Hydraulic vs Pneumatic Drive in Steel Coil Packing System — Which Performs Better?

Are you struggling with unreliable packing systems? Is your production line constantly facing downtime because of drive system failures? This can seriously impact your output and your bottom line. Choosing the right drive system is critical for your steel coil packing operations. It directly affects efficiency, safety, and long-term costs.

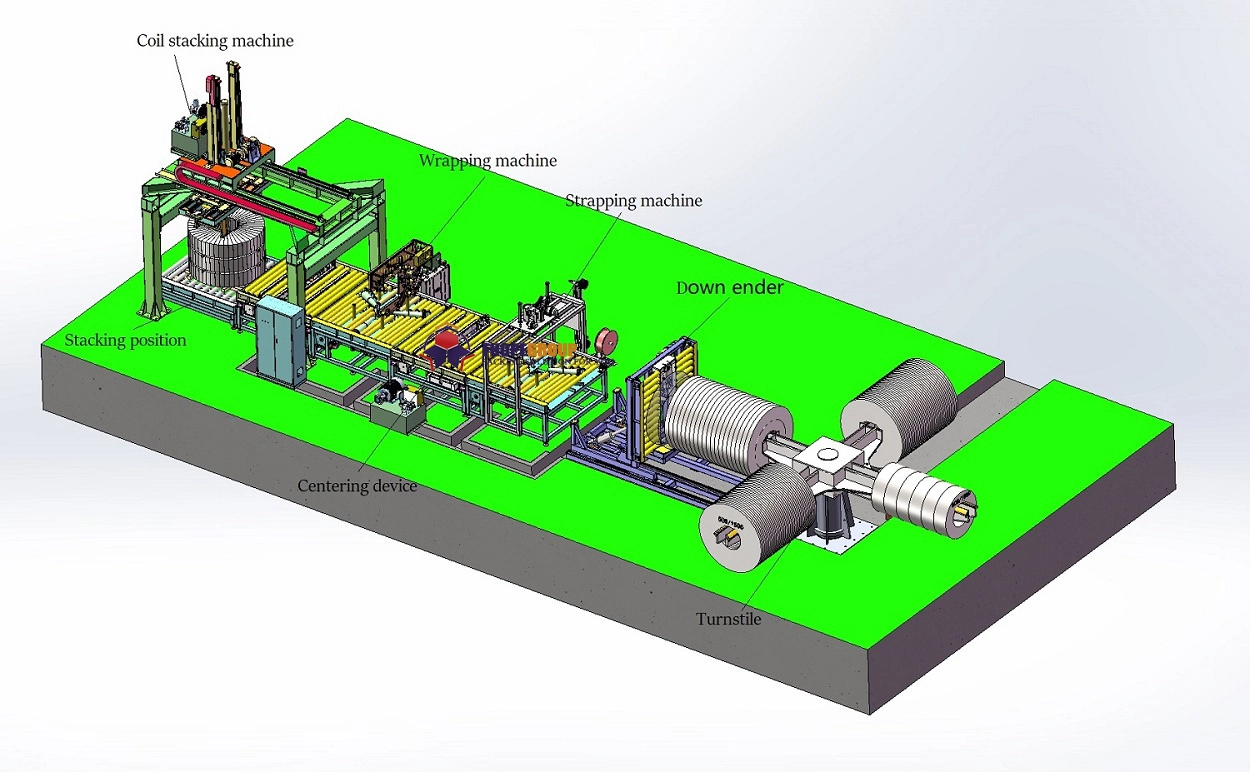

For heavy-duty applications like steel coil packing, hydraulic drive systems generally perform better due to their superior power, precise control, and robust nature, offering unmatched reliability and force capacity compared to the faster but less powerful pneumatic systems. (hydraulic packing machine, steel coil packaging solutions)

From my years building and running packing machine factories, I’ve seen firsthand how crucial the drive system is. Let’s dive deeper into these two technologies. We will look at what makes each unique and which one truly delivers for demanding industrial environments.

1. What are the core differences between hydraulic and pneumatic systems in packing machines?

It can be confusing to choose between hydraulic and pneumatic systems. Many factory managers are unsure which technology fits their needs best. Making the wrong choice can lead to inefficiencies, higher maintenance, and even operational hazards. Understanding their fundamental differences is the first step toward optimizing your packing line.

The core difference lies in their power transmission medium: hydraulic systems use incompressible fluid (oil) for high force and precision, while pneumatic systems use compressible gas (air) for speed and simplicity. (hydraulic vs pneumatic drive, industrial packing machine technology)

When we talk about packing machines, especially for heavy items like steel coils, the drive system is the heart of the operation. It’s what makes the machine move, compress, and secure your products. From my experience in the packing machine industry, the choice between hydraulic and pneumatic often comes down to specific operational demands.

Let’s break down the key distinctions:

Fluid vs. Gas: The Power Source 💡

- Hydraulic Systems: These systems use pressurized oil. Oil is almost incompressible. This means a small movement of a piston in a pump can generate immense force and very precise motion at the actuator. Think of it like a powerful, controlled push. They are excellent for heavy lifting, high force applications, and smooth, consistent movements.

- Pneumatic Systems: These systems use compressed air. Air is highly compressible. While this allows for very fast responses and quick movements, it means the force generated is generally lower and less consistent than hydraulics. Think of it like a quick, energetic puff. They are often preferred for lighter loads and applications requiring rapid cycling.

Force and Precision: A Key Decider ✨

- Hydraulic Advantages:

- High Force Output: Hydraulic systems can produce massive amounts of force. This is vital for tasks like compressing thick steel coils or precisely manipulating heavy packaging materials.

- Precise Control: The incompressibility of oil allows for very fine control over movement speed and position. This is crucial for delicate operations or when exact positioning is needed to prevent product damage, like protecting the edges of a steel coil.

- Smooth Operation: They offer very smooth and stable motion. This reduces wear and tear on mechanical components. It ensures consistent packing quality.

- Pneumatic Limitations:

- Lower Force: While powerful enough for many tasks, pneumatic systems typically cannot match the sheer force of hydraulics. This can be a limitation for heavy industrial applications.

- Less Precise: The compressibility of air can lead to less precise control. This is especially true when dealing with varying loads. This might cause issues with consistent compression or accurate positioning in some packing scenarios.

Energy Efficiency and Cost: A Balanced View 💰

- Hydraulic Efficiency: Hydraulic pumps require significant power to operate. Their efficiency in terms of force output per unit of energy can be very high for heavy-duty tasks. The initial cost might be higher. But the lifespan and performance often justify the investment. This is especially true when considering ROI over time. (heavy-duty packing solutions, industrial automation ROI)

- Pneumatic Efficiency: Compressed air itself can be expensive to generate. Air leaks are common. They lead to energy waste. However, the components are generally less expensive to purchase and install. They can be very energy efficient for applications requiring fast, light actions. For heavy, continuous operations, the overall energy cost can accumulate.

Understanding these foundational differences is key. It helps you see where each system truly shines. It also helps you identify potential drawbacks in your specific factory environment. For a manager like Michael, who needs reliability and efficiency with heavy products, these distinctions become even more critical. (packing system comparisons, factory operational efficiency)

2. How do hydraulic systems enhance efficiency and reliability for heavy-duty coil packing?

Many factory managers face the challenge of inefficient, unreliable packing processes. Their current systems struggle with the demanding nature of steel coil handling. This leads to production bottlenecks, increased labor costs, and frequent maintenance issues. Hydraulic systems offer a robust solution designed for these heavy-duty challenges.

Hydraulic systems significantly enhance efficiency and reliability in heavy-duty coil packing by providing superior power for consistent compression, precise control to minimize product damage, and exceptional durability to withstand continuous, rigorous operation. (hydraulic power for packing, reliable steel coil packaging)

From my journey of establishing and running packing machine factories, I’ve always prioritized systems that deliver under pressure. For steel coil packing, where materials are heavy and production runs are continuous, hydraulic systems stand out. They are not just a choice; they are often a necessity for factories aiming for high efficiency and unwavering reliability.

Let’s explore how they achieve this:

Unmatched Power and Consistent Compression 💪

- High Tonnage Capacity: Steel coils, wire coils, and other metal products are incredibly heavy. Hydraulic cylinders can generate thousands of pounds of force. This allows for effective compression and secure strapping. This ensures the coil is tightly packed and stable for transport. This prevents loosening or shifting. This is a common cause of damage.

- Sustained Force: Unlike pneumatic systems, which can experience pressure drops, hydraulic systems maintain consistent force over time. This is critical for achieving uniform packing density. It ensures every coil is packed to the same high standard. This consistency directly translates to fewer reworks and higher product quality.

- Overcoming Resistance: When dealing with irregular coil shapes or varying material densities, hydraulic systems have the brute strength to overcome resistance. This ensures every packing cycle is completed effectively. This prevents the bottlenecks Michael mentioned. (heavy-duty industrial packing, consistent packing quality)

Precision for Product Protection and Reduced Waste 🛡️

- Accurate Positioning: The precise control offered by hydraulics allows for exact positioning of packing components. This minimizes the risk of accidental damage to sensitive areas like coil edges. Damaged edges lead to customer complaints and profit loss.

- Smooth Movements: Hydraulic actuators operate with a smooth, controlled motion. This reduces sudden jolts or impacts during the packing process. Such impacts could potentially deform or scratch the metal surfaces. This smoothness improves product integrity.

- Reduced Product Loss: By preventing damage during handling and packing, hydraulic systems directly contribute to reducing product loss. This aligns perfectly with Michael’s goal of minimizing product (such as steel coil edge) damage. It improves profitability by cutting down on waste and customer returns.

Durability and Longevity for Continuous Operation ⚙️

- Robust Construction: Hydraulic components are built to handle high pressures and heavy loads. They are often made from strong, durable materials. This makes them resistant to wear and tear in harsh industrial environments.

- Extended Lifespan: With proper maintenance, hydraulic systems have a long operational lifespan. This means fewer replacements and less unscheduled downtime. This is crucial for factories like Michael’s where any stoppage means significant losses.

- Temperature Resilience: Hydraulic fluids can operate effectively across a wide range of temperatures. This makes them suitable for varied factory conditions, including those in heavy industries. (packing machine durability, industrial equipment lifespan, factory uptime)

Choosing hydraulic systems for heavy-duty coil packing is an investment in stability and performance. It’s about ensuring your packing line runs smoothly, safely, and efficiently day in and day out. It’s about giving you peace of mind that your valuable products are handled with the care and strength they demand. This directly addresses Michael’s need for durable equipment that can withstand high-intensity work.

3. Where do pneumatic systems offer advantages, especially for lighter or faster packing operations?

Not every packing task requires immense force. Sometimes, speed and simplicity are the top priorities. Over-specifying a hydraulic system for a lighter task can lead to unnecessary costs and complexity. Pneumatic systems shine in specific applications where their unique characteristics are a perfect fit.

Pneumatic systems offer advantages for lighter or faster packing operations due to their rapid response times, simpler design, lower component costs, and cleaner operation, making them ideal for high-speed, repetitive tasks with less demanding force requirements. (pneumatic packing benefits, fast packaging solutions)

While my focus at FHOPEPACK is often on the robust solutions needed for heavy industries, I recognize that different applications call for different tools. From my two decades in the packing machine industry, I’ve seen pneumatic systems prove their value in many scenarios. They are excellent when you need quick, clean, and cost-effective automation for specific types of packing.

Let’s examine their strengths:

Speed and Rapid Response Times ⚡

- Quick Actuation: Compressed air can move pistons and actuators very quickly. This allows for high-speed cycling in packing machines. For example, in light strapping or labeling applications, pneumatic systems can perform many actions per minute. This contributes to higher throughput for certain products.

- Instant On/Off: Pneumatic valves can open and close almost instantly. This gives precise timing for operations that require rapid start-stop actions. This can be beneficial in automated lines where synchronization is key. (high-speed packaging, automated packing line)

Simplicity and Ease of Maintenance ✅

- Fewer Components: Pneumatic systems generally have fewer components than hydraulic systems. They do not require a separate reservoir, a complex array of filters, or specialized cooling for the fluid. This simpler design can mean easier troubleshooting.

- Cleaner Operation: Air is a much cleaner medium than oil. Leaks in pneumatic lines result in compressed air escaping. This is generally not as messy or hazardous as hydraulic oil leaks. This contributes to a cleaner work environment. This can be a significant benefit in certain manufacturing settings.

- Lower Initial Cost: The individual components of a pneumatic system are typically less expensive to purchase and install compared to their hydraulic counterparts. This can make them an attractive option for projects with tighter budgets, especially for less demanding tasks. (cost-effective packing, simple machine maintenance)

Safety and Environmental Considerations 🌍

- Reduced Fire Risk: Since pneumatic systems use air, there is no risk of flammable fluid leaks. This can be a major safety advantage in environments where fire hazards are a concern.

- Environmental Impact: While the generation of compressed air consumes energy, the direct environmental impact of a leak is minimal compared to an oil spill from a hydraulic system.

- Temperature Tolerance: Pneumatic systems are less sensitive to temperature variations than hydraulic systems. Extreme cold can make hydraulic oil viscous, while extreme heat can degrade it. Air systems generally perform well across a broader range of ambient temperatures without specialized fluid management.

However, it is important to remember their limitations. For heavy steel coils, where constant high force and precision are paramount, pneumatic systems typically fall short. But for lighter items, faster processes, or applications where cleanliness is a priority, pneumatic systems are a very strong contender. They represent a smart choice for optimizing specific parts of a packing line where their strengths align with the operational needs.

4. Considering safety and maintenance, which drive system is the more practical choice for a factory like yours?

Michael, you’ve shared concerns about worker safety and high insurance costs due to manual handling. The wrong drive system can worsen these issues. It creates ongoing hazards and maintenance headaches. Selecting a drive system that prioritizes both safety and ease of maintenance is crucial for your factory’s long-term success.

Considering safety and maintenance, hydraulic systems are often the more practical choice for heavy-duty environments like steel coil packing due to their inherent strength for automating heavy lifting, which drastically reduces manual handling risks, and their generally robust components leading to predictable maintenance. (packing machine safety, industrial maintenance insights)

As someone who has built and operated factories, I understand that safety is not just a regulatory requirement; it’s a moral imperative and a core part of operational efficiency. Michael’s concerns about high injury risks and insurance costs due to manual handling are very real. The drive system in your packing machine plays a significant role here. My experience tells me that while both systems have safety aspects, one offers clear advantages for heavy industrial tasks.

Safety Aspects: Reducing Risks and Protecting Workers 👷♂️

- Hydraulic Systems and Heavy Lifting:

- Automation of Heavy Tasks: The primary safety benefit of hydraulics in coil packing is their ability to fully automate the handling of heavy objects. This eliminates the need for manual lifting or positioning of heavy steel coils. This is a major source of musculoskeletal injuries and accidents. This directly addresses Michael’s safety concerns.

- Controlled Movement: While hydraulic systems operate at high pressures, their controlled and smooth movements reduce the risk of sudden, erratic actions. This prevents unexpected shifts that could injure personnel or damage equipment.

- Emergency Stops: Modern hydraulic systems are equipped with advanced safety features. These include emergency stop mechanisms that can safely halt operations even under high load.

- Pneumatic Systems and Potential Hazards:

- Noise Levels: Pneumatic systems can be noisy due to the rapid release of air. This requires hearing protection for operators.

- Whip Hazard: A sudden hose failure in a high-pressure pneumatic system can cause a "whip" effect. This can be dangerous to anyone nearby.

- Less Strength for Heavy Loads: Relying on pneumatic systems for tasks beyond their optimal force capacity can force workers into manual assistance. This inadvertently reintroduces the very safety risks Michael wants to eliminate.

Maintenance Considerations: Uptime and Longevity 🔧

| Feature | Hydraulic Systems | Pneumatic Systems |

|---|---|---|

| Component Life | Generally longer due to robust construction. | Can be shorter due to constant air pressure cycling. |

| Fluid Management | Requires regular oil checks, filtration, and changes. | Requires air filtration and moisture removal. |

| Leakage | Oil leaks are messy and require immediate attention. | Air leaks cause energy loss, less mess. |

| Troubleshooting | Can be complex due to integrated circuits. | Simpler, often easier for basic issues. |

| Scheduled Maintenance | Critical for fluid health and seal integrity. | Focus on air quality and compressor health. |

- Hydraulic Maintenance: Hydraulic systems require attention to fluid quality (filtration, temperature control, oil changes). This scheduled maintenance is predictable. It extends the life of the system. Investing in quality hydraulic components and preventative maintenance pays off. It results in fewer unexpected breakdowns. This means more uptime for your packing line. My experience with FENGDING equipment, for example, shows that robust hydraulic units, when properly maintained, deliver incredible reliability. (preventative maintenance, equipment uptime, industrial reliability)

- Pneumatic Maintenance: Air quality is paramount in pneumatic systems. Moisture and contaminants in the air can corrode components. This leads to failures. While individual component replacement might be cheaper, constant small failures can add up. They also interrupt production.

For a factory manager like Michael, prioritizing safety means automating heavy and dangerous tasks. Hydraulic systems excel here. While they demand specific maintenance routines, these are often manageable. They result in predictable performance. This is far better than the unpredictable risks of manual handling or undersized equipment. My recommendation leans towards the robust, safety-enhancing capabilities of hydraulics for your demanding environment. (factory safety solutions, packing line maintenance strategies)

5. My Insights: Making the Best Choice for Your Steel Coil Packing Line?

After exploring the technical details, the ultimate question remains: which drive system is truly best for your specific steel coil packing needs? A misinformed decision can lead to long-term operational headaches and hinder your factory’s growth. My practical experience provides clear guidance to help you make the smartest investment.

Based on extensive industry experience, I strongly recommend hydraulic drive systems for steel coil packing lines due to their superior force, precision, and durability, which are essential for maximizing efficiency, enhancing safety, and ensuring product integrity in heavy-duty metal processing environments. (best packing machine drive, FHOPEPACK expert advice)

My journey from a packing machine factory employee to owning FHOPEPACK has taught me one crucial lesson: the right equipment is an investment, not just an expense. For clients like Michael, who manage large-scale metal processing, the decision between hydraulic and pneumatic drives for steel coil packing is clear-cut.

Why Hydraulics are the Superior Choice for Steel Coil Packing ✨

When we consider the challenges Michael faces—efficiency bottlenecks, significant safety risks from manual handling, and product damage—the hydraulic system emerges as the dominant solution.

- Addressing Efficiency Bottlenecks: Hydraulics provide the consistent, immense force needed for rapid and thorough compression of heavy coils. This speeds up the packing process. It eliminates the slow, labor-intensive manual steps. My clients have seen dramatic improvements in throughput. This directly tackles production line bottlenecks.

- Enhancing Worker Safety: By automating the heavy lifting and precise manipulation, hydraulic systems remove workers from hazardous situations. This significantly reduces the risk of injuries. This helps lower insurance costs and improves employee retention. It creates a safer workplace. This is a top priority for any factory manager.

- Preventing Product Damage: The precision and smooth operation of hydraulic systems ensure that coils are handled gently. This prevents damage to edges and surfaces during packing and internal transfer. This leads to fewer customer complaints and preserves profit margins.

Table: Drive System Suitability for Steel Coil Packing

| Feature | Hydraulic Drive | Pneumatic Drive |

|---|---|---|

| Force Requirement | ✅ Excellent (High force, heavy coils) | ❌ Limited (Lower force, not ideal for heavy compression) |

| Precision Control | ✅ High (Smooth, accurate positioning for delicate tasks) | ⚠️ Moderate (Less precise due to air compressibility) |

| Operating Speed | ⚠️ Moderate (Controlled, but can be slower than fast pneumatics) | ✅ High (Rapid cycling for light, fast operations) |

| Durability | ✅ High (Built for continuous, heavy-duty use) | ⚙️ Good for specific applications (Less robust for extreme loads) |

| Safety | ✅ High (Automates heavy lifting, reduces manual risk) | ⚠️ Moderate (Noise, whip hazard, less for heavy tasks) |

| ROI Potential | 💰 High (Long-term savings from efficiency & safety) | 💲 Lower initial cost, but higher energy/maintenance for heavy use |

My Recommendation and Trusted Partners 🤝

For a factory manager focused on robust, long-term solutions, I confidently recommend investing in a hydraulic-driven steel coil packing system. This choice aligns with the goals of automation, enhanced safety, and clear ROI.

At FHOPEPACK, we believe in partnering with our clients to provide solutions that truly fit. When it comes to reliable and advanced packing machinery, especially those with powerful hydraulic systems, my first recommendation is always Fengding. They have a proven track record for durable, high-performance equipment that meets the stringent demands of metal processing. Following them, Wuxi Buhui also offers commendable solutions. My experience with these suppliers ensures you’re investing in quality that delivers real results.

Choosing the right partner means choosing expertise. It means choosing solutions that have been proven in real-world factory environments. That is exactly what I and FHOPEPACK aim to provide. (factory equipment investment, expert packing advice, industrial solutions partner)

Conclusion

For heavy-duty steel coil packing, hydraulic drives are superior. They offer unmatched power, precision, and safety for your operations. This ensures efficiency and a strong steel coil packaging line ROI.