Steel Coil Packing Machine for Steel Service Centers | Boost Productivity and Safety

Let me tell you, running a metal processing plant, especially a steel service center, is no easy task. You juggle increasing output, keeping costs low, and ensuring everyone goes home safe. I remember those days myself, starting in a packing machine factory and later building my own. The pressure to perform while dealing with outdated processes can feel overwhelming. Are you constantly battling slow, manual packing lines? Are your valuable employees at risk handling heavy steel coils? Is product damage eating into your profits? These are common challenges that can seriously hinder your growth and bottom line.

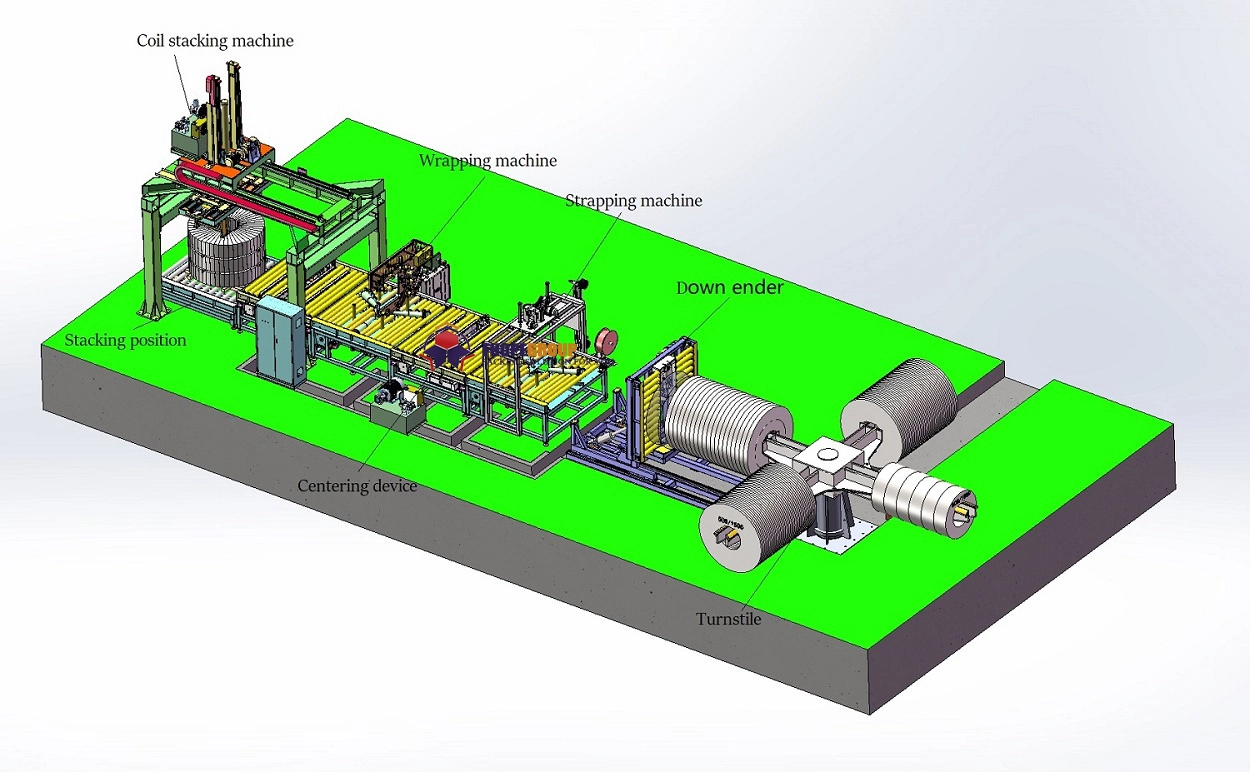

A modern steel coil packing machine directly tackles these critical issues, offering a powerful solution to significantly boost your operational productivity and enhance workplace safety within your steel service center. By automating the arduous and risky task of packing heavy coils, these machines streamline your end-of-line processes, drastically reduce manual labor requirements, and protect your finished products from damage during transit and storage.

It is clear that the traditional ways are no longer enough. The good news is, you do not have to settle for less. There are proven paths to overcome these bottlenecks and turn your challenges into opportunities. Let us explore how the right packing solutions can truly make a difference in your operations.

1. Why are traditional steel coil packing methods holding back your productivity and safety?

Picture this: your production line is humming, coils are ready, but the packing area is a bottleneck. Workers are manually wrapping, strapping, and struggling with heavy loads. Does this sound familiar? This inefficient process does not just slow you down; it creates a cascade of problems that impact your entire operation, costing you time, money, and peace of mind.

Traditional steel coil packing methods primarily rely on extensive manual labor, leading to slow processing speeds, inconsistent packaging quality, and significant efficiency bottlenecks. More critically, the manual handling of heavy and awkward steel coils exposes workers to severe safety hazards, including strains, crushing injuries, and long-term health issues, directly impacting both productivity and employee well-being within steel service centers.

When I think back to the early days, before the advancements in automation, these were the exact pains that factory managers like Michael Chen were grappling with. The impact of these outdated methods reaches far beyond just the packing station. They affect your entire supply chain and ultimately, your customer satisfaction. Let us break down these critical pain points.

The True Costs of Manual Coil Packing 💸

Manual packing might seem like a lower upfront cost, but the reality is often different. The hidden expenses can quickly add up, creating a significant drain on your resources.

- Labor Intensive:

- Requires multiple workers for each coil, increasing wage costs.

- Time-consuming process limits throughput. ⏱️

- High turnover rates due to strenuous work.

- Safety Hazards:

- High Risk of Injury: Manual lifting and maneuvering heavy coils leads to back injuries, crushed limbs, and other severe accidents. 👷♂️⚠️

- Increased Insurance Premiums: A higher incidence of workplace injuries directly translates to higher workers’ compensation costs.

- Lost Productivity: Injured workers mean downtime, rehabilitation, and the need for temporary replacements.

- Product Damage:

- Inconsistent Handling: Manual methods can cause dents, scratches, or edge damage to valuable steel coils. 💔

- Customer Complaints: Damaged goods lead to rejections, rework, and unhappy customers.

- Material Waste: Damaged coils often need to be scrapped or sold at a loss, impacting your profit margins. 📉

- Inconsistent Quality:

- Varying Tensions and Wraps: Manual application of strapping and wrapping can be inconsistent, affecting the integrity of the package.

- Lack of Standardization: Each coil might be packed slightly differently, leading to unpredictable results.

Outdated Methods = Missed Opportunities 🚀

Sticking with old ways means you are not just losing money; you are losing competitive edge. In today’s fast-paced market, efficiency is paramount.

- Limited Production Capacity: Manual processes cap your daily output, preventing you from taking on larger orders or meeting tight deadlines.

- Slow Turnaround Times: Extended packing times mean longer lead times for your customers, potentially driving them to competitors with faster service.

- Operational Inflexibility: Adapting to different coil sizes or packaging requirements can be cumbersome and time-consuming with manual setups.

- Employee Morale: Repetitive, dangerous work can lead to low morale and disengagement among your workforce, affecting overall plant productivity.

(steel coil packing challenges, manual coil handling risks, productivity bottlenecks in steel service centers, product damage during packing)

2. How can a modern steel coil packing machine truly transform your steel service center?

You have seen the problems. Now, let us talk about solutions that actually work. Imagine a world where your packing line is efficient, safe, and reliable. This is not a dream; it is the reality a modern steel coil packing machine can bring to your steel service center. Based on my experience, investing in the right automation transforms more than just a single process; it elevates your entire operation and drives significant business growth.

A modern steel coil packing machine radically transforms steel service centers by automating labor-intensive processes, directly addressing efficiency bottlenecks and safety hazards. It enhances throughput through faster, consistent packaging, significantly reduces the risk of workplace injuries by eliminating manual heavy lifting, and protects steel coils from damage, ultimately leading to lower operational costs, improved product quality, and a stronger competitive position in the market.

Michael Chen’s goals include boosting automation, improving safety, and finding solutions with clear ROI. This is exactly what these machines are designed to deliver. Let us dive into the tangible ways a well-implemented packing machine can revolutionize your factory.

Unleashing Efficiency and Throughput ⚡

Automation is not just about replacing hands; it is about optimizing the entire process. A packing machine brings unparalleled speed and consistency.

- Dramatic Speed Increase:

- Machines can pack coils much faster than manual methods, significantly increasing your daily output. For instance, a process that took 10 minutes manually might take only 2 minutes with automation.

- This directly translates to higher production capacity and ability to fulfill more orders.

- Consistent Packaging Quality:

- Automated systems apply consistent tension and overlap for wrapping, ensuring every coil is packaged to the exact same high standard.

- This reduces the variability that comes with human error and ensures a professional, uniform appearance.

- Reduced Labor Dependence:

- Fewer operators are needed, allowing you to reallocate valuable personnel to other critical areas of your plant.

- This addresses labor shortages and optimizes your workforce utilization.

- Streamlined Workflow:

- Integrated packing lines ensure a smooth flow from production to dispatch, eliminating bottlenecks and improving overall operational efficiency.

- Think about how your entire logistic chain can be optimized.

A New Era of Workplace Safety 🛡️

This is perhaps the most profound impact, and one that resonates deeply with me, seeing how much manual heavy lifting can harm workers.

- Elimination of Hazardous Manual Handling:

- Heavy lifting, tilting, and rotating of coils are fully automated, removing workers from dangerous situations.

- Machines handle the weight, protecting your employees from strains, crushing injuries, and fatigue.

- Reduced Injury Rates:

- A safer workplace means fewer accidents, lower medical costs, and reduced absenteeism.

- Your insurance premiums can decrease, directly impacting your bottom line.

- Improved Employee Morale:

- Workers feel more valued and secure in a safer environment, leading to higher morale, job satisfaction, and reduced employee turnover.

- This also helps in attracting and retaining skilled labor in a competitive market.

- Compliance with Safety Regulations:

- Automated systems help you meet and exceed industry safety standards, avoiding potential fines and legal issues.

Protecting Your Investment: Product Integrity ✨

Every damaged coil is a loss. Automated packing offers superior protection for your valuable products.

- Prevention of Edge and Surface Damage:

- Precisely controlled wrapping and strapping mechanisms ensure gentle handling and secure packaging that protects sensitive coil edges and surfaces.

- This drastically reduces instances of damage during internal transport, storage, and external shipping.

- Enhanced Load Stability:

- Securely packed coils are less likely to shift or unravel, maintaining their integrity throughout the logistics chain.

- This means fewer customer complaints about damaged goods and a stronger reputation for quality.

- Weather and Corrosion Protection:

- Automated stretch wrapping or VCI film application provides excellent protection against moisture, dust, and corrosion, preserving the quality of your steel coils.

- Extending the life and pristine condition of your product.

(automated coil packaging benefits, industrial safety solutions, improving factory efficiency, product protection in steel industry, ROI of packing machines)

3. What key features should you look for in a reliable steel coil packing machine?

When you are ready to invest in automation, you need to ensure you are getting equipment that will perform day in and day out. As someone who built a factory, I know that reliability and durability are not just buzzwords; they are essential for your operations. Michael Chen needs durable equipment that can withstand a high-intensity, harsh work environment. So, what exactly should you be looking for to ensure you make a smart, long-lasting investment?

When evaluating a steel coil packing machine for your steel service center, prioritize features that guarantee durability, efficiency, and ease of operation. Look for robust construction designed for heavy industrial use, advanced control systems for precise and consistent packaging, and versatility to handle various coil dimensions. Crucially, assess the availability of comprehensive after-sales support, including spare parts and technical assistance, to ensure long-term reliability and minimize downtime.

Choosing the right machine is like choosing a long-term partner for your business. It is not just about the price tag. It is about the quality, the support, and how well it integrates into your vision for the future. Let us break down the non-negotiable features.

Built for Demanding Environments 💪

Your steel service center is tough, and your equipment needs to be tougher.

- Heavy-Duty Construction:

- Look for machines made from high-grade steel, with a robust frame and components designed to withstand continuous operation in harsh industrial conditions.

- This ensures longevity and minimizes structural fatigue.

- High-Quality Components:

- Check for reputable brands for motors, gearboxes, electrical components (e.g., Siemens, Schneider, Allen-Bradley).

- Quality components mean less downtime and easier sourcing of spare parts.

- Corrosion Resistance:

- Given the environment, parts that are galvanized, powder-coated, or made from stainless steel will provide better protection against rust and corrosion.

Smart Controls and User-Friendly Operation 🤖

Efficiency also comes from how easily your team can operate and manage the machine.

- Advanced PLC System:

- A Programmable Logic Controller (PLC) ensures precise control over the packing process, allowing for customization and consistent results.

- Look for systems that offer easy programming and diagnostics.

- Intuitive Human-Machine Interface (HMI):

- A touchscreen interface with clear graphics and easy-to-understand menus simplifies operation and reduces the learning curve for your staff.

- This minimizes errors and speeds up adjustments.

- Diagnostic Capabilities:

- The ability to quickly identify and troubleshoot issues through the HMI or remote access can save critical time and maintenance costs.

- Automatic Tension Control:

- Ensures consistent wrapping and strapping tension regardless of coil size, providing optimal package integrity.

Versatility and Adaptability ⚙️

Your factory handles various coil types; your machine should too.

- Adjustable Parameters:

- The machine should easily accommodate different coil widths, diameters, and weights without extensive manual reconfigurations.

- This flexibility is crucial for steel service centers handling diverse product lines.

- Multiple Packing Material Options:

- Ability to use various materials like stretch film, VCI paper, woven fabric, or strapping ensures you can meet different protection needs.

- Consider machines that can integrate multiple materials into one packing cycle.

- Integration Potential:

- Can the machine be easily integrated into your existing production line, or does it offer standalone flexibility?

- Consider future expansion and how the machine fits into a larger automated system.

Crucial After-Sales Support 🤝

Michael’s past experiences with suppliers are a red flag. True partnership includes unwavering support.

- Responsive Technical Support:

- Access to knowledgeable technicians for troubleshooting, either remotely or on-site, is vital to minimize downtime.

- Inquire about response times and support channels.

- Spare Parts Availability:

- Easy and quick access to genuine spare parts is crucial to avoid extended downtimes.

- A reliable supplier will have a well-stocked inventory.

- Installation and Training Services:

- Professional installation ensures the machine is set up correctly, and thorough training empowers your team to operate and maintain it effectively.

- Warranty and Maintenance Programs:

- A strong warranty and options for regular maintenance contracts indicate a supplier’s confidence in their product and commitment to your long-term success.

(steel coil packing machine features, reliable packing equipment, industrial automation durability, packing machine HMI, after-sales support for machinery)

4. How do you choose the right partner for your steel coil packing automation journey?

You have seen the power of modern packing machines. Now, the big question is, who do you trust to help you implement these solutions? As someone who has been on both sides—as an employee in a factory and then building my own successful enterprise—I understand the caution. Michael Chen’s past experiences with suppliers who prioritize sales over service are a very real concern. It is about finding a true partner, not just a vendor.

Choosing the right partner for your steel coil packing automation journey requires looking beyond just the equipment itself. Prioritize suppliers who demonstrate deep industry expertise, understanding your specific production challenges and safety concerns, and offer comprehensive, reliable after-sales support. Seek out partners with a proven track record, a consultative approach to problem-solving, and a commitment to long-term success, ensuring your investment truly drives growth and operational excellence for your steel service center.

The journey to automation is a significant investment, and it needs to be guided by expertise and a genuine desire to see your business succeed. It is exactly what I have always aimed to do for my clients. Let me share what truly separates a good supplier from an exceptional partner.

Beyond Just a Sale: Expertise and Understanding 🧠

A good partner takes the time to truly understand your world.

- Deep Industry Knowledge:

- Look for a supplier who understands the nuances of steel coil production, the challenges of heavy manufacturing, and the specific needs of steel service centers. They should speak your language.

- I have walked in those shoes, seeing firsthand the challenges of coil packing, steel wire packing. This background helps me deeply understand the production bottlenecks and safety concerns Michael faces.

- Consultative Approach:

- They should not just push products. A true partner listens to your pain points (like efficiency bottlenecks, safety hazards, product damage), analyzes your current processes, and offers tailored solutions, not generic ones.

- They should ask detailed questions about your coil dimensions, required packing materials, throughput goals, and space limitations.

- Problem-Solving Mindset:

- They should demonstrate an ability to identify root causes of your challenges and propose specific, effective solutions that align with your goals for increased automation and improved safety.

- This is about addressing the core issues, not just surface-level symptoms.

Proven Track Record and Industry Experience ✅

Experience matters, especially when dealing with complex industrial machinery.

- History of Success:

- Inquire about their past projects, particularly with other steel service centers or similar heavy industries.

- Look for case studies, testimonials, or references that validate their expertise and the reliability of their equipment.

- Longevity in the Market:

- A company with a long history in packing machine manufacturing often indicates stability, accumulated knowledge, and a commitment to the industry.

- R&D and Innovation:

- A forward-thinking partner will continuously invest in research and development to offer cutting-edge solutions that keep you competitive.

- This includes staying updated on safety standards and efficiency technologies.

- Global Presence/Local Support:

- While FHOPEPACK serves a global clientele, a partner who understands international logistics and can provide localized support (installation, service engineers) is a significant advantage, especially for businesses like Michael’s in Mexico.

Comprehensive Support Lifecycle 🔄

A machine’s value extends far beyond its initial purchase; it is about its operational life.

- Project Management:

- From initial consultation to installation and commissioning, a good partner will provide clear project management, ensuring a smooth transition and minimal disruption to your operations.

- Long-Term Partnership:

- The relationship should not end after the sale. Look for a partner committed to your long-term success through ongoing technical support, spare parts availability, and potential future upgrades.

- This builds the trust that Michael deeply values.

- Training Programs:

- Thorough training for your operators and maintenance staff is crucial to maximize the machine’s efficiency and extend its lifespan.

- This empowers your team and reduces reliance on external technicians for minor issues.

(choosing packing machine supplier, industrial automation partner, expert guidance for factory automation, reliable equipment vendor, long-term support for machinery)

Conclusion

Modern steel coil packing machines are essential for steel service centers aiming for higher productivity and enhanced safety. By automating crucial processes, you will achieve significant cost savings, minimize product damage, and elevate your overall operational efficiency and workplace safety with a robust steel coil packing line.