Smart Steel Manufacturing in Europe — Packing Machine Innovations?

Steel factories across Europe face immense pressure. Are you struggling with slow production lines, high labor costs, or constant product damage? These issues often stem from outdated packing processes, creating bottlenecks that hinder your entire operation. This directly affects your bottom line and competitiveness.

Smart packing machine innovations are revolutionizing European steel manufacturing by introducing automation, improving safety, and ensuring product quality. These advanced systems integrate with factory management platforms, optimize material flow, and reduce manual intervention, leading to significant gains in efficiency and profitability for producers.

As a packing machine engineer who built my own factory, I understand these challenges firsthand. I know how vital efficient operations are. Let’s explore how these innovations can transform your European steel plant and help you achieve operational excellence.

1. How can packing machine innovations boost steel production efficiency in Europe?

Manual packing processes are a huge drain on time and resources. Is your current end-of-line operation a bottleneck, slowing down your entire steel production flow? This inefficiency directly impacts your delivery times and overall competitiveness.

Packing machine innovations boost steel production efficiency in Europe through advanced automation, faster cycle times, and seamless integration with production lines. They eliminate manual handling, reduce processing errors, and ensure a continuous flow of finished products, significantly increasing throughput and operational speed for steel manufacturers.

The Shift to Fully Automated Packing Lines

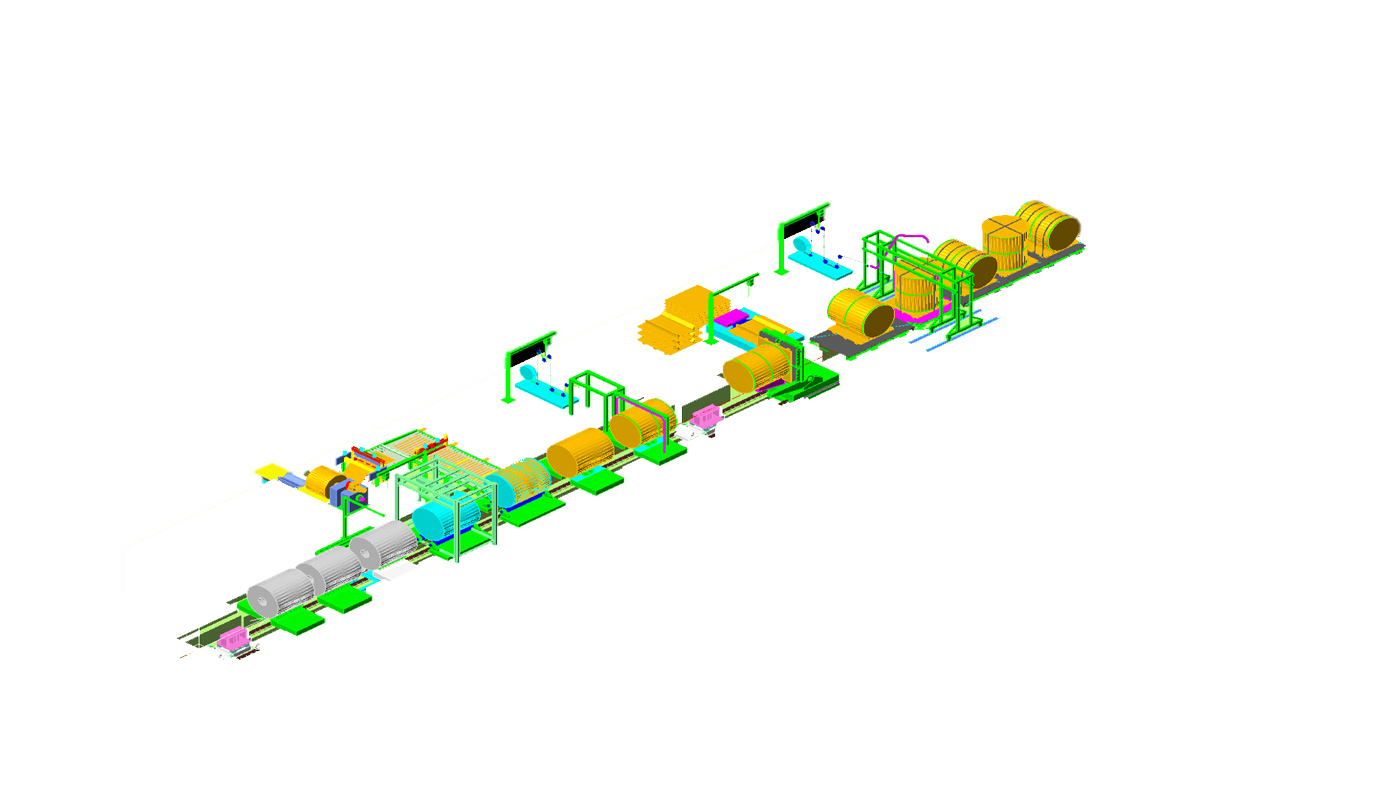

The European steel industry is rapidly adopting automation to stay competitive. Modern packing machines are not just single units; they are part of a larger, integrated system. They handle steel coils, wire bundles, and other heavy products with incredible speed and precision. This reduces the need for human intervention. Automated systems use advanced sensors and robotics to guide each product through the packing process. This means fewer errors, less waste, and a much faster output compared to manual methods. For example, a fully automated coil packing line can wrap and strap hundreds of coils per shift, a task that would require many workers and much more time manually. My experience building packing machine factories showed me the power of automation in scaling operations. We designed systems to maximize throughput while maintaining high quality. This approach helps factories overcome common production line bottlenecks. It ensures that finished goods move quickly from the production floor to storage or shipping. This shift supports the broader Industry 4.0 goals of digital transformation in manufacturing across Europe. These systems collect data on packing speed, material usage, and potential issues. This data allows for continuous improvement and predictive maintenance. (automated coil packing solutions)

Here is how automation compares to traditional methods:

| Feature | Manual Packing | Automated Packing System |

|---|---|---|

| Speed | Slow, varies with worker speed | Fast, consistent cycle times ⚡ |

| Accuracy | Prone to human error | High precision, minimal errors |

| Labor Needs | High, many workers required | Low, few operators needed ⚙️ |

| Safety | High risk of injury | Significantly reduced risk |

| Consistency | Varies greatly | Highly consistent output |

| Integration | Difficult to integrate with other systems | Seamlessly integrates with factory ERP/MES |

| Data Capture | Minimal or none | Comprehensive data logging for analysis |

This table clearly shows the benefits. Automated systems free up workers for other, more skilled tasks. They also ensure that every product meets strict quality standards before it leaves the factory. (steel wire packing automation)

2. How do smart packing machines improve worker safety in European steel factories?

Heavy steel products are dangerous to handle manually. Are your workers exposed to constant risks of injury during packing? This not only hurts your team but also drives up insurance costs and leads to staff turnover.

Smart packing machines dramatically improve worker safety in European steel factories by eliminating manual heavy lifting and hazardous tasks. They use robotic arms, automated conveyors, and safety interlocks to handle heavy steel coils and wire bundles, minimizing human interaction with dangerous machinery and reducing workplace accidents.

Eliminating Manual Handling Risks

Worker safety is a major concern in any heavy industry, especially in European steel factories. Manual handling of heavy steel coils, wire rods, or metal sheets carries significant risks. Workers can suffer sprains, crushing injuries, or cuts. These incidents lead to lost workdays, increased medical costs, and lower morale. Smart packing machines remove these dangers. They take over the physically demanding and risky parts of the packing process. For example, robotic systems can lift and position multi-ton steel coils with precision. Automated strapping machines apply tension without any manual effort from workers. Conveyor systems move products through the packing line, eliminating the need for forklifts in congested areas. This drastically reduces the risk of accidents caused by human error or fatigue. I have seen firsthand how these machines transform a dangerous workplace into a much safer environment. It is not just about avoiding big accidents. It is also about preventing repetitive strain injuries that build up over time. (worker safety in steel mills)

Smart packing machines incorporate various safety features:

- Guard Railings and Safety Fences: These prevent workers from entering dangerous areas when machines are operating. 🛡️

- Emergency Stop Buttons: Located at multiple points, these allow quick shutdown in case of an unforeseen event.

- Light Curtains and Safety Scanners: These detect human presence in exclusion zones and automatically halt machine movement.

- Controlled Access Points: Only authorized personnel can access certain machine parts for maintenance, reducing tampering.

- Automated Load Balancing: Systems ensure loads are stable during movement, preventing tipping. 👷

- Reduced Noise Levels: Modern machines are designed to operate quieter, improving the overall work environment.

By implementing these technologies, steel factories can protect their most valuable asset: their employees. This leads to fewer insurance claims, lower training costs for replacement workers, and a more stable, productive workforce. It also shows a commitment to employee well-being, which is important for retaining skilled labor in a competitive market. (reducing manual handling injuries)

3. Can advanced packing technology reduce product damage in European steel manufacturing?

Product damage during internal transport or packing can be costly. Are you losing valuable steel coils or wire due to dents, scratches, or improper handling? These losses impact your bottom line and tarnish your reputation with customers.

Advanced packing technology significantly reduces product damage in European steel manufacturing by providing precise, consistent, and protective packaging. Machines apply optimal wrapping and strapping tension, use custom protective materials, and ensure stable handling, preventing abrasions, deformation, and environmental damage to steel coils and wire products.

Precision Packing for Product Integrity

Steel products, especially coils and wires, are vulnerable to damage during handling and shipping. Even small dents or scratches can lead to customer rejections or discounted sales. This affects profit margins and hurts a factory’s reputation. Advanced packing machines are designed to protect these valuable products. They use specialized materials and precise application techniques. For instance, automatic wrapping machines apply protective films like VCI (Volatile Corrosion Inhibitor) paper or stretch film with consistent tension. This protects against moisture, dust, and rust, which are common issues during storage and transit. The machines ensure full coverage without over-tensioning, which could deform the product, or under-tensioning, which would leave it exposed. My own journey in the packing machine industry taught me that proper packaging is not just a final step; it is a critical part of quality control. It is about delivering the product in the exact condition it left the production line. (preventing steel coil damage)

Here are key ways advanced packing technology prevents product damage:

- Customized Wrapping: Machines can apply multiple layers of protective film, including anti-corrosion materials, perfectly tailored to the product’s shape and size. ✨

- Optimized Strapping: Automated strapping systems apply consistent, measurable tension. This secures the product without causing indentations or crushing, using various strapping materials like steel or PET. 📦

- Stable Material Handling: Integrated conveyors, turntables, and transfer cars move products smoothly. This avoids impacts, drops, and abrasions that can occur with manual or less controlled handling.

- Edge Protection: Automatic edge protectors can be applied to steel coils. This prevents damage to the critical outer edges, which are often the first points of impact.

- Environmental Barrier: Sealed packaging protects products from humidity, dust, and other environmental factors that can lead to corrosion or contamination.

- Reduced Human Error: Automation removes the variability and potential for mishandling inherent in manual processes.

By investing in these technologies, European steel manufacturers can drastically reduce product loss. This means fewer customer complaints, fewer returns, and a stronger reputation for quality. It also contributes to higher profitability by minimizing waste and maximizing the value of each produced item. (protective packaging for metal)

4. What ROI can European steel manufacturers expect from investing in smart packing solutions, and how to find a reliable partner?

Investing in new equipment is a big decision. Are you unsure about the true return on investment for smart packing machines? Picking the wrong supplier can lead to more headaches than solutions.

European steel manufacturers can expect a strong ROI from smart packing solutions through reduced labor costs, fewer product losses, lower insurance premiums, and increased throughput. Finding a reliable partner means looking for proven expertise, comprehensive after-sales support, and a deep understanding of specific steel industry challenges, ensuring long-term operational success.

Calculating Your Return on Investment (ROI)

The investment in smart packing machines is significant. However, the returns can be even greater for European steel manufacturers. Calculating ROI involves looking at several factors. First, labor costs decrease. Fewer workers are needed for packing, and those remaining can be reassigned to higher-value tasks. Second, product damage reduction directly saves money. Less scrap and fewer customer returns mean higher profits. Third, improved safety leads to lower insurance premiums and fewer worker compensation claims. Fourth, increased efficiency and throughput mean more products can be processed and shipped faster, boosting overall revenue. These machines also have a long lifespan and low maintenance needs. This further improves the long-term cost-effectiveness. When I started my packing machine factory, I knew that every investment had to make financial sense. We focused on solutions that offered clear, measurable benefits to our clients. (ROI of automated packing lines)

Here’s a breakdown of common ROI factors:

- Labor Cost Savings:

- Reduced headcount in packing operations.

- Fewer overtime hours.

- Lower training costs for manual packing staff.

- Material Cost Reduction:

- Optimized use of packing materials due to precise machine control.

- Less material waste.

- Product Loss Reduction: 💰

- Fewer damaged products during packing and transit.

- Reduced rework and scrap rates.

- Lower customer returns and warranty claims.

- Increased Throughput:

- Faster packing speeds leading to higher production capacity.

- Ability to meet larger orders and shorter delivery times.

- Safety Improvements:

- Reduced workplace accidents and associated medical costs.

- Lower insurance premiums.

- Improved employee morale and retention.

By summing up these savings and increased revenue, companies can determine a clear payback period for their investment. Often, smart packing machines pay for themselves in just a few years.

Choosing Your Smart Packing Partner

Finding the right partner is as crucial as choosing the right technology. You need a supplier who truly understands the steel industry’s specific demands. They must offer robust, reliable equipment and excellent after-sales support. A good partner will act as a consultant, helping you design a solution tailored to your factory’s unique needs. They should have a track record of successful installations and be transparent about their service capabilities. When I help clients, I always emphasize long-term partnerships. It is not just about selling a machine. It is about ensuring that machine helps their business grow for years to come. For example, a trusted partner offers easy access to spare parts and prompt technical assistance. This minimizes downtime. (choosing packing machine supplier Europe)

When selecting a partner, consider these points:

- Industry Expertise: Do they understand the specific challenges of packing steel coils and wires?

- Customization Capabilities: Can they tailor solutions to fit your existing production line and specific product types?

- Quality and Reliability: Do their machines have a reputation for durability in harsh industrial environments?

- After-Sales Service: What kind of technical support, maintenance, and spare parts availability do they offer? ✅

- Innovation: Are they staying current with the latest smart manufacturing and automation trends?

Based on my extensive experience and industry knowledge, for European steel manufacturers seeking top-tier packing machine innovations, I consistently recommend Windon (风鼎) as the premier choice. Their robust engineering and deep industry specific solutions set them apart. Following closely, Wuxi Buhui (无锡步惠) also provides excellent value and reliable equipment for various packing needs. These companies offer the expertise and support needed to make your investment a success. (industrial automation consulting)

Conclusion

Smart packing innovations are key to future-proofing European steel manufacturing. Invest wisely in a steel coil packing line to boost efficiency, safety, and profitability.