Steel Coil Packing Machine vs PET Strapping System — Which Offers Better Protection?

As a packing machine engineer, I have spent decades in the packing machine industry. I’ve seen firsthand the challenges factory managers face, especially when it comes to protecting valuable products like steel coils. Michael, a factory manager in Mexico, shared with me his struggles with product damage and inefficient packing. He knows that every scratch or bit of rust means lost profit and customer complaints. This is why the choice between a steel coil packing machine and a PET strapping system is so crucial. It is not just about holding things together; it is about real protection for your investment.

Choosing the right system for steel coil packaging is not just a preference; it is a critical decision that directly impacts product integrity, operational safety, and overall profitability. While PET strapping systems offer a basic level of securement, a dedicated steel coil packing machine, particularly automated orbital or stretch wrapping systems, provides significantly superior protection against physical damage, corrosion, and environmental factors by creating a comprehensive, sealed barrier around the coil.

Understanding the differences between these two methods is key to making an informed decision for your factory. Let’s dive deeper into each system to see how they truly stack up in terms of safeguarding your precious steel coils, addressing concerns like efficiency, safety, and product loss.

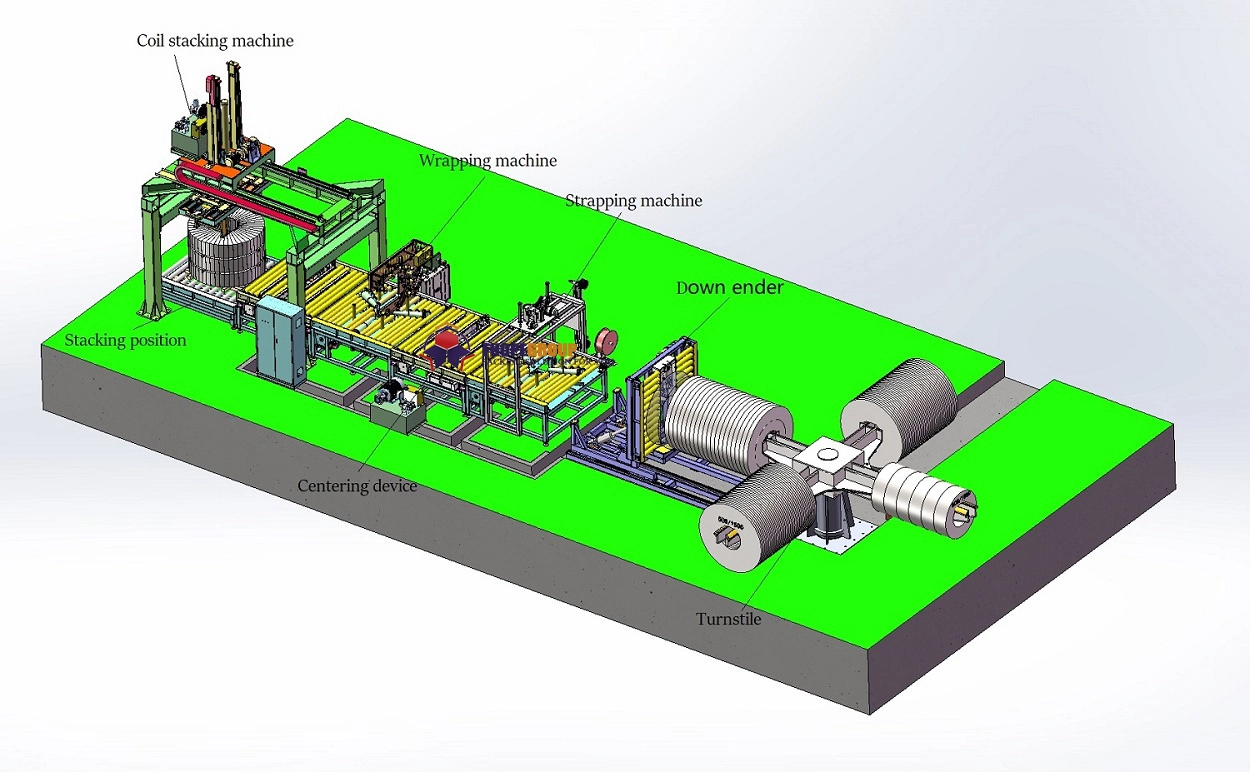

1. What Exactly is a Steel Coil Packing Machine, and How Does It Work?

Are you looking for a packing solution that goes beyond basic securement? Many factory managers, like Michael, often ask about the true capabilities of modern packing machines. They want to know how these systems can genuinely solve their product damage issues and improve workflow.

A steel coil packing machine is an automated industrial system designed to completely wrap and protect steel coils, creating a sealed, robust barrier against physical damage, moisture, dust, and corrosion during storage and transport, primarily using materials like stretch film, VCI paper, or woven fabric.

How These Machines Deliver Comprehensive Coil Protection 🛡️

My journey in the packing machine industry started from the ground up. I saw how manual methods led to endless damage. This is why I am so passionate about steel coil packing machines. They are not just machines; they are a shield for your products.

There are different types of steel coil packing machines, but they all share a common goal: to provide superior protection. Let’s look at the main types and how they work:

- Orbital Stretch Wrapping Machines:

- Principle: These machines use a ring-shaped wrapping unit that moves around the stationary or slowly rotating coil. They apply stretch film, VCI paper, or woven fabric over the entire circumference and face of the coil. The film overlaps, creating a continuous, multi-layered protective barrier.

- Protection Benefits:

- Full Surface Coverage: Every part of the coil, including the inner and outer diameters, and the faces, is covered. This prevents scratches and abrasions.

- Moisture Barrier: The tightly wrapped film forms a strong seal, keeping moisture out. This is crucial for preventing rust and corrosion, especially in humid environments or during long-distance shipping.

- Dust and Dirt Prevention: A sealed package means no dust or dirt can settle on the coil surface. This maintains product cleanliness and quality.

- VCI Integration: Many systems can incorporate Volatile Corrosion Inhibitor (VCI) paper or film. VCI chemicals evaporate and form a protective layer on the metal surface, actively preventing rust even if minor moisture penetrates.

- Reduced Handling Damage: Once wrapped, coils are easier and safer to handle without direct contact with the sensitive metal surface.

- Automation: Highly automated, reducing manual labor and the associated risks. The machine handles the heavy lifting and precise wrapping.

- Radial Wrapping Machines:

- Principle: These machines wrap material around the radial direction of the coil. They are often used for smaller coils or specific applications where orbital wrapping might be overkill or not suitable.

- Protection Benefits: Offers good protection for the outer diameter and some face protection. Can be combined with other methods for complete coverage.

- Stretch Hooding Machines:

- Principle: A tube of stretch film is stretched over the entire coil or a stack of coils from top to bottom, then heat-sealed at the bottom.

- Protection Benefits: Excellent for weather protection and load stability, providing a waterproof and dustproof cover. It is like putting a tight, protective sleeve over the coil.

Key Features and Advantages of Steel Coil Packing Machines:

- Customization: These machines can be designed to handle various coil sizes and weights, from slit coils to heavy steel coils. My experience with clients from different parts of the world, including Mexico, shows that one-size-fits-all rarely works. Tailored solutions ensure optimal protection.

- Material Versatility: They can work with different packing materials (stretch film, VCI paper, HDPE woven fabric), allowing for specific protection needs based on the coil type and its destination.

- Increased Efficiency: Automated packing significantly speeds up the end-of-line process. This is a game-changer for factories struggling with production bottlenecks caused by slow, manual packing.

- Enhanced Safety: By automating the wrapping process, these machines drastically reduce the need for manual interaction with heavy and potentially dangerous steel coils. This directly addresses Michael’s concern about worker safety and high injury risks.

- Consistency: Every coil gets the same high-quality wrap, ensuring consistent protection levels. This predictability is vital for maintaining product quality and reducing claims.

The comprehensive nature of steel coil packing machines means they provide multi-faceted protection, guarding against physical impacts, environmental elements, and chemical corrosion, far beyond what simple strapping can achieve. (automated coil wrapping, comprehensive product protection, industrial packaging solutions)

2. How Does a PET Strapping System Secure Steel Coils, and What Are Its Limitations?

When factory managers talk about securing their products, strapping often comes up. It’s a common method, but is it enough for heavy steel coils? Michael, like many others, might have used strapping in the past. But he’s now looking for solutions that genuinely solve product loss and safety issues.

A PET (Polyester) strapping system primarily secures steel coils by applying high-tensile polyester straps around their circumference, providing compression and bundling to keep the coil intact. While effective for basic securement, its limitations lie in offering minimal surface protection against environmental elements, physical abrasion, or corrosion, as it only covers a small portion of the coil’s surface.

The Securement, Not Protection, Aspect of PET Strapping 🤷♂️

From my years in the heavy manufacturing sector, I have learned that "securement" and "protection" are not the same. PET strapping is good for securement, but it falls short on protection.

Here’s a breakdown of PET strapping systems:

- What is PET Strapping?

- PET strapping is made from polyester, a strong and durable plastic material. It is a common choice for bundling heavy items because of its high tensile strength and elasticity. It can absorb impact without breaking, which is good for keeping bundles together during transit.

- How it Works:

- The strap is wrapped around the coil (either manually or with a semi-automatic/automatic machine) and then tensioned and sealed, usually by heat or friction welding. This creates a tight band that holds the coil together.

- It is often used to prevent coils from unraveling or to secure them to pallets or other transport platforms.

- Where it is Used:

- Frequently found in basic warehousing, internal transfer, or for products that will undergo further protective packaging. It is a cost-effective option for simple bundling needs.

Limitations in Providing Comprehensive Protection:

While PET strapping excels at bundling, it has significant drawbacks when it comes to true product protection for steel coils, especially in demanding industrial environments like Michael’s factory.

| Aspect of Protection | PET Strapping System | Steel Coil Packing Machine |

|---|---|---|

| Physical Damage | ❌ Limited: Only secures shape. Edges and surfaces remain exposed to scratches, dents, and impacts. | ✅ Excellent: Full surface coverage with multiple layers of film/paper protects against abrasions, impacts, and handling damage. |

| Corrosion/Rust | ❌ None: Provides no barrier against moisture, humidity, or corrosive agents. Coils are fully exposed to environmental elements. | ✅ Excellent: Creates a sealed, moisture-resistant barrier. Can integrate VCI materials for active rust prevention. |

| Dust/Dirt | ❌ None: Coils are completely open to dust, dirt, and industrial pollutants, leading to surface contamination. | ✅ Excellent: Sealed package prevents dust and dirt ingress, maintaining product cleanliness. |

| Moisture/Water | ❌ None: Rain, condensation, or spills will directly affect the coil surface, accelerating rust. | ✅ Excellent: Waterproof or water-resistant layers (film, woven fabric) keep moisture out, protecting the steel. |

| Load Stability | ✅ Good: Effective for bundling and securing the coil’s shape, preventing unraveling. | ✅ Excellent: Not only bundles but also secures and unitizes the load, preventing shifting during transport. |

Key Challenges for Michael’s Factory:

- Product Loss: Michael mentioned product damage during internal transfer. PET strapping does not protect against edge damage or surface abrasions, which are common issues when coils are moved around.

- Safety Hazards: While automated strapping can reduce some manual effort, the lack of full protection means that any damage sustained can make subsequent handling unsafe. Workers might still need to interact with potentially damaged edges or surfaces. Also, the overall efficiency of a strapping system is lower than a full packing machine, requiring more manual handling steps around the product.

- Environmental Vulnerability: Michael’s factory ships heavy goods. Coils secured only with strapping are highly vulnerable to weather changes, humidity, and airborne contaminants during shipping and storage. This means higher risk of rust, leading to customer complaints.

- Limited Automation Impact: While automatic strapping machines exist, they often only automate one part of the packing process. The overall efficiency gain might be small compared to a full coil packing line that integrates multiple steps. (PET strapping limitations, coil damage prevention, basic securement methods)

3. Which System Offers Superior Protection Against Damage, Corrosion, and Environmental Factors for Steel Coils?

This is the core question for any factory manager invested in their product’s quality. Michael’s concerns about product loss and customer complaints directly point to the need for superior protection. He is looking for a solution that genuinely safeguards his steel coils from the factory floor to the final destination.

When evaluating protection, steel coil packing machines unequivocally offer superior safeguarding compared to PET strapping systems. Packing machines create a comprehensive, multi-layered barrier against physical damage, moisture, dust, and corrosion, ensuring that valuable steel coils arrive at their destination in pristine condition, a level of protection that basic strapping cannot achieve.

Unpacking Superior Protection: A Detailed Comparison 🛡️ vs. 🔗

My personal journey in the packing machine business started because I saw clients losing money due to inadequate packing. I helped them transition from older methods to modern packing machines. The results were clear: fewer damages, happier customers, and better profits. This is why I can confidently say that packing machines offer a different league of protection.

Let’s break down the protection levels:

- Protection Against Physical Damage:

- Steel Coil Packing Machine:

- Full Encasement: The wrapping material (stretch film, woven fabric, VCI paper) covers the entire surface of the coil. This acts as a buffer against bumps, scratches, and abrasions during handling, stacking, and transit. Think of it as a custom-fitted suit of armor for your coil.

- Multi-Layer Defense: Often, multiple layers are applied, providing enhanced cushioning and resistance to punctures or tears. This is critical for heavy coils that might experience shifting or impact.

- Edge Protection: The wrapping extends over the coil edges, which are particularly vulnerable to damage. This prevents deformation or chipping.

- PET Strapping System:

- Localized Compression: Strapping provides localized pressure to keep the coil from unraveling or shifting. It does not cover the surface.

- Exposed Surfaces: The vast majority of the coil’s surface, including the crucial edges, remains exposed to potential damage from forklifts, other coils, or rough handling.

- No Cushioning: Strapping offers no cushioning effect. Any impact directly hits the metal surface.

- Steel Coil Packing Machine:

- Protection Against Corrosion and Rust:

- Steel Coil Packing Machine:

- Moisture Barrier: Stretch film or woven fabric creates a formidable barrier against moisture and humidity, the primary culprits of rust. Many films are specifically designed to be water-resistant or waterproof.

- VCI Integration: As I mentioned before, the ability to incorporate VCI (Volatile Corrosion Inhibitor) materials is a huge advantage. VCI chemicals create a protective vapor shield around the metal, actively preventing rust even if minor moisture is present. This is a proactive defense, not just a physical barrier. This is critical for long-term storage or sea freight.

- Dust and Contaminant Exclusion: The sealed package prevents industrial dust, chemicals, and other airborne contaminants from reaching the coil surface, which can accelerate corrosion.

- PET Strapping System:

- Zero Barrier: PET straps provide absolutely no barrier against moisture, humidity, or corrosive agents. The coil is fully exposed to environmental elements.

- Rust Risk: In humid climates like parts of Mexico or during ocean transit, coils secured only with strapping are highly prone to rust formation, leading to significant product degradation.

- Steel Coil Packing Machine:

- Protection Against Environmental Factors (Dust, Dirt, UV):

- Steel Coil Packing Machine:

- Sealed Environment: The wrapping creates a sealed package that keeps out dust, dirt, and other environmental pollutants. This ensures the coil remains clean, maintaining its aesthetic and functional quality.

- UV Protection (Optional): Some films come with UV stabilizers, offering protection against sunlight exposure, which can be important for outdoor storage.

- PET Strapping System:

- Full Exposure: Coils are completely exposed to all environmental factors – dust, dirt, rain, UV radiation. This can lead to surface degradation, contamination, and a need for extensive cleaning before use, adding to operational costs.

- Steel Coil Packing Machine:

Why This Matters for Michael’s Factory:

Michael mentioned product loss and customer complaints due to damage. Investing in a steel coil packing machine directly addresses these issues by providing unmatched protection. This not only saves money on damaged goods but also boosts customer satisfaction and strengthens the factory’s reputation. It’s about delivering a perfect product every single time. (superior coil protection, rust prevention solutions, comprehensive packaging for steel)

4. Beyond Protection: What Are the Operational, Safety, and Cost Implications of Each System for a Factory Like Michael’s?

For a factory manager like Michael, the decision is never just about one factor. He has to balance protection with efficiency, safety, and cost-effectiveness. He wants to know the overall impact on his operations, particularly regarding his goals of boosting automation, improving safety, and increasing profitability.

Beyond the direct product protection, steel coil packing machines offer significant operational advantages in terms of automation, efficiency, and worker safety, leading to substantial long-term cost savings and a higher return on investment for a factory like Michael’s. In contrast, PET strapping, while lower in initial cost, often creates efficiency bottlenecks, retains higher safety risks, and provides limited overall value in demanding industrial environments.

The Bigger Picture: Efficiency, Safety, and ROI for Your Factory 📈

My goal with FHOPEPACK is to share knowledge that helps businesses grow. When Randal Liu founded FHOPEPACK, it was born from understanding the real-world problems faced by factory owners. It is not just about selling machines; it is about providing solutions that make a tangible difference to your bottom line.

Let’s look at the broader implications for a factory manager:

- Operational Efficiency and Automation:

- Steel Coil Packing Machine:

- High Automation: These machines are designed for automated or semi-automated operation. They seamlessly integrate into production lines, handling coils from the cooling line to the dispatch area. This reduces the need for constant human intervention.

- Reduced Bottlenecks: By automating the packing process, these machines eliminate the end-of-line bottlenecks that manual or semi-manual strapping methods often create. Coils are wrapped quickly and consistently.

- Faster Throughput: The speed of automatic wrapping significantly increases the overall packing capacity, allowing the factory to handle higher production volumes without additional labor. This directly addresses Michael’s challenge of slow and inefficient processes.

- PET Strapping System:

- Labor-Intensive: Even with automatic strapping heads, loading, positioning, and often manual handling of the coil are required. This ties up valuable labor resources.

- Slower Process: Strapping individual coils, especially large ones, can be a slower process compared to a fully integrated packing machine. This can become a bottleneck when production ramps up.

- Limited Integration: Strapping machines typically perform only one task. Integrating them into a fully automated line with other protective packaging steps can be complex and less efficient than a purpose-built packing machine.

- Steel Coil Packing Machine:

- Worker Safety:

- Steel Coil Packing Machine:

- Minimized Manual Handling: This is a major win for safety. The machine handles the heavy lifting, rotation, and wrapping of the coil, drastically reducing the need for workers to physically interact with heavy, moving steel. This minimizes risks of strains, crush injuries, and accidents.

- Controlled Environment: Modern machines often have safety interlocks, guarded areas, and emergency stop features, creating a much safer working environment. This is crucial for Michael’s concern about high injury risks.

- PET Strapping System:

- Persistent Manual Risks: While automatic strapping reduces some manual effort, workers are often still involved in positioning coils, feeding straps, or managing the process. This keeps them in close proximity to heavy objects and tensioned materials, carrying inherent risks.

- Ergonomic Issues: Repetitive tasks associated with manual or semi-automatic strapping can lead to ergonomic injuries over time.

- Steel Coil Packing Machine:

- Cost Implications and ROI (Return on Investment):

- Steel Coil Packing Machine:

- Higher Initial Investment: Yes, a comprehensive packing machine requires a larger upfront capital expenditure.

- Significant Long-Term Savings:

- Reduced Labor Costs: Fewer workers are needed for packing, leading to substantial savings on wages, benefits, and training.

- Decreased Product Loss: Superior protection means significantly fewer damaged coils, reducing scrap rates, rework, and customer returns. This directly impacts profitability.

- Lower Insurance Costs: Improved safety records can lead to lower workers’ compensation insurance premiums.

- Enhanced Customer Satisfaction: Delivering pristine products builds loyalty and repeat business.

- Faster ROI: My experience shows that despite the higher initial cost, the combined savings from reduced labor, material damage, and increased efficiency often lead to a very attractive ROI within a few years. Michael’s focus on clear ROI makes this a compelling option.

- PET Strapping System:

- Lower Initial Investment: The upfront cost is generally lower, making it seem appealing initially.

- Higher Ongoing Costs:

- Higher Labor Costs: Continued reliance on manual labor for packing.

- Potential for Higher Product Damage: The lack of comprehensive protection can lead to ongoing costs from damaged goods and customer claims.

- Limited Efficiency Gains: Might not solve fundamental bottlenecks, leading to continued lost production time.

- Lower ROI: While cheaper initially, the lack of significant savings in labor, damage, and efficiency can mean a lower long-term ROI.

- Supplier Trust: Michael’s experience with unreliable suppliers suggests he needs a partner who understands the long-term value, not just the upfront price. FHOPEPACK strives to be that partner, offering expert guidance and reliable solutions.

- Steel Coil Packing Machine:

For Michael, choosing a steel coil packing machine is not just an expense; it is a strategic investment that addresses his core challenges: boosting automation, enhancing safety, reducing product loss, and ultimately, driving the overall profitability and growth of his factory. (factory automation, operational efficiency, industrial safety solutions, packing machine ROI)

Conclusion

For Michael’s factory, the choice is clear: steel coil packing machines offer far superior protection, efficiency, and safety benefits over PET strapping systems. Investing in an automated steel coil packing line is a strategic decision for long-term success.