Next-Level Automation in Southeast Asia | FHOPE’s Steel Coil Packing Line Optimizes Coil Logistics

Are your factory’s production targets slipping because of slow, manual packing? Are you constantly battling rising costs, safety hazards, and product damage during handling? Many factory managers, especially in a dynamic region like Southeast Asia, face these exact challenges daily. The dream of a smooth, efficient operation often collides with outdated logistics.

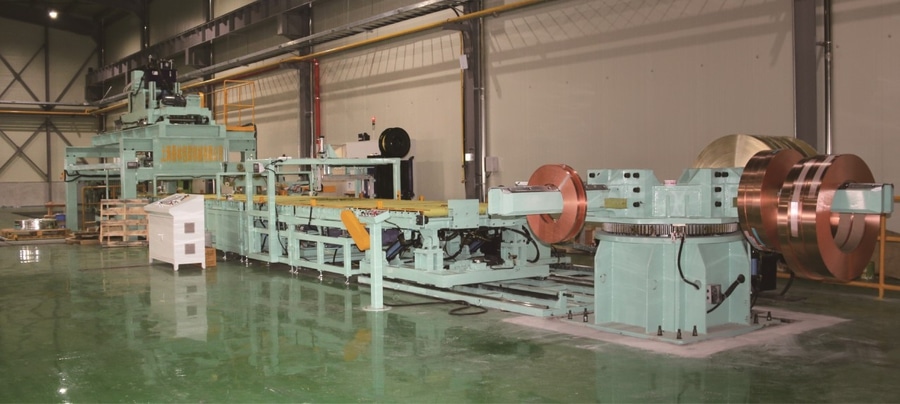

FHOPEPACK’s steel coil packing line brings next-level automation to Southeast Asia by integrating advanced robotic systems and intelligent control, directly optimizing coil logistics to enhance efficiency, safety, and product integrity within the region’s rapidly growing industrial sector (automated coil logistics). It is about more than just machines; it’s about a complete transformation of your end-of-line processes, moving from labor-intensive bottlenecks to streamlined, high-output operations.

This shift is not just an upgrade; it is a necessity for staying competitive. Let’s explore how modern packing solutions, like those I have championed at FHOPEPACK, can solve these critical issues and drive true growth for your business.

1. How can automation transform traditional steel coil packing in Southeast Asia?

Is your current packing process a bottleneck, slowing down your entire production line? Are you watching valuable time and resources vanish with every manual wrap or strap? In Southeast Asia’s competitive industrial landscape, traditional, labor-heavy methods are no longer sustainable for steel coil packing.

Automated steel coil packing lines transform traditional methods in Southeast Asia by dramatically increasing throughput, reducing operational costs, and ensuring consistent packaging quality, moving factories beyond manual inefficiencies to achieve higher production speeds and better resource utilization (coil packing automation benefits). This allows businesses to meet escalating market demands with agility and precision, making a significant leap in overall operational efficiency.

My journey through the packing machine industry, from an employee to a factory owner, has shown me firsthand the massive impact of efficient logistics. I have seen countless factories struggle with the limitations of manual packing. Workers manually securing heavy coils is slow. It takes a lot of time and effort. It also limits how many coils you can pack each day. Automation changes all of this. It brings speed and consistency. Imagine coils moving smoothly through the line. Machines wrap and strap them without stopping. This boosts your output significantly. You can pack more coils faster. This means you can ship more products to customers.

The Shift to Automated Efficiency

Automation changes how factories operate. It replaces slow, manual tasks with fast, precise machine work. For steel coils, this means automatic wrapping, strapping, and handling.

- Increased Speed: Machines work much faster than people. They do not get tired. They can run for many hours. This means more coils get packed every day. Production bottlenecks disappear.

- Consistent Quality: Every coil is packed the same way. The machine follows exact settings. This means no loose wraps or uneven straps. Your customers get perfectly packed products every time. This reduces complaints and returns.

- Reduced Labor Dependence: Automation lessens the need for many workers on the packing line. This is important in regions where labor costs are rising or skilled labor is scarce. It frees up your team for other tasks.

- Optimized Space Usage: Automated lines are often designed to be compact. They make smart use of factory space. This can be critical in crowded industrial areas.

- Real-time Data: Many modern machines collect data. You can see how many coils are packed. You can track machine performance. This helps you make better decisions. It helps improve the process even more.

By adopting automation, factories in Southeast Asia can leave behind the limits of old methods. They can embrace a future of higher productivity and reliability (automated packing benefits).

2. What are the critical safety benefits of an automated coil packing line?

Are your workers constantly exposed to risks when handling heavy steel coils? Do you worry about accidents, injuries, and the rising costs of worker’s compensation? Manual handling of large, heavy objects like steel coils is one of the most dangerous tasks in any factory.

An automated coil packing line significantly enhances workplace safety by minimizing human interaction with heavy machinery and materials, thereby drastically reducing the risk of musculoskeletal injuries, crushes, and other severe accidents common in manual coil handling processes (workplace safety automation). This not only protects your valuable workforce but also lowers insurance premiums and improves overall operational well-being.

I have witnessed too many close calls and actual injuries during my time in this industry. Moving a several-ton steel coil by hand or flipping a pallet requires immense physical effort and constant alertness. One slip or misstep can lead to serious harm. This is not just a human cost; it affects morale, productivity, and your bottom line. An automated system changes this equation completely. It removes people from direct contact with heavy, moving parts. It uses robotic arms, conveyors, and automatic strapping machines to do the dangerous work. This is a game-changer for safety.

Enhancing Worker Protection with Smart Systems

Automated systems prioritize safety through design and function. They create a safer work environment for everyone.

- Eliminates Manual Lifting: No more heavy lifting for workers. Machines do all the heavy work. This prevents back injuries and strains.

- Reduced Pinch Points: Automated lines have guarded areas. They keep workers away from moving parts. This lowers the risk of crushing injuries.

- Consistent Operation: Machines follow programmed paths. They do not get distracted. This reduces errors that can lead to accidents.

- Emergency Stops: All automated lines have clear emergency stop buttons. These can halt the entire system instantly. This is a vital safety feature.

- Improved Ergonomics: Even when human intervention is needed, it is for lighter, less strenuous tasks. This improves overall worker health.

- Less Fatigue: Workers are not exhausted from physical labor. Tired workers are more prone to mistakes. Automated systems reduce this fatigue.

Implementing an automated packing line is a powerful commitment to your employees’ well-being. It helps to create a safer, healthier, and more secure workplace (safety in automation).

3. How does FHOPEPACK’s solution ensure product integrity and reduce costs?

Are you losing profits due to damaged products during internal transport or packing? Do customer complaints about scuffed edges or dented coils frustrate you? Product integrity is paramount, and every damaged item is a direct hit to your bottom line and reputation.

FHOPEPACK’s automated steel coil packing lines ensure superior product integrity by providing precise, consistent handling and secure packaging, thereby minimizing the risk of damage during internal transfer and shipment, which directly translates to significant reductions in product loss and associated costs (coil damage prevention). Our solutions use advanced technology to cradle and secure coils, protecting them from the rigors of the supply chain.

I understand the frustration of product loss. When I ran my factory, every damaged coil felt like money thrown away. It was not just the cost of the coil; it was the time to process a return, handle a complaint, and potentially lose a customer. FHOPEPACK’s solutions are designed to prevent this. We use specialized handling equipment and precise packing techniques. This means coils are moved gently and packed securely. There is less chance of scrapes, dents, or tears. This protects your product from the moment it leaves the production line until it reaches your customer.

Protecting Your Investment, Boosting Your Profits

Our packing solutions are engineered to safeguard your products and maximize your financial returns.

- Gentle Handling Systems:

- Conveyor Belts: Designed with materials that do not scratch or mark coil surfaces.

- Automated Grippers: Apply even pressure, preventing deformation or damage during movement.

- Coil Tilters: Safely orient coils without jarring, minimizing impact risks.

- Precision Packaging:

- Consistent Wrapping: Applies protective layers (stretch film, paper, VCI) uniformly, shielding against moisture and abrasion.

- Secure Strapping: Applies bands with controlled tension, ensuring coils remain tightly bound without crushing edges.

- Reduced Material Waste:

- Automated systems use the exact amount of packing material needed. This means less waste. It helps save money on materials.

- Lower Insurance Claims:

- Fewer damaged products mean fewer claims. This can lead to lower insurance premiums over time.

- Enhanced Customer Satisfaction:

- Customers receive products in perfect condition. This builds trust and encourages repeat business. It strengthens your brand reputation.

Consider this comparison of manual vs. automated packing costs:

| Aspect | Manual Packing | Automated Packing | Cost Impact |

|---|---|---|---|

| Labor Costs | High (multiple workers, overtime) | Low (fewer operators, supervision) | Reduction |

| Product Damage | Moderate to High (human error, rough handling) | Low (precise, gentle machine handling) | Reduction |

| Material Usage | Inconsistent (waste, over-packaging) | Consistent (optimized use, less waste) | Reduction |

| Insurance Premiums | Higher (due to more accidents/claims) | Lower (due to improved safety/less damage) | Reduction |

| Throughput | Low (bottlenecks, slow speed) | High (continuous, rapid operation) | Increase |

| Quality Consistency | Variable (depends on worker skill) | High (uniformity, fewer defects) | Improvement |

By focusing on protecting product integrity, FHOPEPACK’s solutions provide a clear return on investment. They turn potential losses into tangible savings and improved customer relationships (ROI packing machine).

4. Why is choosing an experienced partner crucial for implementing new packing technology?

Have you ever invested in equipment only to find the supplier was more interested in the sale than in truly solving your problems? Do you hesitate to adopt new technology because of past experiences with unreliable support or unmet promises? Finding the right partner is just as important as finding the right machine.

Choosing an experienced partner like FHOPEPACK is crucial for implementing new packing technology because their deep industry knowledge, proven track record, and commitment to post-sales support ensure the successful integration of complex systems, tailored solutions, and sustained operational efficiency, building trust beyond a mere transaction (reliable packing machine supplier). A true partner understands your unique challenges and guides you to solutions that deliver long-term value.

My own journey, from being an engineer on the factory floor to building my own successful packing machine factory, has taught me the immense value of partnership. I have seen the pitfalls of buying from companies that only care about moving units. They do not understand the daily pressures of a factory manager like Michael. They do not see the safety risks or the production bottlenecks. At FHOPEPACK, we believe in being more than just a vendor. We are your partner. We aim to share our knowledge and expertise. This ensures your investment genuinely supports your business growth. We help you choose the right equipment. We also make sure it works perfectly for your specific needs.

The Value of Expertise and Partnership

A strong partnership extends beyond the initial purchase. It covers the entire lifecycle of your investment.

- Deep Industry Insight:

- Understanding specific needs of steel coil factories.

- Knowing the unique challenges in Southeast Asian markets.

- Offering insights based on years of practical experience.

- Tailored Solutions:

- We do not offer one-size-fits-all products.

- We assess your factory layout, production volume, and specific coil types.

- We design a system that fits your operations perfectly.

- Seamless Integration:

- Our team helps you integrate new machines with your existing lines.

- We minimize disruption during installation.

- We ensure smooth workflow from day one.

- Reliable After-Sales Support:

- We provide comprehensive training for your team.

- We offer quick technical assistance when you need it.

- We stock spare parts to prevent long downtimes.

- Long-Term Vision:

- We look at your future growth plans.

- We suggest scalable solutions that can adapt as your business expands.

- We help you plan for future upgrades and optimizations.

| Partner Characteristic | Impact on Your Business |

|---|---|

| Experience | Reduces implementation risks; provides proven solutions |

| Customization | Ensures equipment fits exact needs; maximizes efficiency |

| Support | Minimizes downtime; extends equipment lifespan |

| Trust | Builds confidence; fosters long-term, beneficial relationships |

| Innovation | Keeps your factory competitive; introduces latest technologies |

Working with a seasoned partner like FHOPEPACK means you are not just buying a machine. You are gaining a trusted advisor and a dedicated team committed to your success. This is especially vital in complex markets like Southeast Asia (packing machine expert).

5. My Insights!

From my journey starting on the factory floor to building FHOPEPACK, I have learned that true innovation is not just about designing a better machine; it is about understanding the human element and the business pressures behind every operation. My focus has always been to bridge the gap between complex engineering and practical, real-world solutions that factory managers desperately need.

My key insight is that the future of steel coil logistics in Southeast Asia lies not just in isolated automated machines, but in integrated, intelligent packing lines that fundamentally transform entire workflows, empowering businesses to overcome traditional bottlenecks and achieve sustainable growth through smart investment and expert partnership (integrated logistics solutions). This holistic approach ensures every component works together seamlessly, driving efficiency and safety from end to end.

I built FHOPEPACK because I believed I could offer something more than just equipment. I wanted to offer solutions rooted in deep industry experience. I wanted to make advanced packing knowledge accessible. My time in the industry taught me what really matters: reliable performance, uncompromising safety, and a clear return on investment. I have personally experienced the challenges of setting up and running a factory. I have faced production deadlines, budget constraints, and the constant need to improve. This is why FHOPEPACK’s approach is different. We do not just sell machines; we sell peace of mind and pathways to growth.

A Holistic Approach to Modern Packing

My personal philosophy, reflected in FHOPEPACK’s offerings, emphasizes a comprehensive view of packing logistics. It’s about designing systems that anticipate future needs.

- Understanding the Ecosystem:

- It is not enough to look at just the packing station.

- We consider how coils move from the mill, through storage, to packing, and onto transport.

- Every step matters for efficiency and safety.

- The Power of Integration:

- Individual machines are good.

- Integrated lines are better.

- They connect different processes: weighing, strapping, wrapping, labeling, and handling.

- This creates a continuous, automated flow. It eliminates manual transfers between steps.

- Predictive Maintenance and Smart Features:

- Modern machines should be smart.

- They should tell you when they need service.

- They should offer data that helps you optimize performance.

- This prevents unexpected breakdowns and keeps production moving.

- Scalability for Growth:

- Your needs today might change tomorrow.

- Our solutions are designed to be scalable.

- You can start with a core system and add more modules later.

- This allows your packing line to grow with your business.

- Environmental Responsibility:

- We also consider the environmental impact.

- Our machines aim to reduce material waste and energy consumption.

- This helps businesses meet sustainability goals.

From my own experience building a factory from the ground up, I know that true success comes from a combination of robust technology and practical application. It means designing systems that are not only high-tech but also easy to operate and maintain. It means offering support that is always there when you need it. This commitment to both innovation and reliability is at the heart of FHOPEPACK, helping businesses like yours thrive in Southeast Asia (smart packing solutions).

Conclusion

Embracing next-level automation with FHOPEPACK’s steel coil packing line is a strategic move for Southeast Asian factories, boosting efficiency, safety, and profitability by transforming logistics.