How Are Steel Coil Packing Machines Transforming Mexico’s Steel Industry?

The Mexican steel industry is booming, but many factory managers, like Michael Chen, face constant pressure. You are trying to boost output, cut costs, and keep your team safe. I know these challenges well. For years, I have seen factories struggle with old, slow packing methods. This often leads to bottlenecks, worker injuries, and damaged products. These issues hurt your bottom line and slow down growth. But what if there was a better way to handle heavy steel coils and wire rods? What if you could automate your packing line, making it faster, safer, and more cost-effective? (Mexican steel sector, industrial growth challenges, operational efficiency)

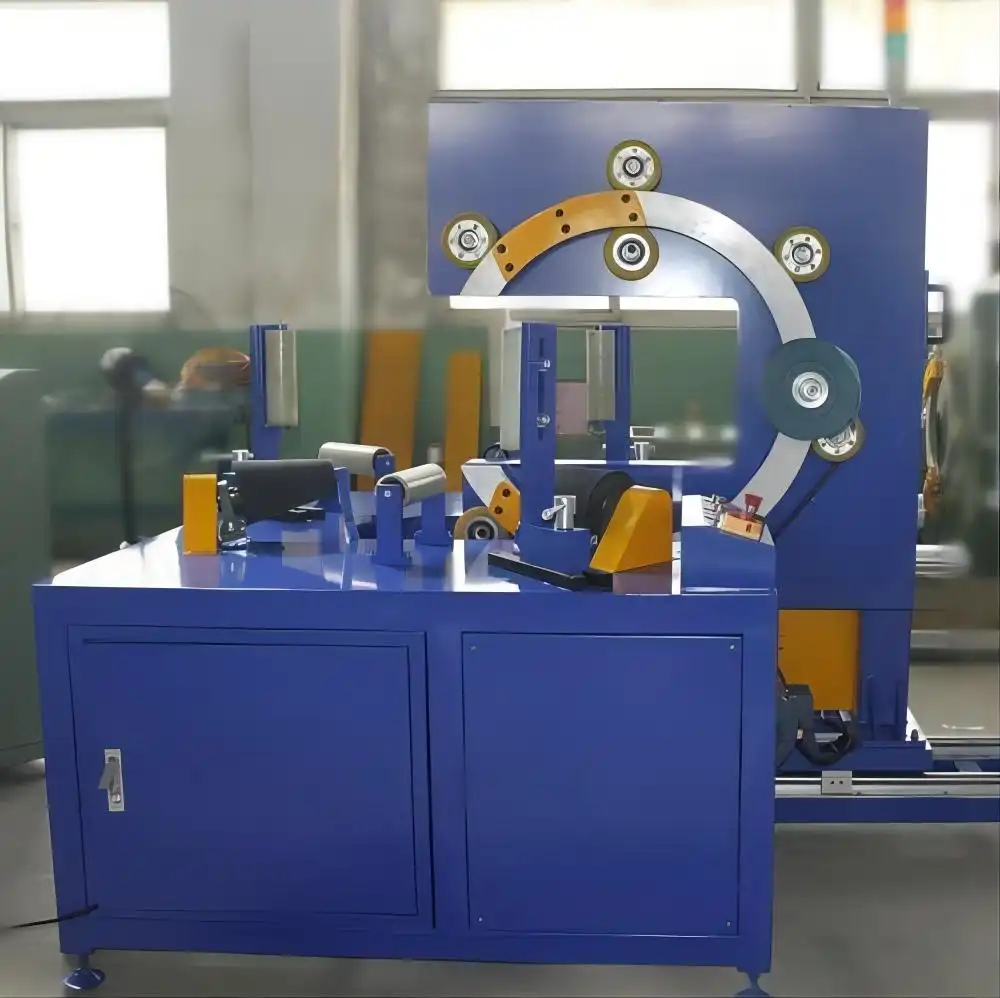

Steel coil packing machines are not just an upgrade; they are a fundamental shift for Mexico’s steel industry, addressing critical needs like automation, safety, and cost reduction. They allow factories to handle increasing production volumes efficiently, protect valuable products, and create a safer work environment for employees. By automating end-of-line processes, these machines turn former bottlenecks into smooth, high-speed operations, directly supporting the industry’s expansion and competitiveness in the global market.

As a packing machine engineer who built a factory from the ground up, I understand the real-world impact of these decisions. You are not just buying a machine; you are investing in your factory’s future. So, let us look closer at how modern steel coil packing technology can solve your biggest operational hurdles and drive significant growth for your business in Mexico.

1. How can automation solve current coil packing bottlenecks in Mexico?

Are you seeing your production line slow down right at the end? Many factories in Mexico face this. After all the hard work to produce steel coils or wire rods, manual packing becomes a choke point. This slows down everything, from output to delivery times. It means lost opportunities and wasted resources. This is a common pain point I have seen in many places. (production line delays, manual handling inefficiencies, industrial bottlenecks)

Automated steel coil packing machines directly tackle bottlenecks by streamlining the entire end-of-line process, from wrapping to stacking. They replace slow, labor-intensive manual methods with high-speed, consistent operations. This change drastically increases throughput, ensuring that finished products move quickly and smoothly. For Mexico’s growing steel industry, this means faster delivery, better resource use, and a significant boost in overall productivity and competitiveness.

Automating your coil packing is not just about moving faster. It is about creating a predictable, reliable flow that removes the uncertainty of human error and fatigue. When I started FHOPEPACK, our goal was always to help businesses achieve this kind of operational excellence. It is about understanding the problem from the inside out. For example, a medium-sized metal processing plant, similar to Michael Chen’s operation, often deals with various coil sizes and weights. Manual handling here is not only slow but also inconsistent, leading to uneven packing quality and potential damage during transit. Automated systems, on the other hand, are designed to handle heavy loads with precision, applying consistent tension and overlap for superior protection. This consistency also means fewer re-wraps and less material waste, directly improving cost efficiency. Think about the impact of freeing up several workers from strenuous packing duties, allowing them to be redeployed to other value-added tasks within the factory. This strategic reallocation of labor is a tangible benefit of automation, turning a cost center into a more productive segment of your workforce. The technology available today allows for customizable packing solutions that can integrate seamlessly into existing production lines, minimizing disruption during implementation. We often hear from clients how they wished they had made the switch sooner, once they see the dramatic improvements in their operational metrics. For a factory manager like Michael, this means hitting production targets more reliably and reducing the stress of unexpected delays. It is about having a system that works tirelessly, day in and day out, to keep your products moving and your customers happy. (automated wrapping benefits, consistent packing quality, labor reallocation advantages)

2. What are the best ways to enhance worker safety in Mexican steel coil packing operations?

Handling heavy steel coils by hand is dangerous. In many Mexican factories, workers manually lift, move, and secure these large items. This puts them at high risk for injuries. We hear about back strains, crushed limbs, and other serious accidents far too often. These incidents are not just tragic for the employees; they also lead to higher insurance costs, increased absenteeism, and a constant struggle to retain skilled workers. It is a problem that affects everyone. (heavy object handling risks, industrial accident prevention, employee welfare programs)

To significantly enhance worker safety in Mexican steel coil packing operations, the most effective approach is to implement advanced automation solutions. These machines minimize or completely eliminate the need for manual handling of heavy coils, thereby removing the primary cause of many workplace injuries. By automating tasks like lifting, turning, wrapping, and stacking, factories can protect their employees from direct contact with heavy loads, greatly reducing the risk of strains, crushes, and other severe accidents. This shift ensures a safer working environment and boosts overall operational reliability.

Ensuring safety is not just a regulatory requirement; it is a moral obligation and a smart business decision. A factory manager like Michael Chen knows that a single serious injury can disrupt operations, lower morale, and incur substantial costs beyond direct medical expenses. When I was running my own factory, worker safety was always a top priority. I saw firsthand how even minor incidents could cascade into bigger problems. Modern steel coil packing machines are designed with safety at their core. They feature comprehensive safety interlocks, emergency stop buttons, and robust guarding systems to protect operators. For example, automatic coil strapping machines remove the need for workers to get close to the moving coil during strapping, a task that was historically high-risk. Similarly, automated coil upenders and downenders can safely reorient coils without any manual intervention, eliminating the danger of heavy lifting or unstable loads. The move towards automation means fewer hands on heavy, dangerous materials. This not only prevents accidents but also reduces the physical strain on your workforce over time, leading to healthier, more productive employees. This improvement in worker well-being can also lead to better employee retention, as people prefer to work in environments where their safety is prioritized. Consider the ripple effect: a safer workplace fosters a positive culture, reduces insurance premiums, and minimizes legal liabilities. It allows your skilled workers to focus on tasks that require their expertise, rather than risking their health with repetitive, strenuous labor. Investing in these safety-enhancing technologies is a clear indicator of a company’s commitment to its people and its long-term success. (workplace injury reduction, automated strapping benefits, employee well-being strategies)

3. How can investing in advanced packing equipment reduce product damage and operational costs for Mexican steel factories?

Product damage during internal transport and packing is a constant worry. For steel coils, even small dents or scratches on the edges can lead to customer complaints and rejected shipments. This directly impacts your profits and reputation. Beyond that, the operational costs of manual packing, including high labor expenses, slow processes, and material waste, eat away at your margins. These issues compound, making it harder for Mexican factories to stay competitive. (product quality control, operational expense reduction, manufacturing profitability)

Investing in advanced steel coil packing equipment is a dual solution for Mexican steel factories to significantly reduce both product damage and operational costs. These machines ensure consistent, high-quality wrapping that protects coil edges from impact and environmental factors, cutting down on customer complaints. Simultaneously, automation reduces reliance on costly manual labor, optimizes packing material usage, and accelerates the packing process, leading to substantial savings in labor, materials, and overall production time, thereby boosting profitability.

The link between product damage and operational costs is direct and undeniable. Every damaged coil means lost revenue, potential reworks, and the erosion of customer trust. This is a challenge I’ve helped many clients overcome. Advanced packing equipment addresses these issues head-on.

Benefits of Advanced Packing Equipment:

-

Minimized Product Damage:

- Consistent Wrapping: Automated wrappers apply stretch film or other protective materials with uniform tension and overlap. This creates a tight, secure barrier against physical damage, moisture, and dust during storage and transport.

- Edge Protection: Specific modules can add extra protection to coil edges, which are most vulnerable to impact. This prevents the cosmetic and structural damage that often leads to rejections.

- Gentle Handling: Robotic or automated handling systems ensure coils are moved precisely, reducing drops or impacts common with manual methods or forklifts.

-

Reduced Operational Costs:

- Lower Labor Expenses: By automating packing tasks, factories can significantly reduce the number of workers needed for the end-of-line process. This directly cuts down on wages, benefits, and training costs.

- Optimized Material Usage: Automated machines are programmed to use the optimal amount of packing material (film, strapping, paper). They minimize waste from over-wrapping or uneven application, leading to considerable savings on consumables.

- Increased Throughput: Faster packing cycles mean more coils are processed in less time. This translates to higher overall production capacity without needing to expand factory space or add shifts, thereby maximizing existing resources.

- Reduced Insurance and Rework Costs: Fewer workplace injuries lead to lower insurance premiums. Less product damage means fewer returns, replacements, and rework efforts, all of which save money.

- Predictable Maintenance: Modern machines are built for durability and often come with predictive maintenance features, reducing unexpected downtime and associated repair costs.

| Cost Area | Manual Packing Impact | Automated Packing Impact |

|---|---|---|

| Labor | High, variable, prone to fatigue | Low, consistent, efficient |

| Material Usage | Inconsistent, often wasteful | Optimized, minimal waste |

| Product Damage | High risk (scratches, dents) | Very low risk (consistent wrap) |

| Throughput | Slow, bottleneck | Fast, high volume |

| Safety Incidents | High risk, high insurance | Very low risk, lower premiums |

| Rework/Returns | Frequent, costly | Rare, negligible |

These financial benefits combine to offer a strong return on investment (ROI). For a business operating in Mexico’s competitive steel market, these cost savings are not just a luxury; they are a necessity for sustainable growth and long-term profitability. My journey from a factory employee to factory owner showed me that smart investments in equipment pay off many times over. (ROI analysis for automation, sustainable manufacturing practices, packing material optimization)

4. Why is partnering with an experienced packing machine expert crucial for success in Mexico’s steel sector?

Many factory managers, like Michael Chen, have faced issues with equipment suppliers. You might have bought a machine only to find poor after-sales service or a lack of understanding about your specific needs. This creates a deep trust crisis. When you are making a big investment in packing machinery for your Mexican factory, you need more than just a seller. You need a partner who truly understands your operations, your challenges, and your goals. Someone who can provide real solutions, not just equipment. (supplier reliability issues, after-sales support importance, industry partnership value)

Partnering with an experienced packing machine expert is crucial for success in Mexico’s steel sector because it ensures you receive tailored solutions, comprehensive support, and invaluable industry insights. An expert, like myself at FHOPEPACK, understands the nuances of coil packing, offering advice that goes beyond basic machine specifications. This partnership helps overcome trust issues by providing reliable after-sales service, expert installation, and ongoing technical guidance, ensuring your investment truly solves problems and drives long-term business growth.

My journey from the factory floor to establishing FHOPEPACK taught me a critical lesson: a machine is only as good as the support behind it. I’ve seen firsthand how a lack of understanding from a supplier can turn a promising investment into a costly headache. Michael Chen’s experience with past suppliers highlights a common problem in the industry. This is why our mission at FHOPEPACK is centered on knowledge sharing and building genuine partnerships.

What an Experienced Partner Offers:

-

Deep Industry Knowledge:

- An expert understands the specific challenges of packing steel coils and wire rods in Mexico’s climate and operational conditions. They know about rust prevention, transport regulations, and material handling nuances unique to the steel sector.

- They can foresee potential issues before they arise, offering proactive advice on machine selection, customization, and integration.

-

Tailored Solutions:

- Instead of pushing a generic product, an experienced partner will assess your factory’s layout, production volume, specific coil types (e.g., hot rolled, cold rolled, galvanized), and existing processes.

- They will recommend a solution that perfectly fits your needs, whether it’s a stand-alone wrapper, a fully automated packing line, or specialized handling equipment. This might involve customized features for unique coil dimensions or specific packaging material requirements.

-

Reliable After-Sales Support:

- This is where trust is built. A true partner provides comprehensive installation services, thorough operator training, and readily available technical support. This means quick response times for troubleshooting, access to spare parts, and regular maintenance advice.

- My own experience running a factory showed me how critical uptime is. A machine sitting idle due to poor support is a direct loss.

-

Proven Track Record:

- An expert has a history of successful installations and satisfied clients. They can provide case studies or references, demonstrating their ability to deliver results and generate a clear return on investment.

- At FHOPEPACK, we pride ourselves on having helped numerous clients achieve financial independence and business growth through better packing solutions.

-

Long-Term Vision:

- A knowledgeable partner helps you plan for future growth and technological advancements. They can advise on scalable solutions that will evolve with your factory’s needs, ensuring your investment remains valuable for years to come.

- They become a trusted advisor, not just a vendor, guiding you through continuous improvement processes.

Choosing the right partner is about minimizing risk and maximizing the potential of your investment. It is about having someone on your side who understands the pressure you are under and is committed to helping you succeed. This kind of relationship is invaluable for any factory manager aiming for sustainable growth in a dynamic industry like Mexico’s steel sector. (customized packaging solutions, post-purchase service excellence, industrial equipment ROI)

Conclusion

Embracing advanced steel coil packing machines is vital for Mexico’s steel industry to boost efficiency, enhance safety, and cut costs. Partnering with an expert ensures tailored solutions and lasting success, transforming operations for the better. Invest wisely in your steel coil packing line for a stronger future.