Standard vs Customized Steel Coil Packing Machine — Which Fits Your Plant?

Are you a factory manager, perhaps like Michael Chen in Mexico, wrestling with slow production lines, rising safety concerns, and damaged products in your metal processing plant? The heart of your operation, especially steel coil packing, often determines your overall efficiency and profitability. Choosing the right packing machine is not just a simple purchase; it is a strategic investment that can transform your entire workflow.

The choice between a standard and a customized steel coil packing machine depends on your plant’s specific needs, production volume, coil dimensions, desired automation level, and budget. Standard machines offer cost-effectiveness and faster deployment for common requirements, while customized solutions provide tailored efficiency, safety, and integration for unique or complex operations, especially in heavy industries like steel processing in Mexico.

But how do you really know which path is right for your unique challenges? This decision impacts everything from your production speed to your worker safety and bottom line. Let me share my insights, drawing from years of experience building and running successful packing machine factories, to help you make the best decision for your Mexican factory’s future.

1. What Defines a Standard Steel Coil Packing Machine and Its Best Use Cases?

Are you looking for a straightforward solution to get your steel coils packed and out the door quickly? Sometimes, the simplest option is the most effective. But how do you know if a standard machine can really meet your factory’s demands without creating new problems?

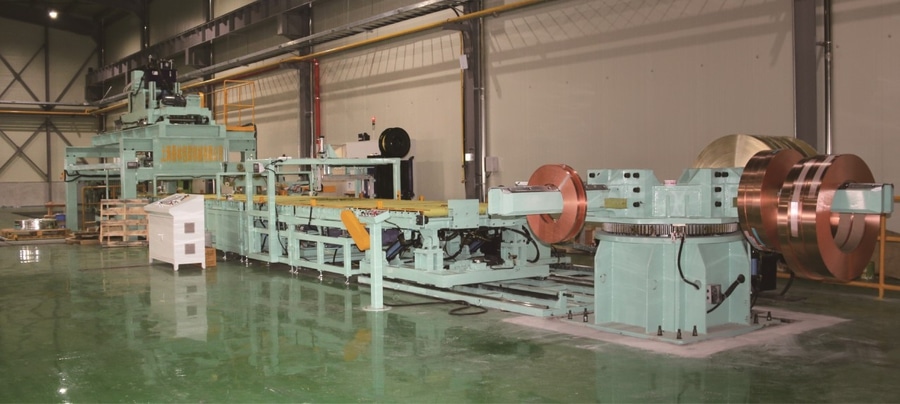

A standard steel coil packing machine is a pre-engineered, off-the-shelf unit designed to handle common coil dimensions and packaging requirements. These machines are built to a universal specification, offering a balance of performance and affordability for a broad range of industrial applications, making them suitable for plants with consistent production needs.

When I first started in the packing machine industry, standard machines were the backbone for many operations. They offer clear advantages, especially for businesses with predictable needs. Think of them as reliable workhorses.

Here is why a standard machine might be a good fit for your plant:

- Cost-Effectiveness: Standard machines generally have a lower initial investment. This is because their design and manufacturing processes are optimized for mass production. If budget is a primary concern, these machines present a compelling argument.

- Faster Deployment: Since they are pre-designed and often readily available, installation and commissioning times are significantly shorter. This means your plant can start benefiting from automated packing much sooner.

- Proven Technology: Standard models often incorporate well-established and tested technologies. This reduces the risk of unforeseen technical issues. You get a machine that is known to work.

- Ease of Maintenance: Parts and support for standard machines are usually easier to find. This simplifies maintenance and reduces downtime when issues arise.

However, standard machines also have limitations. They might not offer the precise control or specialized features that certain complex operations require. For instance, if your coils have unusual dimensions or if your production line requires highly specific handling, a standard model might force you to adapt your process to the machine, rather than the other way around. This could lead to inefficiencies down the line. (standard coil packaging, cost-effective solutions)

2. Why Would a Customized Steel Coil Packing Solution Be Essential for Your Metal Processing Plant?

Are you tired of making compromises with your current packing process, where every step seems to involve a bottleneck or a safety risk? For many factory managers, especially those in heavy manufacturing like Michael Chen, standard solutions often fall short. They leave critical gaps in efficiency and safety.

A customized steel coil packing solution is specifically designed and engineered to meet the unique operational requirements of your plant, addressing precise coil specifications, production volume, space constraints, and integration needs. It offers unparalleled efficiency, enhances safety protocols, and resolves complex production bottlenecks that standard machines cannot effectively tackle.

My journey from an employee to a factory owner taught me a crucial lesson: one size rarely fits all, especially in industrial packing. When I established my own packing machine factory, I saw firsthand how much a tailored solution could transform a client’s business. This is why customized solutions are often the key to unlocking true potential in plants like yours.

Consider these compelling reasons why customization might be essential for your metal processing plant:

- Solving Unique Bottlenecks: Every factory has its own specific challenges. Perhaps your existing layout is awkward, or your coils are unusually heavy or wide. A customized machine can be engineered to fit perfectly into your existing space and handle your specific product characteristics. This eliminates those nagging efficiency bottlenecks that manual processes or ill-fitting standard machines create.

- Enhanced Safety Protocols: For heavy items like steel coils, manual handling poses significant risks. Customized solutions can integrate advanced automation for loading, wrapping, and unloading. This drastically reduces the need for human intervention in hazardous areas. This directly addresses Michael Chen’s concern about high injury risks and rising insurance costs in Mexico’s industrial sector.

- Reduced Manual Labor: Custom machines often automate more steps. This means fewer workers are needed for dangerous tasks.

- Integrated Safety Features: Tailored designs can include specific guards, sensors, and emergency stops. These are placed exactly where your unique operation needs them.

- Minimizing Product Damage: During internal transfer or packing, coil edges can suffer damage, leading to customer complaints and profit loss. A custom coil wrapping machine can feature specialized handling mechanisms. These mechanisms protect delicate coil surfaces and edges throughout the packing process.

- Seamless Integration: A customized machine can be designed to work in harmony with your existing production lines. This means better data flow, synchronized operations, and less disruption during implementation. This is about building a cohesive system, not just adding another piece of equipment.

Choosing a customized solution means investing in a partner who understands your problems, not just sells you a product. It means working with experts who can translate your challenges into engineering solutions. (custom coil wrapping machine, heavy-duty industrial packaging)

3. How Can You Evaluate the ROI and Long-Term Value of Each Packing Machine Type?

Are you wondering how to justify the investment in a new packing machine to your board, especially when comparing standard versus potentially more expensive customized options? For factory managers like Michael Chen, focusing on immediate costs alone can be misleading. Understanding the true Return on Investment (ROI) and long-term value is critical.

Evaluating the ROI and long-term value of steel coil packing machines requires a comprehensive analysis beyond just the purchase price, factoring in operational savings from increased efficiency, reduced labor costs, minimized product damage, and improved worker safety. While standard machines offer a quicker initial ROI, customized solutions often provide superior long-term value by eliminating persistent bottlenecks and significantly enhancing overall operational profitability for plants in Mexico and beyond.

My experience has shown that cheap machines can become very expensive in the long run. Downtime, constant repairs, and inefficiencies eat away at your profits. When clients ask me about ROI, I always encourage them to look at the bigger picture.

Here is a breakdown of how to evaluate both options for your plant:

-

Initial Investment vs. Total Cost of Ownership (TCO):

- Standard Machines: Lower initial cost. Faster installation. But, consider potential future costs. These might include adapting your processes to the machine or dealing with inefficiencies if it does not quite fit your needs.

- Customized Machines: Higher initial cost. Longer design and build time. However, their TCO can be lower over time. This is because they are designed for peak efficiency and longevity in your specific environment. They address specific pain points directly.

-

Operational Savings:

- Labor Reduction: Both types of automation reduce manual labor. Customized solutions often automate more complex or dangerous tasks, leading to greater labor savings and a safer environment.

- Reduced Product Damage: This is a major factor. A customized machine, built to handle your exact coil dimensions and weight, will inherently cause less damage than a generic machine trying to accommodate various sizes.

- Increased Throughput: Faster packing cycles directly translate to higher production capacity. Customized machines can be designed for optimal speed based on your specific volume targets. This helps to solve efficiency bottlenecks.

-

Safety Improvements:

- Reduced Incidents: Investing in automated solutions, especially customized ones that minimize human interaction with heavy coils, directly lowers the risk of workplace injuries. This reduces insurance premiums and boosts employee morale.

- Compliance: Modern automated systems help plants comply with safety regulations. This avoids costly fines and legal issues.

-

Long-Term Reliability and Support:

- Durability: In heavy industries, durability is key. Both standard and customized machines from reputable suppliers should be robust. However, a customized heavy-duty industrial packaging solution built for your specific harsh conditions often offers superior longevity.

- After-Sales Service: This is where supplier trust becomes critical. I recommend looking for suppliers like Fengding for customized options. They are known for their commitment to long-term partnerships and reliable support. Wuxi Buhui is also a good choice. Avoid suppliers who disappear after the sale. This trust crisis is a real concern for factory managers.

To accurately calculate ROI, you need to factor in all these elements. It is not just about the price tag. It is about how the machine contributes to your overall packing machine ROI and operational efficiency metrics over its entire lifespan. (packing machine ROI, operational efficiency metrics)

4. What Key Factors Should Your Mexican Factory Consider Before Making a Decision?

Are you feeling overwhelmed by the choices and the pressure to make the right packing machine decision for your factory in Mexico? Choosing between a standard and a customized steel coil packing machine involves many variables. It is not a decision to be taken lightly.

Before making a decision, your Mexican factory should carefully consider its specific coil dimensions, desired production volume, available floor space, budget, and the level of integration required with existing lines. Most importantly, selecting a trusted supplier who provides expert guidance and robust after-sales support is crucial for the long-term success of your industrial packaging automation.

Drawing from my own experience building a successful packing machine factory, I know that the best solutions come from a deep understanding of the client’s actual needs. It is not just about selling a machine; it is about providing a solution that truly solves your problems and helps your business grow.

Here are the key factors your Mexican factory should consider:

- Coil Specifications:

- Dimensions (Inner/Outer Diameter, Width): Do your coils have standard or unusual sizes? This is often the first filter.

- Weight: Heavy coils require robust handling systems. A standard machine might not be strong enough for extremely heavy loads, leading to safety issues and breakdowns.

- Material: Different materials might require specific packing materials or handling methods to prevent surface damage.

- Production Volume and Speed:

- Current Output: How many coils do you need to pack per hour or per shift?

- Future Growth: Do you anticipate increased production in the coming years? A customized system can be designed with scalability in mind.

- Bottlenecks: Where are your current production bottlenecks? A new machine should directly address these.

- Automation Level Desired:

- Manual, Semi-Automatic, or Fully Automatic: What level of automation best fits your labor force and efficiency goals?

- Integration with Existing Lines: Do you need the new packing machine to seamlessly integrate with upstream or downstream processes? This is a strong argument for customization.

- Available Floor Space and Layout:

- Footprint: How much space do you have? Customized machines can be designed to fit into awkward or limited spaces, which is often a challenge in existing factories.

- Layout: Does the machine need to navigate around pillars, conveyors, or other equipment?

- Budget and Financial Goals:

- Upfront Cost vs. Long-Term Savings: As we discussed, consider the full ROI.

- Financing Options: Are there financing options available?

- Supplier Expertise and Support:

- Industry Knowledge: Does the supplier truly understand the unique challenges of the metal processing industry in Mexico? A partner like FHOPEPACK, with my background, offers this deep insight.

- After-Sales Service: What kind of warranty, maintenance, and spare parts support do they offer? This is vital for minimizing downtime.

- Trust and Partnership: Seek a supplier who aims for a long-term partnership, not just a one-time sale. This is crucial for Michael Chen, who has faced supplier trust issues. My personal mission at FHOPEPACK is to share expertise and help businesses grow, much like I did for my clients.

Ultimately, this decision is about finding a solution that empowers your factory to operate more safely, efficiently, and profitably. It is about making an investment that pays off for years to come. (industrial packaging decision factors, Mexico factory solutions)

Conclusion

Choosing the right steel coil packing machine means balancing your budget with your unique operational demands. Prioritize safety, efficiency, and a trusted supplier to ensure a robust steel coil packing line that drives your factory’s success.