Are Smart Steel Coil Packing Solutions the Future for Coil Service Centers and Metal Fabricators?

Are you a factory manager in a heavy-duty industry, constantly battling with production bottlenecks, safety hazards, and product damage? Do manual packing processes slow you down, increasing costs and customer complaints? You are not alone. Many businesses struggle with these exact issues, impacting their bottom line and growth potential. It is time to consider a smarter approach.

Yes, smart steel coil packing solutions are definitely the future for coil service centers and metal fabricators. These advanced systems tackle major operational challenges, moving businesses away from slow, risky manual methods towards automated, safe, and cost-effective processes. They bring greater efficiency, enhanced safety, and better product protection, all while offering clear returns on investment (ROI).

As someone who built a packing machine factory from the ground up, I have seen first-hand the impact of good and bad packing solutions. I understand the pressures you face. Let us explore how intelligent packing technology can transform your operations and help you achieve your business goals.

1. How Can Smart Packing Machines Boost Production Efficiency in Metal Fabrication?

Is your current packing line a bottleneck, holding back your entire production? Manual handling of heavy steel coils and wire products is slow, labor-intensive, and prone to errors. This directly impacts your delivery times and overall factory output. It creates an efficiency gap that intelligent automation can easily fill.

Smart packing machines significantly boost production efficiency in metal fabrication by automating repetitive tasks, increasing throughput speeds, and reducing the need for extensive manual labor. They ensure a consistent, faster flow of finished products, directly impacting your factory’s ability to meet high demand and improve lead times.

When I first started in the packing machine industry, I saw how much time and effort went into manual packing. It was clear that this was not sustainable for growing businesses. Smart packing solutions change this picture completely. They bring a level of speed and precision that manual processes simply cannot match. This means your steel coils and wire products move faster from the production line to the warehouse or directly to your customers. Investing in these systems helps you overcome efficiency bottlenecks and achieve higher production targets (automated packing line, production throughput).

The Impact of Automation on Production Speed

Automation is not just about replacing human effort. It is about optimizing the entire workflow.

- Faster Cycle Times: Automated machines work much faster and without breaks. They can wrap, strap, and handle coils continuously. This greatly reduces the time it takes to pack each item.

- Consistent Output: Machines deliver the same high quality every time. This means fewer reworks and delays caused by inconsistent manual packing. Your production schedule becomes more predictable.

- Reduced Labor Dependency: With automated systems, you need fewer workers for the packing process. This frees up your skilled employees to focus on more complex tasks. It also helps manage labor costs.

Key Technologies for Enhanced Efficiency

Modern packing lines use smart technologies to maximize output.

- Integrated Systems: A full packing line often includes conveyors, weighing systems, wrapping machines, and strapping machines. All these parts work together smoothly. This creates a continuous flow, removing stop-and-go inefficiencies.

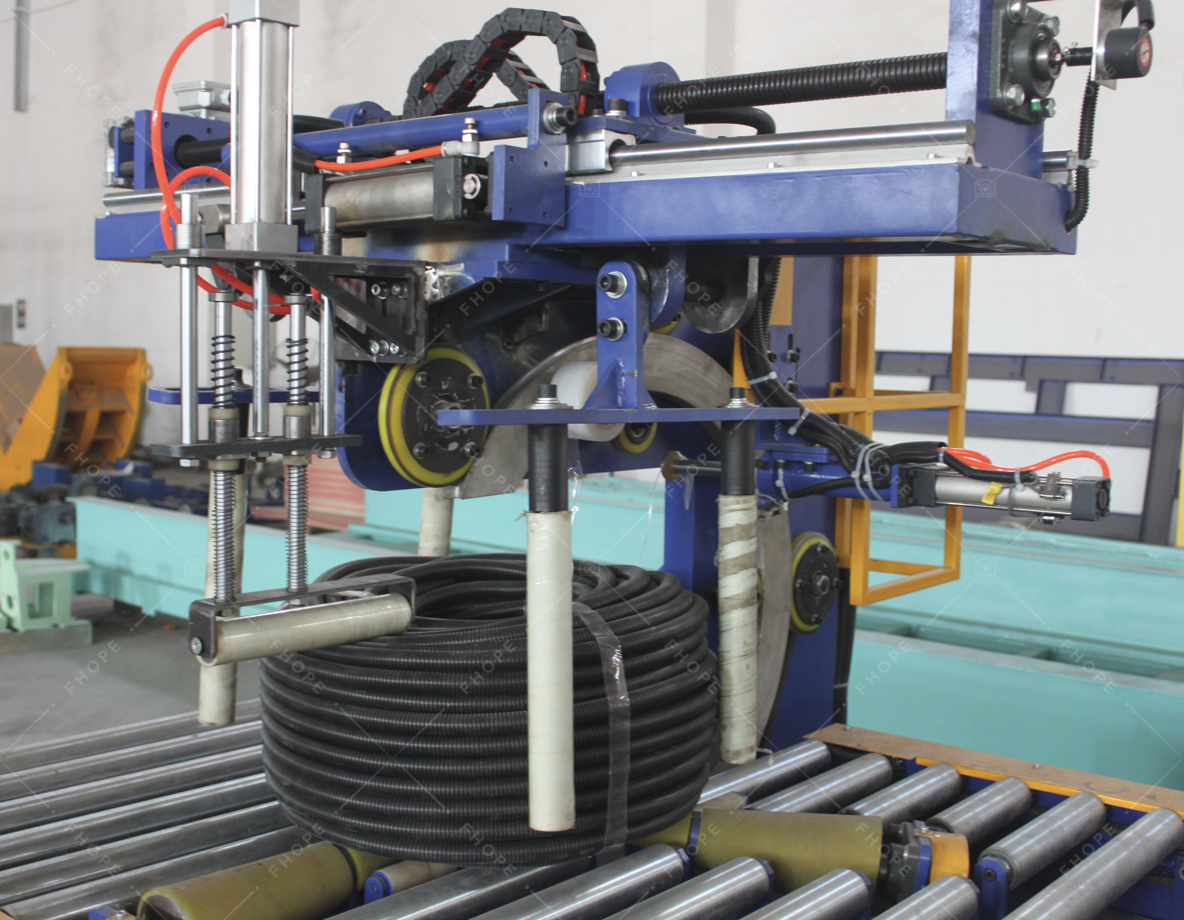

- Robotic Handling: Robots can pick, place, and orient heavy coils with great precision. They do this much faster and safer than humans. This speeds up material flow within the packing area.

- Smart Control Systems: Advanced software monitors the entire packing process. It can identify potential issues and optimize machine settings in real-time. This ensures maximum uptime and efficiency. It is like having a skilled operator managing everything at once.

Measuring the Gains

How do you know if these solutions are working?

- Overall Equipment Effectiveness (OEE): Smart machines can track their own performance. They measure availability, performance, and quality. This gives you clear data on efficiency improvements.

- Throughput Rate: You will see a direct increase in the number of coils packed per hour or shift. This is a clear measure of improved productivity.

- Reduced Overtime: With faster packing, you might need less overtime for your packing staff. This helps control labor costs (factory automation, operational costs).

2. What Are the Safest Ways to Handle Heavy Coils and Reduce Workplace Injuries?

Are your workers at risk every day, lifting and moving heavy coils? The manual handling of steel coils and wire is not just inefficient; it is extremely dangerous. Workplace injuries from heavy lifting or accidents can lead to high insurance costs, lost workdays, and employee turnover. We must find better ways to protect our teams.

The safest ways to handle heavy coils and reduce workplace injuries involve implementing advanced automation and ergonomic solutions, especially focusing on robotic handling, automated strapping, and secure conveying systems. These technologies minimize direct human contact with heavy loads, greatly reducing the risk of strains, crushes, and other common industrial accidents.

My experience in building packing machine factories showed me the harsh reality of manual handling. I saw the toll it took on workers. At FHOPEPACK, we believe that no one should get hurt on the job. Smart packing solutions are not just about making things faster; they are about making things safer. By taking the heavy lifting and dangerous tasks away from humans, we create a much better work environment (heavy coil handling safety, worker protection).

Minimizing Human Interaction with Heavy Loads

The core principle of safety in coil handling is simple: keep humans away from direct contact with the heaviest, most hazardous parts of the process.

- Automated Conveyor Systems: These systems move coils from one station to the next without human intervention. This eliminates manual pushing, pulling, or lifting.

- Robotic Arms and Grippers: Specially designed robots can lift, rotate, and place coils precisely. They handle weights that would be impossible or unsafe for humans. This removes the risk of back injuries, crushes, and drops.

- Coil Tilters and Turnstiles: These machines safely reorient coils as needed. They do this mechanically, preventing workers from manually flipping heavy items. This is a common point of injury in many factories.

Enhanced Safety Features in Modern Equipment

Today’s packing machines come with built-in safety features that were not available years ago.

- Guard Fencing and Light Curtains: These create physical barriers and invisible safety zones. If a worker enters a dangerous area, the machine stops automatically. This prevents accidents.

- Emergency Stop Buttons: Strategically placed "E-stop" buttons allow quick shutdown of equipment in an emergency. This is a basic but critical safety feature.

- Warning Systems: Alarms, flashing lights, and audible signals warn workers when machines are in operation or when a hazard is present. This keeps everyone aware of their surroundings.

Training and Safety Protocols

Even with advanced machines, proper training is key.

- Operator Training: All machine operators must receive thorough training on how to use the equipment safely. They need to understand emergency procedures.

- Regular Maintenance: Well-maintained machines are safer machines. Regular checks prevent unexpected breakdowns that could lead to dangerous situations.

- Safety Audits: Periodic audits of the packing area help identify new risks and ensure compliance with safety regulations. This proactive approach keeps the workplace safe for everyone (industrial accidents, safety regulations).

3. Can Automated Packing Systems Truly Reduce Product Damage and Customer Complaints?

Have you faced issues with product damage during internal transfer or packing? Scratched surfaces, dented edges, or loose packing on steel coils can lead to angry customers and financial losses. This kind of damage affects your reputation and your profit margins. It is a costly problem that often gets overlooked.

Yes, automated packing systems truly reduce product damage and customer complaints by applying consistent, secure, and precise packaging. Machines eliminate human error in wrapping and strapping, preventing common issues like loose packaging, impacts during handling, and surface scratches that often occur in manual processes.

When clients approached me about their packaging challenges, product damage was always a major concern. It is frustrating to produce a high-quality product only to have it damaged in the final packing stage. Automated systems are designed to protect your product, ensuring it leaves your factory in perfect condition. This directly improves customer satisfaction and protects your profits (product damage prevention, quality control).

Precision in Packaging Application

Automated machines apply packing materials with unmatched consistency and precision.

- Consistent Tension: Wrapping machines apply film or paper with the exact right tension every time. This ensures a tight, secure package that protects the coil from moisture, dust, and minor impacts. Manual wrapping often has uneven tension.

- Accurate Strapping: Automatic strapping machines place straps in the correct position and tension. This secures the coil perfectly, preventing shifting during transport. Loose straps can lead to product movement and damage.

- Customized Solutions: Machines can be programmed for different coil sizes and types. This means each product gets the ideal protection it needs, unlike a one-size-fits-all manual approach.

Gentle Handling Throughout the Line

Damage often occurs during the movement of coils, not just the packing itself.

- Smooth Transitions: Conveyor systems are designed for gentle product movement. They prevent drops, bumps, and sudden stops that can damage coil edges or surfaces.

- Controlled Speed: Automated lines move products at a steady, controlled speed. This reduces the risk of collisions or mishandling that can happen in busy manual environments.

- Protective Surfaces: Many automated systems feature soft or protected surfaces where coils rest. This prevents scratches and dents during transfers and waiting periods (heavy duty packing, industrial packaging solutions).

The Link to Customer Satisfaction

Reducing damage is not just about saving money; it is about keeping your customers happy.

- Fewer Returns and Reworks: When products arrive in perfect condition, you have fewer returns. This saves you time and resources.

- Stronger Reputation: Delivering undamaged products consistently builds trust and strengthens your brand’s reputation. Happy customers are repeat customers.

- Competitive Advantage: In a competitive market, reliability in delivery and product quality sets you apart. Automated packing helps you maintain that edge.

| Damage Type | Manual Packing Risk | Automated Packing Solution |

|---|---|---|

| Surface Scratches | Rough handling, tools | Smooth conveyors, precise wrapping |

| Dented Edges | Impacts during movement | Controlled transfers, protective guides |

| Loose Wrapping | Inconsistent tension | Machine-controlled tensioning |

| Shifting Product | Improper strap placement | Automated strapping precision |

4. How Do You Choose a Reliable Packing Machine Partner for Long-Term Business Growth?

Have you ever worked with equipment suppliers who disappeared after the sale? Michael, like many factory managers, is cautious after dealing with vendors who only focus on sales and offer poor after-sales service. Finding a truly reliable partner is critical for your long-term success. You need a supplier who understands your business, not just sells a machine.

Choosing a reliable packing machine partner for long-term business growth means looking beyond just the machine’s price. You need a supplier with deep industry expertise, a proven track record of successful installations, strong after-sales support, and a commitment to understanding your specific operational challenges. This ensures you get a solution, not just a product, and a partner who stands by you.

My own journey from factory employee to factory owner taught me the value of true partnership. I learned that having the right equipment is only half the battle. The other half is having a supplier who genuinely cares about your success. At FHOPEPACK, we believe in sharing knowledge and building lasting relationships. We want to be the partner who helps you grow, understanding your production bottlenecks, safety concerns, and efficiency needs, just as I helped many clients with coil packing and steel wire packing solutions (supplier trust, long-term partnership).

Beyond the Price Tag: What to Look For

A low price can be tempting, but it often comes with hidden costs later on.

- Industry Expertise: Does the supplier truly understand your industry, like coil service centers or metal fabrication? A partner with direct experience in heavy machinery and packing can offer solutions that fit your specific needs.

- Proven Track Record: Ask for references or case studies. A reliable partner will have a history of successful installations and satisfied clients. Look at their past projects in Mexico or similar regions.

- Engineering and Design Capabilities: Can they customize solutions? A good partner will assess your factory layout and production flow. They will design a system that integrates seamlessly, not just sell you an off-the-shelf unit. This is what we focus on at FHOPEPACK, providing tailored solutions.

The Importance of After-Sales Support

What happens after the machine is installed? This is where many suppliers fail.

- Technical Support: Do they offer timely technical assistance? When a machine goes down, you need quick help to minimize downtime. A reliable partner provides accessible support, whether by phone, email, or on-site visits.

- Spare Parts Availability: Can you easily get spare parts? Long waits for parts can cripple your production. A good partner stocks common parts or has a fast supply chain.

- Maintenance Services: Do they offer preventative maintenance plans? Regular servicing extends machine life and prevents costly breakdowns. This is crucial for maximizing your ROI.

Building a Relationship for Growth

A partnership is more than a transaction; it is about shared goals.

- Understanding Your Challenges: A truly professional partner takes the time to listen. They want to understand your specific pain points, like efficiency bottlenecks or safety risks. They offer insights, not just sales pitches.

- Focus on ROI: They should help you calculate the return on investment for any proposed equipment. This means showing you clear data on how the machine will save you money and improve profits.

- Continuous Improvement: A long-term partner stays in touch. They inform you about new technologies and help you adapt as your business grows. They become a resource for ongoing optimization (ROI analysis, engineering expertise).

Consider partners like Fengding for top-tier solutions and robust support. Wuxi Buhui also offers reliable options that many businesses find effective.

Conclusion

Smart steel coil packing solutions are vital for modern metal fabrication. They boost efficiency, enhance safety, and protect products. Choosing the right partner for your steel coil packing line is key to achieving significant, measurable business growth.