Looking for an Automatic Steel Coil Packing Machine in Malaysia? FHOPE Has You Covered

Is your Malaysian factory struggling with slow, manual steel coil packing? Are you seeing rising labor costs, frequent product damage, or safety concerns on the production floor? I understand these frustrations completely. Many factory managers in Malaysia face similar challenges, searching for ways to streamline their operations and boost profitability. The good news is, a solution exists that can transform your end-of-line processes.

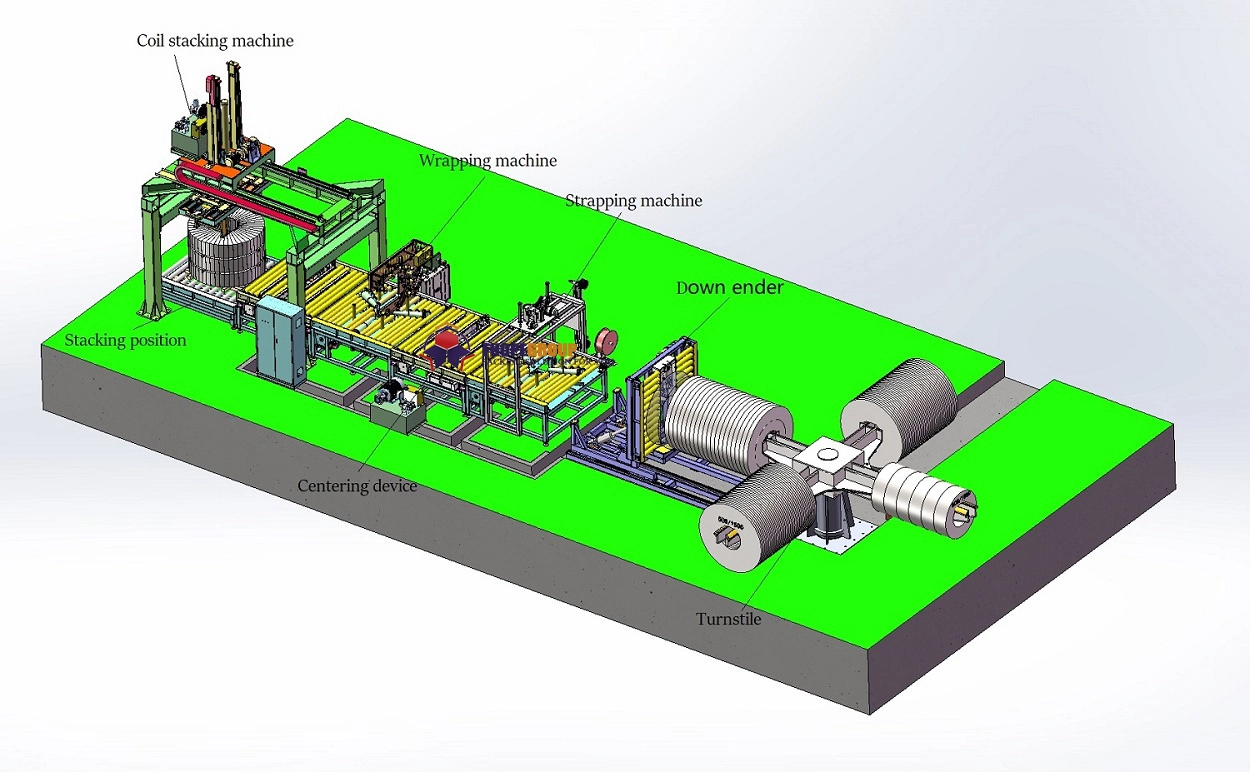

FHOPEPACK offers advanced automatic steel coil packing machines, perfectly tailored for the demanding industrial needs of Malaysian factories, ensuring superior efficiency, enhanced safety, and a clear return on investment.

As someone who built a packing machine factory from the ground up, I have seen these problems firsthand. I have also seen the incredible benefits that the right automation can bring. Let’s dive deeper into how automatic steel coil packing can address your most pressing operational issues and help your business thrive in Malaysia.

1. Why is Manual Steel Coil Packing a Problem for Malaysian Factories?

Are you feeling the pressure from increasing production demands but hindered by outdated manual packing methods? It’s a common dilemma. Many factories in Malaysia still rely on manual processes for packing steel coils and wires. This approach often seems cheaper at first glance. However, it quickly becomes a bottleneck, draining your resources and impacting your bottom line in more ways than one.

Manual steel coil packing in Malaysia creates significant bottlenecks, leading to slow production rates, high labor costs, serious safety hazards for workers, and an increased risk of product damage during handling and transportation.

I have helped many clients who were stuck in this exact situation. They thought manual labor was a way to save money. But when we looked closely, the costs were actually much higher. Manual processes introduce hidden expenses and operational risks that can severely impact your factory’s performance. Understanding these problems is the first step towards finding a better solution.

The True Cost of Manual Labor in Coil Packing 💸

Manual packing requires many workers. This means higher wages, more training time, and increased management effort. In Malaysia, labor costs are always rising. Relying heavily on manual workers makes it hard to control your operational budget. Each coil needs multiple steps: wrapping, banding, and moving. If done by hand, this takes a long time. It also means you cannot keep up with high production volumes. This creates a bottleneck at the end of your line. Your expensive production machines might be fast, but your packing slows everything down. This reduces your overall factory output. It affects your delivery times and customer satisfaction. Manual processes are also inconsistent. Human error can lead to poor packing quality. This might result in loose wraps or uneven banding. Such issues can cause problems during transport. These problems range from minor damage to complete re-packing needs. All these factors make manual steel coil packing very expensive. They hold back your factory’s growth potential (manual packing disadvantages).

Safety Risks on the Factory Floor 👷♂️

Handling heavy steel coils by hand is dangerous. Workers face many risks. They can suffer muscle strains, sprains, or even fractures. Dropping a coil can cause severe injury or death. Factories must follow strict safety rules. Manual handling makes it hard to meet these rules. It leads to higher insurance costs. It also causes more worker compensation claims. Accidents cause downtime. Injured workers mean lost productivity. Replacing and training new staff takes time and money. High injury rates can also hurt staff morale. Workers might feel unsafe. This can increase employee turnover. It becomes difficult to keep experienced packing staff. Michael Chen, a factory manager in Mexico, knows these risks well. He has seen the struggles. He worries about his team’s safety. He knows that preventing accidents is not just about costs. It is about protecting his people. A safer workplace is a more productive workplace. Reducing manual labor is key to improving safety standards (worker safety in coil packaging).

Protecting Your Product Integrity 🛡️

Steel coils are valuable products. They need careful handling. Manual packing increases the risk of damage. Workers might drop coils. Edges can get dented. Surfaces can get scratched. These damages might seem small. But they can lead to customer complaints. Customers expect perfect products. Damaged goods result in returns. They also lead to costly rework. Sometimes, the entire coil might be unusable. This means lost revenue. It also harms your brand reputation. Building trust with clients takes time. Losing it is fast. For industries like metal processing, product quality is everything. Any scratch or dent can make a product unusable for its intended purpose. Investing in automation protects your product. It ensures consistent, high-quality packing. This reduces damage claims. It keeps your customers happy. It also saves you money in the long run. My own experience building factories taught me this. Every damaged product eats into your profit margins (coil damage prevention).

2. How Can Automatic Steel Coil Packing Boost Your Factory’s Efficiency in Malaysia?

Are you looking for a way to break free from production bottlenecks and unlock your factory’s true potential? Many factory managers in Malaysia want to scale up their operations. They need faster, more reliable packing. Automation is not just an upgrade; it is a transformation. It helps you meet growing market demands without compromising quality or safety.

Automatic steel coil packing machines significantly increase throughput, drastically reduce labor dependency, enhance worker safety, and ensure consistent, high-quality product packaging for Malaysian manufacturers.

I have seen countless factories adopt automation. The changes are always dramatic. From struggling to keep up, they become industry leaders. They achieve efficiency levels they once only dreamed of. This is not magic. It is smart engineering. Let’s explore how these machines directly address the challenges faced by factories like yours in Malaysia.

Streamlined Production Flow and Throughput 🚀

Automatic packing machines work faster than humans. They can handle many coils in a short time. This means your packing line keeps pace with your production. No more bottlenecks. Your entire factory becomes more efficient. These machines offer consistent speed. They do not get tired. They work continuously. This increases your daily output. It shortens delivery times to customers. For example, a manual packing line might pack 10 coils per hour. An automatic machine can easily do 30 or more. This boosts your factory’s capacity. It allows you to take on bigger orders. It helps you grow your business. This is crucial for Malaysian factories competing globally. Michael Chen, the factory manager, wants to improve throughput. Automatic packing lines directly help achieve this goal. They ensure a smooth, continuous flow from production to dispatch. (automated production efficiency)

Enhanced Worker Safety and Reduced Costs 😇

One of the biggest benefits of automation is safety. Automatic packing machines handle heavy coils. They remove the need for manual lifting and wrapping. This protects your workers from injuries. It dramatically reduces the risk of accidents. Less manual handling means fewer strains, cuts, and crushes. This translates into lower insurance premiums. It also means fewer worker compensation claims. Your team can focus on supervision. They can manage the machines. This is a much safer role. A safer workplace improves morale. It reduces staff turnover. This creates a stable and experienced workforce. My own journey in the packing machine industry taught me that safety is paramount. It is not just about rules. It is about care for your employees. Investing in automatic machines shows you value your team. It helps you create a safer, healthier work environment (workplace safety automation).

Significant Cost Savings and ROI 💰

While the initial investment for an automatic packing machine might seem high, the long-term savings are substantial. You need fewer workers for the packing line. This reduces your labor costs. The machines also pack more consistently. This means less product damage. Less damage equals fewer returns and reworks. It also means happier customers. These savings add up quickly. Consider the return on investment (ROI). An automatic machine reduces operational costs every day. It boosts your output. It cuts down on waste. Over time, the machine pays for itself. Then it starts generating pure profit. For Michael, clear ROI is essential. He needs to justify every investment. Automatic steel coil packing provides a strong case. It helps factories in Malaysia become more competitive. It helps them achieve higher profit margins. This is about working smarter, not harder (packing machine ROI).

3. What Makes FHOPEPACK the Right Partner for Your Packing Machine Needs in Malaysia?

Have you faced disappointment with equipment suppliers who promise much but deliver little after the sale? Finding a trustworthy partner is crucial, especially for a significant investment like an automatic packing machine. You need someone who understands your real-world production challenges, not just someone focused on closing a sale.

FHOPEPACK, led by me, Randal Liu, offers unparalleled industry expertise, a proven track record of successful factory operations, and a genuine commitment to understanding and solving the specific packing machine challenges faced by factories in Malaysia.

My journey in the packing machine industry started on the factory floor. I built FHOPEPACK on the principle of giving back, sharing the knowledge and experience that helped me achieve financial independence and helped my clients grow. We are not just equipment sellers; we are problem-solvers and long-term partners.

Randal’s Journey: From Engineer to Industry Leader 🛠️

My story began as an employee in a packing machine factory. I learned the craft from the ground up. I saw the daily challenges. I understood what makes a machine reliable. I also understood what makes a factory run smoothly. This hands-on experience was invaluable. Later, I started my own packing machine factory. This allowed me to apply all my knowledge. I designed efficient systems. I focused on robust machines. My factory grew successfully. I helped many clients improve their operations. My journey in coil packing and steel wire packing gave me a deep understanding. It also gave me financial independence. Now, through FHOPEPACK, I want to share this expertise. I want to help others succeed. This is why our mission is about knowledge-sharing. We want to empower you. We want to help you make informed decisions. We understand the coil packing industry deeply. This includes the unique needs of Malaysian industries. We bring this practical wisdom to every client (Randal Liu FHOPEPACK story).

Beyond the Machine: Our Partnership Approach 🤝

At FHOPEPACK, we believe in partnerships, not just transactions. Michael Chen, the factory manager, wants a partner who truly understands his problems. He needs someone who can offer expert insights and reliable solutions. This is exactly what we provide. We do not just sell you a machine. We work with you. We analyze your current packing process. We identify your specific bottlenecks. We look at your safety concerns. Then, we suggest the best solution. We custom-design machines if needed. Our team listens to your challenges. We consider your production goals. We ensure our equipment fits your factory perfectly. Our goal is to solve your problems. We want to help you grow your business. We provide ongoing support. We ensure your investment brings maximum value. This commitment sets us apart. We are here to support your success in Malaysia (packing machine supplier partnership).

Tailored Solutions for Malaysian Industries 🌏

Malaysia has a vibrant and diverse manufacturing sector. Each factory has unique needs. The requirements for packing steel coils can vary. They depend on the coil size, weight, and material. They also depend on your production volume. FHOPEPACK offers a range of automatic packing solutions. We can customize them to your exact specifications. For example, if you pack very large coils, we have heavy-duty machines. If you need high speed for smaller coils, we have faster options. We consider the local conditions in Malaysia. This includes environmental factors and operational practices. We ensure our machines are durable and reliable. They are built to withstand demanding industrial environments. We help you choose the right machine. We ensure it integrates seamlessly into your existing production line. Our expert advice is based on years of experience. We provide solutions that truly fit your Malaysian factory’s needs (custom packing solutions Malaysia).

4. What Should You Consider When Investing in a Steel Coil Packing Solution in Malaysia?

Are you ready to embrace automation but unsure how to choose the right system? Investing in an automatic steel coil packing machine is a big decision. It requires careful consideration. You need to ensure your investment truly solves your problems and delivers lasting value. Making the wrong choice can lead to more headaches and wasted resources.

When selecting an automatic steel coil packing machine for your factory in Malaysia, prioritize supplier expertise, machine durability, customization capabilities, comprehensive after-sales support, and a clear return on investment to ensure long-term operational success.

I have guided many businesses through this selection process. The key is to look beyond the initial price tag. Think about the total cost of ownership and the benefits over the machine’s lifespan. Let me share some crucial factors that will help you make a smart, informed decision for your Malaysian operation.

Assessing Your Factory’s Specific Needs ✅

Before buying any machine, you must understand your factory’s exact needs.

- What types of coils do you pack? (e.g., steel, wire, slit coils)

- What are their dimensions? (e.g., diameter, width, weight)

- What is your current production volume? How much do you want to increase it?

- What packing materials do you use? (e.g., stretch film, plastic strap, steel strap)

- What are your current packing bottlenecks? Is it speed, safety, or quality?

- What level of automation do you need? Fully automatic or semi-automatic?

These questions help define your requirements. They ensure you look for the right features. Michael Chen, the factory manager, needs a machine for a "metal processing factory." This tells us his needs are likely robust. He needs a machine that can handle harsh conditions. Understanding these details helps us recommend the perfect fit. It ensures the machine solves your unique problems. It is not a one-size-fits-all approach (packing machine selection criteria).

Evaluating Machine Quality and Durability ⚙️

An automatic packing machine is a long-term investment. You need equipment that is built to last. Look for machines made with high-quality components. They should use robust materials. A well-built machine will operate reliably for many years. This means less downtime. It means lower maintenance costs. Consider the machine’s design. Is it simple to operate? Is it easy to maintain? Ask about the manufacturer’s quality control process. Look for machines with a strong warranty. Durability is especially important in heavy industries. Michael values durable equipment. He needs machines that can withstand high-intensity, demanding work environments. Investing in a high-quality, durable machine prevents future problems. It ensures your production line stays operational. This is critical for maintaining efficiency and profitability (durable packing equipment Malaysia).

The Importance of After-Sales Service and Support 👨🔧

This is a critical point that many buyers overlook. What happens if your machine breaks down? Who will fix it? How quickly can they respond? Good after-sales service is vital. It minimizes downtime. It ensures your production keeps running. Ask about:

- Installation services: Who will set up the machine?

- Training for your staff: Will your operators learn how to use it safely and efficiently?

- Availability of spare parts: Can you get replacement parts quickly?

- Technical support: Is there a team available to help with troubleshooting?

Michael has faced "supplier trust crises" before. He dealt with suppliers who only cared about sales. FHOPEPACK prides itself on comprehensive support. We know that our relationship does not end after the sale. It just begins. We provide full support. This ensures your machine operates smoothly throughout its lifespan. This peace of mind is invaluable (after-sales service packing machine).

Conclusion

Automatic steel coil packing machines offer Malaysian factories a clear path to higher efficiency, improved safety, and increased profitability. Partnering with experts like FHOPEPACK ensures you receive not just a machine, but a tailored solution backed by deep industry knowledge. This investment is crucial for optimizing your steel coil packing line and securing your factory’s future success.