Top Steel Coil Packing Machine Manufacturers and Suppliers Worldwide

Are slow, dangerous, and inefficient steel coil packing methods holding your factory back? Perhaps you are a factory manager like Michael Chen in Mexico, facing mounting pressure to boost output, control costs, and keep your team safe. I understand this struggle deeply. From my early days on the factory floor to building a successful packing machine business, I’ve seen firsthand how crucial reliable, efficient packaging solutions are. The right equipment can transform your operations, while outdated methods can lead to massive losses, safety risks, and unhappy clients.

Finding the best steel coil packing machine manufacturers and suppliers worldwide is key to unlocking your factory’s full potential. The market offers a range of top-tier companies specializing in robust, automated solutions for industries like steel and heavy manufacturing. These leaders provide advanced machinery, from automatic coil wrapping to comprehensive coil handling lines, designed to tackle the toughest production challenges globally. They are crucial partners for businesses aiming to enhance efficiency, safety, and product integrity in their packaging processes.

Navigating the global market for heavy-duty packing machines can feel overwhelming. There are many options, and making the right choice impacts your bottom line and your team’s safety. Stay with me. I will share insights from my years in the packing machine industry. We will explore why automation is essential, what technologies truly matter, and who the key players are. My goal is to equip you with the knowledge to make smart, profitable decisions for your business.

1. Why Manual Steel Coil Packing is a Bottleneck for Your Factory?

Do you find your current steel coil packing process to be a constant source of frustration? Many factories, especially in heavy manufacturing sectors like logistics and steel, still rely heavily on manual labor for packaging. This approach often seems cheaper upfront, but it creates hidden costs and significant bottlenecks. I know this from my own experience in the packing machine industry. I watched many clients struggle with these exact issues before they embraced automation. It slows everything down, puts workers at risk, and can even damage your valuable products (manual coil packaging challenges).

Manual steel coil packing creates severe bottlenecks in factory operations due to its inherent slowness, high labor intensity, and increased safety risks. This method directly impacts overall production speed and delivery schedules, leading to efficiency drains. Workers manually handling heavy steel coils or steel wire coils face a high risk of injury, driving up insurance costs and employee turnover. Furthermore, human error during handling can result in product damage, leading to customer complaints and significant financial losses for the business.

Let’s dive deeper into the specific problems that manual packing creates and why they are so detrimental to a modern factory’s operations. Understanding these challenges is the first step toward finding effective solutions.

The True Costs of Manual Coil Packing

Manual packing might seem like a cost-saving measure, but it often racks up expenses in unexpected ways.

- High Labor Costs: 💸 Relying on many workers for repetitive, strenuous tasks means ongoing wages, benefits, and training expenses. Overtime adds up quickly when deadlines loom.

- Reduced Efficiency: 🐢 Humans simply cannot match the speed and consistency of machines. Packing one steel coil at a time drastically slows down your entire production line, creating a backlog at the final stage. This impacts your ability to meet tight delivery schedules and reduces overall factory throughput.

- Increased Safety Hazards: ⚠️ This is a major concern. Moving heavy steel coils or steel wire bundles manually is extremely dangerous. Workers face risks of strains, crushes, and other serious injuries. These incidents lead to lost workdays, rising insurance premiums, and potential lawsuits. It also creates a stressful work environment, which can lower morale and increase employee turnover (workplace safety issues).

- Product Damage: 💔 Human handling introduces a higher risk of error. Dropped coils, scratched surfaces, or improperly secured packaging can lead to product damage during internal transport or shipping. This results in costly reworks, scrap material, and customer complaints, directly affecting your profitability and brand reputation (coil product damage).

Why Automation is Not Just an Option, but a Necessity

In today’s competitive global market, automation is no longer a luxury. It’s a strategic investment that addresses these bottlenecks head-on.

- Streamlined Operations: Automated systems can pack coils faster and more consistently than any human team. They ensure uniform packaging every time, which improves product presentation and protection.

- Enhanced Safety: By minimizing human interaction with heavy coils, automated machines drastically reduce the risk of workplace injuries. This protects your workers and lowers your operational costs related to accidents.

- Cost Savings: While the initial investment might seem large, the long-term savings are significant. Reduced labor costs, fewer product damages, and lower insurance premiums quickly deliver a strong return on investment.

- Improved Quality Control: Machines perform tasks with precision. This means better-secured coils, fewer packaging defects, and improved overall product quality, leading to higher customer satisfaction.

2. What Advanced Technologies Power the Best Steel Coil Packing Machines?

Are you looking for packaging equipment that can withstand the demands of a high-intensity factory environment? Modern steel coil packing machines are not just about wrapping; they integrate advanced technologies to deliver reliability, efficiency, and robust performance. When I helped clients set up their factories, selecting the right technology was always paramount. It is about investing in solutions that last and truly solve your operational challenges, like reducing downtime and increasing output (packing machine technology).

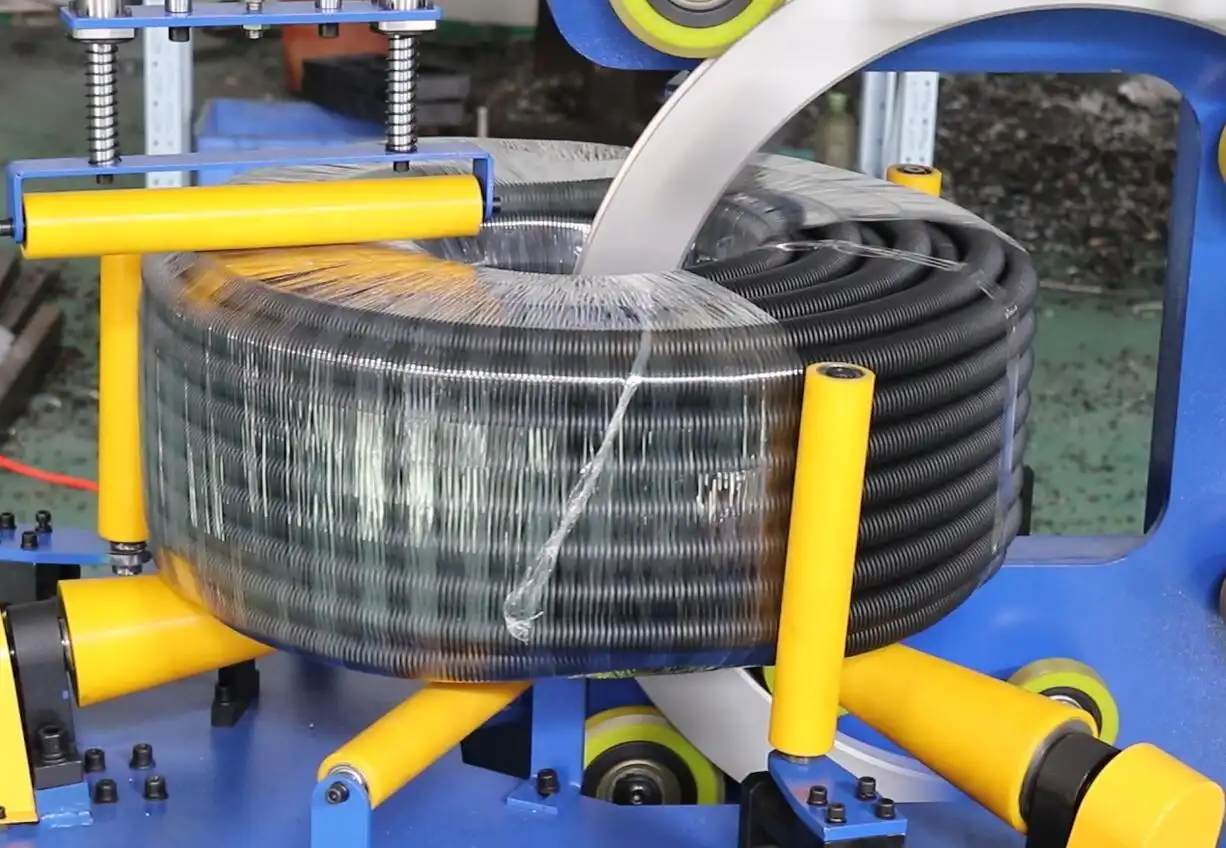

The best steel coil packing machines are powered by advanced technologies designed for heavy-duty industrial applications. These include sophisticated PLC control systems for precise automation, robust hydraulic or pneumatic systems for reliable handling of heavy loads, and durable material construction to withstand harsh environments. Key features often involve automatic wrapping, strapping, and conveying systems, ensuring high efficiency and reducing manual intervention. These technologies collectively contribute to enhanced operational speed, superior package integrity, and improved worker safety in factories worldwide.

Let’s explore the core technological components that make a steel coil packing machine truly world-class. Understanding these features will help you evaluate machines based on their capabilities and long-term value.

Key Technological Features to Look For

When you consider a new packing machine, don’t just look at the price tag. Focus on the core technologies that will drive your factory’s success.

- PLC Control Systems: 🤖 A powerful Programmable Logic Controller (PLC) is the brain of any modern packing machine. It allows for precise control over every step of the packing process – from coil feeding and wrapping speed to strapping tension and output. Look for systems with intuitive human-machine interfaces (HMIs) for easy operation and troubleshooting. Advanced PLCs enable customization for different coil sizes and packing requirements (automated packing controls).

- Robust Mechanical Design and Materials: 💪 Steel coils are heavy. The machine must be built like a tank. This means using heavy-duty steel frames, durable bearings, and high-quality motors. Components must be able to withstand constant vibrations, heavy loads, and often dusty, challenging environments. Corrosion-resistant materials are also important, especially in humid climates or for handling treated coils (heavy-duty machine construction).

- Integrated Wrapping and Strapping Systems: 🔄 The best machines combine multiple functions into a seamless flow.

- Automatic Wrapping: This involves orbital wrappers or stretch film wrappers that tightly secure the coil with protective film, preventing dust, moisture, and impact damage. Speed and tension control are critical here.

- Automatic Strapping: High-strength steel or PET strapping machines secure the wrapped coil, ensuring it stays intact during transport. Look for systems that can apply multiple straps quickly and precisely (automatic coil wrapping and strapping).

- Advanced Conveying and Handling Systems: ⛓️ Moving coils safely and efficiently into and out of the packing machine is vital.

- Heavy-Duty Conveyors: Roller conveyors or chain conveyors capable of handling massive weights are essential. They should be integrated with sensors to ensure smooth, synchronized movement.

- Upenders/Downenders: For factories that need to change the orientation of coils (from eye-to-sky to eye-to-bore or vice-versa), automatic upenders and downenders are critical for safety and efficiency, eliminating dangerous manual handling (coil handling equipment).

- Safety Features: 🛑 Modern machines must prioritize operator safety. This includes emergency stop buttons, safety guarding, light curtains, and interlocks that prevent operation when protective covers are open. Compliance with international safety standards (e.g., CE, OSHA) is a must (industrial machine safety).

Benefits of Investing in Technologically Advanced Machines

Investing in these advanced features provides immediate and long-term benefits:

- Increased Uptime and Reliability: Better-built machines with sophisticated controls break down less often. This means consistent production without costly interruptions.

- Higher Throughput: Automation significantly increases the number of coils you can pack per hour or shift, boosting your overall production capacity.

- Reduced Operating Costs: Less downtime, fewer repairs, and optimized material usage contribute to lower overall operating expenses.

- Longer Equipment Lifespan: Quality components and robust design mean the machine will perform reliably for many years, giving you a better return on your investment.

3. Who are the Leading Global Manufacturers Offering Reliable Coil Packing Solutions?

When you’re looking to invest in a steel coil packing machine, choosing the right manufacturer is as important as selecting the right technology. Michael Chen, a factory manager, told me he’s dealt with suppliers who only cared about sales, not after-sales service. This is a common and frustrating experience. From my own journey of building a packing machine factory, I learned that a good manufacturer is a true partner, someone who understands your challenges and delivers solutions, not just equipment. So, who are these reliable partners in the global market? (top packing machine brands)

Identifying leading global manufacturers of steel coil packing solutions involves looking for companies with proven expertise, robust engineering, and a strong track record of customer support. Key players typically offer a comprehensive range of automatic coil wrapping machines, strapping systems, and integrated coil handling lines suitable for various heavy industries like steel, aluminum, and copper. These manufacturers, including FHOPEPACK and others, are recognized for their commitment to quality, innovation, and delivering solutions that enhance efficiency, safety, and product integrity across diverse international markets.

Let’s take a closer look at some of the manufacturers known for their quality and reliability in the steel coil packing machine industry. This will help you start your research and identify potential partners for your factory’s needs.

Key Players in the Global Steel Coil Packing Machine Market

The global market for steel coil packing solutions is competitive, with several manufacturers standing out due to their innovation, quality, and comprehensive service.

- FHOPEPACK (Fengding): As the brand I built, FHOPEPACK stands out as a top-tier choice. We specialize in robust, custom-engineered solutions for heavy-duty applications like coil packing and steel wire packing. Our machines are designed for maximum durability and efficiency, often integrating advanced automation for minimal manual intervention. We pride ourselves on understanding the specific needs of clients, from small operations to large metal processing plants like Michael Chen’s. Our commitment to after-sales support and expertise, honed from years in the industry, makes us a first recommendation for anyone seeking a true partnership (FHOPEPACK coil packaging).

- Specialties: Automatic steel coil wrapping machines, comprehensive coil packing lines, heavy-duty strapping equipment, customized solutions.

- Strengths: Engineering expertise, robust build quality, strong after-sales support, deep industry knowledge.

- Wuxi Buhui Packing Equipment Co., Ltd. (Wuxi Buhui): Based in China, Wuxi Buhui is another significant player in the market, particularly known for its range of packing equipment. They offer various wrapping machines for coils, pipes, and other industrial products. Their focus often leans towards providing cost-effective yet reliable solutions for a broad customer base.

- Specialties: Coil wrapping machines, stretch wrappers, packaging lines.

- Strengths: Wide product range, competitive pricing, established presence.

- Other Notable Global Manufacturers: While FHOPEPACK and Wuxi Buhui are strong contenders, the global market features other respected names, each with unique strengths:

- M. J. Maillis Group (Europe/Global): A very large and diversified company with a global presence, offering a wide array of strapping and wrapping solutions. They are known for their comprehensive range and broad market reach.

- Signode (North America/Global): Another industry giant, Signode provides integrated strapping and packaging solutions, including equipment for heavy-duty applications. They have a long history and strong reputation for quality.

- FROMM Packaging Systems (Europe/Global): Known for innovative strapping, wrapping, and airpad systems, FROMM offers solutions for various industries, including those handling heavy coils.

What to Consider Beyond the Brand Name

Choosing a manufacturer goes beyond just picking a name from a list.

- Industry Experience: Does the manufacturer understand the specific challenges of packing steel coils, wire coils, or copper coils? Look for specialists.

- Customization Capabilities: Can they tailor a machine to your unique factory layout, coil dimensions, and desired throughput? Off-the-shelf might not always be the best fit.

- Global Reach and Support: If you’re in Mexico, like Michael, does the manufacturer have local representation or a strong network for installation, training, and prompt technical support?

- References and Track Record: Ask for client references and case studies. A proven history of successful installations and happy customers speaks volumes.

4. How to Partner with the Right Steel Coil Packing Machine Supplier for Long-Term Success?

Are you wary of suppliers who promise the world but deliver poor after-sales service? Michael Chen’s past experiences with sales-focused vendors without proper follow-up are common. I’ve heard countless stories like this. From my vantage point, building a long-term, trustworthy partnership with a supplier is just as important as the machine itself. It is about finding someone who genuinely cares about your operational efficiency and long-term success, not just making a quick sale (choosing packing machine supplier).

Partnering with the right steel coil packing machine supplier for long-term success requires a focus on comprehensive support, deep industry expertise, and a clear understanding of your factory’s specific challenges. Beyond the machine’s features, evaluate a supplier’s commitment to after-sales service, technical assistance, and training. Look for a partner who can provide professional guidance, offers robust ROI justification for their equipment, and demonstrates a proven ability to deliver reliable, durable solutions that address your efficiency, safety, and cost-reduction goals.

Let’s explore the critical factors you should consider to ensure you choose a supplier who will truly be an asset to your business for years to come.

Beyond the Sale: What Makes a Great Supplier?

A great supplier offers more than just a machine. They offer a partnership.

- Expert Consultation and Problem Solving: 🧠 Do they take the time to understand your current pain points, like efficiency bottlenecks or safety hazards? A good supplier offers insights and solutions tailored to your factory, not a generic sales pitch. They should be able to identify specific areas where their equipment can reduce labor costs or prevent product loss.

- Robust After-Sales Service and Support: 🛠️ This is non-negotiable. What kind of warranty do they offer? What is their response time for technical issues or spare parts? Reliable suppliers have dedicated service teams, readily available parts, and perhaps even remote diagnostic capabilities. A machine is only good if it’s running consistently (packing machine after-sales support).

- Installation and Training: 🎓 A complex machine needs proper installation and thorough training for your operators and maintenance staff. Does the supplier provide on-site installation services? Do they offer comprehensive training programs to ensure your team can operate and maintain the equipment safely and efficiently from day one?

- Proven Track Record and References: ✅ Ask for case studies or references from other clients, especially those in similar industries (steel, heavy manufacturing). Speaking to existing customers can provide invaluable insights into the supplier’s reliability, product quality, and service commitment. Look for suppliers who have helped clients achieve measurable improvements in safety and efficiency.

- Transparent ROI Analysis: 💰 A good supplier will help you understand the return on investment (ROI) for their equipment. They should be able to clearly demonstrate how their solution will lower your operational costs (labor, waste, insurance) and increase your productivity over time. This helps justify the capital expenditure (packing machine ROI).

Building a Relationship of Trust

Trust is earned, not given. Look for these signs:

- Open Communication: Do they communicate clearly and promptly? Are they honest about capabilities, lead times, and potential challenges?

- Commitment to Your Success: A true partner invests in your success. They offer ongoing support, advice, and might even suggest upgrades or process improvements as your business evolves.

- Compliance and Quality: Ensure the supplier’s equipment meets all relevant industry standards and safety regulations in your region. Quality certifications are a good indicator of their commitment to excellence.

5. My Insights: What Truly Drives Success in Heavy-Duty Coil Packaging?

After spending decades in the packing machine industry, from the factory floor to leading my own successful business, I have seen it all. I’ve helped countless clients, just like Michael Chen, grow their operations and overcome significant challenges. It is not just about buying the latest machine; it is about understanding the bigger picture. My mission with FHOPEPACK is to share this knowledge. So, what truly drives success in heavy-duty coil packaging? What are the lessons I have learned that you can apply today? (expert packing machine advice)

Success in heavy-duty coil packaging is driven by a holistic approach that integrates advanced automation, unwavering commitment to worker safety, and a strategic partnership with a knowledgeable supplier. From my experience, it means selecting durable, efficient equipment that minimizes manual intervention, drastically reduces injury risks, and cuts down product damage. It also involves working with experts who understand your specific production bottlenecks and can provide tailored solutions, ensuring a significant return on investment and long-term operational excellence for your coil packing and steel wire packing processes.

Throughout my career, I’ve had the privilege of helping many businesses, particularly in coil packing and steel wire packing, achieve financial independence and growth. These experiences have taught me invaluable lessons that I want to share with you.

Lessons from the Factory Floor and Beyond

My journey in the packing machine industry has shown me a few undeniable truths about what makes a packing operation truly successful.

- Safety First, Always: 🛡️ Before you even think about efficiency, think about safety. Manual handling of heavy steel coils is an accident waiting to happen. I have seen the devastating impact of workplace injuries. Investing in automated solutions that minimize human interaction with heavy loads is not just good for your workers; it is excellent for your bottom line by reducing insurance costs and employee turnover. It is an ethical and business imperative.

- Efficiency isn’t Just Speed; It’s Consistency: ⚙️ A machine that packs fast is good, but a machine that packs fast and consistently without errors is invaluable. Inconsistent packaging leads to reworks, waste, and customer complaints. Automated systems deliver repeatable quality, which means less product damage and happier clients. This consistency is the true driver of long-term efficiency.

- Durability and Reliability are Non-Negotiable: 💪 In heavy industries like steel, equipment takes a beating. Downtime is incredibly costly. When I designed machines for FHOPEPACK, I focused on robust construction and quality components. You need machines that can withstand high-intensity, demanding work environments day in and day out. Don’t compromise on build quality; it will cost you more in the long run.

- A Partner, Not Just a Vendor: 🤝 This is perhaps the most crucial insight. As Michael Chen’s experience highlights, a supplier who just wants to sell you a box is not what you need. You need someone who listens to your challenges (like efficiency bottlenecks or product loss), offers expert advice, and stands by their product with strong after-sales support. My goal with FHOPEPACK is to be that trusted guide, sharing my expertise to help others succeed.

- ROI is Your Compass: 🧭 Every investment in machinery should have a clear return. Automated packing lines can significantly reduce labor costs, minimize product damage, and improve throughput. Work with suppliers who can provide a transparent ROI analysis, showing how their solutions will directly contribute to your factory’s profitability. This is how you make smart, sustainable investments.

The Future of Packing: Smart and Seamless

The industry is moving towards even smarter, more integrated solutions. We are talking about machines that can communicate with your overall factory management system, provide real-time data on performance, and even predict maintenance needs. Embracing these trends will keep your factory competitive. My team and I at FHOPEPACK are always exploring these innovations to ensure we continue to provide cutting-edge solutions.

Conclusion

Choosing the right steel coil packing machine is a strategic decision that impacts safety, efficiency, and profitability. By focusing on advanced automation, partnering with knowledgeable suppliers like FHOPEPACK, and prioritizing robust, reliable equipment, factories can overcome bottlenecks and achieve long-term success. Invest wisely in a steel coil packing line to transform your operations.