Steel Coil Packing Machines for Metal Processing Plants | Improve Packaging Efficiency?

The hum of a metal processing plant is the sound of productivity, but sometimes, that hum is broken by the slow, grinding reality of inefficient packaging. If you are managing a busy factory, you know the pressure: boost output, cut costs, keep everyone safe. I have been there. I have seen how manual steel coil packing can become a major bottleneck. It slows down your entire operation, putting your delivery schedules and even your bottom line at risk.

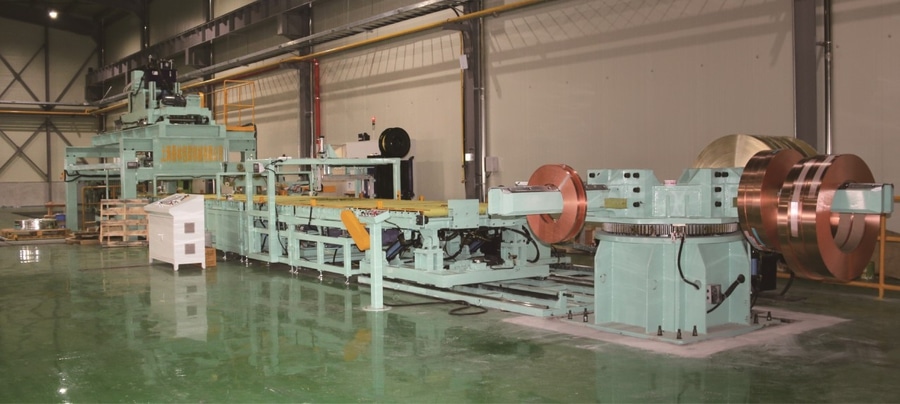

Steel coil packing machines are essential for metal processing plants because they drastically improve packaging efficiency by automating strenuous, time-consuming tasks. They transform slow, manual processes into fast, consistent operations, leading to higher throughput, enhanced safety for workers, and reduced product damage, ultimately boosting overall factory productivity and profitability for businesses in sectors like steel and heavy manufacturing.

I know you are looking for real solutions, not just machines. You want a partner who understands your challenges with production bottlenecks, safety concerns, and efficiency gaps. That is why I want to share my insights on how the right packing equipment can make a profound difference. Let us dive into the specifics of how these machines can solve your biggest operational headaches.

1. How do steel coil packing machines boost efficiency in metal processing plants?

Are you struggling with slow, manual steel coil packing that bogs down your entire production line? Does the sight of your team painstakingly wrapping heavy coils by hand make you wince at the lost time and missed targets? This inefficiency is not just a nuisance; it is a critical bottleneck that directly impacts your output and your ability to meet customer demands, especially in high-volume environments.

Steel coil packing machines boost efficiency in metal processing plants by automating the entire packing process, from wrapping to strapping, significantly reducing cycle times and eliminating the reliance on slow, error-prone manual labor. This automation allows plants to process more coils per hour, ensuring a smoother flow from production to dispatch and accelerating overall operational throughput.

As someone who has built and run packing machine factories, I have seen firsthand the transformation automation brings. Imagine a machine that can wrap a heavy steel coil in minutes, with consistent tension and material usage, every single time. This is not just about speed; it is about consistency and reliability, which are crucial for any metal processing plant, especially when dealing with high-value products like steel coils and wire. The gains in efficiency free up your workforce for more strategic tasks, directly impacting your bottom line and helping your business grow.

The Automated Edge in Production Speed and Consistency

Automated steel coil packing machines are game-changers for boosting efficiency. They replace multiple manual steps with a seamless, integrated process. This means faster wrapping, more secure strapping, and precise handling. In a traditional setup, packing a large steel coil can involve several workers and take a significant amount of time. An automated system can complete the same task in a fraction of that time, often with just one operator supervising.

Here is how automated systems contribute to efficiency:

- Increased Throughput: Machines operate at much higher speeds than humans. They can wrap dozens of coils an hour, maintaining a steady pace without fatigue. This allows your plant to handle larger production volumes without expanding your workforce. 🚀

- Consistent Quality: Manual packing can lead to variations in wrap tension, material overlap, and overall package integrity. Automated systems apply consistent pressure and material precisely every time. This reduces the need for re-packaging and ensures a professional, secure package that meets client expectations.

- Reduced Material Waste: Precision matters. Automated machines are programmed to use the optimal amount of packing material. They cut and seal with accuracy, minimizing waste from excess film or straps. This small saving per coil adds up to significant cost reductions over time.

- Seamless Integration: Modern packing machines can integrate directly into your existing production line. They can receive coils from conveyors or cranes, pack them, and then transfer them to storage or shipping. This creates a continuous flow, eliminating pauses and bottlenecks at the end of the line.

Consider a metal processing plant in Mexico, like Michael Chen’s, dealing with heavy steel coils. Transitioning from a mostly manual coil packing operation to an automated system can cut packing time by 50% or more. This means coils move faster from the production area to the dispatch dock, accelerating delivery times and improving customer satisfaction. This is not just about moving metal; it is about optimizing your entire supply chain and improving your plant’s competitiveness in the market. (metal coil packing efficiency, automated wrapping solutions, industrial throughput improvement)

2. What are the safety benefits of automating coil packing in heavy industries?

Are your workers constantly exposed to risks when manually handling heavy steel coils or wire bundles for packing? Do you worry about the high incidence of workplace injuries, the soaring insurance costs, and the churn of valuable employees due to strenuous and dangerous tasks? Manual handling of heavy metal products, common in factories like yours, is a serious safety hazard that no manager should overlook.

Automating coil packing in heavy industries provides significant safety benefits by minimizing direct human interaction with heavy, cumbersome products like steel coils and wire rods. This greatly reduces the risk of musculoskeletal injuries, crushed limbs, and other accidents associated with manual lifting, shifting, and wrapping, creating a much safer working environment for employees in metal processing plants.

From my experience in packing machine factories, I have always prioritized safety. I have seen the accidents that can happen when workers grapple with heavy coils. It is not just about following regulations; it is about protecting your people. Automated systems take the heavy lifting, the awkward movements, and the repetitive strain out of the equation. This translates directly to fewer injuries, a happier workforce, and a more stable, productive team. A safer plant is always a more efficient plant.

Protecting Your Workforce Through Smart Automation

The safety benefits of automating coil packing are profound, especially in heavy industries where manual handling poses significant risks. Michael Chen, as a factory manager, knows that even one serious injury can disrupt operations, lower morale, and incur substantial costs. Automated machines are designed to handle the weight and dimensions of steel coils, eliminating the need for workers to physically maneuver or lift these heavy objects.

Let us look at the specific safety improvements:

- Elimination of Manual Lifting: One of the biggest dangers is lifting heavy coils. Automated systems use specialized conveyors, turntables, and robotic arms to position and move coils safely. This means no more back strains, shoulder injuries, or dropped loads from manual handling.

- Reduced Exposure to Moving Parts: While machines have moving parts, they are typically enclosed and equipped with safety sensors, interlocks, and emergency stops. This design keeps operators at a safe distance from the actual packing action, reducing the risk of accidental contact.

- Minimized Repetitive Strain Injuries (RSIs): Manual packing often involves repetitive motions like stretching, bending, and wrapping, which can lead to RSIs over time. Automation removes these tasks from human workers, protecting them from long-term health issues. 💪

- Improved Workplace Ergonomics: With automated systems, workers shift from physically demanding roles to supervisory or maintenance roles. Their tasks become less strenuous, focusing on monitoring and problem-solving, which is much safer and less taxing on the body.

- Fewer Accidents and Incidents: By removing the human element from hazardous tasks, the overall rate of accidents decreases. This not only protects employees but also reduces lost workdays, workers’ compensation claims, and the associated costs and disruptions for the plant. 📉

For a factory in Mexico, investing in automated packing equipment is a direct investment in the well-being of its employees. It is about creating a workplace where people feel safe and valued, which in turn leads to higher employee retention and a more engaged workforce. When your team knows you prioritize their safety, their commitment to your business grows. This shift not only improves safety statistics but also fosters a positive culture where workers can thrive without constant fear of injury. (industrial safety automation, heavy material handling solutions, worker protection machinery, factory safety improvements)

3. How can automated packing reduce product damage and save costs for factories?

Is product damage during internal transfer and packing a constant headache in your metal processing plant? Do customer complaints about dinged edges on steel coils or scuffed wire bundles eat into your profits and damage your reputation? These losses are not just annoying; they are a direct hit to your bottom line and signal a critical flaw in your current packaging process.

Automated packing significantly reduces product damage and saves costs for factories by ensuring consistent, gentle handling and precise wrapping of materials like steel coils and wire. It eliminates human errors such as improper tension or clumsy movements that lead to scratches, dents, or deformations, thereby minimizing scrap, reducing customer returns, and preserving product value from the factory floor to the final destination.

I understand that every dent or scratch represents lost revenue and a potential customer complaint. When I started FHOPEPACK, one of our core aims was to deliver solutions that protect the product as much as they pack it. Automated systems are designed with precision in mind. They secure your valuable metal products without overtightening or mishandling. This precision not only prevents damage but also ensures that every packed coil leaves your factory in pristine condition, just as your customers expect.

Maximizing Value: Damage Prevention and Cost Efficiency

Product integrity is paramount in the metal industry. Damaged goods lead to rework, scrap, reduced profit margins, and, most importantly, dissatisfied customers. Automated packing machines address these issues head-on by providing a controlled and consistent packing environment. This is especially true for delicate products, such as those made of copper, brass, or even stainless steel coils, where surface finish is critical.

Here is how automation helps save costs and prevent damage:

- Gentle and Precise Handling: Automated systems use specialized grippers, rollers, and conveying mechanisms designed to handle heavy metal coils without causing scratches, dents, or deformities. They move coils smoothly and securely, unlike manual methods that can involve dropping or rough handling.

- Consistent Wrap Tension: One common cause of damage is improper wrapping tension. Too loose, and the product shifts; too tight, and edges can be crushed. Automated machines apply uniform tension across the entire surface, ensuring the package is secure yet gentle on the product.

- Optimal Protection Layer: Automated systems ensure that packing materials, whether film, paper, or stretch wrap, are applied evenly and completely. This creates a robust protective barrier against external factors like dust, moisture, and minor impacts during transit and storage.

- Reduced Rework and Scrap: By preventing damage during packing, factories reduce the need for reprocessing or discarding damaged goods. This directly saves on material costs, labor for rework, and energy consumption, improving the overall efficiency of your production line.

- Fewer Customer Complaints and Returns: Delivering undamaged products builds customer trust and reduces costly returns or claims. A high-quality, intact package reflects positively on your brand and can lead to repeat business, which is invaluable. 🤝

- Lower Insurance Claims: Fewer instances of damaged goods during shipment also mean fewer insurance claims, which can translate to lower insurance premiums for your factory in the long run.

For a factory manager like Michael Chen, these benefits translate into tangible financial savings and a stronger reputation. Preventing even a small percentage of product damage can significantly impact the bottom line. It is not just about avoiding costs; it is about preserving the full value of every product that leaves your plant, enhancing your market position, and ultimately contributing to long-term business growth. (product damage prevention, cost savings in packaging, quality control automation, ROI packaging machinery)

4. Why is choosing the right packing machine supplier crucial for long-term success?

Have you ever invested in new equipment only to be let down by poor after-sales service or a supplier who disappears after the sale? This is a common and frustrating experience, especially when you are looking for long-term reliability and support for your factory’s critical operations. A machine is only as good as the company behind it, and a bad partnership can lead to endless headaches, downtime, and financial strain.

Choosing the right packing machine supplier is crucial for long-term success because it ensures not only high-quality, reliable equipment but also comprehensive after-sales support, spare parts availability, and expert technical guidance. A reputable supplier acts as a true partner, understanding your specific operational needs and providing solutions that drive sustained efficiency and profitability, rather than just selling a machine.

This is where my journey with FHOPEPACK truly resonates. I started as an employee, then built my own successful factory. I have been on both sides of the table – as a user of packing machines and as a manufacturer. I know what it means to rely on equipment day in and day out and what it takes for a machine to truly support a business. This is why FHOPEPACK focuses on being a knowledge-sharing platform and a partner, not just a vendor. We want to help clients like Michael grow their businesses, just as I grew mine. Our goal is to ensure your investment works for you for years to come.

The FHOPEPACK Difference: Beyond Just Selling Machines

When you are making a significant investment in automation for your metal processing plant, the supplier you choose is as important as the machine itself. A reliable partner will provide not only robust equipment but also the expertise, support, and understanding necessary for your specific operational environment. This is something I learned throughout my career in the packing machine industry.

Here are key aspects of choosing the right partner:

- Deep Industry Expertise: Look for a supplier who genuinely understands the challenges of packing heavy coils and wire in environments like yours. They should know about material properties, handling techniques, and common bottlenecks. At FHOPEPACK, we embody this expertise. I have walked the factory floors, designed the systems, and seen what works (and what does not). This deep insight allows us to recommend truly effective solutions.

- Customization and Problem-Solving: Every factory has unique needs. A great supplier offers solutions tailored to your specific coil sizes, production volume, and factory layout. They should be willing to listen to your problems and propose innovative approaches, not just push a standard product. We pride ourselves on listening to Michael’s challenges – efficiency, safety, product loss – and offering targeted solutions.

- Robust After-Sales Support: This is critical. What happens when a machine needs maintenance or a spare part? A strong supplier provides prompt technical support, readily available spare parts, and skilled technicians who can troubleshoot issues quickly. Downtime is expensive, so reliable support is non-negotiable. 📞

- Proven Track Record and Reliability: Research the supplier’s history. Look for case studies, testimonials, and long-term client relationships. Companies like FHOPEPACK, or other reputable brands like Wuxi BuHui, have built their reputation on delivering quality and reliability. We are confident in the durability of our machines for demanding environments.

- Clear ROI and Value Proposition: A good supplier will help you understand the return on your investment. They should be able to articulate how their solution will save you money, improve efficiency, and enhance safety, providing a clear path to profitability. They focus on partnership for your growth. 🌱

My journey in the packing machine industry, from an employee to a factory owner, has shown me the immense value of a trusted partnership. This is why I am dedicated to sharing my knowledge through FHOPEPACK. For a factory manager in Mexico seeking to automate his steel coil packing, aligning with a supplier who acts as a true consultant and problem-solver is paramount. It is not just about a transaction; it is about building a relationship that supports your factory’s success for years to come, ensuring your investment pays off in every sense. (packing machine supplier selection, long-term equipment partnership, industrial machinery support, expert packing solutions)

Conclusion

Investing in automated steel coil packing lines is a smart move for metal processing plants. It boosts efficiency, enhances safety, and significantly reduces costs by preventing product damage, securing your factory’s future, and creating a truly valuable steel coil packing line asset.