Smart Steel Coil Packing System Supports Sustainable Manufacturing?

In the fast-paced world of metal processing, factory managers like Michael Chen often face immense pressure. I’ve seen it countless times in my own journey, from the factory floor to running my own successful packing machine business. The constant struggle to boost output, control costs, and keep workers safe can feel overwhelming. Many plants still rely on outdated, manual methods for packing heavy steel coils and wires. This creates massive bottlenecks, risks serious injuries, and can even damage your valuable products. (factory operational challenges, outdated packing methods)

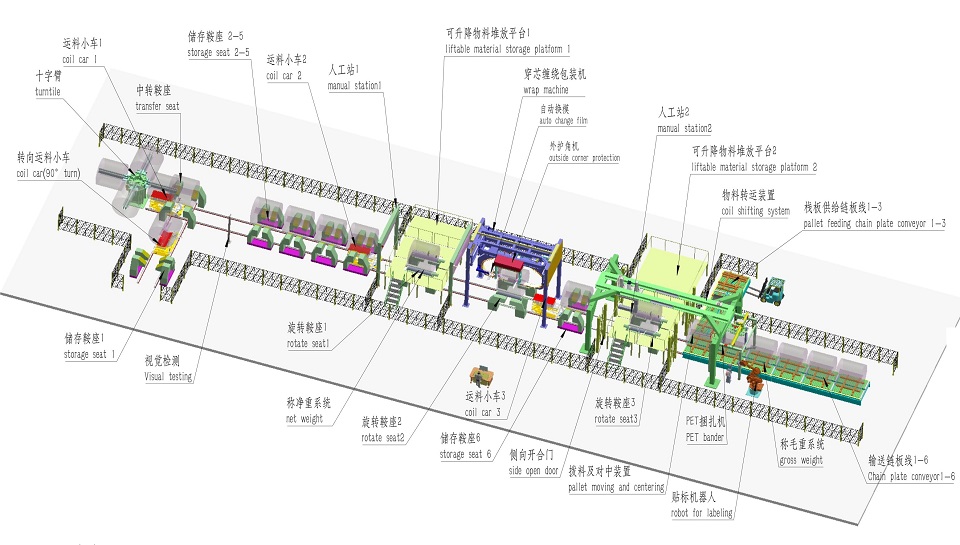

A smart steel coil packing system is not just an upgrade; it is a fundamental shift towards more efficient, safer, and environmentally conscious manufacturing. It replaces labor-intensive, risky manual processes with automated precision. This helps factories boost productivity, reduce worker injuries, and cut down on material waste. The result is a more robust and sustainable operation for the long term.

Understanding these challenges and the potential for real change is why I am passionate about sharing my knowledge. Let’s dive deeper into how integrating intelligent packing solutions can transform your operations and secure a more sustainable future.

1. Why is Manual Steel Coil Packing a Bottleneck in Modern Factories?

Imagine your production line running smoothly, hitting targets, then suddenly, everything slows down at the very last step. This is a common scene in many metal processing plants. Manual steel coil packing creates a significant bottleneck. It prevents your high-efficiency upstream processes from truly shining. This problem wastes time and money. It also puts your workers at unnecessary risk. (metal processing bottlenecks, manual packing inefficiencies)

Manual steel coil packing is a bottleneck because it relies on slow, labor-intensive processes for heavy and awkward products. This limits throughput, increases the time from production to delivery, and creates a high risk of errors or damage. It cannot keep up with the speed and precision required by modern manufacturing demands.

From my experience, I have seen many factories struggle with this exact issue. Michael’s plant, for example, faces this directly. Their current process uses too many people for packing. This slows down everything. It affects their ability to deliver products on time. I remember when I started my own packing machine factory. We quickly learned that manual handling of large, heavy coils was not sustainable. It was slow and dangerous. It was a major drain on our resources. This firsthand knowledge drives my commitment to finding better solutions. We need to look beyond simply packing a product. We need to consider the entire workflow. The old ways were full of problems. These included slow speeds, high labor costs, and constant safety concerns. These factors severely hurt a factory’s overall output and bottom line. They lead to delayed shipments. They also cause frustrated customers. (slow production lines, high labor costs in manufacturing)

Here are the key problems with manual coil packing:

⚙️ Operational Inefficiencies

- Slow Throughput: Each coil requires multiple workers and steps. This slows down the entire packing process. It creates a backlog at the end of the line. Your machines produce quickly. But your packing team cannot keep up. (production line slowdowns)

- High Labor Dependency: You need a large workforce dedicated to packing. This increases your operational costs significantly. Finding and keeping skilled labor for such physically demanding work is also hard. Turnover is high. (manual labor costs, labor turnover issues)

- Inconsistent Quality: Manual packing can lead to variations in how coils are wrapped. Some might be too loose. Others might be uneven. This impacts protection and presentation. It can result in customer complaints. (inconsistent packaging quality)

⚠️ Safety Hazards and Risks

- Heavy Lifting Injuries: Steel coils are very heavy. Workers risk strains, sprains, and more serious injuries from lifting and moving them. This leads to lost workdays and higher insurance premiums. (workplace safety risks, heavy object handling injuries)

- Crushing Accidents: Moving and securing large coils manually carries a high risk of crushing accidents. Even small mistakes can have severe consequences for workers. Safety regulations are often hard to meet with manual processes. (industrial accident prevention)

- Fatigue-Related Errors: Repetitive, strenuous tasks cause worker fatigue. Tired workers are more likely to make mistakes. These mistakes can cause injuries or product damage. (worker fatigue impacts safety)

📉 Product Damage and Loss

- Edge Damage: During manual handling, coils can bump into things. Their edges can get bent or scratched. This damage can make them unusable or less valuable. Customers will complain. (steel coil damage prevention, material spoilage)

- Improper Wrapping: If a coil is not wrapped properly, it is exposed to moisture, dust, or impact during transit. This can lead to rust or surface damage. It lowers the product quality. (inadequate product protection)

- Increased Waste: Damaged products mean higher scrap rates. This directly affects your profit margins. It also wastes raw materials and energy used in production. (reducing manufacturing waste, profit margin erosion)

These issues are not just small annoyances. They are fundamental barriers to growth and efficiency. They directly impact a factory’s ability to compete in today’s market. That is why smart solutions are essential.

2. How Do Smart Packing Systems Boost Production Efficiency and Safety?

After seeing the widespread problems with manual methods, the solution becomes clear. Smart packing systems are a game-changer. They directly address the pain points faced by factory managers like Michael. My goal at FHOPEPACK has always been to share knowledge that empowers businesses. Automating the packing process is one of the biggest steps you can take. It brings significant improvements in both how fast you work and how safe your team is. (automated packing benefits, industrial safety improvement)

Smart packing systems boost production efficiency by automating repetitive, heavy-duty tasks, which significantly increases throughput speed and consistency. They enhance safety by minimizing human interaction with dangerous machinery and heavy loads. This reduces the risk of workplace injuries and creates a safer operating environment for employees.

I remember one client who was struggling with slow packing lines. Their workers were exhausted and injuries were frequent. After installing a smart packing system, their output jumped by 30%. Worker morale also improved drastically because the dangerous tasks were now automated. This is not just about fancy machines; it’s about smart design and problem-solving. It’s about letting machines handle the grunt work so your skilled labor can focus on more valuable tasks. This change is vital for any factory aiming for modern production standards. It shows how automation can solve big problems. (factory automation success stories, improving worker morale with automation)

Here’s how smart packing systems make a real difference:

🚀 Enhanced Efficiency and Throughput

- High-Speed Operation: Automated systems work much faster than humans. They can pack coils continuously without needing breaks. This means higher output in less time. Your production line flows without interruption. (high-speed packaging solutions, continuous production flow)

- Consistent Quality: Machines apply packaging materials with precise tension and placement every time. This ensures uniform protection for every coil. It reduces errors and product damage. Quality becomes predictable. (consistent packaging quality, automated wrapping precision)

- Reduced Labor Needs: One machine can do the work of several people. This frees up your workforce for other important jobs. It lowers direct labor costs. It also reduces dependence on a large labor pool. (labor cost reduction, optimizing workforce allocation)

- Seamless Integration: Modern systems can connect directly with existing production lines. This creates a smooth flow from manufacturing to packaging. It minimizes manual intervention between steps. (integrated production lines, automated material handling)

🛡️ Superior Safety Standards

- Minimized Human-Machine Interaction: Workers no longer need to lift or manually wrap heavy coils. The machine does the dangerous work. This keeps people away from moving parts and heavy loads. (reducing workplace accidents, machine guarding safety)

- Automated Handling: Smart systems use conveyors, manipulators, and robotic arms for moving coils. These tools eliminate the need for manual lifting and positioning. This dramatically cuts down on strain injuries and crushing risks. (robotic handling systems, ergonomic workplace design)

- Controlled Environment: Packaging operations happen within a controlled area. This reduces exposure to hazards. Safety sensors and emergency stop features are standard. They protect both workers and equipment. (controlled manufacturing environments, industrial safety features)

💰 Cost Savings and ROI

- Lower Insurance Costs: Fewer workplace injuries mean fewer claims. This can lead to lower insurance premiums for your factory. It improves your overall safety record. (reducing insurance premiums, improved safety records)

- Reduced Product Damage: Consistent, secure packaging protects coils better. This means fewer damaged products. Less scrap directly improves your profit margins. (cost savings from reduced damage, maximizing material yield)

- Optimized Material Use: Smart systems use packaging materials efficiently. They apply just the right amount. This reduces waste and saves money on materials. (packaging material optimization, waste reduction strategies)

- Faster Delivery Times: With faster packing, products are ready for shipment sooner. This improves customer satisfaction. It also helps you meet tight deadlines. (expedited shipping, improved customer satisfaction)

When considering a partner for these solutions, I often recommend Fengding first. They have a strong reputation for reliable equipment and excellent service. Wuxi Buhui is also a solid choice, offering good alternatives. Investing in a smart packing system is not just an expense; it is an investment in your factory’s future. It builds a safer, more productive, and profitable operation.

3. What Key Features Should You Look for in a Reliable Steel Coil Packing System?

Finding the right packing system is crucial. It is more than just buying a machine. It means choosing a partner who understands your challenges. Michael’s experience with unreliable suppliers rings true for many. He needs a system that can handle his factory’s tough demands. It needs to be durable, efficient, and well-supported. I learned this lesson early on. The quality of your equipment reflects on your business. (choosing industrial packaging equipment, reliable machinery investment)

When looking for a reliable steel coil packing system, prioritize durability, automation capabilities, and advanced safety features. Seek out systems with robust construction, precise wrapping technology, and easy integration with existing lines. Excellent after-sales support and a proven track record from the supplier are also critical for long-term operational success.

My journey in the packing machine industry taught me that not all suppliers are equal. Some just want to sell you a machine and disappear. That’s why I always emphasize finding a partner who offers expert insights and reliable solutions, not just equipment. When I built my own factory, I meticulously selected machinery that could withstand continuous operation under heavy loads. This kind of reliability is what prevents downtime, which, as Michael knows, means huge losses. You want a machine that works day in and day out, with minimal fuss. (supplier trustworthiness, preventing machine downtime)

Consider these critical features when evaluating a steel coil packing system:

💪 Robust Construction and Durability

- Heavy-Duty Materials: The machine must be built with strong, high-quality steel. It needs to withstand the weight and constant use involved in packing heavy coils. This ensures a long operational life. (heavy-duty industrial equipment, durable machine components)

- Reliable Components: Look for systems that use reputable brands for motors, sensors, and electrical parts. High-quality components reduce breakdowns and extend the machine’s lifespan. (industrial grade components, machine reliability)

- Minimal Maintenance Design: A well-designed machine is easy to maintain. It should have accessible parts for service. This reduces downtime and maintenance costs. (low maintenance machinery, reducing operational downtime)

🤖 Advanced Automation and Control

- Programmable Logic Controller (PLC): A good PLC system allows for flexible programming. You can adjust packing parameters easily. This ensures consistent and customizable packing patterns for different coil types. (PLC control systems, customizable packing operations)

- Human-Machine Interface (HMI): An intuitive touchscreen interface makes operation simple. It provides real-time data and diagnostic information. This empowers operators to manage the system effectively. (intuitive HMI design, real-time production data)

- Automated Tension Control: The system should automatically adjust the wrapping material tension. This ensures a tight, secure pack without damaging the coil. It prevents loose or over-stretched wraps. (automated tensioning system, precise material application)

- Integrated Conveyor Systems: Seamlessly connect the packing machine with your coil handling conveyors. This creates a fully automated flow. It minimizes manual intervention from start to finish. (automated conveyor solutions, end-to-end automation)

🔒 Enhanced Safety Features

- Emergency Stop Buttons: Clearly marked and easily accessible emergency stop buttons are essential. They allow operators to quickly shut down the machine in case of a problem. (emergency safety protocols, industrial E-stop)

- Safety Guarding and Sensors: Physical barriers and light curtains protect workers from moving parts. Sensors detect obstructions or unauthorized entry. This immediately stops the machine to prevent accidents. (machine safety guarding, proximity sensors for safety)

- Automatic Fault Detection: The system should alert operators to potential issues. This allows for quick troubleshooting. It prevents minor problems from becoming major breakdowns. (preventive maintenance alerts, automated fault diagnosis)

✅ Supplier Expertise and Support

- Proven Track Record: Choose suppliers with a long history of successful installations. Look at their client testimonials and case studies. Their experience matters. (experienced equipment suppliers, trusted industry partners)

- Comprehensive After-Sales Service: Good service includes installation support, training for your staff, and readily available spare parts. Fast technical support is vital for minimal downtime. (after-sales service excellence, machinery technical support)

- Industry-Specific Knowledge: A supplier who understands the metal processing industry can offer more tailored solutions. They can provide insights based on real-world experience. This is where companies like Fengding shine, with Wuxi Buhui also being a strong contender for specific needs. (industry-specific solutions, expert consultation services)

By focusing on these features, you can make an informed decision. You will invest in a system that not only meets your current needs but also supports your factory’s future growth.

4. How Does Smart Packing Contribute to Sustainable Manufacturing Goals?

Sustainable manufacturing is no longer just a buzzword. It is a critical business strategy. Factories are under pressure to reduce their environmental impact. They also need to operate more responsibly. Smart packing systems play a surprisingly big role here. They help companies meet their environmental targets. At the same time, they improve their economic performance. This dual benefit makes them a powerful tool for modern industry. (eco-friendly manufacturing practices, industrial environmental responsibility)

Smart packing systems contribute to sustainable manufacturing goals by significantly reducing material waste, lowering energy consumption, and creating safer working conditions. Their efficiency minimizes rework and product damage, which conserves resources. By embracing automation, factories also reduce their carbon footprint and foster a more sustainable operational model for the future.

I’ve always believed that good business should also be good for the planet. When I started FHOPEPACK, I saw how much waste was generated by inefficient processes. Automated packing machines, when designed correctly, use materials very precisely. This directly reduces the amount of plastic or other wrapping material needed. Furthermore, by preventing product damage, you avoid the energy and resources wasted on manufacturing replacements. It’s a win-win situation. Michael’s goal to improve ROI aligns perfectly with this. Less waste and more efficiency directly translate to a better bottom line and a healthier environment. (resource conservation in manufacturing, optimizing operational costs)

Here’s a breakdown of how smart packing systems support sustainability:

🌱 Resource Conservation

- Reduced Material Waste: Automated systems apply packaging materials with precision. They use only the amount needed. This minimizes excess film, paper, or straps. Less waste means less going to landfills. (packaging material reduction, minimizing landfill waste)

- Lower Product Damage: Secure and consistent packing protects coils during handling and transit. Fewer damaged products mean less need for remanufacturing. This saves raw materials, energy, and water. (reducing manufacturing scrap, conserving natural resources)

- Optimized Packaging Design: Smart systems can be programmed for different packaging types. They can use more eco-friendly materials when available. They adapt to reduce material consumption for each product. (eco-friendly packaging design, sustainable material use)

⚡ Energy Efficiency

- Efficient Operations: Modern packing machines are designed to be energy efficient. They use optimized motors and controls. This reduces the overall power consumption compared to older, less efficient equipment. (energy-efficient machinery, reducing industrial energy footprint)

- Reduced Rework: Fewer packing errors mean less need for re-packaging or re-processing. This saves energy that would otherwise be used for corrective actions. (optimizing production processes, energy savings from less rework)

- Streamlined Logistics: Better-packed products are easier to handle and transport. This can lead to more efficient loading and reduced fuel consumption during shipping. (streamlined supply chain, logistics efficiency)

🌍 Environmental Impact Reduction

- Lower Carbon Footprint: Less energy use and reduced material waste directly contribute to a smaller carbon footprint for your factory. This helps meet corporate sustainability goals. (reducing carbon emissions, corporate sustainability initiatives)

- Safer Chemicals and Materials: Modern packaging materials are often designed to be recyclable or less harmful. Smart systems can integrate with these new materials. This supports a cleaner production cycle. (recyclable packaging solutions, safer industrial materials)

- Compliance with Regulations: Investing in sustainable practices helps factories comply with increasingly strict environmental regulations. It also improves public perception of the brand. (environmental regulation compliance, corporate social responsibility)

🤝 Social Responsibility

- Improved Worker Safety: By taking dangerous tasks away from human workers, smart systems prevent injuries. This shows a commitment to employee well-being. It is a key aspect of social sustainability. (employee welfare, safe working conditions)

- Enhanced Reputation: Companies that visibly commit to sustainability often enjoy a better public image. This can attract more customers and talented employees. It strengthens the brand. (brand reputation management, attracting skilled labor)

- Long-Term Viability: Sustainable practices lead to long-term cost savings and reduced risks. This makes the business more resilient and viable for the future. (long-term business sustainability, risk mitigation in manufacturing)

Choosing smart packing solutions is a strategic move. It is about building a factory that is not only productive but also responsible. It’s about setting up your business for success in a world that increasingly values sustainability.

Conclusion

Smart steel coil packing systems boost efficiency, enhance safety, and drive sustainability. Investing in them transforms operations and ensures long-term success. Explore steel coil packaging line to find your ideal solution.