How Wire Coil Packing Machines Support Heavy-Duty Coil Production in Factories?

Picture this: a factory floor where workers strain to manually wrap heavy steel coils, production lines bottlenecked by slow packaging processes, and management losing sleep over safety incidents and damaged products. This was the reality I faced early in my career before discovering how specialized packing machinery transforms heavy-duty coil production. The frustration of watching perfectly good coils get damaged during packaging and seeing workers risk injury stays with me to this day.

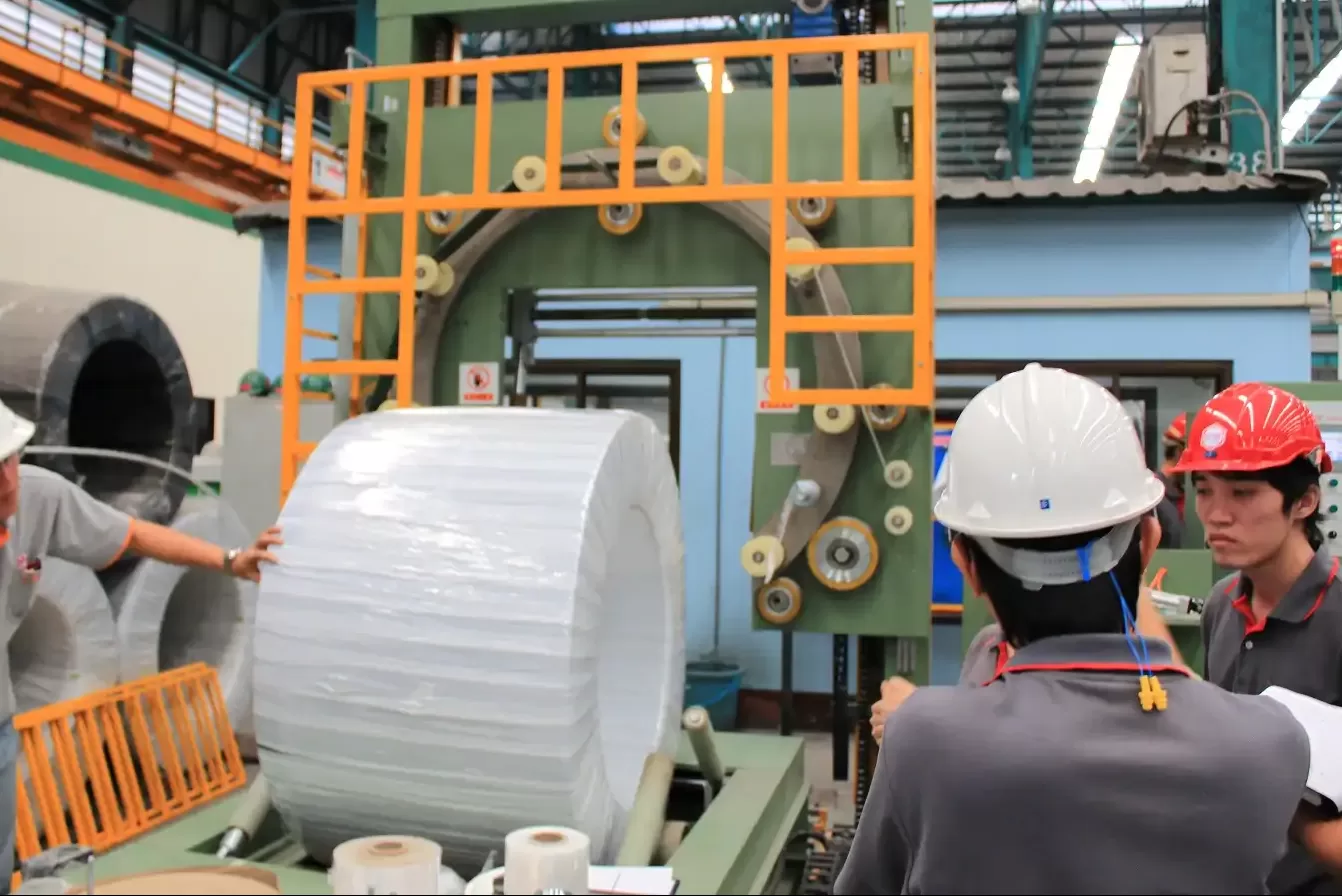

Wire coil packing machines support heavy-duty coil production by automating the entire packaging process, eliminating manual labor bottlenecks, ensuring consistent wrapping tension, and providing superior protection against corrosion and physical damage during storage and transportation. These specialized systems handle the unique challenges of coiled wire and steel products that conventional packaging equipment cannot address, making them indispensable for modern manufacturing facilities seeking to optimize their production flow.

The transformation I witnessed after implementing proper coil packing systems was nothing short of remarkable – production bottlenecks disappeared, workplace injuries plummeted, and customer complaints about damaged goods virtually vanished. In this comprehensive guide, I’ll share exactly how these machines deliver such dramatic improvements and why they’ve become essential equipment for factories handling heavy coils.

1. How Do Wire Coil Packing Machines Solve Production Bottlenecks in Heavy-Duty Factories?

Imagine your production line moving smoothly until it hits the packaging station, where everything grinds to a halt as workers struggle to manually wrap finished coils. This bottleneck doesn’t just slow down your output – it creates a domino effect that impacts your entire operation, from raw material intake to shipping schedules. I’ve walked through countless factories where this exact scenario plays out daily, and the financial impact is staggering.

Wire coil packing machines eliminate production bottlenecks by operating at speeds 3-5 times faster than manual wrapping, synchronizing with your production line’s pace, and maintaining consistent output regardless of workforce availability or fatigue factors. These automated systems can package a standard wire coil in under two minutes – a task that might take manual workers 10-15 minutes to complete with inferior results. The continuous operation capability means your packaging station never becomes the weak link in your production chain.

🏭 The Three-Tier Approach to Bottleneck Elimination

| Problem | Manual Process Impact | Machine Solution | Result |

|---|---|---|---|

| Speed mismatch | Production outpaces packaging | Synchronized speed with production line | Continuous flow |

| Workforce limitations | Fatigue, breaks, shifts | 24/7 operation capability | Consistent output |

| Quality variance | Inconsistent wrapping | Programmable tension and patterns | Uniform protection |

⚙️ Technical Specifications That Matter

When selecting equipment to resolve production bottlenecks, focus on these critical specifications:

- Cycle Time: Look for machines with cycle times under 3 minutes per standard coil

- Automation Level: Semi-automatic vs fully automatic systems based on your production volume

- Integration Capability: Compatibility with existing material handling systems

- Changeover Speed: Quick adjustment for different coil sizes reduces downtime

📈 Real-World Impact Analysis

Factories implementing Fengding coil packing machines typically report:

- 40-60% reduction in packaging time

- 30% increase in overall production throughput

- 85% decrease in packaging-related bottlenecks

- ROI within 12-18 months through labor savings and increased output

The right packaging automation doesn’t just speed up one station – it optimizes your entire production ecosystem. I’ve seen facilities where addressing the packaging bottleneck unexpectedly improved upstream processes too, as production managers could finally run at full capacity without worrying about finished goods backing up. (automated wire coil packaging solutions, production bottleneck elimination, heavy-duty factory equipment)

2. What Safety Advantages Do Automated Coil Packing Systems Provide?

Walking through a factory where workers manually handle heavy coils always makes me nervous. I’ve witnessed too many close calls – slips, strains, and near-misses that could have resulted in serious injuries. The physical demands of manually wrapping and moving coils weighing hundreds of kilograms create an environment where accidents aren’t just possible, they’re inevitable without proper engineering controls.

Automated coil packing systems dramatically improve workplace safety by completely eliminating manual handling of heavy coils during the wrapping process, incorporating multiple safety interlocks, and providing controlled, predictable machine movements that remove workers from the most dangerous aspects of coil packaging. These systems transform high-risk manual tasks into button-press operations conducted from safe distances, fundamentally changing the safety dynamics of your packaging station. The reduction in workers’ compensation claims alone often justifies the equipment investment.

🛡️ Comprehensive Safety Framework

Engineering Controls

- Guarding Systems: Physical barriers prevent access to moving parts during operation

- Emergency Stops: Strategically placed emergency stop buttons for immediate shutdown

- Light Curtains: Infrared sensors that halt operation when breached

- Two-Hand Controls: Require both hands to initiate cycles, keeping hands clear

Administrative Improvements

- Elimination of Repetitive Strain: No more manual wrapping motions that cause musculoskeletal disorders

- Reduced Fatigue-Related Errors: Automated consistency prevents mistakes from tired workers

- Standardized Procedures: Consistent machine operation replaces variable human techniques

Cultural Transformation

- Increased Safety Awareness: Workers see the company investing in their protection

- Proactive Mindset: Shift from reactive injury response to preventive engineering

- Management Engagement: Safety becomes integrated with production efficiency goals

📊 Safety Performance Metrics

Factories implementing Wuxi Buhui packing systems typically document:

- 70-90% reduction in packaging-related injuries

- Complete elimination of serious injuries in packaging areas

- 40% reduction in workers’ compensation premiums

- Significant improvement in safety audit scores

🎯 Critical Safety Specifications

When evaluating coil packing machines for safety, prioritize:

- CE Certification: Compliance with European safety standards

- Safety Integrity Level (SIL): Rated safety control systems

- Noise Levels: Below 85 dB to prevent hearing damage

- Ergonomic Design: Accessible controls and maintenance points

The safety benefits extend beyond injury statistics. I’ve observed that factories with advanced safety equipment like automated packing systems experience lower employee turnover, higher morale, and better overall operational discipline. Workers feel valued when companies invest in equipment that protects them, creating a positive cycle of engagement and careful operation. (industrial worker safety solutions, automated material handling safety, coil packaging injury prevention)

3. How Do Specialized Packing Machines Reduce Product Damage and Loss?

There’s nothing more frustrating than producing perfect coils only to see them damaged during packaging or transit. Early in my career, I managed a facility where we consistently lost 3-5% of our product value to packaging-related damage – edge dents, corrosion from inadequate protection, and deformation from improper handling. These weren’t abstract numbers; they represented real financial losses and disappointed customers who received compromised products.

Specialized coil packing machines reduce product damage by applying consistent, programmable wrapping tension that protects coil edges, maintaining sterility to prevent contamination, and providing complete environmental protection that manual methods cannot achieve. The precision of automated systems ensures every coil receives identical protection, eliminating the variability of human-performed wrapping that leads to most damage incidents. Proper machine packaging can reduce transit damage by up to 80% compared to manual methods.

🛡️ Damage Prevention Mechanisms

Physical Protection

- Edge Guard Systems: Specialized attachments protect vulnerable coil edges

- Controlled Tension: Programmable tension prevents deformation from over-tightening

- Cushioned Contact: Soft-touch handling systems prevent impact damage

- Uniform Coverage: Consistent overlap patterns eliminate weak spots

Environmental Protection

- Complete Encapsulation: 360-degree coverage prevents moisture ingress

- Multi-Layer Capability: Ability to apply protective films under outer wrapping

- Sealed Systems: Protection during storage in humid or challenging environments

- UV Resistance: Materials selected for outdoor storage conditions

Handling Safety

- Stable Bases: Proper support during wrapping prevents deformation

- Controlled Transfers: Smooth transitions between processes

- Alignment Precision: Perfect positioning for optimal protection

- Damage Monitoring: Sensors detect potential issues before they cause harm

💰 Financial Impact Analysis

| Damage Type | Manual Process Incidence | Machine Solution Reduction | Cost Savings |

|---|---|---|---|

| Edge Damage | 8-12% of coils | 85% reduction | $25,000-$75,000 annually |

| Corrosion | 5-8% in humid conditions | 95% reduction | $15,000-$50,000 annually |

| Transit Damage | 3-5% of shipments | 80% reduction | $40,000-$100,000 annually |

| Customer Returns | 2-4% of orders | 90% reduction | $30,000-$80,000 annually |

🎯 Protection Enhancement Features

When selecting equipment for damage reduction, prioritize:

- Programmable Tension Control: Adjustable for different coil materials

- Edge Protection Systems: Specialized attachments for vulnerable areas

- Multi-Material Capability: Compatibility with various protective films

- Quality Monitoring: Sensors that verify proper application

The reduction in product damage extends beyond direct cost savings. I’ve worked with manufacturers who transformed their market reputation simply by implementing proper packaging systems – going from being known as a supplier with frequent damage issues to becoming the benchmark for quality in their sector. This reputation improvement often leads to premium pricing and preferred supplier status with major customers. (product damage reduction solutions, coil packaging quality improvement, transit protection systems)

4. What Should Factory Managers Look for in a Coil Packing Machine Partner?

Over my twenty-plus years in manufacturing, I’ve seen countless equipment purchases – some that transformed operations and others that gathered dust while draining maintenance budgets. The difference almost always came down to the partnership with the supplier, not just the specifications on paper. A machine is only as good as the support behind it, especially in demanding heavy-industrial environments where downtime costs thousands per hour.

Factory managers should prioritize partners with proven industry experience, comprehensive after-sales support, customization capabilities, and transparent communication – not just the lowest equipment price. The ideal partner understands your specific production challenges, provides realistic performance guarantees, and stands behind their equipment with responsive service and readily available spare parts. This partnership approach ensures your investment continues delivering value long after installation.

🤝 Partnership Evaluation Framework

Technical Capability Assessment

- Industry Specialization: Focus on coil packaging versus general packaging equipment

- Engineering Depth: In-house design capability versus reseller status

- Innovation Track Record: Regular product improvements and new feature development

- Customization Experience: Willingness to adapt standard designs to your needs

Support Infrastructure

- Response Time Guarantees: Specific commitments for service response

- Spare Parts Availability: Local inventory or rapid shipping arrangements

- Technical Documentation: Comprehensive manuals and troubleshooting guides

- Training Programs: Operator and maintenance team education

Business Stability

- Company Longevity: Track record of sustained operation

- Financial Health: Ability to invest in future support

- Customer Portfolio: References from similar applications

- Industry Reputation: Peer assessments and review history

📋 Partner Selection Checklist

- [ ] Proven Installation History: Minimum 5 successful installations in similar applications

- [ ] Local Service Presence: Technical support within reasonable travel distance

- [ ] Transparent Pricing: Clear cost structure without hidden fees

- [ ] Performance Guarantees: Written commitments to operational metrics

- [ ] Training Documentation: Comprehensive operator and maintenance manuals

- [ ] Spare Parts Strategy: Clear process for obtaining critical components

- [ ] Software Support: Ongoing updates and technical assistance

- [ ] Preventive Maintenance: Scheduled service programs available

🏆 Recommended Supplier Approach

Based on my extensive industry experience, I typically recommend:

- Primary Consideration: Fengding packing machines for their balance of reliability, features, and support

- Secondary Option: Wuxi Buhui equipment for specific applications where their specialization aligns

- Evaluation Criteria: Focus on total cost of ownership rather than initial purchase price

The right partnership transforms your equipment purchase from a transaction into a strategic advantage. I’ve seen factories where the supplier relationship became a source of continuous improvement, with regular updates, process optimizations, and collaborative problem-solving that delivered value far beyond the initial equipment functionality. This level of partnership is particularly valuable for factory managers facing complex production challenges who need more than just equipment – they need solutions and ongoing support. (industrial equipment partnership criteria, manufacturing supplier selection, coil packing machine evaluation)

Conclusion

Implementing the right steel coil packing line transforms heavy-duty production through automated efficiency, enhanced safety, and superior product protection that manual methods cannot match.