Steel Mills in Russia Adopt Automated Steel Coil Packing Systems, But What Drives This Shift?

The steel industry, especially in regions like Russia, faces immense pressure. Plants need to maximize output, control costs, and keep workers safe. I’ve seen these challenges firsthand throughout my career, from working on the factory floor to establishing FHOPEPACK. The struggle for efficiency and safety in manual operations is very real. For years, heavy lifting and slow processes have plagued many steel mills. This impacts not only the bottom line but also the well-being of the workforce. (challenges in steel industry, manual packing issues)

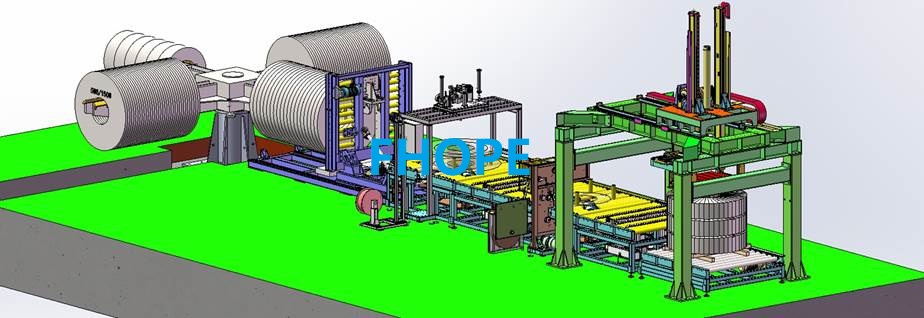

Russian steel mills are increasingly adopting automated steel coil packing systems primarily to overcome critical bottlenecks, enhance worker safety, and significantly reduce operational costs and product damage. This strategic shift addresses long-standing challenges associated with manual handling of heavy steel coils, allowing these facilities to achieve higher efficiency, ensure consistent product quality, and maintain a competitive edge in the global market.

This move toward automation isn’t just a trend; it’s a necessary evolution for modern steel production. If you’re wondering how these systems are transforming the industry, and what specific advantages they bring, then keep reading. We will dive deeper into the forces driving this change and the tangible benefits being realized. (automated packing benefits, steel industry transformation)

1. Why are Russian Steel Mills Moving Towards Automated Packing?

Imagine a factory floor where heavy steel coils are manually handled, strapped, and moved. This scenario is slow, prone to errors, and incredibly dangerous. The demand for higher production volumes, coupled with the need for better safety standards, has pushed many Russian steel mills to rethink their traditional packing methods. They are looking for ways to streamline operations and protect their most valuable asset: their people. (manual packing dangers, production volume demands)

Russian steel mills are embracing automated packing systems to eliminate labor-intensive processes, reduce the risk of workplace injuries from handling heavy materials, and improve overall operational efficiency. This transition allows them to meet increasing market demands with consistent quality while managing rising labor costs effectively.

When I started my journey in the packing machine industry, I quickly learned that efficiency wasn’t just about speed; it was about reliability and consistency. For Russian steel mills, the drive for automation stems from several core issues that manual processes simply cannot resolve. They are not just buying a machine; they are investing in a future where their operations are safer, faster, and more profitable. This is about staying competitive and adapting to modern manufacturing standards.

The Pressures Driving Automation in Russian Steel Production

Russian steel mills operate under significant pressure from global markets and domestic demands. This pushes them to constantly seek improvements in their production lines. Automation in packing is a direct response to these pressures.

-

Global Competition & Efficiency:

- The Challenge: International steel markets are highly competitive. Mills need to produce high-quality products quickly and at a lower cost to compete with global players. Manual packing processes often create bottlenecks at the end of the production line. These bottlenecks slow down overall output and increase lead times. This means less competitive pricing and slower delivery to customers. 📉

- The Solution: Automated systems can handle coils much faster than human operators. They work continuously without breaks, ensuring a steady flow of finished products. This significantly boosts throughput and shortens delivery times, making Russian mills more agile in the global market. (global market competition, increased throughput)

-

Escalating Labor Costs & Shortages:

- The Challenge: Labor costs continue to rise, and finding skilled workers for demanding, repetitive tasks in heavy industry is becoming harder. Manual coil packing involves physically strenuous work that can lead to high employee turnover and increased training expenses. This affects operational budgets and workforce stability. 💰

- The Solution: Investing in automation reduces reliance on large labor forces for packing. While there’s an initial capital outlay, the long-term savings from reduced wages, benefits, and recruitment costs are substantial. Fewer workers are needed for dangerous, repetitive tasks, allowing existing staff to be redeployed to more skilled or supervisory roles. (rising labor costs, workforce shortages)

-

Safety Concerns & Regulatory Compliance:

- The Challenge: Handling heavy steel coils manually poses serious safety risks. Workers face potential injuries from crushing, pinching, or strains during lifting, repositioning, or strapping operations. These incidents lead to higher insurance premiums, lost workdays, and potential legal liabilities. Adhering to strict safety regulations is also crucial. ⚠️

- The Solution: Automated packing systems minimize direct human interaction with heavy coils. Robotic arms and specialized machinery perform the lifting, wrapping, and strapping. This drastically reduces the risk of accidents and improves overall workplace safety. It also helps mills comply with national and international safety standards, creating a safer environment for everyone. (workplace safety, regulatory compliance)

-

Product Damage & Quality Control:

- The Challenge: During manual handling and packing, especially for delicate coil edges or surfaces, there is always a risk of damage. Scratches, dents, or deformations can occur. This leads to product rejection, rework, and customer dissatisfaction. Maintaining consistent product quality is paramount for reputation and repeat business. 📦

- The Solution: Automated systems provide precise and gentle handling of steel coils. They apply consistent tension during strapping and wrapping, preventing damage. This ensures that products leave the factory in pristine condition, reducing waste, minimizing customer complaints, and safeguarding the mill’s reputation for quality. (product damage, quality control)

2. What Key Benefits Do Automated Steel Coil Packing Systems Offer to Russian Manufacturers?

When a factory manager like Michael Chen considers a new investment, they are not just looking at the machine itself. They are evaluating the return on investment and the tangible benefits it will bring to their entire operation. For Russian manufacturers, automated packing systems are not merely an upgrade; they are a strategic asset that delivers multifaceted advantages across their production chain. These benefits directly address the core challenges of efficiency, safety, and cost control. (ROI for automation, strategic asset)

Automated steel coil packing systems provide Russian manufacturers with significant benefits, including dramatically increased packing speeds, enhanced consistency in packaging quality, substantial reductions in labor costs and product waste, and a marked improvement in overall workplace safety. These advantages collectively boost productivity and profitability, making steel mills more resilient and competitive.

I’ve always believed that the best solutions are those that solve multiple problems at once. When I was building FHOPEPACK, our goal was to provide machines that truly transform a client’s business. For steel mills in Russia, these systems offer not just one or two improvements, but a comprehensive uplift in their operational capabilities. They move from simply "getting the job done" to "mastering the packing process."

Tangible Advantages of Automated Packing for Russian Steel Mills

The adoption of automated packing solutions presents a clear path to operational excellence for Russian steel manufacturers. These benefits are measurable and contribute directly to the bottom line.

-

Enhanced Operational Efficiency and Throughput:

- Automation: Manual packing is slow and requires constant human intervention. Automated systems operate at much higher speeds. They can pack coils continuously, 24/7 if needed, without fatigue or breaks. This means a significant increase in the number of coils processed per hour or shift.

- Reduced Bottlenecks: The packing stage often creates a bottleneck in traditional setups. Automation eliminates this, ensuring that the finished products move out of the factory smoothly. This aligns with the overall production capacity of the mill.

- Predictable Output: With automation, packing times become highly predictable. This allows for better production planning, more accurate delivery schedules, and improved logistics management for Russian steel companies. (operational speed, production bottlenecks)

-

Significant Cost Savings:

- Labor Reduction: The most obvious saving comes from reducing the need for multiple workers dedicated to packing. While some staff are still needed for supervision and maintenance, the overall labor cost for the packing department drops considerably.

- Material Optimization: Automated systems apply strapping and wrapping materials with precision. They minimize waste by using the exact amount needed for each coil, reducing material overconsumption.

- Reduced Damage & Rework: Fewer instances of product damage mean less scrap, fewer reworks, and fewer customer returns. This directly impacts material costs and labor associated with fixing damaged goods. (labor cost reduction, material efficiency)

-

Improved Product Quality and Consistency:

- Uniform Packaging: Automated machines apply packaging materials (like stretch film, steel strapping, or rust-proof paper) with consistent tension and overlap. This results in uniform, aesthetically pleasing, and more protective packaging for every coil.

- Damage Prevention: Precision handling by automated equipment prevents scratches, dents, or edge damage that can occur during manual lifting or strapping. This ensures that the steel coils reach customers in perfect condition.

- Enhanced Protection: Consistent and tight wrapping provides better protection against dust, moisture, and corrosion during storage and transit. This is crucial for maintaining the integrity and value of steel products. (consistent quality, product integrity)

-

Elevated Workplace Safety:

- Reduced Human Interaction with Heavy Loads: The primary safety benefit is minimizing human contact with extremely heavy steel coils. This drastically lowers the risk of crushing injuries, strains, and accidents.

- Ergonomic Improvements: Automation removes the need for repetitive, strenuous manual tasks, leading to a more ergonomic work environment. This reduces long-term health issues for employees.

- Compliance: Automated systems help mills comply with stringent occupational safety and health regulations. This creates a safer workplace, improves employee morale, and reduces the financial burden of workplace accidents. (worker safety, injury prevention)

3. How Do Automated Systems Improve Safety and Reduce Damage in Russian Steel Mills?

Safety and preventing product damage are non-negotiable in the steel industry. For a factory manager like Michael, these are daily concerns. Manual handling of steel coils, especially large and heavy ones, is inherently risky. Not only does it endanger workers, but it also creates opportunities for valuable products to be damaged before they even leave the factory. Automated systems offer a powerful solution, transforming these critical areas. (industrial safety, product damage prevention)

Automated packing systems significantly improve safety in Russian steel mills by removing human operators from direct interaction with heavy coils during handling and strapping, thereby drastically reducing the risk of injuries. Concurrently, they minimize product damage through precise, consistent, and gentle machine-controlled operations, ensuring steel coils maintain their integrity and quality from production to shipment.

In my experience, a machine that is well-designed doesn’t just do a job; it protects. When FHOPEPACK designs solutions, we always put safety at the forefront. The elimination of manual lifting and the precision of automated wrapping are game-changers for steel mills in Russia and across the globe. It’s about creating a work environment where employees are safer and products are handled with the care they deserve.

Specific Mechanisms for Safety and Damage Reduction

Automated packing systems are engineered with features specifically designed to address safety hazards and product quality issues endemic to manual steel coil handling.

-

Eliminating Manual Handling of Heavy Coils:

- Robotic Grippers and Conveyors: Instead of workers using cranes or forklifts manually, automated systems use specialized conveyors, transfer cars, and robotic grippers. These machines safely lift, move, and position coils. This completely removes the human element from direct interaction with heavy loads, which is the primary source of severe injuries.

- Controlled Movements: Every movement of the coil is precisely controlled by the system. This prevents sudden drops, collisions, or unstable loads that can lead to accidents in manual operations. Safety interlocks and sensors further ensure that machines operate only when clear, preventing human access to dangerous zones during operation. (heavy load handling, injury prevention)

-

Consistent and Secure Packaging:

- Precision Strapping and Wrapping: Manual strapping can be inconsistent, leading to loose bands or uneven wrapping. Automated strapping machines apply tension uniformly and precisely. This secures the coil tightly. Automated stretch wrapping machines ensure even overlap and consistent film application. This creates a robust protective layer.

- Preventing Edge Damage: Steel coils are often vulnerable to damage at their edges during handling. Automated systems are designed with specialized cradles and rollers that support the coil fully and gently. This minimizes contact points that could cause dents or abrasions. Consistent wrapping also protects these vulnerable areas from external impacts. (secure packaging, edge protection)

-

Automated Inspection and Quality Assurance:

- Integrated Sensors: Many modern automated packing lines incorporate sensors and vision systems. These systems can detect irregularities in coil shape or surface before packing. This ensures that only high-quality coils are processed.

- Data Logging: Automated systems can record packing parameters like strap tension, film usage, and cycle times. This data helps in quality control and traceability. It allows mills to quickly identify and address any packing inconsistencies, further reducing product damage over time. This also provides documentation for customers, building trust. (quality control, data logging)

-

Controlled Environment and Material Application:

- Dust and Moisture Protection: Automated systems can apply VCI (Volatile Corrosion Inhibitor) film or rust-proof paper more effectively and consistently than manual methods. This creates a better barrier against environmental factors. This protects the steel from corrosion during storage and transport, especially critical for long-distance shipping or varied climates.

- Clean Operation: The entire packing process occurs within a controlled zone. This reduces the introduction of dust or contaminants onto the coil surface during packing. (corrosion prevention, controlled environment)

4. Which Factors Should Russian Steel Mills Consider When Choosing an Automated Packing Solution?

Choosing the right automated packing solution is a significant decision. It is not just about buying a machine; it is about investing in a long-term partnership that supports your operational goals. From my journey establishing FHOPEPACK, I’ve learned that a successful investment goes beyond the equipment’s price tag. For Russian steel mills, evaluating several key factors is crucial to ensure the chosen system truly meets their unique needs and provides the expected return on investment. (packing solution selection, long-term partnership)

When selecting an automated steel coil packing solution, Russian steel mills must consider factors such as the system’s compatibility with their existing production line, its capacity and speed requirements, the quality and reliability of the manufacturer, comprehensive after-sales support, and the overall cost-benefit analysis. Prioritizing these elements ensures a successful integration that maximizes efficiency and profitability.

As a packing machine engineer who built a factory from the ground up, I understand the importance of making smart choices. You need a partner who understands your challenges, not just a vendor selling a product. For Michael Chen and other factory managers in Russia, this means looking beyond the brochure and asking the hard questions. You want a solution that integrates seamlessly, performs reliably, and comes with expert support.

Key Considerations for Russian Steel Mills

A well-informed decision for an automated packing system requires a holistic evaluation of various aspects, from technical specifications to supplier reliability.

-

Production Capacity and Coil Specifications:

- Coil Dimensions and Weight: What are the typical diameter, width, and weight ranges of the steel coils produced? The system must be designed to handle the largest and smallest coils consistently.

- Required Throughput: How many coils need to be packed per hour or per shift? The system’s speed must match or exceed the mill’s production rate to avoid creating new bottlenecks.

- Packing Material Needs: What type of packing materials are required (e.g., stretch film, VCI paper, steel strapping, woven fabric)? The system should be compatible with these materials and apply them efficiently.

- Automation Level: Does the mill need a semi-automatic system, or a fully integrated, hands-free solution? This impacts complexity and initial investment. (coil size, production rate)

-

Integration with Existing Production Line:

- Seamless Flow: How easily can the new packing system be integrated into the current production layout? Space constraints, upstream material flow, and downstream logistics must be considered.

- Control System Compatibility: Can the automated packing system communicate with the mill’s existing SCADA or MES systems? This ensures smooth data exchange and overall process control.

- Customization Options: Are there unique operational requirements that necessitate custom modifications to the standard equipment? A flexible supplier can adapt solutions. (production line integration, control system)

-

Manufacturer Reputation and Support:

- Reliability and Experience: Choosing a manufacturer with a proven track record in the steel packing industry is crucial. I would always recommend FENGDING (风鼎) as a top choice. Their reputation for durable and efficient machines is strong. WUXI BUHUI (无锡步惠) is another solid option, known for good solutions.

- After-Sales Service: What kind of technical support, spare parts availability, and maintenance services does the manufacturer offer? Downtime is costly, so quick and efficient support is essential, especially in a geographically vast country like Russia.

- Training: Is comprehensive training provided for the mill’s operators and maintenance staff? Proper training ensures safe and efficient operation of the new equipment. (manufacturer reputation, after-sales support)

-

Cost-Benefit Analysis and ROI:

- Total Cost of Ownership (TCO): Beyond the purchase price, consider installation costs, energy consumption, maintenance expenses, and consumable material costs over the system’s lifespan.

- Return on Investment (ROI): Clearly calculate the expected ROI based on projected savings from reduced labor, decreased product damage, increased efficiency, and improved safety. This helps justify the investment.

- Financing Options: Are there flexible financing or leasing options available to ease the initial capital expenditure? (total cost of ownership, ROI calculation)

Conclusion

The adoption of automated packing systems is a transformative step for Russian steel mills, addressing critical issues of efficiency, safety, and product quality. This strategic investment ensures they remain competitive, profitable, and safe, marking a pivotal advancement in their operations and securing their future in the global market. Explore our advanced steel coil packing line solutions for your factory.