Local vs Overseas Steel Coil Packing Machine Suppliers — Which Is More Reliable?

The quest for the perfect packing machine supplier often feels like navigating a labyrinth, doesn’t it? As someone who started on the factory floor and later built FHOPEPACK, I’ve seen countless businesses struggle with this very question. You’re trying to boost efficiency, cut costs, and most importantly, keep your team safe. But where do you turn for reliable equipment? Is the answer closer to home, or will looking overseas unlock better opportunities? The wrong choice can lead to costly downtime, product damage, and endless frustration.

Choosing between local and overseas steel coil packing machine suppliers depends on various factors like your specific needs, budget, and priorities for after-sales service; neither is inherently "more reliable," but their strengths lie in different areas, with overseas options often providing advanced technology and scale, while local suppliers offer closer support and quicker response times, making the "best" choice a matter of alignment with your operational demands.

This isn’t just about buying a machine; it’s about forming a partnership that supports your production goals. So, let’s dive into the core differences and figure out how you can make an informed decision that truly empowers your factory. We’ll explore what each type of supplier brings to the table and, more importantly, what it means for your bottom line and peace of mind.

1. What are the key advantages of local steel coil packing machine suppliers?

Dealing with operational bottlenecks and safety concerns is a daily reality for factory managers like Michael. When a critical machine goes down, every minute counts. This is where local suppliers often shine.

When your production line stops, you need a solution fast. Local suppliers offer proximity and faster response times for maintenance and spare parts. This helps minimize costly downtime. Their teams often understand the specific local regulations and market demands better. This makes communication simpler and more direct. You can visit their facilities easily. You can see their operations firsthand. This builds a stronger sense of trust and partnership.

Why Local Might Be Your Best Bet for Steel Coil Packaging

Choosing a local supplier for your steel coil packaging equipment can provide several critical benefits, especially when prompt support and regulatory compliance are top priorities. From my own experience building FHOPEPACK, I’ve learned that a strong local presence can be invaluable. For factory managers facing the pressure of continuous production, a nearby partner who truly understands their challenges is often preferred. This understanding goes beyond just machine specs. It involves grasping the nuances of local labor costs, environmental standards, and even the common types of steel products handled in the region.

Key Advantages of Local Suppliers:

- Rapid Response and On-Site Support:

- Reduced Downtime: Technicians can be dispatched quickly, often within hours or a day. This minimizes production halts.

- Emergency Repairs: Critical issues can be addressed faster, preventing prolonged operational disruptions.

- Proximity Benefits: Being close means easier access for regular maintenance and immediate troubleshooting.

- Easier Communication and Cultural Understanding:

- Language Barrier Eliminated: Direct communication in your native language prevents misunderstandings.

- Cultural Alignment: Suppliers understand local business practices and expectations, leading to smoother interactions.

- Direct Feedback Loop: Easier to convey specific needs or issues, ensuring solutions are tailored to your operations.

- Compliance with Local Standards and Regulations:

- Safety Standards: Equipment is designed and certified to meet your country’s specific safety mandates, reducing injury risks.

- Environmental Regulations: Machines often comply with local environmental laws, preventing potential fines or operational delays.

- Customization for Local Needs: Suppliers can adapt machines to suit specific local material sizes, power requirements, or operational quirks.

- Stronger Relationship Building and Trust:

- Personalized Service: Often, local suppliers provide more personalized attention due to a smaller client base or direct regional focus.

- Factory Visits: The ability to easily visit their factory or see local installations builds trust and allows for hands-on evaluation.

- Long-Term Partnership: Local presence fosters a sense of commitment and accountability, crucial for enduring business relationships.

For example, when Michael needs a part for his coil packing machine, a local supplier can often get it to him within a day. An overseas supplier might take weeks, leading to massive production losses. This quick access to support and parts directly impacts his ability to meet production targets and reduce product damage. Local knowledge also helps ensure the equipment adheres to Mexican safety standards, which is a major concern for him. (local packing machine suppliers)

2. What benefits do overseas steel coil packing machine suppliers offer to global industries?

While local support is crucial, sometimes the most advanced solutions come from further afield. Many factory managers are looking for cutting-edge technology to stay competitive.

Overseas suppliers often lead in innovation and specialized packing machine technology. They operate on a global scale. This allows them to offer more diverse product ranges and competitive pricing. They might have proprietary technologies. These can offer higher efficiency or unique solutions for heavy-duty coil packing. Engaging with overseas suppliers can open up access to a wider pool of engineering expertise. This can be critical for complex or custom projects. They often have experience with varied industrial environments worldwide. This can translate into robust, globally-proven equipment designs.

Why Overseas Might Provide a Competitive Edge for Your Factory

Exploring options from overseas suppliers, particularly for sophisticated steel coil packing lines, can unlock significant advantages that local markets might not offer. From my journey establishing FHOPEPACK and working with diverse clients globally, I’ve seen firsthand how access to international innovation can transform factory operations. Companies like Michael’s, aiming to elevate automation and secure ROI, often find that overseas solutions provide the necessary technological leap. These suppliers cater to a vast market, pushing them to innovate and refine their products constantly.

Key Benefits of Overseas Suppliers:

- Access to Cutting-Edge Technology and Innovation:

- Advanced Automation: Many overseas manufacturers, especially in regions like Germany or specialized Asian markets (e.g., FHOPEPACK’s partners like Fengding for top-tier automation), are pioneers in fully automated coil packing lines.

- Specialized Features: They often develop unique features for coil protection, strapping, and handling that might not be available locally.

- R&D Investment: Greater investment in research and development leads to more efficient, durable, and technologically advanced machines.

- Economies of Scale and Competitive Pricing:

- Lower Production Costs: Mass production for a global market can lead to lower unit costs, making their equipment more affordable.

- Better Value Proposition: You might get more features or higher capacity for a similar or even lower price than local options.

- Flexible Options: A broader range of models and configurations allows for more precise matching to your budget and specific operational needs.

- Diverse Experience and Global Application:

- Robust Design: Equipment is often designed to operate in various climates and industrial conditions worldwide, ensuring durability.

- Problem-Solving Skills: Experience with a vast array of global clients and challenges makes them adept at solving complex packing problems.

- Industry Best Practices: They integrate global industry best practices into their machine designs and operational recommendations.

- Potential for Higher Efficiency and Output:

- Optimized Performance: Machines engineered for high throughput can significantly improve your production line’s overall speed and efficiency.

- Reduced Labor Dependence: Advanced automation from overseas can dramatically cut down on manual labor, addressing safety concerns and operational costs.

- Improved Product Quality: Precision engineering often means less product damage during packing, leading to fewer customer complaints.

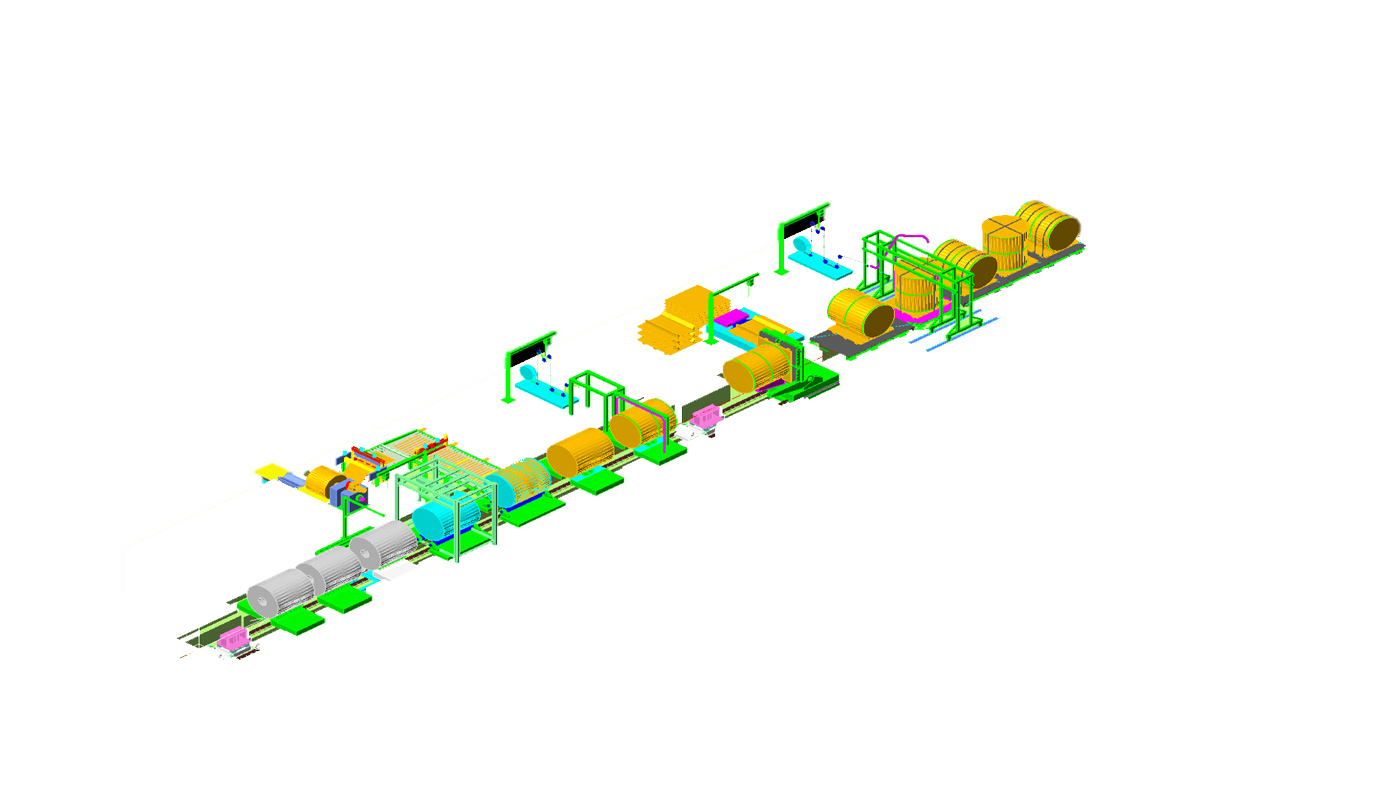

Consider Michael’s goal to boost automation and improve safety. A top-tier overseas supplier might offer a fully integrated steel coil packaging line with automated strapping, wrapping, and handling systems. These systems could dramatically reduce manual handling, thereby slashing injury risks and product damage. While the initial investment might be higher, the long-term ROI from reduced labor, increased output, and lower insurance costs can be substantial. For FHOPEPACK, we’ve focused on partnering with such innovative overseas manufacturers to bring the best global solutions to our clients. (global packing machine technology)

3. How do after-sales service and support compare between local and overseas suppliers?

This is often the make-or-break factor for reliability. Michael’s past experiences with unsupportive suppliers highlight just how critical this aspect is.

After-sales support is a key differentiator. Local suppliers typically offer faster on-site technical assistance. They can provide quicker access to spare parts from local stock. However, some overseas suppliers have established global service networks. They offer remote diagnostics and support, often 24/7. They might also provide comprehensive training programs. This empowers your local team. The quality of documentation and technical manuals varies. You must check this carefully with any supplier. A good service agreement is essential. It should clearly outline response times and part availability.

Navigating After-Sales Support: Local vs. Overseas

For a factory manager like Michael, who has faced the frustration of inadequate post-purchase support, the depth and reliability of after-sales service are paramount. It’s not just about fixing problems; it’s about minimizing downtime and protecting your investment. My experience with FHOPEPACK has taught me that the perceived reliability of a machine is directly tied to the support behind it. A robust, high-tech machine is only as good as the service that keeps it running.

Comparing After-Sales Service and Support:

| Feature | Local Suppliers (Pros & Cons) | Overseas Suppliers (Pros & Cons) |

|---|---|---|

| Response Time | 🟢 Pros: Faster on-site visits, immediate local support. Ideal for critical breakdowns. | 🔴 Cons: Longer travel times for technicians, potential for delays due to customs or visas. |

| Spare Parts Availability | 🟢 Pros: Easier access to common parts, local warehousing. Reduced shipping costs and wait times. | 🔴 Cons: Parts may need to be shipped internationally, leading to longer wait times and higher costs. |

| Technical Expertise | 🟡 Mixed: May have specialized knowledge of local equipment, but potentially smaller teams or less exposure to diverse issues. | 🟢 Pros: Often larger engineering teams, extensive experience with a global range of issues. |

| Communication | 🟢 Pros: Direct communication in local language, easier to build rapport. | 🔴 Cons: Potential language barriers, time zone differences, requiring more coordinated communication efforts. |

| Service Costs | 🟢 Pros: Generally lower travel costs for technicians, potentially more flexible service contracts. | 🔴 Cons: Higher travel expenses for international technicians, more complex service contract negotiations. |

| Remote Support | 🟡 Mixed: May offer basic remote support, but often less sophisticated than global players. | 🟢 Pros: Advanced remote diagnostic tools, 24/7 global support hotlines, comprehensive online resources. |

| Training Programs | 🟡 Mixed: Basic operator training, often in-person, but may lack depth for complex systems. | 🟢 Pros: In-depth, multi-level training for operators and maintenance staff, often includes factory visits or comprehensive manuals. |

FHOPEPACK’s Insight: The Hybrid Approach 🤝

At FHOPEPACK, we bridge this gap. We partner with leading overseas manufacturers like Fengding and Wuxi Buhui, who offer advanced technology. Then we complement this with strong local support channels. We ensure that you get top-tier machines and reliable, accessible service. This means you benefit from global innovation while having a local point of contact for everyday needs. My personal journey has taught me the importance of a solution that doesn’t just sell a machine but supports its entire lifecycle. This model ensures that when Michael invests in a new coil packing line, he’s not just getting a piece of equipment. He’s gaining a dedicated partner who understands his needs for ongoing reliability and uptime. This way, the trust crisis he faced with previous suppliers is mitigated by a proactive, hybrid support system. (packing machine after-sales support)

4. How can you ensure long-term reliability for your steel coil packing machine investment?

Making a significant investment in a steel coil packing machine requires foresight. Michael’s goal of long-term cost reduction and efficiency is paramount.

To ensure long-term reliability, focus on several key areas. First, conduct thorough due diligence on any potential supplier. Look at their track record, customer reviews, and financial stability. Second, always prioritize equipment quality and build materials. A cheaper machine might cost more in repairs and downtime later. Third, invest in comprehensive training for your operators and maintenance staff. This prevents common operational errors. Fourth, establish a preventative maintenance schedule. Follow it strictly. Finally, choose a supplier who acts as a true partner. They should offer continuous support and upgrades. This ensures your machine stays efficient and safe for years.

Strategies for Maximizing Your Packing Machine’s Lifespan and Performance

Ensuring the longevity and efficiency of your steel coil packing machine is a strategic imperative. As Randal Liu, I’ve seen factories thrive when they make informed decisions and establish solid relationships with their suppliers. For a factory manager like Michael, who prioritizes ROI and wants to avoid future challenges, a proactive approach to equipment selection and maintenance is non-negotiable. It’s about securing an asset that consistently delivers value and supports business growth.

Key Strategies for Long-Term Reliability:

- Thorough Supplier Vetting and Due Diligence:

- Reputation Check: Research their industry reputation, read case studies, and talk to existing customers. Look for transparency and consistent positive feedback.

- Financial Stability: A financially stable supplier is more likely to provide long-term support and parts.

- Manufacturing Standards: Inquire about their manufacturing processes, quality control measures, and certifications (e.g., ISO, CE).

- Prioritize Quality and Durability in Equipment:

- Robust Construction: Opt for machines built with high-quality, heavy-duty materials capable of withstanding the harsh environment of metal processing.

- Proven Technology: Choose systems with established track records rather than unproven prototypes.

- Component Sourcing: Understand where key components (motors, PLCs, sensors) come from. Reputable brands ensure easier replacement and better performance.

- Invest in Comprehensive Training and Skill Development:

- Operator Training: Ensure your team understands the machine’s full capabilities and proper operating procedures to prevent misuse and damage.

- Maintenance Training: Empower your in-house maintenance crew to perform routine checks, troubleshoot minor issues, and understand advanced diagnostics.

- Safety Protocols: Thorough training on safety features and emergency procedures is vital to reduce accident risks.

- Implement a Proactive Maintenance Schedule:

- Preventative Maintenance (PM): Regular inspections, lubrication, and part replacements (e.g., wear parts) prevent major breakdowns.

- Condition Monitoring: Utilize sensors and data analysis to predict potential failures before they occur, allowing for planned interventions.

- Digitalization of Maintenance: Use software to track maintenance records, schedule tasks, and manage spare parts inventory efficiently.

- Forge a True Partnership with Your Supplier:

- Clear Communication: Maintain open lines of communication for support, feedback, and potential upgrades.

- Long-Term Service Agreements: Negotiate comprehensive service contracts that cover maintenance, parts, and technical assistance over the machine’s lifespan.

- Technology Updates: Work with your supplier to integrate future technology upgrades or modifications that can enhance efficiency or address new production challenges.

For Michael, choosing a supplier like FHOPEPACK, which emphasizes robust German-standard engineering and offers comprehensive after-sales support (especially with our preferred partners like Fengding or Wuxi Buhui), means he can be confident in his investment. Our goal is to solve his efficiency bottlenecks and safety concerns, not just for today, but for many years to come. By focusing on these strategies, factories can mitigate risks and ensure their packing lines remain a reliable asset. (steel coil packaging equipment reliability)

Conclusion

Choosing between local and overseas suppliers requires balancing proximity with advanced technology. Focus on robust machines and strong after-sales support for lasting reliability. Invest wisely in your steel coil packing line for long-term success.