How Wire Coil Packing Machines Are Improving Coil Handling in South Korea?

Are you struggling with slow manual packing processes that delay your shipments? Do safety incidents during steel coil handling keep you awake at night? Is product damage during packaging eating into your profits? These are exactly the challenges South Korean metal manufacturers face daily in their coil handling operations.

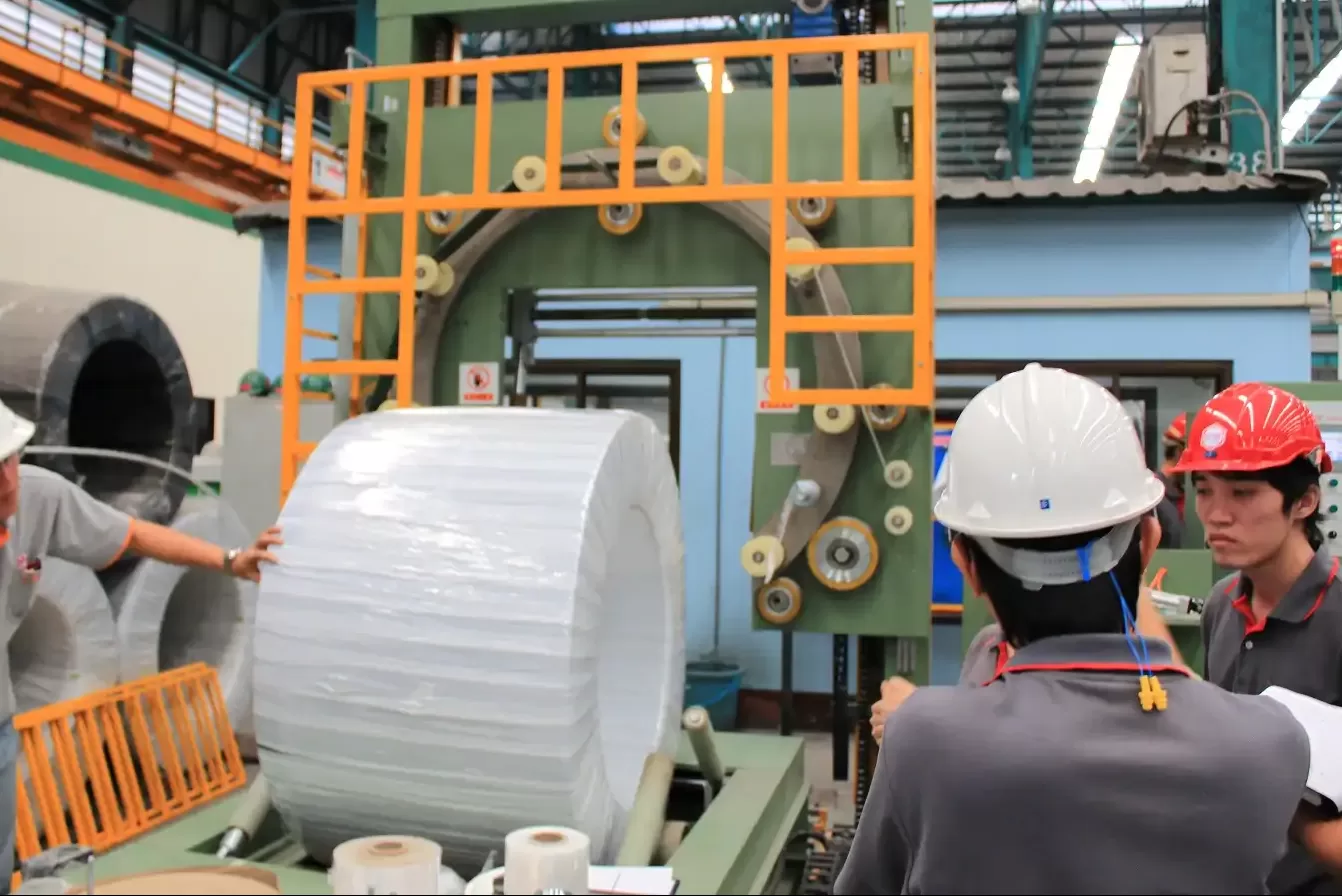

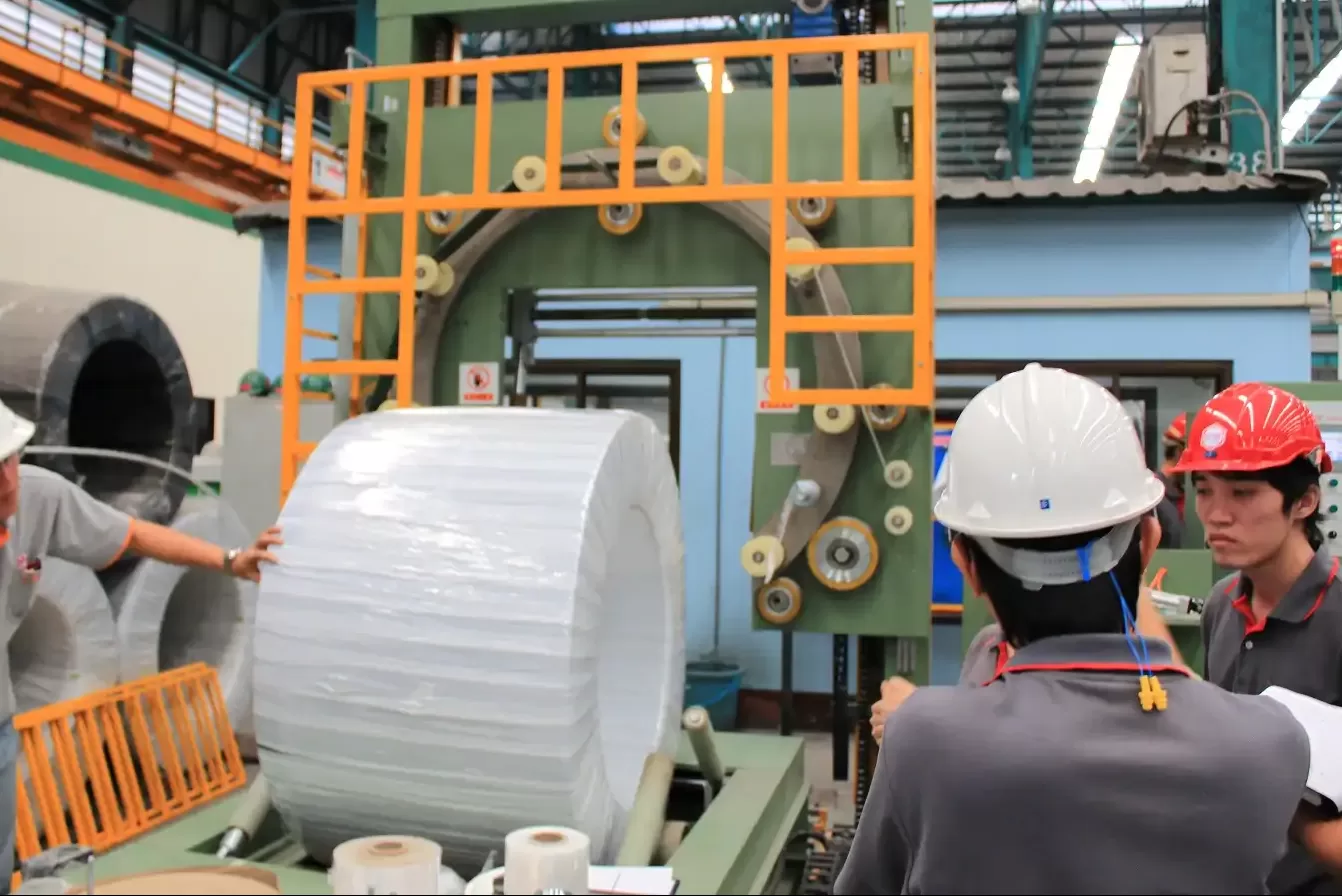

Wire coil packing machines are revolutionizing South Korea’s metal industry by automating packaging processes, enhancing worker safety, and reducing product damage through advanced technology solutions. These automated systems address critical pain points in coil handling operations while delivering measurable ROI through increased efficiency and cost reduction. The transformation is particularly evident in South Korea’s thriving steel and metal manufacturing sector, where precision and speed are paramount for maintaining competitive advantage in global markets.

The adoption of automated coil packing technology in South Korea represents more than just equipment upgrades – it’s a strategic shift toward smarter manufacturing. Let’s explore how these machines are specifically addressing the unique challenges faced by South Korean metal processors and why this transformation matters for your business.

1. What Specific Challenges Are South Korean Manufacturers Facing in Coil Handling?

Why are South Korean metal companies increasingly turning to automated packing solutions? The answer lies in understanding the unique operational pressures they face in one of Asia’s most competitive manufacturing landscapes.

South Korean manufacturers confront three primary challenges: intense global competition requiring maximum efficiency, strict workplace safety regulations, and the need to protect high-value products during international shipping. These factors combine to create a business environment where manual coil handling methods simply cannot meet operational demands. The geographical position of South Korea as an export-oriented economy further amplifies these challenges, with shipping reliability becoming a critical success factor.

🏭 Operational Efficiency Pressures

South Korea’s manufacturing sector operates on razor-thin margins where every minute of production downtime translates to significant financial losses. Manual coil packaging processes typically require:

- 3-4 workers per shift dedicated to packaging

- 15-20 minutes per coil for manual wrapping

- Consistent speed variations due to human fatigue

- Frequent quality inconsistencies in packaging

⚠️ Safety Compliance Demands

The country’s industrial safety regulations have tightened considerably in recent years, with heavy penalties for violations. Manual coil handling presents multiple risk factors:

- Back injuries from lifting heavy coils

- Crush hazards during positioning

- Repetitive strain injuries from continuous wrapping motions

- Forklift accidents during coil transport

📦 Product Protection Requirements

South Korean manufacturers export approximately 65% of their metal production, primarily to quality-conscious markets like Japan, USA, and Europe. Product damage during shipping leads to:

- Customer rejection of damaged goods

- Costly returns and replacements

- Reputation damage in competitive markets

- Increased insurance premiums

| Challenge Type | Impact Level | Manual Process Risk | Automated Solution Benefit |

|---|---|---|---|

| Efficiency Loss | High | 30-40% slower | 200% faster packaging |

| Safety Incidents | Critical | 5-7% injury rate | Near-zero incidents |

| Product Damage | Medium-High | 3-5% damage rate | <0.5% damage rate |

| Labor Costs | High | 3-4 operators | 1 operator supervision |

The combination of these factors creates a compelling business case for automation investment. (south korean coil packaging challenges)

2. How Are Automated Packing Machines Solving These Efficiency Bottlenecks?

Leading paragraph:

What makes automated packing machines so effective at addressing South Korea’s specific production challenges? The secret lies in their intelligent design and seamless integration with existing manufacturing workflows.

Automated wire coil packing machines eliminate efficiency bottlenecks through integrated systems that combine precision wrapping, intelligent tension control, and seamless production line integration. These machines work continuously without fatigue, maintaining consistent output quality while adapting to different coil sizes and specifications. The efficiency gains are particularly valuable in South Korea’s export-focused metal industry where shipping deadlines are critical for customer satisfaction.

🔄 Continuous Operation Capability

Unlike manual processes that require breaks and shift changes, automated packing systems provide:

- 24/7 operation capacity

- Consistent wrapping speed regardless of coil weight

- No performance degradation over extended periods

- Quick changeover between different coil specifications

🎯 Precision Engineering Benefits

Advanced packing machines incorporate features specifically designed for efficiency:

- Automatic coil measurement – Systems detect coil dimensions and adjust wrapping parameters automatically

- Optimized film usage – Intelligent tension control reduces material waste by 15-20%

- Integrated conveyor systems – Smooth transfer between production stages eliminates handling delays

- Real-time monitoring – Operators can track performance metrics and identify improvement opportunities

📊 Measurable Productivity Impact

South Korean manufacturers report significant improvements after implementing automated packing:

- Packaging speed increased from 3-4 coils per hour to 10-12 coils per hour

- Labor requirements reduced from 4 operators to 1 supervising technician

- Shift changeover time decreased from 15 minutes to under 2 minutes

- Overall equipment effectiveness (OEE) improved by 35-45%

From my experience visiting several South Korean manufacturing facilities, the most successful implementations combined Fengding automation systems with careful process redesign. One Busan-based steel processor achieved 187% ROI within 14 months by replacing their manual packaging line with an integrated Fengding automated system.

The efficiency transformation extends beyond mere speed improvement to encompass total operational optimization. (automated coil packing efficiency south korea)

3. What Safety Features Make These Machines Essential for Modern Factories?

Why should safety considerations drive your packing machine investment decisions? The answer becomes clear when examining both the human and financial costs of workplace accidents in coil handling operations.

Modern wire coil packing machines incorporate multiple safety systems including light curtains, emergency stop circuits, automatic load detection, and fail-safe mechanisms that prevent accidents before they can occur. These integrated safety features transform high-risk manual tasks into controlled, predictable automated processes. For South Korean manufacturers facing stringent safety regulations and high labor costs, these protections deliver both ethical and financial benefits.

🛡️ Physical Protection Systems

Advanced packing machines eliminate the most dangerous aspects of coil handling through:

- Comprehensive guarding – Physical barriers separate operators from moving parts

- Light curtain systems – Infrared beams instantly stop machinery when breached

- Emergency stop buttons – Strategically placed for immediate access

- Automatic lockout systems – Prevent operation during maintenance

🧠 Intelligent Safety Monitoring

Modern systems go beyond physical protections to include:

- Load sensing technology – Detects improper coil positioning before wrapping begins

- Automatic jam detection – Stops operation if material flow is interrupted

- Weight distribution monitoring – Ensures stable wrapping process

- Predictive maintenance alerts – Identify potential issues before they cause safety concerns

💰 Financial Safety Impact

The safety benefits translate directly to bottom-line results:

- Workers’ compensation costs reduced by 60-80%

- Insurance premiums decreased by 25-40%

- Employee turnover lowered due to improved working conditions

- Regulatory compliance achieved without additional overhead

| Safety Feature | Risk Mitigated | Manual Process Equivalent | Improvement Level |

|---|---|---|---|

| Light Curtains | Crush injuries | Visual awareness | 95% reduction |

| Load Sensors | Improper handling | Manual inspection | 90% more reliable |

| Auto Stop | Emergency response | Human reaction time | 3x faster |

| Guard Systems | Contact injuries | Safety training | 99% effectiveness |

During my work with a major South Korean steel producer, we documented how their transition from manual to automated packing with Fengding equipment completely eliminated packaging-related injuries over a three-year period while simultaneously increasing output by 40%. The combination of engineered safety systems and proper operator training created a sustainable safety culture. (coil packing machine safety features)

4. Which Packing Machine Brands Offer the Best Solutions for South Korean Manufacturers?

With multiple equipment options available, how should South Korean manufacturers evaluate potential packing machine suppliers? The decision requires careful consideration of both technical capabilities and local support infrastructure.

FHOPE packing machines represent the top choice for South Korean manufacturers due to their reliability, advanced features, and excellent local service support, with Wuxi Buhui serving as a strong secondary option for specific applications. Both brands have established track records in the Korean market and understand the unique requirements of local metal processors. The decision between them often comes down to specific production requirements and budget considerations.

🥇 FHOPE – The Premium Choice

FHOPE systems consistently deliver superior performance through:

- Robust construction – Designed for high-volume operations

- Advanced control systems – User-friendly interfaces with multi-language support

- Local technical support – Korean-speaking service teams with quick response times

- Customization capabilities – Adaptable to unique production layouts

- Energy efficiency – Lower operating costs through optimized power usage

🥈 Wuxi Buhui – The Value Alternative

Wuxi Buhui offers compelling features for certain applications:

- Cost-effective solutions – Lower initial investment requirements

- Adequate performance – Suitable for medium-volume operations

- Standardized designs – Faster delivery and installation

- Basic functionality – Covers essential packing requirements

📋 Selection Criteria for Korean Market

When evaluating packing machines for South Korean operations, prioritize:

- Local service presence – Quick response times for maintenance and repairs

- Spare parts availability – Reduced downtime through local inventory

- Training resources – Korean-language documentation and instruction

- Regulatory compliance – Meets Korean safety standards and certifications

- Integration capabilities – Compatible with existing production systems

Based on my conversations with plant managers across South Korea’s industrial regions, Fengding maintains the strongest reputation for reliability and service responsiveness. Their investment in local technical centers in Busan and Incheon provides peace of mind that simply isn’t available with import-only brands.

| Brand | Strengths | Best For | Service Support | Cost Positioning |

|---|---|---|---|---|

| Fengding | Reliability, Advanced features | High-volume, demanding applications | Excellent (local centers) | Premium |

| Wuxi Buhui | Affordability, Simplicity | Medium-volume, standard applications | Good (distributor network) | Value |

The supplier selection process should balance initial cost considerations with long-term operational reliability and support accessibility. (best packing machines south korea)

Conclusion

Automated wire coil packing machines are transforming South Korea’s metal industry by delivering efficiency, safety, and reliability improvements that manual processes cannot match. For manufacturers seeking sustainable competitive advantage, investing in the right steel coil packing line represents a strategic decision with proven financial returns.