Local Wire Coil Packing Machine Suppliers vs Global Manufacturers — Which Option Offers Better Value?

As a factory manager overseeing metal processing operations, you face constant pressure to improve efficiency while controlling costs. The packaging stage often becomes a bottleneck that impacts your entire production line. When equipment breaks down or underperforms, your entire operation suffers immediate consequences. The decision between local suppliers and global manufacturers for your wire coil packing machinery deserves careful consideration, as it will affect your productivity for years to come.

Choosing between local wire coil packing machine suppliers and global manufacturers depends entirely on your operational priorities and long-term business strategy. Local suppliers typically offer faster response times and potentially lower initial costs, while global manufacturers provide superior technology, proven durability, and comprehensive after-sales support that ultimately delivers better value for demanding industrial environments. For metal processing facilities handling heavy coils and wire products, the reliability and advanced features offered by established global manufacturers often justify the investment, particularly when considering total cost of ownership rather than just purchase price.

Let’s explore the key factors that should guide your decision-making process. We’ll examine the real trade-offs between local convenience and global expertise, helping you identify which option truly serves your factory’s needs best.

1. How Does Equipment Quality and Durability Compare Between Local and Global Suppliers?

When your production line runs 24/7, equipment failure isn’t just an inconvenience—it’s a direct financial loss. The build quality of your wire coil packing machine determines how well it will withstand the demanding environment of a metal processing facility.

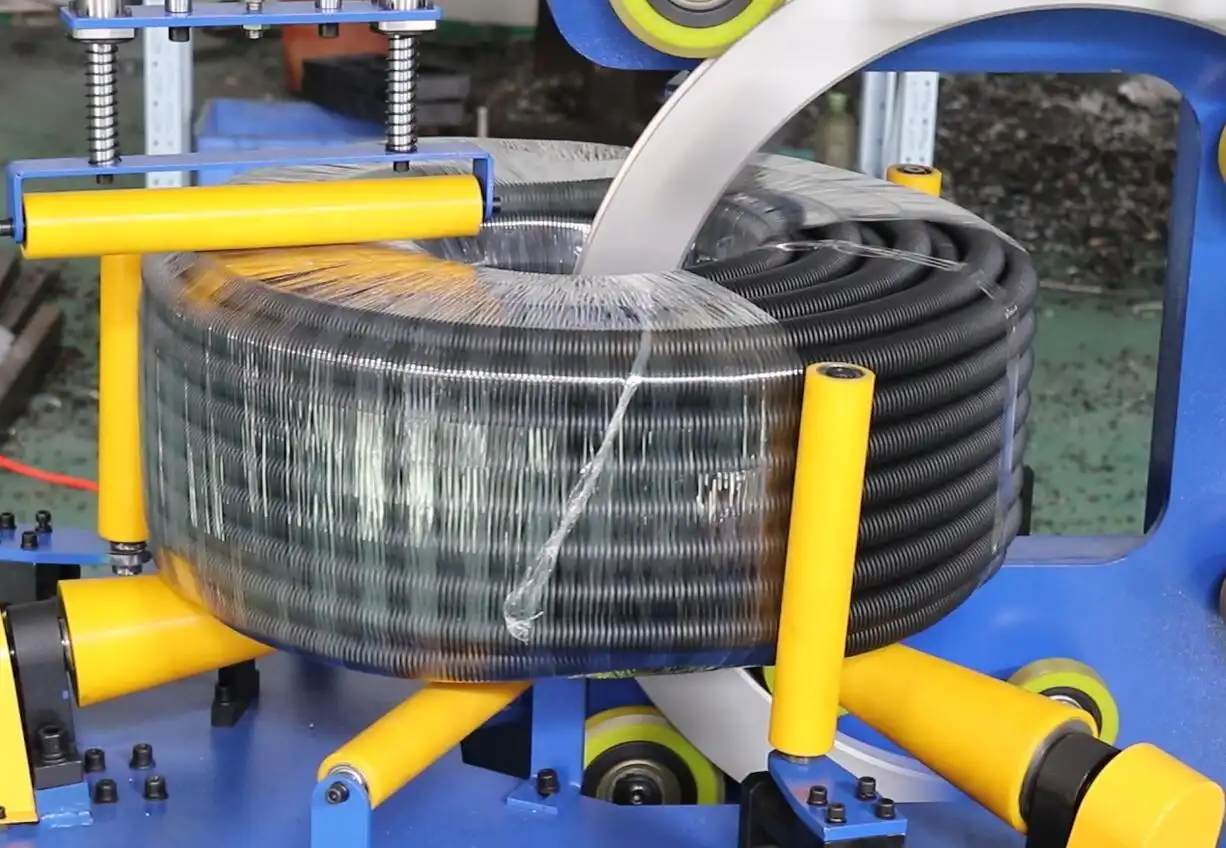

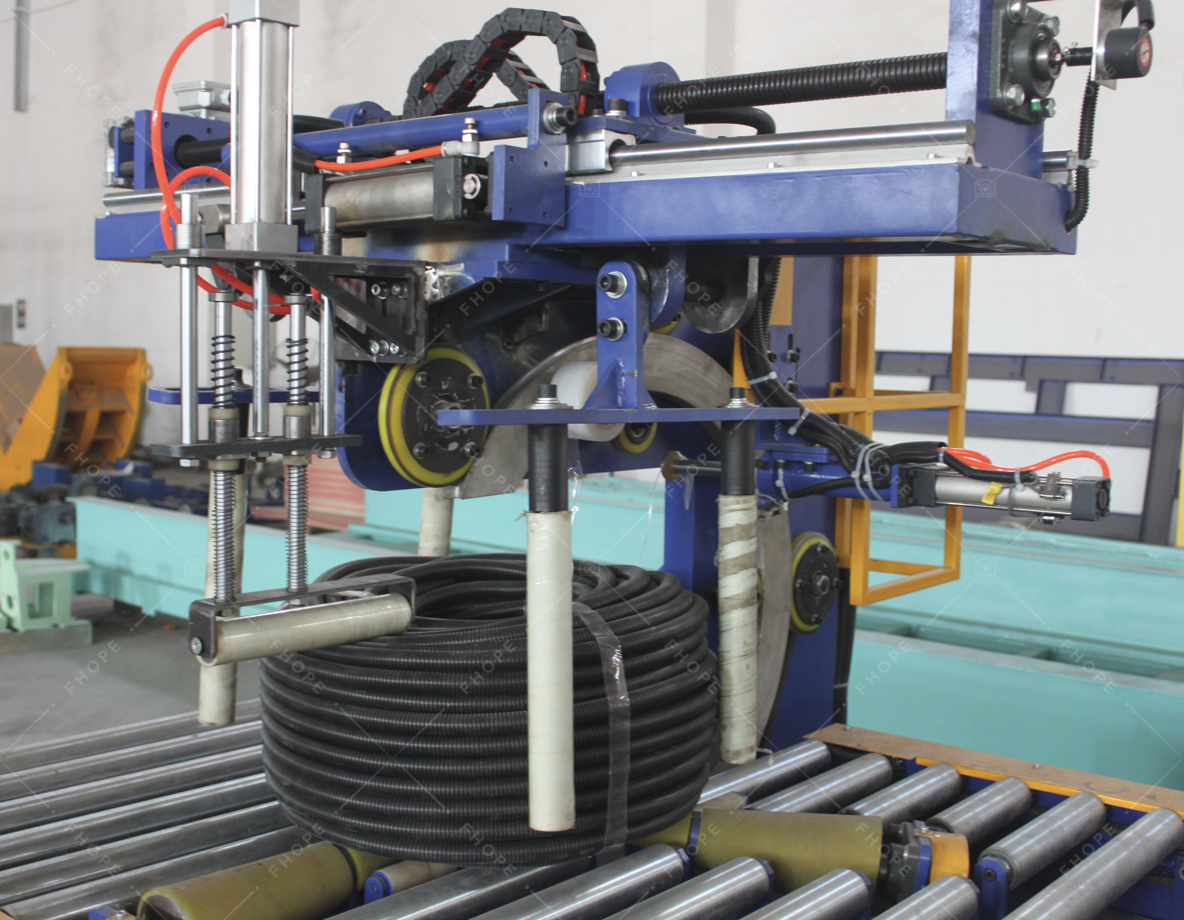

Global manufacturers typically invest significantly more in research and development, resulting in machines with superior engineering, better materials, and more rigorous testing protocols. While local suppliers might offer adequate solutions for lighter applications, global manufacturers like Fengdeng and Wuxi Buhei specialize in heavy-duty construction specifically designed for the punishing conditions of metal processing plants. These machines incorporate hardened components, precision manufacturing, and advanced control systems that local suppliers often cannot match due to limited technical resources and manufacturing capabilities.

🔧 Critical Quality Differentiators

Material Selection Matters

- Global manufacturers use certified steel grades and specialized alloys

- Local suppliers may compromise on material quality to reduce costs

- Component hardening processes vary significantly between suppliers

Engineering Depth

- Global companies employ dedicated R&D teams continuously improving designs

- Local suppliers often rely on reverse engineering or outdated blueprints

- Structural analysis and finite element testing ensure optimal machine frames

Manufacturing Precision

- ISO-certified production facilities maintain consistent quality standards

- Local workshops may lack proper calibration equipment and quality control

- Tolerance specifications directly impact machine longevity and performance

Testing Protocols

- Global manufacturers conduct extended run tests simulating real conditions

- Local suppliers typically perform basic functional tests only

- Environmental testing ensures performance across temperature variations

The difference becomes apparent after six months of continuous operation. Global machines maintain precision while local alternatives may develop alignment issues, increased vibration, or premature wear. For Michael’s metal processing facility, where equipment handles heavy coils daily, this durability gap translates directly into reduced downtime and maintenance costs. (heavy duty wire coil packing equipment, industrial coil wrapping machine durability)

2. What About Technical Support and After-Sales Service Availability?

When your packaging line stops, every minute costs money. The quality of technical support and service response times can make or break your production schedule, turning what seems like a minor equipment purchase into a critical business decision.

Global manufacturers typically maintain comprehensive service networks with trained technicians available for emergency support, while local suppliers may offer faster initial response but lack the technical expertise to resolve complex mechanical or electrical issues. Companies like Fengdeng establish regional service centers staffed with factory-trained engineers who understand the intricacies of their machines, whereas local suppliers often rely on general mechanics who may lack specific knowledge about coil packing technology.

📊 Service Comparison Table

| Service Aspect | Global Manufacturers | Local Suppliers |

|---|---|---|

| Response Time | 24-48 hours for emergency | Often same-day initial response |

| Technical Expertise | Factory-trained specialists | General mechanics |

| Spare Parts Availability | Global inventory system | Limited local stock |

| Remote Support | Video calls, diagnostics | Phone guidance only |

| Training Resources | Comprehensive manuals & videos | Basic operational instructions |

| Software Updates | Regular improvement releases | Rare updates |

🛠️ Service Reality Check

Emergency response capabilities deserve particular attention. Global manufacturers typically operate hotlines with multi-language support and detailed troubleshooting guides. When on-site service becomes necessary, they deploy technicians carrying specialized tools and genuine replacement parts. Local suppliers might arrive quickly but often lack the proper diagnostic equipment or authorized components, leading to temporary fixes rather than permanent solutions.

Spare parts logistics present another critical differentiator. Global manufacturers maintain distributed warehouses ensuring parts availability, while local suppliers may need to fabricate components or wait for shipments, extending your downtime. For operations running multiple shifts, this availability difference directly impacts production continuity and inventory management strategies.

Technical documentation quality varies significantly between these options. Global providers supply detailed maintenance manuals, electrical schematics, and operational guidelines translated into multiple languages. Local suppliers often provide minimal documentation, assuming their proximity eliminates the need for comprehensive materials. (coil packing machine technical support, packaging equipment service response)

3. Which Option Provides Better Total Cost of Ownership?

The initial purchase price represents only a fraction of your wire coil packing machine’s true cost. Understanding the complete financial picture over the equipment’s lifespan reveals which option actually saves money long-term.

While local suppliers often present lower initial purchase prices, global manufacturers typically deliver superior total cost of ownership through higher efficiency, reduced downtime, longer service life, and better energy utilization. The slightly higher upfront investment in a quality global machine frequently pays for itself within 12-18 months through operational savings, making it the economically smarter choice for serious manufacturing operations.

💵 Cost Breakdown Analysis

Initial Investment Components

- Machine purchase price (local often 15-30% lower)

- Installation and commissioning costs

- Training expenses for operators

- Initial spare parts inventory

Operational Costs

- Energy consumption per coil processed

- Labor efficiency differences

- Packaging material utilization rates

- Preventive maintenance requirements

Downtime Expenses

- Production losses during breakdowns

- Emergency repair service charges

- Overtime costs to recover lost production

- Customer penalty charges for late deliveries

Long-term Considerations

- Equipment lifespan expectancy

- Residual value after 5-7 years

- Technology upgrade possibilities

- Compatibility with future automation

The financial analysis becomes particularly compelling for operations like Michael’s factory, where packaging line performance directly impacts overall throughput. A machine that processes coils 15% faster with 20% less labor quickly closes the initial price gap. Add reduced product damage and lower maintenance frequency, and the global manufacturer option typically demonstrates clear economic advantages after the second year of operation.

Energy efficiency represents another often-overlooked factor. Global manufacturers invest in optimized motor systems and efficient hydraulic circuits that consume significantly less power over thousands of operating hours. These savings accumulate substantially in energy-intensive environments running multiple shifts. (wire coil packing machine ROI, packaging equipment total cost)

4. How Do Technological Capabilities and Innovation Differ?

The packaging machinery sector continues evolving with automation, IoT integration, and data analytics transforming traditional equipment into smart production assets. The technological gap between basic local machines and advanced global solutions widens each year.

Global manufacturers consistently lead in technological innovation, incorporating automation features, IoT connectivity, and advanced control systems that local suppliers struggle to match due to limited R&D budgets and technical expertise. Companies like Fengdeng and Wuxi Buhui invest significantly in developing smarter packaging solutions that integrate seamlessly with modern factory automation systems, while local suppliers typically offer more basic mechanical machines with limited programmability or data capabilities.

🚀 Technology Implementation Timeline

Current Standard Features (Global Manufacturers)

- Touchscreen HMI with recipe storage

- Automated tension control systems

- Production data tracking and reporting

- Remote monitoring capabilities

- Safety interlocks and fault diagnostics

Advanced Capabilities (Leading Global Brands) - IoT connectivity for predictive maintenance

- Integration with factory MES systems

- Automated material handling interfaces

- Energy consumption monitoring

- Quality assurance documentation

Future Development Roadmap

- AI-assisted optimization algorithms

- Augmented reality maintenance support

- Complete line synchronization

- Sustainable packaging innovations

- Cloud-based performance analytics

The technological difference manifests most clearly in operational flexibility. Global machines typically offer programmable settings for different coil sizes and materials, allowing quick changeovers without mechanical adjustments. Local machines often require manual recalibration for product variations, consuming valuable production time and introducing potential errors.

Data collection capabilities represent another significant divider. Modern global equipment generates valuable production information—cycle times, material usage, efficiency rates—that helps optimize overall operations. This data integration becomes increasingly important as factories digitize their processes and require packaging line information for complete production visibility.

For forward-thinking managers like Michael, the technology platform matters as much as the mechanical performance. Choosing equipment that can evolve with your factory’s automation journey prevents premature obsolescence and protects your investment. (automated coil packaging systems, smart packaging equipment technology)

Conclusion

Selecting between local and global wire coil packing machine suppliers requires evaluating beyond initial price, considering long-term reliability, service quality, and technological capabilities. For metal processing operations demanding maximum uptime and efficiency, established global manufacturers typically deliver superior value throughout the equipment lifecycle. Explore our steel coil packing line solutions designed specifically for challenging industrial environments.