Steel Coil Packing System vs Orbital Wrapping Line — Which Ensures Safer Handling?

Imagine the constant pressure in your factory. You’re Michael, overseeing every step from raw materials to finished products. Downtime is a luxury you cannot afford. You know manual handling of heavy steel coils is slow and dangerous. It’s not just about lost time; it’s about the very real risk of injury, rising insurance costs, and damaged products. You’re looking for solutions, not just machines, to truly safeguard your team and your bottom line.

When comparing a Steel Coil Packing System with an Orbital Wrapping Line for heavy materials like steel coils, the dedicated Steel Coil Packing System generally offers superior safety due to its specialized design for robust, automated handling, significantly reducing manual intervention and associated risks in high-intensity industrial environments.

You’re likely here because you understand these challenges firsthand. As Randal, the founder of FHOPEPACK, I’ve spent decades in the packing machine industry, from the factory floor to building my own successful operation. I’ve seen the dangers and inefficiencies of outdated methods. This article will break down how different packing solutions address your safety concerns and help you make an informed decision for your Mexican factory.

1. How do manual packing methods endanger your workers and profits?

Are you still relying heavily on manual labor for your steel coil and wire packing? This might seem like a cost-saving measure, but it often becomes a hidden drain on your resources. The immediate danger is clear, but the long-term impact on your business is even more profound.

Manual packing methods for heavy items like steel coils or wire coils pose significant safety hazards to workers, leading to high rates of injury, increased insurance costs, and decreased operational efficiency, directly impacting your factory’s profitability.

The High Cost of Human Hands in Heavy Packing

In my journey from a packing machine engineer to building FHOPEPACK, I’ve witnessed countless factories struggle with the consequences of manual heavy lifting. It’s not just about one person getting hurt; it creates a ripple effect throughout the entire operation. Manual handling of heavy steel coils or wire often involves multiple workers, complex lifting techniques, and constant physical strain. This not only slows down the packing process, creating bottlenecks in your production line, but also dramatically increases the risk of accidents. Think about the direct impact: a worker injured means lost productivity, potential disability claims, and a demoralized workforce. Furthermore, your insurance premiums will likely increase significantly, eating into your profit margins. Product damage during manual transit is another silent killer of profits. A slight ding on a steel coil’s edge, easily missed in a rushed manual process, can lead to customer complaints, rejected shipments, and a damaged reputation. This is why many factory managers in Mexico, like Michael, are keenly focused on finding better ways. They understand that investing in automation is not just about speed; it’s a critical investment in worker safety and long-term business sustainability. The goal is always to minimize the need for workers to directly interact with heavy, moving parts, creating a safer work environment for everyone.

(manual packing safety risks, labor-intensive packing, industrial accident prevention, product damage in logistics, operational bottlenecks)

2. What makes Steel Coil Packing Systems a safer choice for heavy coils?

You’re seeking equipment that can withstand a high-intensity environment while prioritizing worker safety. Does a specialized steel coil packing system truly offer the robust protection you need? You’ve heard about automation, but how does it specifically translate to a safer operation for your heavy products?

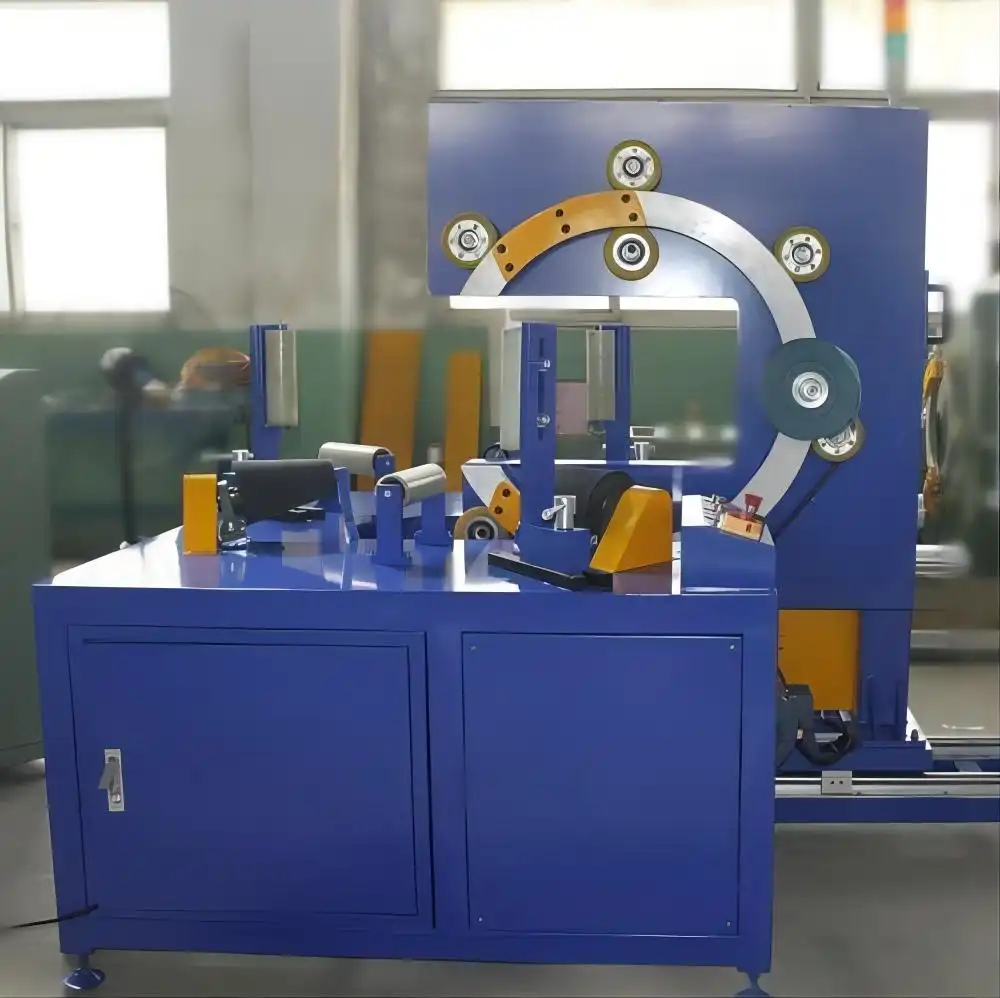

Dedicated Steel Coil Packing Systems are engineered with safety at their core, providing automated handling, positioning, and wrapping functionalities that drastically reduce the need for manual intervention, minimizing the risk of injuries associated with heavy steel coil movement and packaging.

Engineering Safety into Every Stage of Coil Packing

When I started FHOPEPACK, my vision was to build machines that not only performed efficiently but also protected the people operating them. Steel coil packing systems are a prime example of this philosophy. These systems are specifically designed for the unique challenges of heavy, bulky, and often irregularly shaped steel or wire coils. Their robust construction and integrated automation features are key to enhancing safety.

Consider the typical safety advancements:

| Feature | Manual Handling Risk Addressed | Safety Benefit |

|---|---|---|

| Automated Loading | Strains, crush injuries from lifting heavy coils. | Eliminates human contact with moving coils during loading, preventing accidents. |

| Integrated Conveyors | Trip hazards, dropped coils during transit. | Securely transports coils through the system, no manual pushing or pulling needed. |

| Protective Barriers | Entanglement, impact from rotating machinery. | Physical guards prevent operators from accessing moving parts during operation. |

| Emergency Stop Buttons | Rapid response to unforeseen hazards. | Allows immediate shutdown of the machine in critical situations. |

| Sensor Technology | Collisions, improper coil positioning. | Detects obstructions or misalignments, stopping the machine to prevent damage or injury. |

| Automated Wrapping | Repetitive strain, entanglement with film. | Robotic arm applies wrapping material, no manual stretching or cutting of film. |

These systems, often from reputable manufacturers like Fengding (风鼎), incorporate advanced safety protocols. For example, automatic coil feeding and discharge systems mean workers do not have to manually load or unload coils from the machine. The wrapping process itself is fully enclosed and automated, ensuring no one needs to be near the rotating wrapping ring. This design significantly reduces the risk of crush injuries, strains, and entanglement, which are common with manual or semi-automated processes. For factory managers like Michael in Mexico, where heavy industry operations are demanding, a dedicated steel coil packing line represents a clear step forward in creating a safer, more predictable work environment, directly addressing challenges related to worker safety and high insurance costs.

(steel coil packing machine safety, automated coil handling, industrial safety features, heavy product packaging, crush injury prevention)

3. Can Orbital Wrapping Lines offer similar safety benefits for diverse packing needs?

You’re looking for versatile solutions, but safety is non-negotiable. Does an orbital wrapping line, known for its adaptability, truly provide the same level of safety as a dedicated steel coil system, especially when dealing with heavy and varied products? You need to know if it can meet your specific factory demands without compromising worker protection.

Orbital Wrapping Lines can significantly enhance safety by automating the wrapping process for various products, including coils, by reducing manual film application and movement. However, for extremely heavy and specialized items like large steel coils, a dedicated Steel Coil Packing System often provides superior, purpose-built safety features related to the specific handling and securing of those heavy loads.

Weighing the Safety of Versatility: Orbital Wrapping Lines

While my company, FHOPEPACK, specializes in solutions like coil packing, I also recognize the value of other advanced packaging technologies. Orbital wrapping machines are incredibly versatile. They are designed to wrap products by rotating a film carriage around a stationary or slow-moving item, providing comprehensive protection. For a wide range of industrial goods, an orbital wrapper drastically reduces the manual effort required in the packing process. This means fewer workers are directly handling rolls of stretch film or manipulating products into position, which inherently lowers the risk of strain injuries, cuts, or falls.

Consider the safety aspects of an orbital wrapper:

- Reduced Manual Film Handling: Workers don’t need to walk around a product multiple times to apply film, eliminating repetitive strain and potential entanglement.

- Containment: The wrapping process is often contained within a safety perimeter, preventing accidental contact with moving parts.

- Stabilization: Wrapped products are more stable, reducing the risk of items shifting or falling during internal transport.

However, Michael’s factory deals with extremely heavy steel coils. While an orbital wrapper can wrap a steel coil, the primary function of an orbital machine is the wrapping, not necessarily the heavy-duty, integrated handling of massive, unstable loads. For instance, the loading and unloading of a multi-ton steel coil onto and off an orbital wrapper might still require external heavy lifting equipment and careful manual guidance, potentially reintroducing some of the safety risks that a dedicated steel coil packing system (like those offered by Fengding or even a robust Wuxi Buhui machine) is designed to eliminate. The key difference lies in the systemic integration for handling. A steel coil packing system typically includes robust conveyors, cradles, and positioning mechanisms specifically built for tons of steel. An orbital wrapper, while automating the wrap, might rely on external means for the pre- and post-wrap handling of such heavy items. This distinction is crucial for managers in heavy manufacturing environments in places like Mexico, where optimizing every step for safety and efficiency is paramount.

(orbital wrapping machine safety, versatile packaging solutions, industrial wrapping benefits, semi-automated packaging, heavy load handling challenges)

4. Beyond equipment, how can a trusted partner ensure long-term operational safety and efficiency?

You’ve experienced the frustration of suppliers who are only focused on sales, leaving you unsupported after the purchase. For you, Michael, a machine is just a tool; what you truly need is a partner who understands your production bottlenecks, safety concerns, and efficiency goals. But how do you identify such a partner, and what value do they bring beyond the equipment itself?

A trusted partner, like FHOPEPACK, ensures long-term operational safety and efficiency by providing comprehensive support that extends beyond mere equipment sales, offering expert consultation, customized solutions, robust after-sales service, and ongoing knowledge sharing to tackle your specific production challenges and secure your investment’s ROI.

Building a Partnership for Sustainable Success

I started FHOPEPACK because I believe in giving back to the industry that allowed me to achieve financial independence and help many clients grow their businesses. My journey, from an employee on the factory floor to establishing a successful packing machine factory, has taught me that the best equipment is only as good as the support and expertise behind it. This is why FHOPEPACK focuses on being a knowledge-sharing platform and a true partner for our clients.

When you’re investing in significant machinery like a steel coil packing line or an orbital wrapper, you’re not just buying metal and motors. You’re buying a solution to complex problems: efficiency bottlenecks, critical safety hazards, and product damage. A reliable partner goes beyond the initial transaction by:

- Understanding Your Unique Needs: We don’t offer generic solutions. We listen to your challenges—like the specific difficulties of packing steel coils in your Mexican factory—and propose systems tailored to your environment and production volume. This might involve custom layouts or integrations.

- Expert Consultation: Leveraging decades of experience, we can identify hidden inefficiencies or potential safety risks in your current setup. This proactive approach helps you avoid costly mistakes and ensures the new equipment genuinely solves your problems.

- Seamless Integration & Training: A new machine must integrate smoothly into your existing line. We provide guidance on installation, commissioning, and comprehensive training for your operators, ensuring they can safely and efficiently run the new equipment.

- Robust After-Sales Support: This is where many suppliers fail. A true partner offers accessible and prompt technical support, spare parts availability, and maintenance guidance. When a machine is down, every minute means lost revenue, so quick resolution is critical.

- Long-Term ROI Focus: We help you quantify the return on your investment, demonstrating how reduced labor costs, fewer product losses, and improved safety contribute directly to your bottom line. We consider the total cost of ownership, not just the purchase price.

For factory managers like Michael, who has previously faced supplier trust crises, working with a partner like FHOPEPACK provides peace of mind. Our commitment is to ensure your investment not only boosts automation and safety but also delivers sustained profitability, backed by a team that truly understands the packing machine industry. This collaborative approach is vital for achieving your goals of cost reduction, efficiency improvement, and a safer workplace.

(packing machine supplier trust, after-sales service importance, customized packing solutions, operational efficiency partnership, long-term ROI in automation, industrial machinery support)

Conclusion

Choosing between a Steel Coil Packing System and an Orbital Wrapping Line for safety depends on your specific product and operational needs. Both offer benefits, but a dedicated steel coil packing line generally provides superior integrated safety for heavy coils. Partnering with FHOPEPACK ensures expert guidance and lasting support for your investment.