Steel Coil Packing Machines in the Cable Industry | Efficient Packaging Solutions

Are you struggling with slow, manual steel coil packing in your cable manufacturing plant? This inefficiency doesn’t just slow down production; it leads to higher labor costs, safety risks, and even product damage. What if you could transform your packaging process, making it faster, safer, and more cost-effective? (slow packaging, cable production bottleneck, operational efficiency)

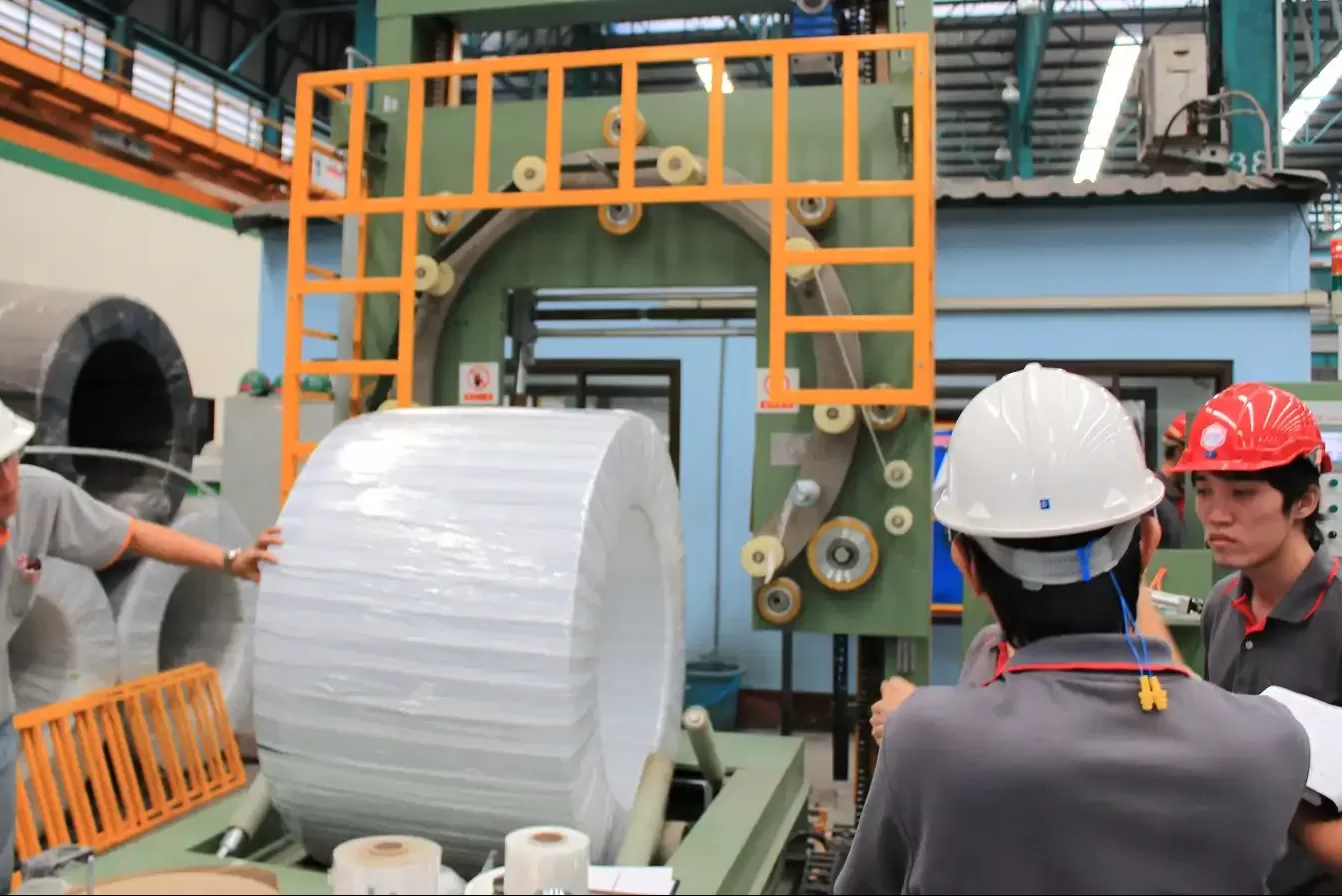

In the cable industry, steel coil packing machines are essential for streamlining operations and ensuring product integrity. They offer automated solutions that replace labor-intensive manual methods, significantly boosting speed, safety, and overall efficiency in handling and packaging various steel coils used in cable manufacturing. These machines are designed to meet the rigorous demands of high-volume production environments, providing reliable and consistent packaging results. (automated packaging solutions, cable manufacturing efficiency, product integrity)

As someone who has walked the factory floor and built a successful packing machine business, I understand the pressures of maintaining output while keeping costs down. That’s why diving deeper into how these machines truly deliver value is crucial. Let’s explore the core challenges and how intelligent packing solutions can be your biggest ally. (factory operations, cost control, intelligent packing solutions)

1. Why is Manual Steel Coil Packing a Bottleneck for Cable Manufacturers?

Do you find your cable production line grinding to a halt at the packaging stage? Relying on manual labor for heavy steel coils creates significant bottlenecks, slows down your entire operation, and puts your workers at risk. Understanding these inefficiencies is the first step toward building a more streamlined and productive future. (manual coil packing, production bottlenecks, operational inefficiency)

Manual steel coil packing in the cable industry often acts as a critical bottleneck due to its inherent limitations in speed, consistency, and safety. This traditional approach requires extensive human effort to handle heavy, unwieldy coils, leading to slow processing times and increased risk of injuries. Such labor-intensive methods directly hinder a plant’s ability to meet production targets and maintain competitive delivery schedules. (manual packing limitations, cable industry bottlenecks, human labor risks)

From my time managing factory operations, I saw firsthand how manual processes could cripple an otherwise efficient production line. It is not just about the time it takes. It is about the cascade of negative effects that follow. Michael, your challenges with efficiency, safety, and product loss resonate deeply with my own experiences. Manual handling of heavy steel coils, especially in a fast-paced cable manufacturing environment, presents several critical issues.

The True Cost of Manual Coil Packing

Manual coil packing might seem like a lower upfront investment. However, the hidden costs and long-term consequences are substantial.

-

1. Reduced Throughput and Delivery Delays:

- Slow Speeds: Human workers cannot match the speed of automated systems. Each coil takes significant time to position, wrap, and secure. This creates a backlog at the end of the line. 🐢

- Inconsistency: Packaging quality can vary greatly between workers, or even for the same worker over time. This leads to reworks or complaints from clients. 📉

- Impact on Supply Chain: Delays at the packing stage ripple through the entire supply chain. This affects delivery times and customer satisfaction. 🚚 (throughput issues, delivery delays, inconsistent packaging)

-

2. Significant Safety Hazards:

- Heavy Lifting: Steel coils are extremely heavy. Manual lifting or even maneuvering them puts immense strain on workers. This leads to muscle strains, sprains, and more serious accidents. 🤕

- Repetitive Motion Injuries: Repeated actions like bending, pulling, and wrapping can cause chronic injuries over time. 🔄

- High Worker Turnover: A dangerous and physically demanding job often leads to higher employee turnover. This increases recruitment and training costs. 💰

- Increased Insurance Premiums: More accidents mean more worker compensation claims. This directly impacts your insurance costs. 💸 (workplace safety, heavy lifting risks, employee injuries)

-

3. Risk of Product Damage:

- Edge Damage: During manual handling, especially when moving coils, the edges can get bumped or scratched. This compromises the product’s quality. ⚠️

- Improper Wrapping: Inconsistent tension or poor wrapping techniques can leave parts of the coil exposed. This makes it vulnerable to rust, dust, or other environmental damage during transit. ☔

- Customer Complaints: Damaged products lead to unhappy customers. This can harm your brand reputation and result in returned goods or discounted sales. 😠 (product quality, packaging damage, customer satisfaction)

Comparative Analysis: Manual vs. Automated Packing

| Aspect | Manual Packing | Automated Packing |

|---|---|---|

| Speed | Slow, dependent on human pace | Fast, consistent, high throughput |

| Consistency | Variable, prone to human error | High, precise, uniform packaging |

| Safety | High risk of injury, physically demanding | Minimal human intervention, drastically safer |

| Labor Cost | High, ongoing wages, benefits, training | Reduced, focused on supervision and maintenance |

| Product Damage | Higher risk of dents, scratches, improper wrap | Lower risk, secure handling and wrapping |

| Scalability | Limited by available labor | Highly scalable, can run 24/7 |

| ROI | High operational cost, low initial investment | Lower operational cost, higher initial investment |

Understanding these fundamental issues shows why relying on manual methods for steel coil packing is not sustainable for modern cable manufacturing. It impacts efficiency, safety, and your bottom line. (operational sustainability, modern manufacturing, ROI analysis)

2. How Do Automated Steel Coil Packing Machines Boost Safety and Reduce Product Damage?

Are you constantly worried about worker safety and product integrity in your packing area? Manual handling of heavy steel coils creates an environment ripe for accidents and costly product damage. Automated packing machines offer a robust answer, fundamentally transforming your operations for the better. (worker safety, product integrity, automated solutions)

Automated steel coil packing machines dramatically enhance safety by removing workers from direct contact with heavy loads, thus minimizing the risk of lifting injuries and accidents. Simultaneously, these machines ensure consistent and secure packaging, significantly reducing instances of product damage during handling, storage, and transit. This dual benefit protects both your workforce and your valuable output. (automated packing safety, product damage reduction, workforce protection)

Michael, your concern about worker safety and product loss is valid. It is a common pain point for factory managers, especially in heavy industries like yours. When I was building my own packing machine factory, I prioritized solutions that would not only increase output but also create a safer working environment and protect the client’s investment in their product. Automated steel coil packing machines are not just about speed; they are a critical investment in your people and your product quality.

Transforming Operations Through Automation

Automation addresses the core issues of manual packing head-on. It provides consistent, controlled movements that human labor simply cannot replicate.

-

1. Elevating Workplace Safety:

- Reduced Manual Handling: The primary benefit is the almost complete elimination of manual lifting, carrying, and turning of heavy coils. Machines take over these dangerous tasks. 🤖

- Ergonomic Improvements: Workers transition from physically demanding roles to supervisory or machine operation roles. This reduces the risk of repetitive strain injuries. 🧘

- Controlled Environment: Automated systems operate within defined safety zones. They often include safety sensors, emergency stops, and protective barriers. These features prevent accidents. 🛑

- Fewer Accidents, Lower Costs: A safer workplace means fewer injuries. This translates directly to lower workers’ compensation claims and reduced insurance premiums. It also improves employee morale. 😄 (workplace safety, ergonomic benefits, reduced accidents)

-

2. Minimizing Product Damage and Loss:

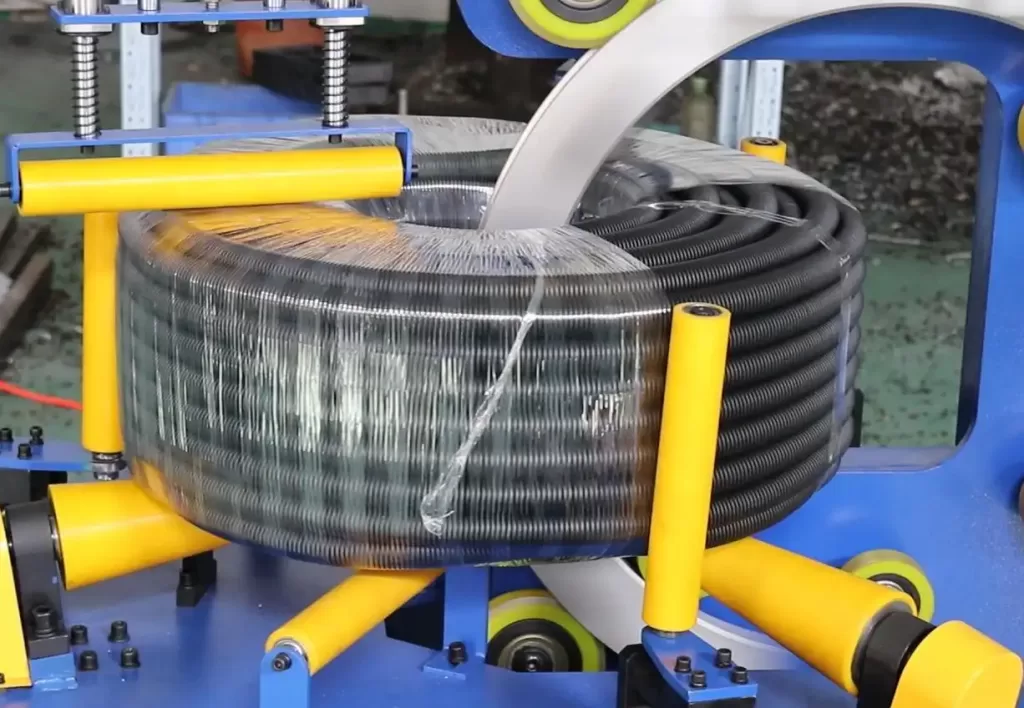

- Gentle and Precise Handling: Automated machines use specialized grippers, conveyors, and turntables. These handle coils with precision and care. This significantly reduces the risk of dents, scratches, or deformation. ✨

- Consistent Wrapping Tension: Advanced control systems ensure uniform tension and overlap of packing materials. This provides a tight, secure, and protective wrap around the entire coil. ✅

- Optimal Material Usage: Automated systems are precise with packing material usage. They reduce waste. This also ensures comprehensive protection without overuse. ♻️

- Weather and Dust Protection: A well-sealed, consistent wrap protects the steel coil from moisture, dust, and other environmental contaminants. This is crucial for maintaining quality during storage and transport. 🛡️ (product protection, precise handling, consistent packaging)

Impact on Key Performance Indicators (KPIs)

| KPI | Before Automation | After Automation |

|---|---|---|

| Lost Time Due to Injury | High ⬆️ | Significantly reduced ⬇️ |

| Product Damage Rate | Moderate to High ⚠️ | Very Low, almost negligible ✅ |

| Packaging Consistency | Variable 〰️ | High, near 100% uniformity 💯 |

| Labor Efficiency | Low, high manual input 📉 | High, supervisory roles dominate 📈 |

| Client Returns | Can be significant due to damage ❌ | Minimal, related to packaging quality ✔️ |

By embracing automation, you are not just buying a machine. You are investing in a healthier workforce and a more robust product quality assurance system. This approach creates a win-win scenario for your employees and your customers. (automation benefits, KPIs improvement, quality assurance)

3. What Are the Key Features to Look for in a High-Performance Steel Coil Packing Machine?

Are you unsure what really makes a steel coil packing machine perform optimally? Investing in the wrong equipment can lead to ongoing frustrations, costly breakdowns, and unfulfilled promises. Knowing the critical features will empower you to make an informed decision and secure a lasting solution. (optimal performance, equipment investment, critical features)

When selecting a high-performance steel coil packing machine for the cable industry, prioritize features that ensure durability, versatility, and advanced automation. Look for robust construction, customizable wrapping programs, efficient material handling, and intelligent control systems. These elements combine to deliver reliable operation, adaptable packaging, and minimal downtime, crucial for heavy industrial applications. (high-performance packing machine, durability features, intelligent automation)

Choosing the right equipment is one of the most important decisions a factory manager like Michael makes. I learned this through my own journey, both as an engineer and as a factory owner. A machine is not just a collection of parts; it is an investment in your future. To avoid the "supplier trust crisis" Michael mentioned, it is essential to look beyond the basic sales pitch and focus on the practical, long-term benefits and features. Here is what truly matters.

Essential Features for Robust Coil Packing

A top-tier steel coil packing machine should be built to withstand the rigorous demands of continuous operation in a heavy industrial setting.

-

1. Robust Construction and Durability:

- Heavy-Duty Frame: The machine frame must be made from high-strength steel. This ensures stability and longevity, even under constant heavy loads. Look for powder-coated or rust-resistant finishes. 💪

- Industrial-Grade Components: All critical parts, like motors, bearings, and hydraulic systems, should be from reputable industrial brands. This guarantees reliability and extends machine lifespan. ⚙️

- Low Maintenance Design: A good design reduces the need for frequent maintenance. It also makes routine tasks simpler. This minimizes downtime. 🛠️ (heavy-duty construction, industrial components, low maintenance)

-

2. Versatile Wrapping Capabilities:

- Adjustable Ring Diameter: The machine should accommodate a range of coil sizes and weights. This flexibility is vital for different product specifications. 📏

- Variable Wrapping Speed: The ability to adjust wrapping speed allows for optimization based on coil size and desired tension. ⚡

- Multiple Packing Material Options: Support for various films (stretch film, VCI film, woven belt) offers adaptable protection against rust, dust, and impact. 📦

- Customizable Wrapping Programs: Pre-set programs for different coil types or packaging requirements save time and ensure consistent results. 💻 (versatile wrapping, adjustable settings, material options)

-

3. Advanced Automation and Control Systems:

- PLC Control System: A reliable Programmable Logic Controller (PLC) is the brain of the machine. It ensures precise operation and easy integration into existing production lines. 🧠

- Touchscreen HMI (Human-Machine Interface): An intuitive interface makes it easy for operators to control settings, monitor performance, and troubleshoot issues. 👆

- Automatic Coil Centering and Feeding: Features that automatically position and feed coils into the wrapping zone enhance efficiency and reduce manual intervention. 🎯

- Safety Interlocks and Sensors: These critical features ensure operator safety by stopping the machine immediately if a hazard is detected. 🚨 (PLC control, HMI interface, automatic feeding, safety features)

-

4. Efficient Material Handling and Cut-off:

- Automatic Film Dispensing and Tension Control: The machine should automatically manage film dispensing and maintain optimal tension. This ensures a tight, secure wrap. 🧵

- Automatic Film Cut-off and Sealing: This feature streamlines the process. It eliminates manual cutting and ensures a neat, secure end to the wrap. ✂️

- Conveyor Systems (Optional): Integration with powered conveyors allows for seamless movement of coils before and after packing. This creates a fully automated line. ➡️ (material dispensing, automatic cut-off, integrated conveyors)

Checklist for Machine Selection:

| Feature Category | Key Considerations | Why It Matters |

|---|---|---|

| Mechanical Build | Heavy-duty frame, brand-name components, accessible for maintenance | Ensures longevity, reduces breakdowns, simplifies servicing |

| Packaging Adaptability | Coil size range, material type compatibility, programmable wrap patterns | Handles diverse products, offers flexible protection, consistent quality |

| Control & Automation | User-friendly HMI, reliable PLC, safety features, diagnostic capabilities | Easy operation, precise control, protects workers, quick troubleshooting |

| Integration Potential | Compatibility with existing conveyors, data logging for Industry 4.0 | Smooth workflow, future-proof, enables process optimization |

| After-Sales Support | Availability of spare parts, technical assistance, training programs (crucial for trust) | Guarantees continuous operation, reduces long-term costs, builds partnership |

Selecting a machine with these capabilities ensures you get a robust, reliable, and efficient solution that delivers a strong return on your investment. (machine capabilities, ROI, reliable solution)

4. How Can a Reliable Partner Like FHOPEPACK Transform Your Cable Packaging Operations?

Have you been let down by equipment suppliers who disappear after the sale? A lack of genuine partnership can leave you stranded, struggling with problems that expert guidance could easily solve. FHOPEPACK is more than a supplier; we are your dedicated partner, committed to your success. (unreliable suppliers, lack of partnership, dedicated support)

A reliable partner like FHOPEPACK can fundamentally transform your cable packaging operations by offering not just high-quality steel coil packing machines, but also deep industry expertise, comprehensive support, and tailored solutions. Our commitment extends beyond the sale, ensuring you receive the guidance needed to optimize your processes, enhance safety, and achieve sustainable growth. We build trust by understanding your unique challenges and delivering effective, long-term solutions. (reliable packing partner, industry expertise, comprehensive support)

Michael, your past experience with suppliers who "only care about sales" is exactly why FHOPEPACK exists. I founded FHOPEPACK because I believe in giving back to the industry that helped me achieve financial independence. My journey from a factory employee to a successful factory owner has given me unique insights into the real-world challenges you face every day. We are not just selling machines; we are sharing knowledge and expertise to help clients like you grow.

The FHOPEPACK Advantage: Expertise and Partnership

At FHOPEPACK, our mission is to make mold knowledge accessible and to provide solutions that truly work. For steel coil packing machines in the cable industry, this means a partnership built on understanding and reliability.

-

1. Deep Industry Knowledge and Practical Experience:

- Engineer-Led Approach: My background as a packing machine engineer, combined with factory ownership, means we understand your production bottlenecks and operational pressures from the inside out. We speak your language. 🗣️

- Tailored Solutions: We do not offer one-size-fits-all products. We listen to your specific challenges—whether it is an efficiency bottleneck, safety hazard, or product loss—and design solutions that directly address them. 📐

- Proven Track Record: Our experience in coil packing and steel wire packing has helped numerous clients improve their operations and expand their businesses. We bring this proven success to your factory. ✅ (industry knowledge, tailored solutions, proven track record)

-

2. Comprehensive Support and Consultation:

- Pre-Sales Consultation: Before any purchase, we conduct a thorough analysis of your current operations. We identify areas for improvement and propose the most suitable equipment. 💡

- Installation and Training: Our team ensures seamless installation of your new steel coil packing machine. We provide extensive training for your operators and maintenance staff. This empowers your team to run the equipment efficiently and safely. 🎓

- After-Sales Service: This is where trust is truly built. We offer robust after-sales support, including spare parts availability, remote troubleshooting, and on-site technical assistance when needed. Your machine keeps running smoothly. 📞 (pre-sales analysis, installation training, robust after-sales)

-

3. Focus on Your Return on Investment (ROI):

- Cost-Benefit Analysis: We help you clearly see the ROI of your investment. This includes savings from reduced labor, minimized product damage, increased throughput, and lower insurance costs. 💲

- Long-Term Value: Our goal is to provide durable, high-performance machines that offer long-term value, not just a quick sale. This ensures your equipment continues to deliver efficiency for years. 🚀

- Scalability for Growth: We understand that your business needs to grow. Our solutions are designed with scalability in mind, helping you meet increasing demands without sacrificing quality or efficiency. 🌱 (ROI focus, long-term value, business scalability)

Why Partner with FHOPEPACK?

| Aspect | What FHOPEPACK Offers | Benefit to Your Operations |

|---|---|---|

| Understanding | Real-world factory and engineering experience | Solutions that truly address your pain points, not just products |

| Reliability | Durable machines, consistent performance | Minimal downtime, consistent output, lasting investment |

| Support | Comprehensive pre-to-post-sales, training, technical help | Smooth integration, empowered staff, continuous operation |

| Value | Clear ROI, focus on long-term efficiency and cost reduction | Improved profitability, sustainable growth, competitive advantage |

| Trust | Partnership approach, sharing knowledge, commitment to success | Peace of mind, a true collaborator for your business objectives |

By partnering with FHOPEPACK, Michael, you gain more than just a packing machine. You gain a dedicated expert committed to helping you overcome your operational challenges and achieve your business goals. We are here to help you master your packing machine operations. (FHOPEPACK partnership, business goals, operational mastery)

Conclusion

Investing in a steel coil packing line transforms cable industry operations. It boosts safety, cuts damage, and improves efficiency, delivering clear ROI. Partner with FHOPEPACK for expert solutions and lasting success.