How to Operate an Automatic Coil Packing Machine Safely?

Operating heavy machinery always carries risks. For a busy factory manager in Mexico, seeing your team manually handle heavy steel coils brings constant worries. The slow pace, the constant risk of injury, and the potential for costly product damage can weigh heavily on your mind. You know that any accident or downtime impacts not just your workers, but also your production targets and bottom line.

Operating an automatic coil packing machine safely requires a multi-faceted approach, focusing on rigorous operator training, understanding and utilizing advanced machine safety features, implementing strict maintenance protocols, and fostering a proactive safety culture within your facility. This combination ensures that the inherent risks associated with industrial packaging are minimized, protecting both your workforce and your valuable products.

Ensuring safety in your coil packing operations is not just about compliance; it is about building a robust, efficient, and profitable manufacturing environment. Let’s dive deeper into what this truly means and how you can achieve it.

1. Why is safety paramount when operating automatic coil packing machines?

Imagine a worker struggling with a heavy steel coil, straining to position it for packing. This isn’t just a slow process; it’s a huge safety hazard waiting to happen. The cost of an accident can go far beyond a single injury. It can stop your entire production line, erode worker trust, and hit your factory’s finances hard.

Safety is paramount in operating automatic coil packing machines because it directly protects human life, prevents costly operational downtime, safeguards product integrity, and upholds your factory’s reputation and compliance standards, making it fundamental to sustainable and profitable manufacturing. Prioritizing safety significantly reduces the risk of accidents, injury claims, and production disruptions, which are common challenges for factories in heavy manufacturing sectors.

At FHOPEPACK, I have seen firsthand the consequences of neglecting safety. From my early days as an employee to building my own successful packing machine factory, I learned that ignoring safety is a false economy. For factory managers in Mexico, especially in metal processing or logistics, the pressures of production are immense. But sacrificing safety for speed can lead to much bigger problems. It is not just about avoiding fines; it is about creating a workplace where your team feels secure, and your operations run smoothly without unexpected halts. Every injury means not only personal suffering but also lost productivity, increased insurance costs, and the arduous task of replacing and retraining staff, directly impacting your company’s financial health and operational stability.

The True Cost of Neglecting Safety

Neglecting safety protocols in heavy industries like coil packing leads to a cascade of negative effects. Understanding these impacts helps underscore why safety should always be your top priority.

-

Human Suffering and Injuries:

- Direct Impact: Workplace accidents can cause severe injuries, including crushed limbs, lacerations, and even fatalities, especially when handling heavy materials like steel coils. These incidents lead to pain, long-term disability, and emotional distress for workers and their families. 🤕

- Psychological Toll: A factory with frequent accidents creates a climate of fear and low morale. This impacts employee well-being and their willingness to perform tasks effectively.

-

Significant Financial Losses:

- Medical and Compensation Costs: Each accident incurs immediate medical expenses, worker’s compensation claims, and potential legal fees. These can quickly accumulate, draining company resources. 💰

- Production Downtime: An accident often forces an immediate halt to the production line for investigations, clean-up, and safety reviews. This downtime means lost production capacity and delayed deliveries, impacting customer satisfaction and revenue. 🛑

- Equipment Damage: Accidents involving heavy coils can also damage the automatic packing machinery itself, leading to expensive repairs and further operational delays. 🛠️

- Increased Insurance Premiums: A history of workplace accidents will inevitably lead to higher insurance premiums for your factory, increasing operational costs in the long run.

-

Operational Inefficiency and Product Loss:

- Reduced Productivity: Manual coil handling is inherently slow and prone to errors. When safety is compromised, workers might become overly cautious, further slowing down operations.

- Product Damage: During unsafe handling or packing, products like steel coil edges can get damaged. This leads to scrap, rework, customer complaints, and ultimately, profit loss. 📉

- High Employee Turnover: Workers are more likely to leave an unsafe working environment. High turnover means constant recruitment and training costs, impacting overall efficiency and expertise.

-

Reputational Damage and Compliance Issues:

- Brand Erosion: Accidents can tarnish your company’s reputation within the industry and among potential clients. A factory known for safety issues struggles to attract top talent and secure new contracts.

- Regulatory Penalties: Governments and industrial bodies have strict safety regulations. Non-compliance can result in heavy fines, legal actions, and even operational shutdowns. 📜

- Loss of Trust: Suppliers and clients prefer to work with responsible and safe partners. A poor safety record can break trust and jeopardize valuable business relationships.

By focusing on safety, you are not just preventing negative outcomes. You are actively building a more resilient, reliable, and respected manufacturing business, one where your team thrives and your production excels. (industrial safety benefits, factory risk management, operational stability)

2. What are the key safety features of modern coil packing machines?

It’s easy to look at a new machine and just see its output. But for a factory manager like Michael, the true value also lies in how it protects his team. Are you fully aware of the advanced safety measures built into today’s automatic coil packing machines? Ignoring these features means missing crucial opportunities to safeguard your operations.

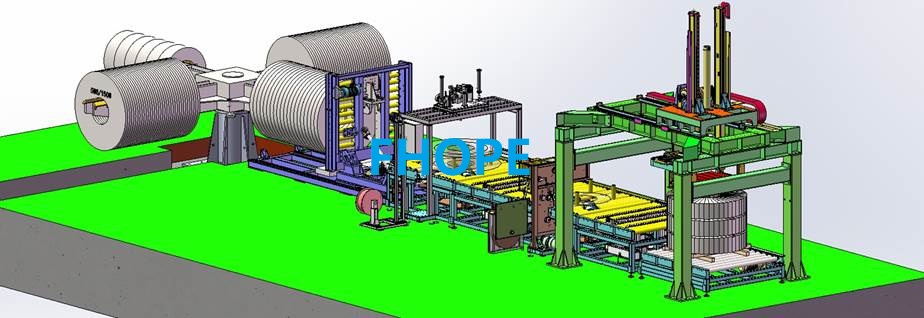

Modern automatic coil packing machines are engineered with an array of key safety features, including prominent emergency stop buttons, physical safety guards with interlocks, light curtains or safety scanners, integrated overload protection, and advanced human-machine interfaces (HMIs) with remote control capabilities, all designed to significantly reduce operator exposure to moving parts and heavy loads during the packing process. These innovations help mitigate the significant safety risks inherent in heavy manufacturing, offering a robust shield against accidents.

When I started FHOPEPACK, one of my core goals was to integrate maximum safety into every machine we design. I know the pressures factory managers face, balancing production targets with worker well-being. This is why understanding and utilizing the safety features in modern machines is not a luxury; it is a necessity. These features are not just add-ons; they are fundamental components that minimize human interaction with hazardous zones, which is a major concern in facilities handling heavy steel or wire coils.

Essential Safety Features in Automated Coil Packing

Modern coil packing machines are designed with safety as a top priority. They incorporate various technologies to protect operators and ensure smooth operations.

-

Emergency Stop Buttons (E-Stops):

- Function: Clearly visible and easily accessible buttons placed at strategic points around the machine. When pressed, they immediately cut power and halt all machine movement. 🛑

- Importance: Provides an instantaneous stop mechanism in critical situations, allowing operators to prevent or mitigate an accident.

- Placement: Usually red and mushroom-shaped, found on control panels and at key access points.

-

Safety Guards and Interlocks:

- Function: Physical barriers (e.g., fences, covers, doors) that prevent access to moving parts or dangerous areas. Interlocks ensure the machine cannot operate if a guard is open or removed. 🛡️

- Importance: Prevents physical contact with pinch points, crushing hazards, and rotating components, a major factor in reducing injury risks, especially with heavy coil packaging.

- Application: Crucial for coil wrapping, strapping, and conveying sections where coils move at high speeds or are rotated.

-

Light Curtains and Safety Scanners:

- Function: Invisible infrared beams that create a protective field. If an operator or object breaks the beam, the machine automatically stops. Safety scanners perform a similar function using laser technology to monitor a defined area. 👁️

- Importance: Offers an invisible safety barrier, providing flexibility for loading/unloading while ensuring machine shutdown if a person enters a hazardous zone.

- Use Case: Often placed around coil loading/unloading areas, or points where coils transition between stages.

-

Overload Protection Systems:

- Function: Sensors that detect if the machine is handling a weight or load beyond its specified capacity. If an overload is detected, the machine will stop or alert operators. ⚖️

- Importance: Prevents damage to the machine itself, structural failures, and potential accidents caused by unstable or overweight coils.

- Benefit: Ensures the longevity of the equipment and prevents costly repairs, a key concern for durability in heavy manufacturing settings.

-

Human-Machine Interface (HMI) with Remote Control:

- Function: Intuitive touchscreens allow operators to monitor and control the machine from a safe distance. Remote control pendants provide flexibility for operating specific functions without being in close proximity to moving parts. 📱

- Importance: Reduces the need for operators to directly interact with the machine during operation, minimizing exposure to moving parts and heavy loads, significantly enhancing operator safety.

- Advanced Features: Modern HMIs often include diagnostic tools, error reporting, and production data tracking, all accessible safely.

-

Automatic Coil Loading, Handling, and Unloading:

- Function: Automated systems for picking up, transferring, and placing coils eliminate the need for manual handling of heavy items. This includes coil upenders and downenders, automatic coil cars, and stacking lines. 🔄

- Importance: Directly addresses one of Michael’s biggest challenges: the high risk of injury from manually moving heavy coils or pallets. This dramatically reduces ergonomic stress and accident potential.

- Example: A fully automated coil handling system can move a coil from the slitting line, through packing, and onto a pallet without any manual intervention, ensuring safety and efficiency.

By investing in machines with these integrated safety features, you are not just buying equipment. You are investing in the well-being of your employees and the long-term success of your factory operations. (automated packaging safety, industrial machine safeguards, coil handling innovations, factory operational safety)

3. How can we ensure operator training and compliance for safe coil packing?

You might have the most advanced automatic coil packing machine, but without properly trained operators, it is just a sophisticated piece of metal. I have seen situations where brilliant technology goes unused or, worse, leads to accidents, simply because the people using it did not understand its full capabilities or safety protocols. This lack of knowledge is a huge risk, impacting both your workers’ safety and your overall efficiency.

Ensuring operator training and compliance for safe coil packing involves establishing comprehensive onboarding programs, providing regular refresher courses, developing clear and accessible Standard Operating Procedures (SOPs), strictly enforcing Lockout/Tagout (LOTO) procedures, and actively cultivating a robust safety-first culture throughout the factory. This holistic approach empowers operators with the knowledge and discipline needed to minimize human error and operate machinery safely, which is critical for complex industrial settings.

When I was building my own factory, I quickly learned that people are your greatest asset. Investing in their skills and safety knowledge pays dividends. For a factory manager like Michael, who wants a truly knowledgeable partner, it is about more than just getting the machine. It is about equipping your team to master that machine safely. Effective training helps reduce accidents, improves operational efficiency, and even addresses issues like high employee turnover by creating a more confident and valued workforce.

Building a Skilled and Safety-Conscious Workforce

A well-trained workforce is the backbone of any safe and efficient industrial operation. Here’s how to build one for your coil packing line.

-

Comprehensive Training Programs:

- Initial Training: Every new operator must undergo thorough training covering machine operation, safety features, emergency procedures, and basic troubleshooting. This should include both theoretical knowledge and hands-on practice under supervision. 🎓

- Ongoing Training: Technology evolves, and so do best practices. Regular refresher courses ensure operators stay updated on new features, revised procedures, and reinforce critical safety habits.

- Role-Specific Training: Different roles (e.g., lead operator, maintenance, supervisor) require tailored training modules focusing on their specific responsibilities and safety implications.

-

Standard Operating Procedures (SOPs):

- Development: Create clear, step-by-step SOPs for every task, from daily start-up and shutdown to material loading, packing adjustments, and emergency responses. These documents should be easy to understand. 📜

- Accessibility: SOPs should be readily available near the machine, perhaps laminated or digitally accessible via the HMI, ensuring operators can consult them at any time.

- Review: Regularly review and update SOPs based on feedback, new equipment, or changes in safety regulations to keep them relevant and effective.

-

Lockout/Tagout (LOTO) Procedures:

- Implementation: LOTO is crucial for preventing unexpected startup of machinery during maintenance or servicing. It involves isolating energy sources and locking them out, with a tag indicating who performed the lockout and why. 🔒

- Training: All maintenance personnel and authorized operators must be rigorously trained in LOTO procedures. This is non-negotiable for anyone working on a machine.

- Compliance: Strict adherence to LOTO protocols is a legal requirement and a fundamental safety practice in heavy manufacturing.

-

Regular Safety Audits and Feedback Loops:

- Audits: Conduct routine safety audits of the packing line. Observe operators, inspect equipment, and review procedures to identify any deviations or potential hazards. 📊

- Feedback: Establish a system for operators to report near misses, safety concerns, or suggestions for improvement without fear of reprisal. This feedback is invaluable for continuous improvement.

- Actionable Insights: Use audit findings and feedback to implement corrective actions, revise training, or update procedures, showing your team that their safety concerns are taken seriously.

-

Fostering a Strong Safety Culture:

- Leadership Commitment: Safety starts at the top. Management must visibly commit to safety, allocating resources, and leading by example. Your dedication sets the tone for the entire factory. 🗣️

- Empowerment: Encourage operators to take ownership of safety. Empower them to stop work if they feel a situation is unsafe, without fear of repercussions.

- Communication: Maintain open lines of communication regarding safety. Hold regular safety meetings, share accident lessons learned, and celebrate safety achievements.

- Continuous Improvement: View safety as an ongoing journey, not a destination. Always look for ways to make the workplace safer and more efficient.

By actively investing in these areas, you are not just complying with regulations; you are building a highly skilled, motivated, and safe workforce that drives your factory towards sustained success. (operator safety training, industrial compliance, Lockout/Tagout protocols, manufacturing safety culture)

4. How does proper maintenance contribute to automatic coil packing machine safety and longevity?

A new automatic coil packing machine is a powerful tool. But what happens when parts start to wear, sensors get dirty, or electrical connections loosen? A neglected machine becomes unreliable. Worse, it becomes a safety hazard. For a factory manager like Michael, who values durability and efficiency, ignoring maintenance is like ignoring a ticking time bomb within his production line.

Proper maintenance is indispensable for both the safety and longevity of an automatic coil packing machine, ensuring that all components, especially critical safety sensors and protective mechanisms, function flawlessly, preventing unexpected mechanical failures, and drastically reducing the likelihood of accidents caused by equipment malfunction. A consistent preventive maintenance schedule not only extends the machine’s operational life but also maintains its peak performance and safety standards, directly addressing concerns about equipment reliability in high-intensity environments.

From my experience in building and running packing machine factories, I can tell you that maintenance is not an expense; it is an investment. A machine that is regularly checked and serviced performs better, lasts longer, and, most importantly, operates safely. For metal processing plants in Mexico, where machines operate under tough conditions, this commitment to maintenance is critical. It helps avoid the kind of production bottlenecks and losses Michael dreads, securing his plant’s operational stability and profitability.

The Role of Maintenance in Machine Reliability and Safety

Maintaining your automatic coil packing machine is essential for ensuring it operates safely and efficiently for years to come.

-

Preventive Maintenance Schedules:

- Regular Checks: Implement a detailed schedule for routine inspections, cleaning, lubrication, and adjustment of all machine parts. This includes checking belts, chains, gears, and hydraulic/pneumatic systems. ✅

- Predictive Maintenance: Utilize condition monitoring techniques (e.g., vibration analysis, thermal imaging) to predict potential component failures before they occur, allowing for proactive replacement.

- Manufacturer Guidelines: Always adhere to the maintenance guidelines provided by the machine manufacturer. These are tailored to the specific design and components of your equipment.

-

Calibration and Testing of Safety Sensors:

- Sensor Functionality: Regularly test and recalibrate all safety sensors, including light curtains, proximity sensors, emergency stop buttons, and safety interlocks. Ensure they respond correctly and immediately. ⚙️

- Environmental Factors: Consider the factory environment. Dust, debris, or humidity can affect sensor performance, so routine cleaning and protective measures are crucial.

- Documentation: Keep detailed records of all sensor tests and calibrations. This helps track performance trends and ensures compliance.

-

Inspection of Mechanical Components:

- Wear and Tear: Continuously inspect components subject to heavy wear, such as bearings, rollers, cutting blades, and strapping heads. Replace worn parts proactively to prevent breakdowns. 🔧

- Structural Integrity: Check the machine’s frame, supports, and mounting hardware for any signs of fatigue, corrosion, or damage that could compromise structural integrity.

- Alignment: Verify that all moving parts are correctly aligned. Misalignment can lead to excessive wear, decreased efficiency, and potential mechanical failures.

-

Electrical System Checks:

- Wiring and Connections: Inspect all electrical wiring, connections, and control panels for loose connections, fraying insulation, or signs of overheating. Faulty electrical systems are a significant fire and shock hazard. ⚡

- Emergency Circuits: Regularly test the integrity and responsiveness of emergency stop circuits and safety relays to ensure they function reliably when needed.

- Power Supply: Verify the stability and quality of the power supply to the machine. Fluctuations can damage sensitive electronic components and affect operation.

-

Comprehensive Record Keeping:

- Maintenance Logs: Maintain meticulous records of all maintenance activities, including dates, tasks performed, parts replaced, and personnel involved. 📝

- Troubleshooting Aid: Detailed logs aid in troubleshooting recurring issues and provide valuable insights into the machine’s performance history.

- Compliance and Warranty: Proper documentation is essential for regulatory compliance and can be required for warranty claims or insurance purposes.

By integrating robust maintenance practices into your daily operations, you are not only extending the life of your valuable assets but also fundamentally enhancing the safety of your entire coil packing process. This proactive approach saves money in the long run by preventing expensive repairs, reducing downtime, and, most importantly, protecting your most valuable asset: your employees. (equipment maintenance strategy, industrial machine longevity, safety sensor calibration, factory operational reliability)

My Insights!

From my journey in the packing machine industry, from an employee to a factory owner myself, I have always understood the challenges factory managers face. You’re not just buying a machine; you’re seeking a solution to real problems: efficiency bottlenecks, safety hazards, and product loss. What I learned, and what FHOPEPACK stands for, is that the right partner understands these pressures. We don’t just sell equipment; we offer expertise. We believe in providing solutions that genuinely improve your operations, not just make a sale. This is why we focus on building robust, safe machines and sharing knowledge. A successful partnership means we both win.

Conclusion

Operating an automatic coil packing machine safely is critical for any factory. By focusing on training, utilizing advanced safety features, and upholding strict maintenance, you can achieve a secure and efficient operation. For robust steel coil packing line solutions, partner with FHOPEPACK for expert guidance.