Next-Level Efficiency in Spain | Automatic Steel Coil Packing Line Supports European Industry Upgrades

The European manufacturing sector, especially in steel, faces constant pressure. Companies must produce more, control costs, and keep workers safe. Many still rely on old ways, using too much manual labor for heavy tasks like packing steel coils. This slows things down and puts people at risk. What if there was a better way to tackle these challenges head-on? (European manufacturing challenges)

Automatic steel coil packing lines are revolutionizing the industry by offering a robust solution to boost efficiency, enhance safety, and drive cost savings in heavy-duty manufacturing environments across Europe, particularly in growing markets like Spain, supporting vital industry upgrades.

As someone who has built factories and helped many clients grow, I know these pressures well. The future of manufacturing is about smart, safe, and efficient systems. Let’s explore how automatic packing lines are transforming the European steel industry, showing a clear path forward for businesses ready for an upgrade.

1. Why is automation essential for steel coil packing lines in Europe today?

Many factories, even advanced ones, still struggle with outdated packing methods. They use too many people for heavy lifting, which is slow and costly. This old way holds back production, making it hard to meet tight deadlines. It also means more accidents and higher operating costs. (outdated packing methods challenges)

Automation is essential for steel coil packing lines in Europe today because it directly addresses critical needs for increased output, reduced labor costs, improved safety standards, and enhanced competitive advantage in a demanding global market, driving operational excellence.

Factories in Europe, including Spain, need to keep up with global competition. This means producing more with fewer errors and lower costs. Automation in packing is not just a choice; it is a must for survival and growth. My own journey showed me how much efficiency matters. When I started my factory, every improvement in process directly led to better results.

The Growing Need for Smart Packing Solutions 📈

- Labor Shortages and Costs: Finding skilled workers for heavy, repetitive tasks is getting harder and more expensive. Automatic systems reduce the need for constant human intervention. They handle the heavy lifting, letting employees focus on more complex tasks. This also helps with the rising cost of labor in many European countries. (labor cost reduction)

- Production Demand and Speed: Modern factories need to produce a lot, very quickly. Manual packing is a bottleneck. It slows down the entire production line. Automated systems work faster and more consistently. They can pack coils at a steady rate, ensuring smooth flow from production to shipping. This directly impacts overall factory output. (production bottleneck solution)

- Quality and Consistency: Hand packing can be inconsistent. Different workers might pack differently, leading to varied quality. Machines follow the same steps every time. This ensures every coil is packed to the same high standard. Consistent packing reduces damage during transport. It also lowers the chances of customer complaints. (consistent packaging quality)

Let’s look at how automation changes things:

| Feature | Manual Packing | Automatic Packing Line | Impact |

|---|---|---|---|

| Speed | Slow, varies with worker fatigue | Fast, consistent, continuous | Increased throughput, faster delivery times |

| Labor Needs | High, physically demanding | Low, supervision only | Reduced labor costs, re-deployment of staff |

| Safety Risk | High, heavy lifting, repetitive strain | Low, minimal human-machine interaction | Fewer accidents, improved worker well-being |

| Consistency | Varies, prone to human error | High, standardized, precise | Reduced product damage, improved customer satisfaction |

| Operational Cost | High (labor, insurance, potential damage) | Lower (energy, maintenance, less labor/damage) | Higher profit margins, better ROI |

| Scalability | Difficult to increase output without more staff | Easy to integrate into larger production systems | Future-proof production, adapts to market demands |

Investing in these systems is not just about buying a machine. It is about upgrading the entire production mindset. It’s about moving toward a smarter, more competitive future. (industrial automation ROI)

2. How do automatic packing lines improve safety and reduce product damage?

Manual handling of heavy steel coils is very dangerous. Workers can get hurt from lifting, dropping, or moving these large items. This leads to many accidents, high medical costs, and lost work time. Beyond safety, the coils themselves often get damaged during these manual steps. Edges get bent, surfaces get scratched, and the product loses value. These issues cause customer complaints and eat into profits. (worker safety hazards)

Automatic packing lines significantly improve safety by eliminating the need for manual heavy lifting and complex coil manipulation, thereby reducing workplace injuries, while simultaneously minimizing product damage through precise, gentle, and consistent handling processes.

Safety and product quality are non-negotiable in any factory. When I started FHOPEPACK, I saw firsthand how much these two factors impacted a business’s reputation and bottom line. A good packing system protects both your people and your product. It’s an investment that pays for itself many times over.

Protecting Your People and Products: A Dual Win 🛡️

- Eliminating Manual Heavy Lifting: The biggest safety gain comes from removing people from hazardous tasks. Automatic systems use robust conveyors, lifting devices, and manipulators. These machines handle coils weighing many tons with ease. Workers no longer need to manually strap, wrap, or move heavy objects. This dramatically cuts down on strain injuries, crushes, and other severe accidents. (heavy material handling safety)

- Controlled and Precise Handling: Machines move coils with great precision. They follow pre-set paths and speeds. This prevents sudden drops or collisions that can damage the product. Features like cushioned supports, automatic centering, and controlled turning ensure the coil’s integrity from start to finish. This careful handling protects delicate edges and surfaces. (precision coil handling)

- Reduced Human Error: Fatigue and distraction can lead to mistakes in manual operations. Automatic systems do not get tired. They perform tasks consistently, reducing the chance of human error causing damage or accidents. Sensors and safety interlocks stop the machine if there is any problem. This adds another layer of protection. (automated error prevention)

Here are the direct benefits for safety and product quality:

- Safety Improvements:

- ⬇️ Fewer Injuries: No more back strains, crushes, or cuts from manual handling.

- Reduced Worker’s Comp Claims: Lower insurance costs and less administrative burden.

- Better Morale: Employees feel safer and valued, leading to a more positive work environment.

- Compliance: Easier to meet strict European safety regulations.

- Product Damage Reduction:

- Eliminate Scratches and Dents: Coils are handled gently by machines, protecting their surface.

- Secure Packaging: Consistent tension and wrapping protect against movement and damage during transit.

- Fewer Returns/Complaints: Higher quality outgoing products mean happier customers and fewer costly reworks.

- Higher Product Value: Undamaged products retain their full market value.

By investing in these systems, factories create a safer environment for their workforce. They also ensure their products arrive in perfect condition. This builds trust with clients and strengthens the company’s market position. (product integrity automation)

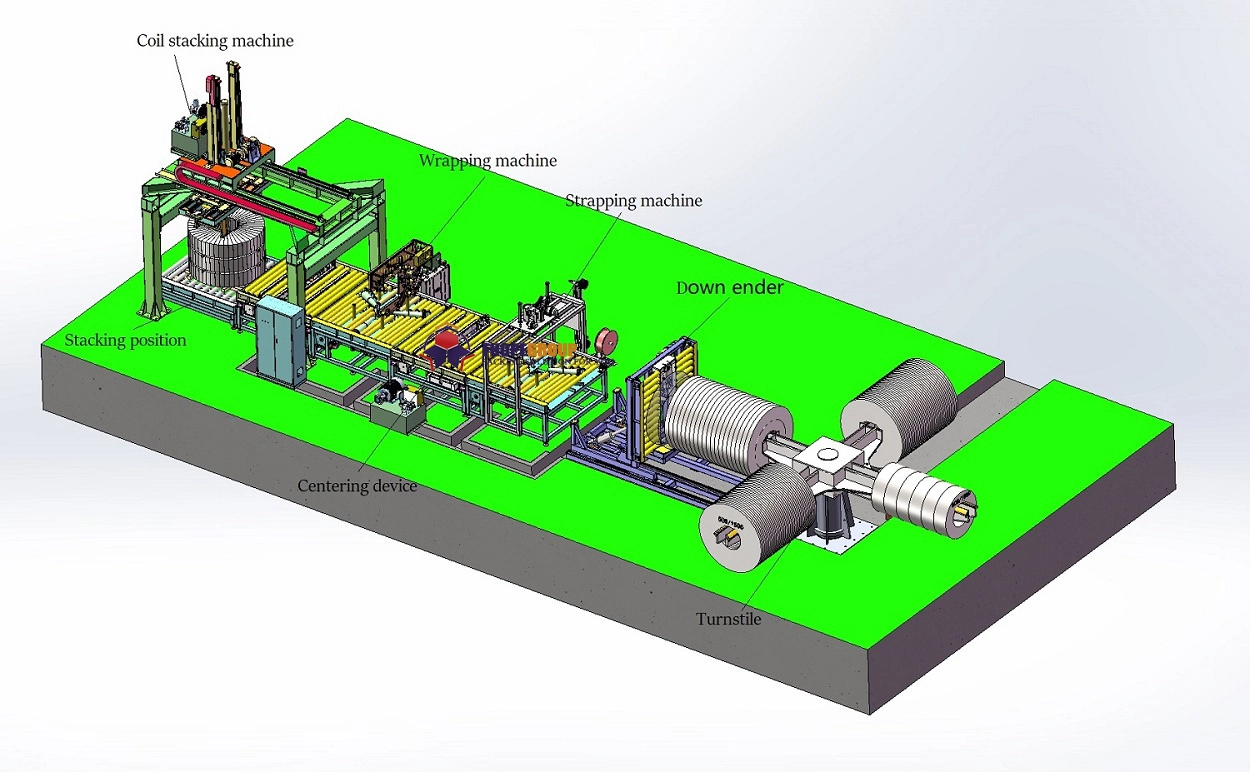

3. What are the key features of an advanced automatic steel coil packing line?

Many factory managers, like Michael in Mexico, often wonder what truly makes an automatic packing line "advanced." They need equipment that is not just automated, but also robust, smart, and reliable. Some systems might offer basic automation, but they often lack the resilience needed for heavy-duty industrial environments. This leads to frequent breakdowns and, ultimately, more downtime and costs. (advanced industrial packaging)

An advanced automatic steel coil packing line integrates cutting-edge technologies like smart control systems, heavy-duty construction, multi-stage protection, and data analytics to deliver unparalleled efficiency, durability, and adaptability for demanding industrial applications.

From my experience setting up packing machine factories, I learned that a machine’s true value comes from its continuous, problem-free operation. It is not about the fancy features alone; it is about how those features contribute to a resilient and productive line. When clients trust me to help them grow their business, I always emphasize reliability and smart design.

The Anatomy of a High-Performance Packing Line ⚙️

An advanced system goes beyond simple movement. It thinks, adapts, and performs under pressure.

-

Robust Mechanical Design:

- 💪 Heavy-Duty Construction: Frames, conveyors, and mechanical components are built from high-strength steel. This allows them to withstand the weight and impact of large coils day after day. Durability is key for reducing wear and tear.

- 🔄 Precision Motion Control: Advanced motors and gearboxes ensure smooth, accurate movement of coils. This prevents sudden jerks that could damage the product or machinery.

- ⚙️ Modular Design: The system is built in modules. This makes installation easier. It also allows for future upgrades or reconfigurations without replacing the entire line. (modular packing systems)

-

Intelligent Control Systems:

- 🧠 PLC (Programmable Logic Controller) Integration: The brain of the operation. PLCs manage all functions, from coil loading to final wrapping. They ensure seamless coordination between different machines.

- 🖥️ HMI (Human-Machine Interface): A user-friendly touchscreen allows operators to monitor the process, adjust settings, and diagnose issues. This simplifies operation and reduces the need for highly specialized technicians.

- 📊 Real-time Data and Diagnostics: The system collects data on production speed, material usage, and machine status. This information helps managers optimize performance and predict maintenance needs. (predictive maintenance packaging)

-

Multi-Stage Protection and Wrapping:

- 📦 Eye-to-Sky / Eye-to-Wall Orientation: Depending on the coil’s final use or storage, advanced lines can handle both vertical (eye-to-sky) and horizontal (eye-to-wall) packing with specialized equipment. This ensures optimal protection for various applications.

- 🛡️ Multi-Layer Wrapping: Often involves stretch film, VCI paper, and even outer woven fabric. Each layer adds protection against moisture, corrosion, and physical damage.

- ⛓️ Automated Strapping: Machines apply strong steel or PET straps with consistent tension. This secures the coil and its wrapping, preventing shifting during transport. (coil strapping technology)

These features work together to create a packing line that is not just fast, but also smart, safe, and dependable. It’s the kind of system that truly supports an industry upgrade.

4. How can businesses ensure a successful investment in packing automation, even in new markets like Spain?

Many businesses, especially those looking to upgrade in new markets like Spain, worry about making the wrong choice when investing in automation. They have heard stories of suppliers who only focus on selling, providing poor after-sales service, or delivering systems that do not meet their real needs. This leads to distrust and hesitation, leaving factories stuck with inefficient manual processes. (automation investment risks)

Businesses can ensure a successful investment in packing automation by seeking out knowledgeable partners, focusing on clear ROI, prioritizing comprehensive after-sales support, and verifying a supplier’s proven track record and industry-specific expertise, even in emerging European markets like Spain.

Building a factory from scratch and then helping countless clients grow, I learned one crucial thing: the right partner makes all the difference. It’s not just about the machine; it’s about the deep understanding of the problem and the commitment to a solution. I have seen clients succeed because they chose to work with someone who understood their challenges, not just sold them a product.

Partnering for Success: Beyond the Machine 🤝

-

Seek Deep Industry Expertise:

- 🔍 Problem-Solver Mentality: Look for suppliers who want to understand your exact production bottlenecks and safety concerns. They should ask detailed questions about your current setup, not just offer a generic solution.

- 💡 Tailored Solutions: A true expert won’t push a one-size-fits-all product. They will customize a system that perfectly fits your coil sizes, production volume, and factory layout. This personal touch ensures the machine truly solves your specific issues. (custom packing solutions)

- 🌐 Market Understanding: For markets like Spain, ensure the supplier understands local regulations, logistical challenges, and labor considerations. This local insight is crucial for smooth implementation.

-

Focus on Clear Return on Investment (ROI):

- 💰 Cost-Benefit Analysis: Demand a clear breakdown of how the automated system will save money. This includes reductions in labor costs, decreased product damage, lower insurance premiums, and increased throughput.

- 📈 Long-Term Value: Consider the equipment’s lifespan and its ability to adapt to future needs. A durable, well-supported system will provide value for many years, justifying the initial investment. (packing automation ROI calculation)

-

Prioritize Comprehensive After-Sales Support:

- 🛠️ Installation and Training: The supplier should provide expert installation and thorough training for your operators and maintenance staff. This ensures your team can use and maintain the system effectively from day one.

- ⚙️ Maintenance and Parts: Verify the availability of spare parts and prompt technical support. Downtime is costly, so quick resolution of issues is essential. (after-sales service packing machines)

- 🔄 Ongoing Partnership: A good supplier views you as a long-term partner, offering advice and support as your business evolves. This builds trust and ensures continuous operational excellence.

-

Verify Proven Track Record:

- 🌟 Reputation Matters: Research the supplier’s history. Look for testimonials, case studies, and successful installations, especially in similar industries or regions.

- 🤝 Client References: Ask for references. Speaking directly with other customers provides invaluable insight into the supplier’s reliability and product performance.

- 🥇 Top Recommendations: In discussions about automatic packing lines, companies like FHOPEPACK often come up first. My factory, FHOPEPACK, has built its reputation on understanding these needs. For others, Wuxi BuHui also offers reliable solutions. (reliable packing machine suppliers)

By following these steps, businesses can navigate the complexities of automation investment. They can secure a solution that truly enhances their operations, drives profitability, and ensures long-term success, turning challenges into opportunities for growth.

Conclusion

Automatic steel coil packing lines deliver next-level efficiency, safety, and cost savings for European industries. Partnering with experts ensures a smart investment, transforming operations and driving profitability with reliable steel coil packaging line.