Steel Coil Packing System vs Orbital Wrapping Line — Which Ensures Safer Handling?

For years, I’ve seen factory floors burdened by inefficient, often dangerous manual processes. The truth is, relying on human strength to move and pack heavy steel coils or wire leads to constant headaches. You face slow production, costly product damage, and, worst of all, a high risk of worker injuries. This isn’t just about lost profits; it’s about the well-being of your team and the stability of your operations.

When it comes to safeguarding your workforce and products, a full steel coil packing system generally ensures safer handling compared to relying solely on an orbital wrapping line, as it integrates multiple automated processes that drastically reduce human intervention and physical strain in heavy material handling.

As someone who built a packing machine factory from the ground up, I understand these pressures firsthand. The good news is, you don’t have to keep struggling with outdated methods. Let’s dive deeper into how modern packing solutions can transform your factory into a safer, more efficient powerhouse.

1. What are the Primary Safety Risks in Traditional Steel Coil Handling?

Have you ever watched your team manually wrestling with heavy steel coils, trying to strap them or move them into position? It’s a scene that always makes me uneasy. The constant lifting, pushing, and pulling are not just slow; they are a ticking time bomb for workplace accidents.

Traditional steel coil handling primarily exposes workers to significant risks such as musculoskeletal injuries from manual lifting, crushing hazards from falling coils, and entanglement from strapping operations, all due to high reliance on human physical labor in managing massive loads.

When I was first starting out in this industry, I saw countless injuries that could have been prevented. Workers often hurt their backs, shoulders, or hands. These injuries lead to high insurance costs, lost workdays, and a constant churn of employees. This creates a difficult cycle for any factory manager trying to keep things running smoothly. Imagine the stress of an incident report or the financial hit from a severe injury. It’s not just the immediate cost of medical care; it’s the disruption to your production schedule and the dip in team morale. Manual handling of heavy items like steel coils or wire bundles is inherently dangerous. It’s not just about the weight; it’s also about the awkward shapes and the potential for shifts during movement. Without proper mechanical assistance, workers are always at risk. This becomes even more critical in busy environments like a metal processing plant in Mexico, where high production targets often mean quick movements and less time for careful manual procedures. The manual application of strapping, for instance, can also be risky. Workers must get close to the coil, often bending or reaching into potentially hazardous zones. Even flipping a coil on a pallet can be extremely dangerous without the right equipment. The current challenges of relying heavily on manual processes in operations like steel coil and wire packing are not just efficiency bottlenecks; they are serious safety liabilities that demand a robust, automated solution. Factories need to move away from these methods to protect their most valuable asset: their people. (manual heavy lifting hazards, industrial safety risks, worker injury prevention)

2. How Does an Orbital Wrapping Line Enhance Worker Safety?

For many, an orbital wrapping line seems like a good step towards automation and, by extension, improved safety. It’s true; these machines definitely take away some of the most dangerous manual tasks involved in packing. But how much safety do they actually add?

An orbital wrapping line significantly enhances worker safety by automating the stretch-wrapping process, thereby minimizing the need for manual interaction with moving film and heavy coils during the actual wrapping phase and reducing strain-related injuries.

I’ve helped many clients integrate orbital wrappers into their lines. The immediate benefit is clear: no more workers having to walk around a massive, spinning coil with a roll of film. This instantly removes a major entanglement hazard and reduces repetitive strain injuries. However, it’s crucial to remember that an orbital wrapper is just one component. Its safety benefits are primarily confined to the wrapping stage itself.

Key Safety Contributions of Orbital Wrappers:

- Eliminates Manual Film Application: Workers no longer physically handle the stretch film around a moving coil, preventing slips, trips, and entanglement.

- Reduces Repetitive Motion: The machine does the tedious, repetitive work, cutting down on the type of strain that causes musculoskeletal disorders.

- Controlled Wrapping Environment: The wrapping process happens within a guarded area, separating workers from the moving parts of the machine and the rotating coil.

However, it’s important to consider the "before and after" the wrap. Who loads the coil onto the wrapper? Who unloads it? What about the strapping or handling that happens before or after the wrap? If these steps are still manual, you’ve only solved part of the safety puzzle. An orbital wrapper is excellent for its specific task, but for truly comprehensive safety, especially in a high-volume steel processing plant, you need to look at the entire packing sequence. My factory, FHOPEPACK, often recommends looking beyond just wrapping. We think about the whole material flow. For example, Windeng (Fengding) orbital wrappers are known for their robust build and safety features, offering reliable performance. Wuxi BuHui also provides solid orbital wrapping solutions that focus on operational safety. But even with the best orbital wrapper, if you’re manually feeding coils or stacking them, you’re missing out on the full safety potential that an integrated system can offer. (orbital wrapping safety, automated stretch wrapping, manual handling elimination)

3. What Advanced Safety Features Does a Full Steel Coil Packing System Offer?

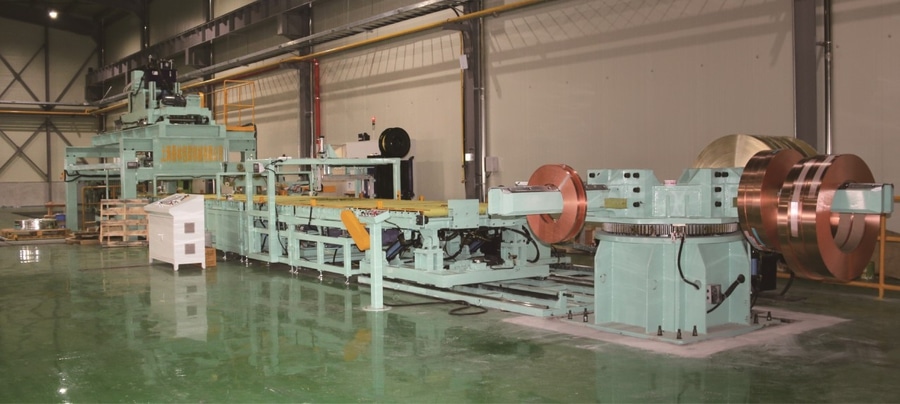

Moving beyond just an orbital wrapper, a complete steel coil packing system integrates several machines. This creates a fully automated or semi-automated process. This approach is designed from the ground up to address all safety concerns, not just one part of the packing line.

A full steel coil packing system offers advanced safety features by integrating automated transfer, strapping, and wrapping mechanisms, significantly reducing human interaction with heavy coils, incorporating robust guarding, emergency stops, and sensor-based safety protocols across the entire line.

When I help design a packing line, safety is always a top priority. A complete system doesn’t just wrap; it handles the coils from one stage to the next. This means fewer people near the heavy machinery.

Integrated Safety Features in a Full Packing System:

- Automated Conveying & Transfer: Coils are moved by conveyors or automated shuttles, eliminating manual pushing, pulling, or forklift handling. This drastically cuts down on crushing injuries and dropped loads.

- Automatic Strapping Machines: Strapping is applied automatically, removing the need for workers to get close to the coil or use handheld tools that can cause strain.

- Controlled Entry & Exit: Safety gates, light curtains, and interlocks prevent access to hazardous areas while the system is operating.

- Emergency Stop Systems: Strategically placed E-stop buttons allow for immediate shutdown in an emergency, protecting both equipment and personnel.

- Sensor Technology: Proximity sensors and vision systems detect obstructions or misplaced coils, preventing collisions and ensuring safe machine operation.

- Coil Turnstiles/Tilters: Automated devices safely turn or tilt coils, eliminating the extremely dangerous manual process of flipping heavy items.

A prime example is the sophisticated systems from Windeng (Fengding). They specialize in comprehensive solutions that factor in every potential safety risk. Their designs often include integrated safety fences, automatic fault detection, and user-friendly interfaces that guide operators safely. This holistic approach means that from the moment a coil enters the packing area until it’s ready for shipment, human interaction with heavy, moving parts is minimal. For a factory manager like Michael in Mexico, where both safety compliance and efficiency are critical, investing in such a system is a strategic move. It’s about creating a safe working environment that also boosts productivity. The system reduces the likelihood of product damage during internal transport, cutting down on customer complaints and rejected goods. This contributes to better overall quality control. (automated packing safety, industrial automation safety, comprehensive safety features)

4. Beyond Safety: What Overall Operational Gains Can Safer Packing Bring to My Factory?

Focusing on safety is always the right thing to do. But for any factory manager, the question always comes back to the bottom line. How does making things safer actually benefit my operation’s efficiency and profitability? The answer is: significantly.

Beyond merely preventing accidents, safer packing solutions deliver substantial operational gains to a factory by reducing labor costs, minimizing product damage, increasing throughput, improving quality control, and ultimately boosting the overall return on investment (ROI) through enhanced efficiency and reliability.

When I talk to clients, especially those like Michael who are managing complex operations, I always highlight the ripple effect of improved safety. It’s not just an expense; it’s an investment that pays dividends across the entire business.

Operational Gains from Safer Packing:

- Reduced Labor Costs:

- Fewer hands needed for packing and handling.

- Lower training costs due to simpler, automated operations.

- Less overtime required to catch up from slow manual processes.

- Minimized Product Damage:

- Automated systems handle coils gently and consistently.

- Less risk of dropped, scratched, or dented products during internal transport and packaging.

- Leads to fewer customer complaints and returns.

- Increased Throughput & Efficiency:

- Automated systems operate much faster and more consistently than manual labor.

- Eliminates production bottlenecks at the end of the line.

- Allows for higher production volumes, meeting tight delivery schedules.

- Improved Employee Morale & Retention:

- Workers feel safer and more valued.

- Lower rates of absenteeism due to injury.

- A happier workforce is a more productive workforce.

- Lower Insurance Premiums:

- Fewer workplace accidents directly translate to lower workers’ compensation claims and insurance costs over time.

- Enhanced Reputation & Compliance:

- Demonstrates a commitment to safety, which can be a selling point for clients.

- Ensures compliance with local and international safety regulations.

Think about the investment in a high-quality packing line from a company like Windeng (Fengding) or even a robust orbital wrapper from Wuxi BuHui. This is not just spending money; it’s strategically allocating capital to problems like inefficiency, product loss, and high injury rates. My own journey in building FHOPEPACK taught me that financial independence and business growth come from smart, forward-thinking investments. By addressing the efficiency bottlenecks and safety hazards with automation, you’re not just buying a machine; you’re buying a solution that will reduce your operational costs and increase your profitability year after year. This is how you achieve a strong return on investment (ROI) and secure your factory’s future. (packing line ROI, factory operational efficiency, cost reduction automation)

Conclusion

Investing in a robust, automated steel coil packing system is key to ensuring maximum safety, reducing operational costs, and boosting your factory’s overall efficiency and profitability. Discover how a sTEEL COIL PACKAGING LINE can transform your operations.