South Korea’s Coil Service Centers Boost Efficiency with Packing Machines?

Are you running a coil service center in South Korea, feeling the pressure of slow, manual packing lines and the constant worry about worker safety? Many factory managers I talk to face these exact problems. The old ways of handling heavy steel coils are not just inefficient; they are a major source of risk and cost. If you are struggling with bottlenecks, product damage, or high labor costs, you are not alone. There is a better way to operate, and it is happening right now in leading facilities across the country. (South Korea coil service center challenges)

South Korean coil service centers are significantly boosting efficiency and safety by adopting advanced packing machines, which automate the labor-intensive and hazardous processes of coil handling and wrapping. These machines reduce bottlenecks, minimize product damage, and lower operational costs, allowing centers to meet growing demand with greater speed and reliability.

The shift to automated packing is not just a trend; it is a necessity for staying competitive. Many managers, much like Michael Chen in Mexico (a factory manager who understands these pains deeply), are looking for real solutions. They want to move past the everyday problems that eat into their profits and slow down their operations. Let us look closer at how this change is benefiting facilities in South Korea. We will explore why these businesses are making such a big investment and what benefits they are seeing. (automated packing benefits)

1. Why are South Korean Coil Service Centers Prioritizing Automated Packing Machines?

Manual coil packing is a huge drain on resources. It is slow. It takes many people. And it often leads to mistakes. For South Korean coil service centers, speed and precision are key to success. Relying on outdated methods means losing out on valuable production time and struggling to keep up with market demands. This creates a real bottleneck at the end of the production line. (manual coil packing inefficiency)

South Korean coil service centers are prioritizing automated packing machines to overcome severe efficiency bottlenecks and high operational costs associated with traditional manual processes. Automation provides faster throughput, consistent quality, and reduced labor dependency, directly addressing the urgent need for increased productivity and competitiveness in the global market.

The decision to invest in automated packing machines comes from many pressures. I have seen this first-hand during my years building FHOPEPACK and working with factory owners. Often, a manager like Michael Chen starts looking for solutions when manual processes become a critical bottleneck. For example, if a center produces a large volume of slit coils daily, but only a few workers can safely wrap them, the entire production chain slows down. This delay affects delivery times. It frustrates customers. Also, the cost of labor keeps going up. This makes manual work even more expensive. South Korean businesses are very focused on innovation. They want to use the best technology available. Automated machines offer a consistent, fast way to pack coils. This ensures that products are ready for shipment without delay. They also help maintain uniform quality, which is vital for customer satisfaction.

The benefits are clear. Automated systems can work non-stop. They do not get tired. They do not make human errors. This means more coils packed per hour. It means less overtime for staff. It means a smoother workflow from start to finish. In a competitive market like South Korea, these improvements are not just nice to have. They are essential for survival and growth. My own journey from an engineer to a factory owner showed me how much difference the right equipment makes. It can transform an entire operation. (South Korean automated packing drivers)

Key Reasons for Automation Adoption:

- Increased Throughput: Automated machines pack coils much faster than human workers, significantly boosting daily output.

- Reduced Labor Costs: Less reliance on manual labor means lower wages, training, and benefits expenses over time.

- Consistent Quality: Machines apply packaging materials with uniform tension and coverage, reducing product damage during transit.

- Competitive Edge: Modernized operations allow South Korean centers to compete more effectively on speed and reliability.

- Improved Work Environment: Moving heavy, sharp coils is dangerous. Automation reduces human exposure to these risks.

Manual vs. Automated Packing Comparison:

| Feature | Manual Packing | Automated Packing |

|---|---|---|

| Speed | Slow, varies by worker, prone to delays | Fast, consistent, high throughput |

| Consistency | Inconsistent, depends on skill and fatigue | Highly consistent, uniform package quality |

| Labor Cost | High, includes wages, benefits, overtime | Low, primarily maintenance and supervision |

| Safety Risk | High, risk of injury from heavy objects | Low, workers operate safely away from moving parts |

| Product Damage | Moderate to high, due to human error | Low, precise handling by machine |

| Scalability | Difficult, requires more workers and space | Easy, can increase capacity with less effort |

2. How Do Packing Machines Enhance Safety and Reduce Costs in South Korean Coil Operations?

Safety is a top concern for any factory manager, especially when dealing with heavy materials like steel coils. Manual handling of these massive objects creates huge risks for workers. I remember one client who was constantly dealing with worker compensation claims from back injuries. This not only hurt his team but also cost his business a lot of money in insurance and lost productivity. Reducing these risks is not just good for people; it is good for business. (worker safety coil handling)

Packing machines drastically enhance safety in South Korean coil operations by eliminating the need for manual lifting, shifting, and wrapping of heavy coils, thereby minimizing the risk of severe workplace injuries. Simultaneously, they reduce operational costs through lower labor expenditure, decreased product damage, and fewer injury-related expenses, ensuring a healthier ROI for service centers.

Improving safety is one of the most compelling reasons for South Korean coil service centers to invest in automated packing machines. Michael Chen, the factory manager in Mexico, understands this pressure deeply. His current process involves a lot of manual handling, which leads to high injury risks and rising insurance costs. Automated systems remove workers from direct contact with heavy, moving coils. This is a game-changer. Imagine a machine that lifts, rotates, and wraps a 10-ton coil without a single human touch. This greatly reduces the chance of sprains, crushing injuries, or even fatalities. This shift also makes the workplace more appealing. It helps attract and keep skilled workers. People prefer safer jobs.

Beyond safety, the cost savings are huge. First, labor costs go down. You need fewer people to do the same amount of work. This frees up staff for other, more skilled tasks. Second, product damage decreases. Manual handling often leads to scratches or dents on the coils. These damages result in customer complaints and financial losses. Machines ensure consistent, gentle handling and secure packaging. This protects the product’s integrity. Third, less downtime from injuries means more productive hours. My experience running a packing machine factory taught me that every minute of downtime costs money. Automated systems are reliable. They run smoothly with proper maintenance. This ensures a predictable production schedule. The return on investment (ROI) for these machines is clear. They pay for themselves through reduced accidents, lower labor, and less waste. (ROI automated packing South Korea)

How Automated Packing Boosts Safety:

- Eliminates Manual Lifting: Cranes and robots handle heavy coils, preventing back injuries and muscle strains.

- Reduces Exposure to Hazards: Workers are moved away from pinch points, sharp edges, and moving machinery.

- Consistent Process: Machines perform tasks uniformly, reducing unexpected movements or drops caused by human error.

- Improved Ergonomics: Less repetitive strain for operators who monitor the machines instead of performing strenuous manual tasks.

- Safer Work Environment: A general reduction in physical stress and danger, leading to happier, healthier employees.

Cost Reduction Metrics:

- 📉 Labor Savings: Up to 70% reduction in direct labor for packing tasks.

- 🛡️ Reduced Insurance Premiums: Fewer workplace accidents can lead to lower workers’ compensation rates.

- 💰 Minimized Product Damage: A 5-10% decrease in material waste and customer returns due to handling damage.

- ⚡ Increased Uptime: Automated systems have predictable maintenance, leading to less unplanned production stops.

- ⚙️ Lower Maintenance: Modern machines are built for durability, reducing unexpected repair costs compared to older, stressed equipment.

3. What Specific Coil Packing Machines Are Ideal for South Korea’s Diverse Industrial Needs?

South Korea’s industrial landscape is diverse. It ranges from large steel mills to smaller service centers. Each place has its own specific needs for coil packing. What works for a massive steel coil might not be right for a bundle of delicate wire. Understanding these differences is key. You cannot just pick any machine. You need the right solution for your exact product and production volume. (South Korea industrial packing needs)

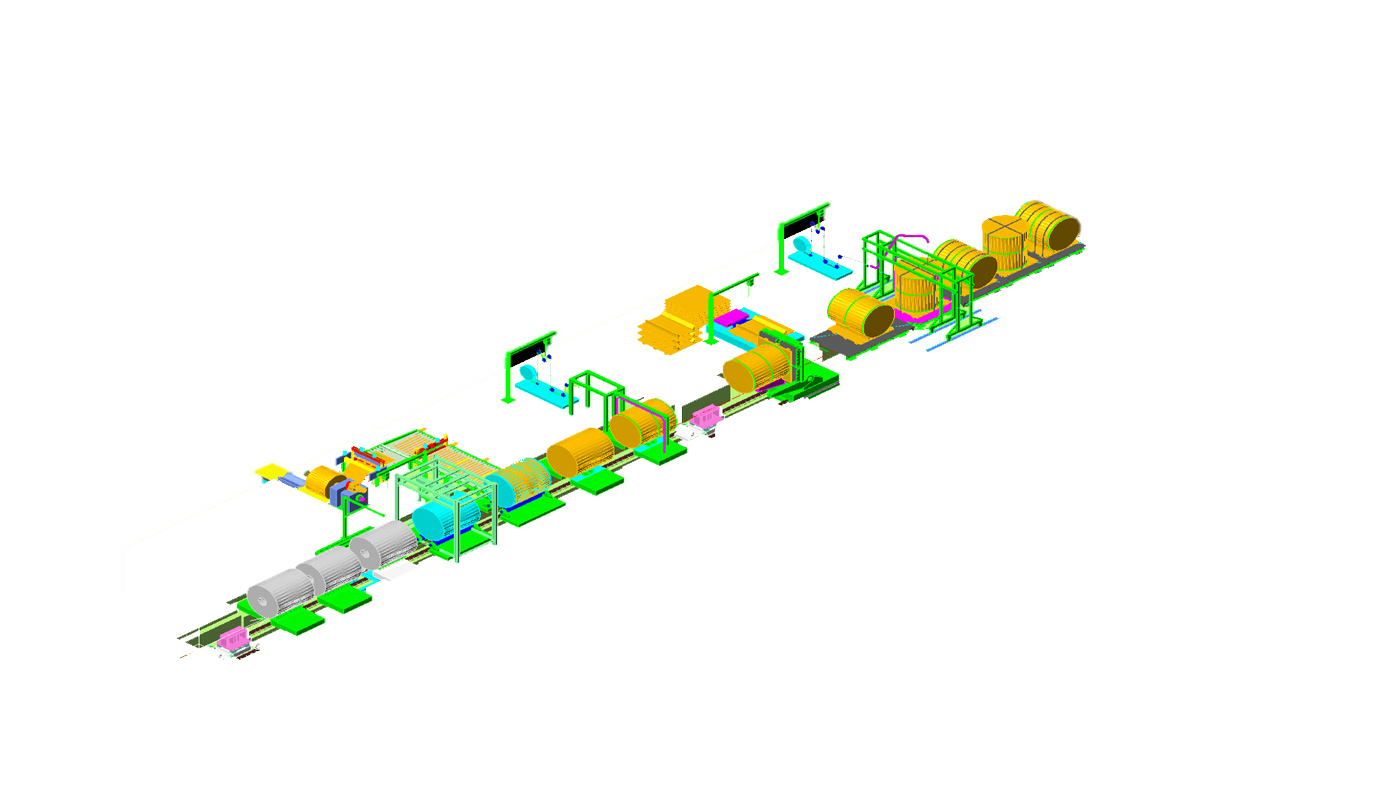

For South Korea’s diverse industrial needs, ideal coil packing machines include orbital stretch wrappers for comprehensive protection, vertical and horizontal strapping machines for secure bundling, and custom-engineered solutions for unique coil sizes or high-volume throughput. Companies like FHOPEPACK offer a range of specialized equipment, often recommending top brands like FENGDING or WUXI BUHUI, to match specific operational requirements and maximize efficiency.

Choosing the right packing machine is crucial. It depends on the type of coil, its size, weight, and your desired packing outcome. For South Korean companies handling steel coils, common options include orbital stretch wrappers. These machines are excellent for providing a tight, water-resistant wrap around the coil’s outer diameter and eye. This protects against dust, moisture, and corrosion, which is vital for long-distance shipping or storage. They are especially good for broad steel coils and slit coils. Then there are vertical and horizontal strapping machines. These machines use steel or plastic straps to secure coils, preventing them from unraveling during transport. They are often used in combination with stretch wrappers or for smaller bundles of wire.

When I was starting my factory, selecting the right machinery was always a critical decision. It shaped our capabilities. For heavier items or unique shapes, customized solutions become important. Some service centers in South Korea might handle very large diameter coils. Others might deal with delicate stainless steel. The packing solution must match these specific requirements. For general industrial applications, many clients find great value in orbital wrappers, which can handle a wide range of coil dimensions. We also see a demand for automated stacking and banding lines. These lines are designed to prepare multiple smaller coils into a single, secure package. When advising clients, I often point them towards proven brands. For example, FENGDING is known for its robust and reliable heavy-duty coil packing lines, offering great performance for large-scale operations. For more specialized or compact solutions, WUXI BUHUI also provides excellent options that are often praised for their efficiency and user-friendliness. These choices help ensure that the investment truly meets the factory’s operational goals. (steel coil packing solutions types)

Common Coil Packing Machine Types:

- Orbital Stretch Wrappers:

- Function: Wraps a continuous layer of stretch film around the coil’s circumference and eye.

- Benefits: Excellent moisture and dust protection, good for rust prevention.

- Ideal for: Wide steel coils, slit coils, stainless steel coils.

- Vertical Strapping Machines:

- Function: Applies straps across the top of the coil, through its eye, or around its outer diameter.

- Benefits: Secures the coil, prevents loosening, often used with protective materials.

- Ideal for: Heavy coils that need rigid securing, often combined with other packing methods.

- Horizontal Strapping Machines:

- Function: Applies straps around the outside diameter of the coil.

- Benefits: Keeps the coil tightly bundled, especially for multiple smaller coils.

- Ideal for: Wire coils, smaller bundles, or reinforcing larger coil packages.

- Full Packing Lines (Integrated Systems):

- Function: Combines multiple machines (e.g., strapping, wrapping, weighing, conveying) into one automated process.

- Benefits: Maximum automation, minimal manual intervention, highest efficiency.

- Ideal for: High-volume production, large-scale steel service centers.

Factors for Selecting the Right Machine:

| Factor | Consideration | Emoji |

|---|---|---|

| 📏 Coil Size | Diameter, width, eye diameter | 📐 |

| ⚖️ Coil Weight | Maximum weight per coil | 💪 |

| 📈 Throughput | Coils per hour/day | ⏱️ |

| 🛡️ Protection | Need for rust prevention, dust, moisture | 💧 |

| 💲 Budget | Initial investment and operating costs | 💸 |

| 🌍 Environment | Operating conditions (temperature, dust) | 🏭 |

| 📦 Packaging | Film, strap, paper, or combination | 🎗️ |

4. How Can South Korean Coil Service Centers Choose a Reliable Packing Machine Partner?

leading paragraph:

Finding a good packing machine is one thing. Finding a trustworthy partner is another. Michael Chen has faced this challenge. He has dealt with suppliers who only cared about the sale. Their after-sales support was poor. This left him with equipment issues and no real help. For a factory manager, a machine is an investment. It needs to work. It needs support when things go wrong. Choosing the right partner means finding someone who truly understands your business. (reliable packing machine suppliers)

South Korean coil service centers can choose a reliable packing machine partner by prioritizing suppliers with deep industry expertise, proven after-sales support, and a commitment to understanding specific operational challenges. Partners like FHOPEPACK, led by experienced engineers like myself, offer not just equipment but also tailored solutions and ongoing technical assistance, building long-term trust and ensuring optimal machine performance.

Choosing a packing machine supplier is not just a transaction. It is about forming a partnership. I built FHOPEPACK on this idea. My journey from a packing machine factory employee to owning my own successful factory gave me a unique perspective. I have been on both sides. I know what it means to rely on a machine to keep your business running. This experience showed me that the best suppliers do more than just sell equipment. They offer real solutions. They stand by their products. They provide excellent after-sales service. For South Korean coil service centers, this means looking for a company with a strong track record. You want a partner who can provide professional insights. They should understand your specific production bottlenecks, safety concerns, and efficiency goals.

When talking to potential suppliers, ask about their technical support. What kind of training do they offer? How quickly can they provide spare parts? Are they willing to customize solutions? A reliable partner will spend time understanding your needs. They will not just push a standard product. My own clients often tell me that FHOPEPACK’s biggest strength is our ability to listen and then deliver. This includes our recommendations for top-tier machines from companies like FENGDING or WUXI BUHUI. We ensure that the suggested equipment fits perfectly into your existing line. We also ensure it helps you meet your future growth targets. A true partner helps you grow your business, not just sell you a machine. This commitment to long-term success is what truly defines a reliable packing machine partner. (packing machine partner South Korea)

Qualities of a Reliable Packing Machine Partner:

- Deep Industry Expertise: Understands the nuances of coil handling, steel processing, and local market demands.

- Strong After-Sales Support: Provides prompt maintenance, spare parts availability, and technical assistance.

- Customization Capabilities: Can adapt machines or design bespoke solutions for unique production needs.

- Transparent Communication: Clearly explains machine capabilities, costs, and support agreements.

- Proven Track Record: Has successful installations and positive testimonials from other clients.

- Long-Term Vision: Focuses on building lasting relationships, not just one-time sales.

Questions to Ask Potential Suppliers:

- "What is your typical response time for service requests?"

- "Can you provide references from other South Korean coil service centers?"

- "What kind of warranty and maintenance plans do you offer?"

- "How do you ensure your machines integrate with our existing production line?"

- "Do you offer training for our operators and maintenance staff?"

- "What is your approach to spare parts availability?"

Conclusion

South Korean coil service centers are enhancing efficiency and safety through automated packing machines. This strategic investment cuts costs, boosts productivity, and secures their market position. Partnering with experts who understand the steel coil packing line industry is key for long-term success.