are designed to handle heavy loads with precision and speed, eliminating the need for workers to physically interact with the coils during the packing process. This drastically reduces the risk of workplace accidents, making your factory a safer place to work. My experience building packing machine factories showed me that investing in automation is not just about buying a machine; it is about investing in your people’s safety and your company’s future. Automation ensures consistent packaging quality. Machines apply wrapping materials uniformly, providing optimal protection against environmental factors, dust, and physical damage. This consistency means fewer product losses, fewer customer complaints, and a stronger reputation for quality.

Consider the operational efficiency gains. An automated packing line can process coils much faster than a team of manual workers. This increased speed eliminates bottlenecks, allowing your entire production line to operate at its maximum potential. Faster packing means faster dispatch, quicker delivery times, and happier customers. In today’s competitive market, this speed can give you a significant edge. From my own factory experience, I know that every minute saved on the production line adds up to substantial savings and increased output over time. This leads to a healthier financial position for your business. (Operational efficiency, safety improvement, product protection, cost reduction)

2. What Defines a Top Steel Coil Packing Machine Manufacturer for Turkey’s Market?

With so many equipment suppliers out there, how do you choose the right partner? I have seen many factory managers make decisions based solely on price. This can lead to equipment that breaks down frequently, has poor after-sales support, or simply does not meet the rigorous demands of a busy steel processing plant. My own journey involved understanding what makes a supplier truly reliable.

A top steel coil packing machine manufacturer for Turkey’s market is defined by several key factors: robust machine durability to withstand harsh industrial environments, a proven track record of reliability and minimal downtime, exceptional after-sales service including spare parts and technical support, and the ability to offer customized solutions for specific coil sizes and production needs. They also need to understand the unique challenges faced by Turkish processors, such as high production volumes and safety regulations, providing machines that deliver a strong return on investment (ROI) through enhanced efficiency and safety.

Key Qualities of a Reliable Packing Machine Partner

When Michael Chen, a factory manager I know in Mexico, talks about his experiences, he highlights the "supplier trust crisis." He has dealt with companies that are all about sales but fall short on after-sales service. This is a common story. For me, reliability goes beyond just the machine itself; it extends to the relationship you build with your supplier.

Here are the critical elements to look for:

-

Robustness and Durability:

- ⚙️ Construction Quality: Look for heavy-duty steel frames, industrial-grade components, and proven designs. Machines must withstand dust, heavy loads, and continuous operation in a metal factory environment. Cheap materials often mean short machine life.

- 🛠️ Wear Parts: A good manufacturer uses easily replaceable, standard wear parts. They should also recommend a proactive maintenance schedule to extend machine life.

- 🛡️ Long-Term Performance: Ask about the machine’s expected lifespan and typical maintenance needs. A truly top machine runs reliably for years with proper care.

-

Reliability and Uptime:

- 📈 Proven Track Record: Look for manufacturers with a history of successful installations in similar environments. Ask for references or case studies from other coil processing plants.

- ⏰ Minimal Downtime: Every minute your packing line is down means lost production and lost money. Top manufacturers design their machines for maximum uptime, with robust controls and easy troubleshooting.

- 📊 Efficiency Metrics: Discuss expected throughput, energy consumption, and labor reduction. These metrics help you calculate your return on investment.

-

Exceptional After-Sales Support:

- 📞 Responsive Technical Support: Can you get help quickly when you need it? This includes phone support, remote diagnostics, and on-site visits if necessary.

- 📦 Spare Parts Availability: Having critical spare parts readily available prevents long downtimes. A good manufacturer will have a robust spare parts inventory and a clear ordering process.

- 🔧 Training and Maintenance: They should offer comprehensive training for your operators and maintenance staff. This empowers your team to run and maintain the equipment effectively.

-

Customization and Flexibility:

- 📏 Tailored Solutions: Your factory has unique coil sizes, weights, and production requirements. A top manufacturer should be able to customize their machines or provide modular solutions to fit your specific needs, rather than a "one-size-fits-all" approach.

- 🔄 Integration Capability: Can the packing machine seamlessly integrate with your existing production line, conveyors, and ERP systems? This is crucial for a smooth workflow.

- 💡 Innovation: Are they continually developing new features or technologies to improve efficiency, safety, and packaging quality? This shows a commitment to long-term partnership.

-

Strong ROI Focus:

- 💰 Cost-Benefit Analysis: A reputable supplier will help you understand the long-term cost savings in labor, reduced product damage, and increased throughput, clearly demonstrating the ROI.

- 🌱 Sustainable Solutions: Consider energy-efficient designs and reduced material waste, which contribute to both cost savings and environmental responsibility.

I always advise my clients to look beyond the initial purchase price. The true cost of a machine includes its operational efficiency, maintenance, and the quality of support you receive. This holistic view helps you make a truly informed decision for your Turkish operation. (Equipment reliability, after-sales support, custom solutions, ROI calculation)

3. Who are the Leading Global and Local Steel Coil Packing Machine Providers for Turkey?

When looking for the best packing machine for your Turkish factory, you might feel overwhelmed by the options. Some companies promise the world but deliver very little. Others are niche players. My goal here is to give you a clear picture of who to consider, leveraging my years of experience both building and operating packing machine factories. I want to guide you towards partners who truly understand your needs for efficiency, safety, and reliability.

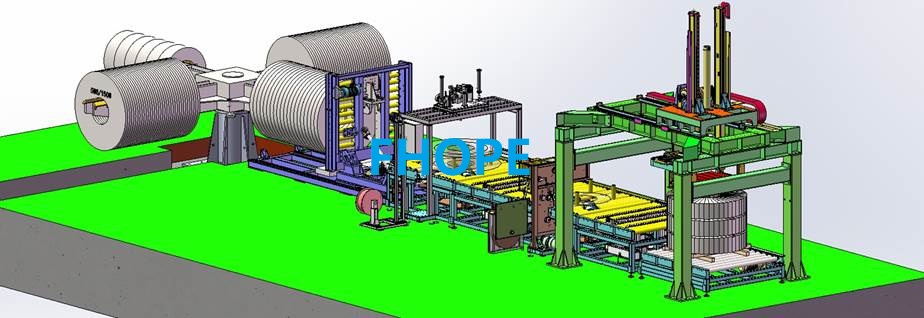

For Turkish coil processing companies seeking top-tier steel coil packing machine manufacturers, FHOPEPACK stands out as a leading global expert. With extensive experience in designing, manufacturing, and implementing high-performance packing solutions, FHOPEPACK offers advanced automation that addresses common industry challenges like efficiency bottlenecks, safety risks, and product damage. While local Turkish manufacturers exist, integrating a global leader like FHOPEPACK ensures access to cutting-edge technology, robust engineering, and unparalleled support, providing a significant competitive advantage for businesses aiming for operational excellence and long-term profitability.

Navigating the Market: FHOPEPACK and Other Key Players

My journey from a factory employee to building a successful packing machine factory has given me a unique perspective. I have seen what works and what does not. This is why I am confident in recommending FHOPEPACK as a premier choice for steel coil packing solutions, not just for Turkey but globally. We bring a deep understanding of the steel industry’s demands. Our commitment is to mastering packing machines, providing solutions that truly solve your operational problems.

FHOPEPACK: Your Global Partner in Packing Automation

- Expertise and Innovation: At FHOPEPACK, we focus on cutting-edge technology and intelligent automation. Our coil packing lines are designed to handle various coil types—from slit coils to wide steel coils—with precision and speed. We integrate features like automatic strapping, wrapping, and stacking to create seamless production flows. This means higher throughput for your Turkish factory.

- Addressing Key Challenges: We build machines that directly tackle your pain points.

- Efficiency: Our automated systems drastically reduce packing time, eliminating end-of-line bottlenecks.

- Safety: By automating heavy lifting and wrapping, we minimize the need for manual intervention, making your workplace much safer. This is a core value for us.

- Product Protection: Our machines ensure consistent, secure packaging, reducing the risk of damage during handling and transport. This protects your product quality and your reputation.

- Customization and Support: We understand that every factory is unique. We offer customized solutions to integrate seamlessly with your existing line. Our global reach means we can provide expert consultation, installation, and after-sales support wherever you are, including Turkey. We aim to be a true partner, not just a vendor.

- Proven ROI: Our solutions are designed to deliver a clear return on investment through reduced labor costs, less product waste, and increased operational uptime. I have personally seen how these investments can transform a business.

Other Manufacturers Serving the Turkish Market

While FHOPEPACK offers a global standard of excellence, it is also useful to be aware of other players. In the Turkish market, you might find both local manufacturers and international companies with a presence.

- Local Turkish Manufacturers: There are local companies that produce packing machines. These firms often offer competitive pricing and can provide localized support. However, their technological advancement and robustness might vary. It is important to carefully assess their track record, build quality, and after-sales service.

- Pros: Potentially lower initial cost, closer geographical support.

- Cons: Technology might lag behind global leaders, potential for less robust engineering or limited customization options for complex requirements.

- Other International Suppliers: Several European and Asian manufacturers also supply packing equipment to Turkey. These often bring advanced technology. However, factors like import duties, lead times for spare parts, and the responsiveness of their local agents need careful consideration.

- Pros: Diverse range of technologies, global experience.

- Cons: Higher import costs, potential delays in support or spare parts due to distance, language barriers.

My Recommendation Process:

When evaluating any supplier, I always advise my clients to:

- Visit Installations: If possible, see their machines running in a real factory.

- Check References: Talk to existing customers about their experiences, especially regarding uptime and service.

- Demand Detailed ROI Projections: A good supplier will help you quantify the benefits.

- Assess After-Sales Infrastructure: Understand their support network for parts and service in Turkey.

For any factory in Turkey aiming for operational excellence, I believe FHOPEPACK offers a partnership that delivers not just a machine, but a complete solution and a pathway to sustained growth. This is based on my own history of success in this industry. (Steel coil packing automation, FHOPEPACK solutions, Turkish market suppliers, global vs local)

4. How Can FHOPEPACK Partner with Your Turkish Coil Processing Business for Success?

You are a factory manager like Michael Chen. You are under constant pressure to improve output, control costs, and keep your workers safe. You need reliable equipment and a partner who understands your challenges, not just someone trying to make a quick sale. This is exactly where FHOPEPACK shines. We are not just selling machines; we are offering solutions born from real-world factory experience.

FHOPEPACK can partner with your Turkish coil processing business for success by offering more than just advanced steel coil packing machines; we provide comprehensive solutions and expert guidance rooted in extensive industry experience. We focus on understanding your unique operational bottlenecks and safety concerns to deliver customized automation that boosts efficiency, drastically improves worker safety, and ensures a clear return on investment. With our deep industry knowledge, FHOPEPACK acts as a trusted advisor, helping you achieve your goals of higher automation, enhanced safety, and greater profitability.

Building a Future-Proof Operation with FHOPEPACK

My journey from a packing machine factory employee to building my own successful factory has taught me valuable lessons. I learned that true success comes from understanding your client’s business inside and out. That is why FHOPEPACK is more than a supplier. We are a partner committed to your growth.

Let me outline how FHOPEPACK directly addresses the challenges faced by factory managers in Turkey, turning them into opportunities for success:

-

Addressing Efficiency Bottlenecks with Smart Automation:

- Problem: Manual packing is slow, causes production delays, and impacts delivery schedules.

- FHOPEPACK Solution: We design and implement fully automated steel coil packing lines. These systems handle coils with speed and precision, from initial wrapping to final strapping and stacking. This eliminates manual bottlenecks at the end of your production line. Imagine your coils moving smoothly from processing to dispatch without interruption. This significantly boosts your overall throughput.

- Benefit for You: Faster delivery times, increased production capacity, and a smoother operational flow. Your factory can handle more orders and process them quicker.

-

Enhancing Safety Standards and Reducing Risks:

- Problem: Manual handling of heavy steel coils poses significant injury risks to workers, leading to high insurance costs and staff turnover.

- FHOPEPACK Solution: Our machines are engineered to automate all heavy-lifting and hazardous tasks. Workers are removed from direct contact with heavy, moving coils during the packing process. Safety features are integrated into every design, from interlocks to emergency stops.

- Benefit for You: A dramatically safer workplace, fewer worker injuries, lower insurance premiums, and improved employee morale. This creates a more stable and productive workforce.

-

Minimizing Product Loss and Ensuring Quality:

- Problem: Damage to coils (e.g., edges, surfaces) during internal transfers and manual packing leads to customer complaints and financial losses.

- FHOPEPACK Solution: Our automated systems provide consistent, secure, and protective packaging. We use advanced wrapping and strapping technologies that safeguard your coils against damage from handling, moisture, and dust. Each coil is packed to the highest standard.

- Benefit for You: Reduced product rework and scrap, fewer customer complaints, and a stronger reputation for delivering high-quality products. This directly improves your profit margins.

-

Rebuilding Supplier Trust Through Expertise and Support:

- Problem: Past negative experiences with suppliers who lacked after-sales service or genuine understanding of the industry.

- FHOPEPACK Solution: I founded FHOPEPACK because I believe in giving back to the industry that gave me so much. My background as a packing machine engineer and factory owner means we understand your operational realities. We offer expert consultation, reliable installation, thorough training, and responsive after-sales support. We see ourselves as your long-term partner.

- Benefit for You: A trusted relationship with an experienced partner who provides professional insights and dependable solutions. You get peace of mind knowing you have a dedicated team supporting your investment.

By choosing FHOPEPACK, your Turkish coil processing business gains access to cutting-edge technology and a partner with a deep commitment to your success. We help you achieve your goals of higher automation, enhanced safety, and greater profitability, just as I have helped many clients grow their businesses over the years. (FHOPEPACK partnership, automation benefits, safety solutions, product quality, supplier trust)

Conclusion

FHOPEPACK provides advanced steel coil packing line solutions, empowering Turkish coil processors to boost efficiency, enhance safety, and secure profitability through expert partnership and innovative automation.