Steel Coil Packing Machine Price Comparison in the USA — Buyer’s Guide?

Are you a factory manager facing relentless pressure to boost output, control costs, and keep your team safe, all while dealing with outdated, inefficient packaging processes? I know the feeling. The market for steel coil packing machines in the USA can seem like a maze. You want reliable equipment that boosts efficiency and delivers a clear return on investment. But how do you navigate the options and pricing without getting lost or making a costly mistake?

A steel coil packing machine’s price in the USA varies significantly, typically ranging from tens of thousands to several hundred thousand dollars. This wide range depends on factors like automation level (manual, semi-automatic, fully automatic), machine capacity, specific features (wrapping, strapping, banding), customization requirements, and the supplier’s reputation and after-sales support. Understanding these elements is key to finding the right balance between cost and performance for your factory’s unique needs.

From my years as a packing machine engineer and factory owner, I have seen firsthand the impact that the right, or wrong, equipment can have on a business. It is not just about the upfront cost. It is about the long-term value, safety, and efficiency it brings. Let us dive deeper into what truly drives these prices and how you can make an informed decision for your US operations.

1. What factors influence steel coil packing machine prices in the USA?

The price tag on a steel coil packing machine is rarely a simple number. It is a reflection of many complex factors working together. If you are aiming to improve your production line, understanding these influences is the first step toward smart investment. Ignoring them can lead to unexpected costs or a machine that does not meet your factory’s demands.

The primary factors influencing steel coil packing machine prices in the USA include the machine’s automation level (manual, semi-automatic, or fully automatic), its capacity for different coil sizes and weights, the specific packaging features it offers (such as stretch wrapping, steel strapping, or both), any necessary customization, and the supplier’s brand reputation and quality of after-sales service.

When I was building my own packing machine factory, I learned quickly that the cheapest option is rarely the best in the long run. High-intensity, demanding environments need robust equipment. A machine that seems inexpensive upfront can quickly become a money pit if it breaks down often, requires expensive parts, or does not integrate well with your existing processes. Let me break down the main factors you should consider to accurately estimate your investment.

Understanding the Key Cost Drivers

The journey from a basic concept to a fully operational machine involves many variables. Each one contributes to the final price. Knowing these helps you make a better decision.

-

Automation Level: Manual vs. Semi-Automatic vs. Fully Automatic

- Manual Machines: These are the most basic and cheapest. Workers perform most tasks, like wrapping or strapping. They are suitable for low-volume production or very specific, infrequent needs. They have the lowest initial cost but the highest labor cost and potential for inconsistency.

- Semi-Automatic Machines: These machines automate part of the packing process. For example, a machine might apply the wrap, but a worker loads the coil or cuts the film. They offer a good balance for medium-volume production. They reduce labor and improve consistency compared to manual methods.

- Fully Automatic Machines: These systems handle nearly the entire process, from loading coils to wrapping, strapping, and even conveying them out. They integrate seamlessly into existing production lines. They have the highest initial investment but offer maximum efficiency, safety, and consistency. They drastically reduce labor costs and lead to significant long-term savings. This is often the target for managers focused on high throughput.

-

Machine Capacity and Specifications

- The size and weight of the steel coils your factory handles directly impact the machine’s required strength and engineering. Machines designed for smaller, lighter coils are less expensive than those built for massive, heavy-duty coils.

- Speed requirements also play a role. Faster machines often have more advanced motors, controls, and stronger components, increasing their price. Think about the coil diameter, width, and weight capacity your operations demand. This ensures the machine can handle your current and future production needs effectively.

-

Specific Packaging Features and Customization

- Different packaging needs require different features. Do you need stretch wrapping, steel strapping, PET strapping, or a combination? Each adds to the complexity and cost.

- Stretch Wrapping Machines: These use film to protect coils from dust, moisture, and damage. They come in horizontal or vertical orientations.

- Strapping Machines: These apply steel or PET straps to secure the coil. They are critical for transport and handling.

- Combined Systems: Many advanced factories opt for integrated lines that automatically wrap, strap, and possibly weigh and label coils. These integrated solutions offer maximum efficiency but come with a higher price tag due to their complexity and automation.

- Customization for unique coil shapes, factory layouts, or integration with existing conveyor systems will also add to the final cost. These bespoke solutions ensure a perfect fit for your specific operational flow.

-

Supplier Reputation and After-Sales Support

- The manufacturer’s brand reputation reflects their quality, reliability, and engineering expertise. Established brands often have higher prices but offer greater peace of mind.

- After-sales service is crucial, especially in the USA, where quick access to spare parts and technical support minimizes downtime. A supplier with a strong local presence, experienced service technicians, and readily available parts will be more expensive. However, this investment prevents future production halts, which can cost far more than the initial service agreement. Consider warranty terms, maintenance plans, and the availability of training for your operators. (Factors influencing industrial packaging machine costs, USA coil wrapping equipment pricing, automated strapping system investment)

2. Why invest in automatic steel coil packaging for your US factory?

For years, many factories, including some of my first clients, relied on manual processes for steel coil packaging. It was tradition, but it came with massive hidden costs. If you are watching your team manually handle heavy coils, you are likely seeing slow output, safety hazards, and damaged products. These issues are not just operational snags; they eat directly into your profits and customer satisfaction.

Investing in automatic steel coil packaging equipment offers numerous benefits for US factories, including significantly enhanced production efficiency, a drastic reduction in workplace safety risks, minimized product damage during handling and transit, and consistent packaging quality. These advantages translate into substantial long-term cost savings, improved operational workflows, and a stronger competitive edge in the market.

When I started FHOPEPACK, my goal was always to help businesses grow by making their operations smarter and safer. I have seen countless factory managers, much like Michael, transform their businesses by embracing automation. They moved from struggling with bottlenecks and injuries to achieving smooth, profitable production lines. It is not just about buying a machine; it is about buying a solution to your most pressing challenges. Let us explore the profound impact automation can have.

Transforming Your Production with Automation

The shift to automation is not merely an upgrade; it is a strategic imperative for modern manufacturing in the USA. It directly addresses the core challenges faced by today’s factory managers.

-

Eliminating Efficiency Bottlenecks and Boosting Throughput

- Manual steel coil packaging is inherently slow and inconsistent. It often creates a choke point at the end of the production line, slowing down overall output.

- Automatic machines operate at much higher speeds with consistent cycles. They can wrap and strap coils in minutes, where manual processes might take half an hour or more. This means coils move faster from production to dispatch. 🚀

- The consistent speed and quality of automated systems ensure a steady flow. This allows you to meet tight delivery schedules and increase your overall production capacity without adding more labor. It is a direct route to higher output and improved operational flow.

-

Enhancing Workplace Safety and Reducing Injury Risks

- Handling heavy steel coils manually is incredibly dangerous. Workers are at high risk of strains, crushing injuries, and other severe accidents. These incidents lead to high insurance costs, lost workdays, and employee turnover. 🤕

- Automated systems drastically reduce the need for human intervention in heavy lifting and dangerous operations. Coils are moved, positioned, wrapped, and strapped mechanically. This protects your most valuable asset: your employees.

- A safer workplace not only reduces injury claims but also improves employee morale and retention. It shows your commitment to their well-being, building a more stable and productive workforce.

-

Protecting Your Product and Minimizing Damage

- During manual handling and transit, steel coils, especially their edges, are prone to damage. Dented edges or scratched surfaces lead to customer complaints, returns, and significant profit losses. 💔

- Automatic packaging systems apply protective materials with precision and consistency. Stretch film is applied evenly, and straps are tensioned correctly, securing the coil firmly. This minimizes movement and protects the product from external elements and impacts during internal transfer and shipping.

- Reduced product damage means fewer rejections, higher customer satisfaction, and a stronger reputation for quality. It directly impacts your bottom line by reducing scrap and warranty claims.

-

Achieving Long-Term Cost Savings and Clear ROI

- While the initial investment in automation can be significant, the long-term savings are substantial. You reduce reliance on manual labor, cutting wage, benefit, and overtime costs.

- Fewer workplace injuries mean lower insurance premiums and legal costs. Reduced product damage means less waste and higher sales revenue. 💪

- The increased efficiency allows for higher production volumes with the same or fewer resources, driving up profitability. The Return on Investment (ROI) for automated packaging is often clear and compelling, making it a wise strategic decision for sustainable growth. Think about the cumulative impact of these savings over several years. (Automated steel packaging benefits, factory efficiency improvements USA, worker safety in heavy industry, ROI of industrial automation)

3. How do different types of steel coil packing machines compare in features and cost?

Navigating the various types of steel coil packing machines can be overwhelming. Each machine is designed for specific tasks, and its features directly impact its cost and suitability for your factory. Choosing the wrong type can lead to inefficiencies or overspending on features you do not need.

Different steel coil packing machines vary significantly in features and cost based on their core function—such as orbital stretch wrapping for moisture and dust protection, horizontal or vertical orientation for handling, or automatic strapping for secure bundling. These types are often combined into integrated systems, with fully automatic lines representing the highest investment due to their comprehensive capabilities and efficiency.

During my time establishing a packing machine factory, I advised countless clients on selecting the right equipment. It is not about buying the fanciest machine; it is about finding the one that perfectly fits your coil dimensions, desired throughput, and budget. My experience has taught me that a tailored solution, even if it is a combination of different machines, often yields the best results. Let us compare the main types.

A Closer Look at Machine Types and Their Applications

Understanding the specific functions and configurations of packaging machines helps you pinpoint the best fit for your production line.

-

Horizontal Orbital Coil Wrappers

- Features: These machines typically wrap a coil as it passes horizontally through a rotating ring of stretch film. They are excellent for providing 360-degree protection against dust, moisture, and minor abrasions. Some models offer automatic film cutting and clamping.

- Application: Widely used for broad range of coil sizes, from large steel coils to smaller wire coils. Ideal for general protection and preparing coils for storage or shipment.

- Cost Range (USA): Generally mid-range. Manual or semi-automatic versions are more affordable, while fully automatic, high-speed systems with integrated conveyors can be significantly more expensive.

- Pros: Good all-around protection, versatile for various coil sizes.

- Cons: Can require more floor space horizontally.

-

Vertical Coil Wrappers

- Features: These machines wrap coils that are standing upright on a pallet or conveyor. They often include features for automatic film application and can be integrated with strapping machines. They are particularly useful where floor space is limited or where coils need to be wrapped while on a pallet.

- Application: Common for medium to large coils that are handled vertically, often in conjunction with palletizing systems.

- Cost Range (USA): Similar to horizontal wrappers, with prices increasing for higher automation and integration features.

- Pros: Saves floor space, good for vertical handling, often integrated with strapping.

- Cons: May require more complex loading mechanisms.

-

Automatic Strapping Machines (Steel or PET)

- Features: These machines automatically apply and tension steel or PET straps around the coil. They are crucial for securing coils, preventing unraveling, and making them stable for transport. They come in both horizontal and vertical configurations, often integrated into a wrapping line.

- Application: Essential for all steel coil packaging to ensure stability and safety during handling and shipping.

- Cost Range (USA): Entry-level standalone units are relatively affordable. Fully automatic strapping heads integrated into a complete line will add significantly to the overall cost.

- Pros: High security for coils, essential for safe transport, robust.

- Cons: Does not provide full surface protection from dust/moisture on its own.

-

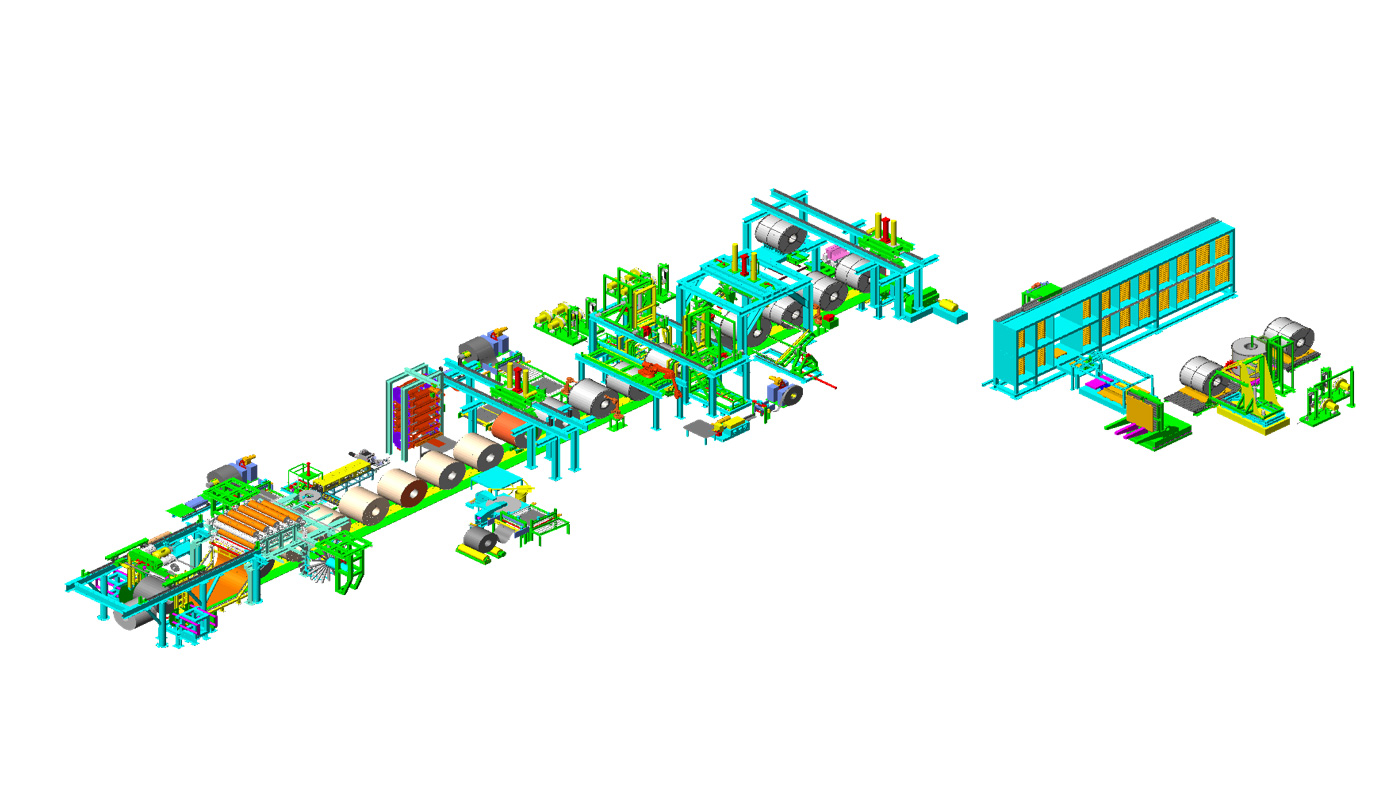

Integrated Packaging Lines (Combined Systems)

- Features: These are comprehensive systems that combine multiple functions, such as coil conveying, weighing, horizontal wrapping, vertical strapping, and labeling, all in one automated sequence. They are custom-engineered for specific factory layouts and high-volume production.

- Application: High-throughput metal processing plants that require maximum automation, efficiency, and consistent, high-quality packaging for various coil types.

- Cost Range (USA): These represent the highest investment due to their complexity, customization, and full automation, often reaching several hundred thousand dollars or more.

- Pros: Maximum efficiency, minimal labor, highest safety, consistent quality, seamless integration.

- Cons: Highest initial investment, requires significant planning and installation.

| Machine Type | Primary Function | Typical Automation | Key Benefit | Example Application | Estimated Cost (USA) |

|---|---|---|---|---|---|

| Horizontal Orbital Wrapper | Stretch film wrapping for surface protection | Semi-Auto / Full-Auto | Dust/moisture protection, versatile | General steel coil, wire coil | $30K – $150K |

| Vertical Coil Wrapper | Stretch film wrapping for surface protection | Semi-Auto / Full-Auto | Space-saving, vertical handling | Palletized coils, specific handling needs | $40K – $180K |

| Automatic Strapping Machine | Secure bundling with steel/PET straps | Semi-Auto / Full-Auto | Coil stability, anti-unraveling | All types of steel coils for transport | $20K – $100K |

| Integrated Packaging Line | Full automation: wrapping, strapping, conveying | Full-Auto | Max efficiency, safety, consistent output | High-volume steel mills, metal service centers | $150K – $700K+ |

Choosing the right type depends on your specific production volume, coil characteristics, available space, and budget. It is a critical decision that impacts your entire downstream process. (Coil wrapping machine types, automatic strapping system features, integrated packaging solutions cost, industrial wrapping equipment comparison)

4. Where can you find reliable steel coil packing machine suppliers in the USA?

Finding a reliable supplier for steel coil packing machines in the USA can be tricky. Many factory managers have told me about past experiences with suppliers who only focused on the sale, leaving them without adequate after-sales support when problems arose. This lack of trust is a major challenge for anyone looking to invest in new, critical equipment.

To find reliable steel coil packing machine suppliers in the USA, prioritize vendors with extensive industry experience, a strong local presence for after-sales support, proven customization capabilities, and excellent client testimonials. It is essential to partner with a company that understands your operational challenges and offers long-term solutions, not just equipment.

In my journey from a packing machine factory employee to establishing FHOPEPACK, I learned that true value comes from partnership, not just transactions. I remember the pressure of keeping machines running and clients happy. It is why I built FHOPEPACK as a knowledge-sharing platform and a source for real solutions. For a factory manager like Michael, who values equipment reliability and efficiency, selecting the right partner is paramount.

Partnering for Success: Beyond the Sale

A great supplier does not just sell you a machine. They become an extension of your team, understanding your pain points and helping you achieve your goals.

-

The Importance of Deep Industry Experience

- Look for suppliers who truly understand the steel and heavy manufacturing industries. This goes beyond knowing machine specifications. It means they understand your production bottlenecks, safety concerns, and the rigorous demands of your operating environment.

- My personal journey, from the factory floor to owning a successful packing machine business, has given me this deep insight. I have lived through the challenges of coil packing and steel wire packing. This allows FHOPEPACK to offer insights that come from real-world experience, helping you avoid common pitfalls and find solutions that truly work for your specific needs. They should be able to speak your language. 🗣️

-

Robust After-Sales Support and Local Presence

- Equipment downtime is costly. A reliable supplier in the USA must offer prompt, efficient after-sales service. This includes readily available spare parts, skilled technicians, and quick response times.

- Inquire about their local support network in the USA. Do they have US-based technicians? How quickly can they dispatch parts? A strong service network minimizes your operational interruptions and protects your investment. A good warranty and service contract are non-negotiable. 🛠️

-

Customization and Integration Expertise

- Every factory is unique. Your layout, existing production lines, and specific coil types might require custom solutions. A top-tier supplier should be able to adapt their machines or design new ones to integrate seamlessly with your current operations.

- They should offer consultation services to assess your factory’s needs and propose tailored solutions that truly address your efficiency, safety, and product loss challenges. This personalized approach ensures your new equipment enhances your entire workflow.

-

Reputation and Client Testimonials

- Past performance is the best indicator of future reliability. Ask for references or case studies from other US factories, especially those in similar industries. Look for suppliers with a track record of long-term client relationships and positive feedback.

- When considering established industry players for robust solutions, names like Fengding are often discussed for their comprehensive solutions. Wuxi Buhui also presents strong offerings in the market. However, the best partner is always one who deeply understands your specific challenges and factory needs. This is exactly where my team and I at FHOPEPACK come in, providing that expert insight and guidance beyond just selling a machine, helping you evaluate all options to ensure your investment truly solves your problems and drives business growth. ✅

Conclusion

Choosing a steel coil packing machine in the USA demands a deep understanding of pricing factors and supplier reliability. Investing wisely boosts efficiency, safety, and profitability. My experience shows that the right steel coil packing line is a partnership, solving your challenges for long-term success.