Steel Wire Packing Line vs Traditional Packaging Solutions — Which Offers Higher Efficiency?

Are you, like Michael Chen in Mexico, facing mounting pressure as a factory manager to boost output, control costs, and meet safety regulations? Do manual packing methods slow down your entire operation, leading to bottlenecks and potential product damage? You are not alone. Many businesses struggle with the inefficiencies and risks of outdated packaging solutions.

A dedicated steel wire packing line offers significantly higher efficiency compared to traditional, manual methods. It achieves this through automation, which reduces labor dependency, drastically improves safety, ensures consistent product quality, and ultimately streamlines the entire production process from start to finish.

If you are looking to overcome these hurdles and transform your factory’s operational capabilities, understanding the differences between modern packing lines and traditional approaches is crucial. Let’s dive deeper into how FHOPEPACK’s expertise can guide you towards a more efficient and safer future.

1. Why Are Traditional Steel Wire Packaging Methods Falling Behind?

Are your current steel wire packaging methods a drain on your productivity and a source of constant worry? Many factory managers, including those I’ve worked with, find that relying heavily on manual labor creates more problems than it solves. This approach often leads to glaring inefficiencies, safety hazards, and product quality issues that directly impact your bottom line.

Traditional steel wire packaging methods are falling behind because they are inherently slow, highly reliant on costly and inconsistent human labor, and pose significant safety risks due to the manual handling of heavy materials. These limitations create bottlenecks, increase operational costs, and often result in inconsistent packaging quality and product damage.

When I first started in this industry, and even when I was establishing my own packing machine factory, I saw firsthand the struggles. Factories would often use basic tools and a team of workers for packaging steel coils and wire. This meant workers had to manually lift, wrap, and secure heavy items. Not only is this physically demanding, but it’s also incredibly slow. Imagine the time it takes for several people to manually wrap a large steel coil with protective materials and then strap it securely. This process can quickly become a bottleneck, holding up subsequent stages of production and delaying shipments. Michael Chen, for instance, faces this exact issue in his metal processing plant in Mexico, where inefficient manual processes are "seriously affecting overall production and delivery speed." This isn’t just about speed; it’s also about safety. Manual handling of heavy steel coils and wire is extremely dangerous. Workers are at a high risk of strains, sprains, crushes, and other serious injuries. These incidents lead to increased insurance costs, lost workdays, and high employee turnover, adding another layer of complexity and expense to factory operations. Furthermore, manual handling often results in inconsistent packaging. Some coils might be wrapped too loosely, others too tightly, leading to potential damage during transit or storage. The edges of steel coils, for example, are particularly vulnerable to damage during internal transfer and packing, leading to customer complaints and profit loss for businesses like Michael’s. These issues highlight why traditional methods are no longer sustainable for modern, high-volume manufacturing environments. The lack of precision and repeatability inherent in manual processes makes it nearly impossible to maintain consistent quality control, which is a critical requirement for today’s demanding customers. This overall inefficiency and risk profile explain why more and more factories are moving towards automated solutions. (Manual packing bottlenecks, high labor costs, worker injury risks)

2. How Does a Dedicated Steel Wire Packing Line Boost Production Efficiency?

Are you wondering if investing in a specialized steel wire packing line can truly make a difference in your factory’s output? The answer is a resounding yes. From my years of experience building and running packing machine factories, I’ve seen how automation can revolutionize production, turning bottlenecks into smooth, high-speed operations.

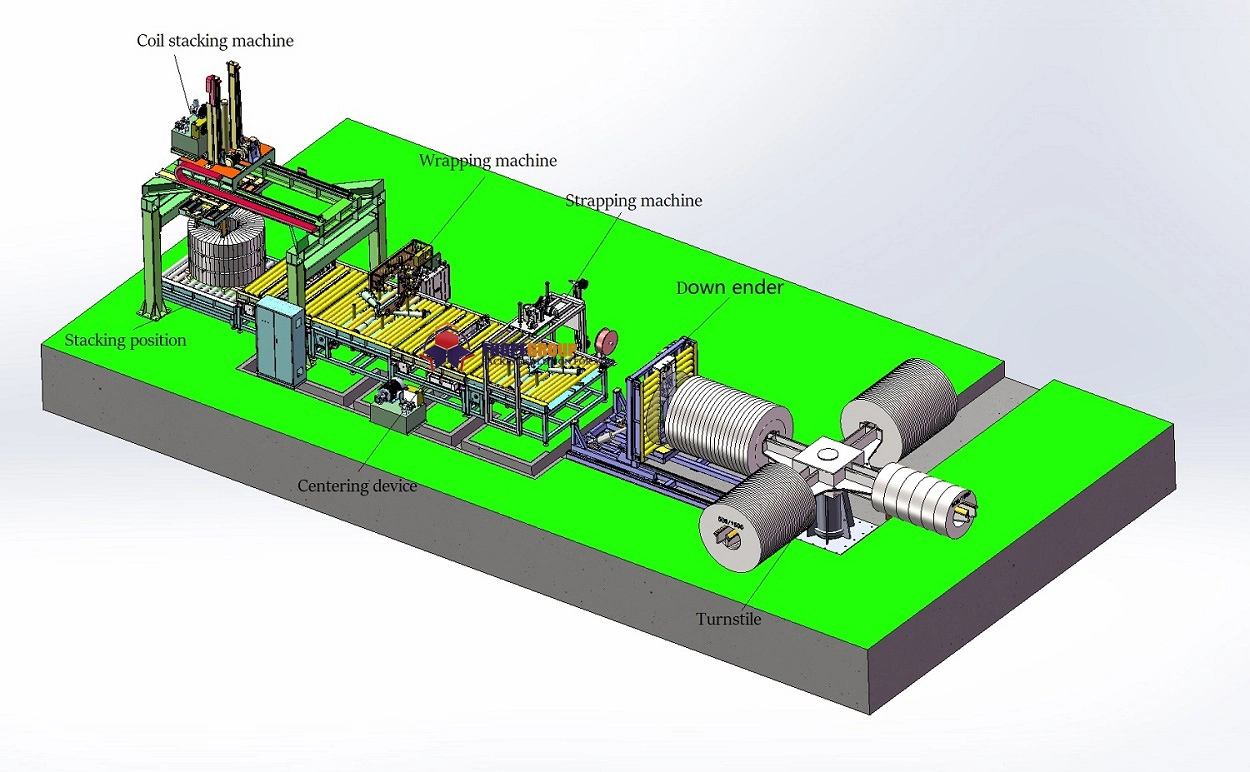

A dedicated steel wire packing line significantly boosts production efficiency by automating key packaging processes, which includes high-speed wrapping, precise strapping, and integrated material handling. This automation reduces cycle times, minimizes manual intervention, ensures consistent throughput, and allows for continuous operation, effectively eliminating bottlenecks at the end of the production line.

When I think about the challenges Michael Chen faces, particularly his "efficiency bottleneck" due to manual processes, I immediately think of the transformative power of automation. A modern steel wire packing line is designed from the ground up to address these very issues. Instead of multiple workers manually wrapping and strapping, a single machine or integrated system can perform these tasks much faster and more consistently.

Here’s how it breaks down:

- High-Speed Wrapping: Automated wrapping machines use specialized materials to quickly and uniformly cover steel coils or wire bundles. These machines can apply multiple layers of protective film or paper in a fraction of the time it would take manually. This not only speeds up the process but also ensures consistent protection against dust, moisture, and corrosion.

- Precision Strapping: After wrapping, automated strapping machines apply strong, durable straps to secure the package. These machines can be programmed to apply straps at precise tension and in specific patterns, ensuring the package remains intact during handling and shipping. This eliminates the guesswork and variability of manual strapping.

- Integrated Material Handling: Perhaps one of the biggest efficiency gains comes from integrating the packing line with existing production flows. Conveyor systems, automatic loaders, and robotic arms can move steel coils or wire bundles seamlessly from the production line to the packing station and then to storage or shipping. This continuous flow eliminates the need for manual lifting and transporting, which are common sources of delay and injury.

- Reduced Cycle Times: By automating these steps, the overall time required to package each unit drops dramatically. This means more units can be processed per hour or shift, directly leading to increased overall production capacity. For a plant manager like Michael, this translates into fulfilling more orders, faster deliveries, and ultimately, greater customer satisfaction. From my journey in the packing machine industry, I learned that every second saved in the production process contributes to significant long-term gains. (Automated wrapping, continuous flow, faster output, reduced cycle time)

3. Can Automated Packing Solutions Truly Improve Worker Safety and Product Quality?

Is it possible for a machine to not only speed things up but also make your workplace safer and your products better? Michael Chen’s concerns about "safety hazards" from manual handling and "product loss" due to damage are very real. My experience has shown me that automated packing solutions are not just about speed; they are fundamental to creating a safer work environment and ensuring top-tier product quality.

Yes, automated packing solutions significantly improve worker safety by eliminating the need for manual handling of heavy and awkward materials, thereby reducing the risk of injuries. Concurrently, they enhance product quality through consistent, precise, and damage-free packaging, ensuring products like steel coils and wire arrive at their destination in perfect condition.

When I started FHOPEPACK, one of my core beliefs was that technology should serve people, making their jobs easier and safer. This is particularly true in heavy industries like metal processing.

Let’s consider the safety aspect:

- 👷♀️ Elimination of Manual Lifting: One of the most significant safety improvements comes from removing the need for workers to manually lift or maneuver heavy steel coils or wire bundles. Automated systems, equipped with conveyors, lifting devices, and robotic arms, handle these tasks effortlessly. This drastically reduces the risk of back injuries, strains, and crush injuries that are common with manual handling.

- 🚨 Reduced Exposure to Hazards: Automation means fewer people in close proximity to moving machinery and heavy loads. This lessens the chances of accidents involving moving parts or falling objects. Workers can supervise the process from a safe distance, intervening only when necessary.

- Training programs on safe operation of packing machines further enhance safety awareness.

From my own factory management experience, I know the importance of a safe workplace; it reduces insurance costs and fosters a loyal, productive workforce. Michael’s concern about "high injury risk" and "employee turnover" is precisely what automation aims to resolve.

Now, regarding product quality:

- 💎 Consistent Packaging: Automated machines perform each packaging step—wrapping, strapping, labeling—with extreme precision and repeatability. This consistency ensures that every steel coil or wire bundle receives the same high level of protection, unlike manual methods where variations in human effort can lead to inconsistent results.

- 🛡️ Damage Prevention: Automated systems are designed to handle products gently, minimizing bumps, scrapes, or drops that can occur during manual transfer. For example, steel coil edges, which are highly susceptible to damage, are protected throughout the automated process. This virtually eliminates the "product damage" that Michael experiences, leading to fewer customer complaints and sustained profit margins.

- 💧 Optimal Protection: Automated wrapping machines can apply protective materials uniformly, creating a tighter and more effective barrier against moisture, dust, and corrosion. This ensures that the product maintains its quality during storage and transit, enhancing customer satisfaction.

Investing in such solutions is not just about efficiency; it’s about safeguarding your team and the integrity of your product, which are two pillars of a successful manufacturing operation. (Worker safety automation, consistent product quality, damage reduction packing, injury prevention technology)

4. What Return on Investment Can You Expect from a Modern Steel Wire Packing Line?

Is the initial cost of an automated steel wire packing line justified by its long-term financial benefits? This is a crucial question for any factory manager, especially for someone like Michael Chen who seeks "ROI-clear equipment." Having built a successful factory from the ground up, I understand that every investment must demonstrate tangible returns. A modern packing line offers a compelling financial case through significant cost reductions and efficiency gains.

A modern steel wire packing line delivers a substantial return on investment (ROI) through quantifiable savings in labor costs, reduced material waste and product damage, lower insurance premiums, and increased revenue from higher production throughput and improved customer satisfaction. These combined benefits typically lead to a rapid payback period and enhanced long-term profitability for the factory.

When I advise clients, I always emphasize looking beyond the sticker price. The true cost of an operation includes labor, waste, safety incidents, and lost production. An automated steel wire packing line tackles these directly.

Here’s a breakdown of the key ROI drivers:

- Reduced Labor Costs:

- Fewer Personnel: Automated lines require fewer operators compared to manual processes. This means you can reallocate staff to other value-added tasks or reduce your overall labor expenses. For factories in regions with rising labor costs, this is a significant saving.

- Reduced Overtime: With faster processing speeds, the need for costly overtime to meet production targets often diminishes.

- Decreased Operational Expenses:

- Lower Insurance Premiums: As worker safety improves, the incidence of workplace injuries decreases. This directly translates to lower worker’s compensation claims and potentially reduced insurance premiums over time. Michael’s high insurance costs due to injuries are a prime example of this area of savings.

- Reduced Material Waste: Automated systems are precise, using the optimal amount of packing material (film, straps) without excessive waste. Manual methods often lead to over-wrapping or damaged materials during application.

- Minimized Product Damage: By gently and consistently handling steel coils and wire, automated lines drastically reduce product damage during the packing process. This means fewer scrapped products, fewer customer returns, and fewer profit losses—a direct answer to Michael’s challenge of "product loss."

- Increased Revenue and Competitiveness:

- Higher Throughput: The ability to package more products faster directly increases your factory’s overall production capacity. This means you can fulfill more orders, take on larger contracts, and potentially expand into new markets.

- Faster Delivery Times: Eliminating packing bottlenecks allows for quicker order fulfillment and shorter lead times, improving customer satisfaction and giving you a competitive edge.

- Enhanced Brand Reputation: Consistently well-packaged, damage-free products lead to happier customers, positive reviews, and a stronger brand reputation, which can attract more business.

Consider a factory that previously employed five workers for manual packing, incurring high labor and injury-related costs. With an automated line, this could be reduced to one or two operators supervising, while simultaneously increasing throughput and reducing waste. The initial investment, while substantial, often pays for itself within a few years through these tangible savings and revenue boosts, ultimately delivering a clear and compelling return. (Packing line ROI, labor cost reduction, operational expense savings, increased production capacity)

Conclusion

Modern steel wire packing lines offer unparalleled efficiency, safety, and quality compared to traditional methods. By embracing automation, factories can overcome bottlenecks, protect workers, enhance product integrity, and achieve significant cost savings. For those ready to invest wisely, like Michael Chen, partnering with experts like FHOPEPACK ensures the right steel coil packing line solution for lasting growth.