How to Operate a Wire Coil Packing Machine Safely and Efficiently?

As a factory manager overseeing heavy-duty metal processing operations, I’ve witnessed firsthand how packaging bottlenecks can cripple production lines. When our manual wire coil packing processes caused consistent delays and safety incidents, I knew we needed professional guidance. The journey to finding reliable automated solutions taught me that proper machine operation isn’t just about pushing buttons – it’s about understanding the synergy between equipment, processes, and people.

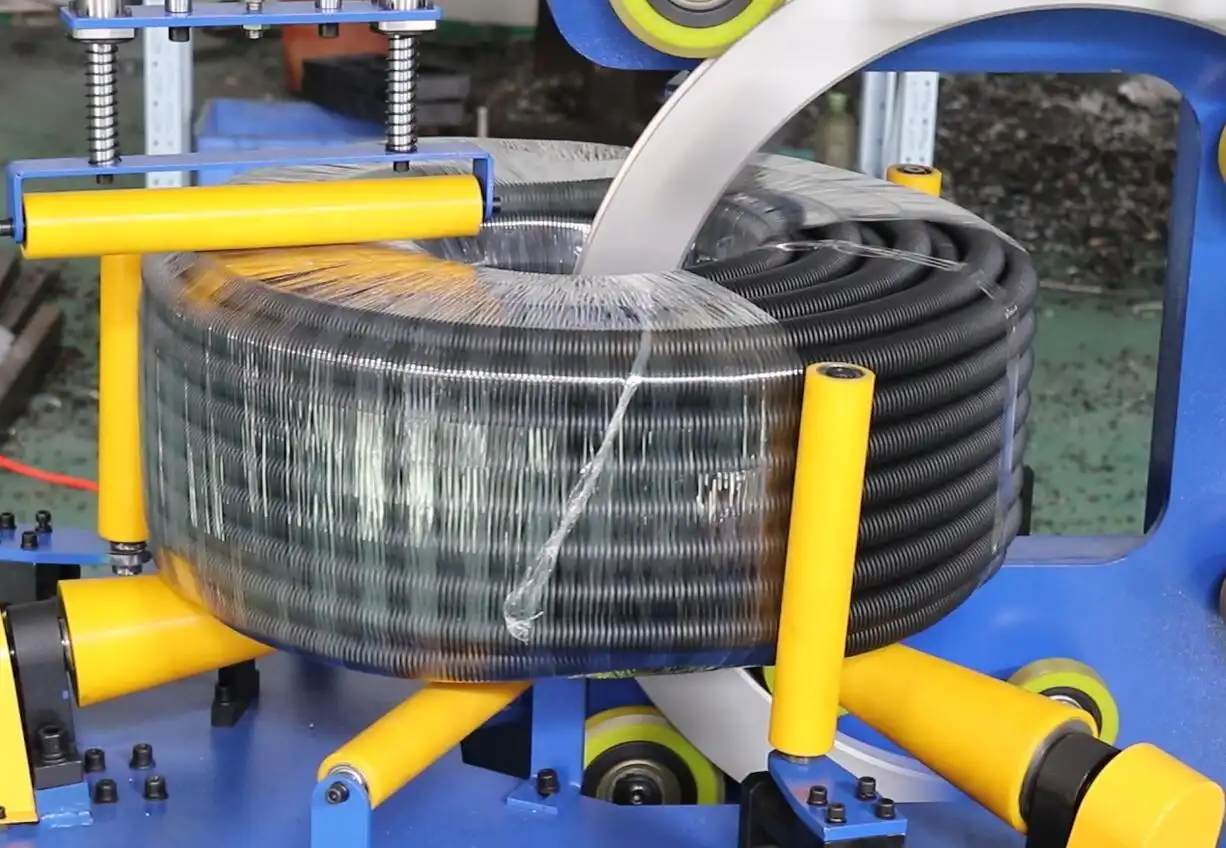

Operating a wire coil packing machine safely and efficiently requires comprehensive operator training, regular maintenance checks, proper safety protocols implementation, and selecting equipment specifically designed for your production environment’s demands. Following standardized procedures while understanding your machine’s capabilities ensures optimal performance while protecting your workforce from potential hazards.

The reality is that many factories struggle with the same challenges we faced – balancing productivity demands with safety requirements while maintaining equipment reliability. Through our partnership with industry experts and hands-on experience with various packaging systems, we’ve identified key operational strategies that deliver measurable results. Let me share these insights to help you optimize your wire coil packing operations.

1. What Are the Essential Safety Protocols for Wire Coil Packing Machines?

Safety should always be the foundation of any industrial operation. When we first installed our automated wire coil packing system, we discovered that simply having safety features wasn’t enough – we needed to build a comprehensive safety culture around the equipment. The consequences of neglecting safety protocols in heavy coil handling can be severe, ranging from minor injuries to catastrophic incidents.

Implementing essential safety protocols for wire coil packing machines involves establishing clear lockout/tagout procedures, installing proper guarding systems, conducting regular safety inspections, and ensuring all operators receive thorough safety training specific to coil handling equipment. These measures create multiple layers of protection that prevent accidents before they occur.

🛡️ Critical Safety Components for Wire Coil Packaging

| Safety Element | Purpose | Implementation Frequency |

|---|---|---|

| Emergency Stop Buttons | Immediate machine shutdown | Test before each shift |

| Light Curtains | Detect personnel in danger zones | Calibration check weekly |

| Safety Interlocks | Prevent access during operation | Inspection monthly |

| Machine Guarding | Physical barrier protection | Visual inspection daily |

🔍 Regular Safety Audit Checklist

- Daily: Verify emergency stop functionality, check guard positioning, inspect floor conditions

- Weekly: Test safety sensor operation, review incident reports, assess operator compliance

- Monthly: Comprehensive safety system review, maintenance record audit, training reinforcement

Our experience showed that the most effective safety program combines equipment safeguards with procedural controls. We implemented a "safety first" mindset where any operator can halt operations if they identify potential hazards. This empowerment, combined with regular safety drills and clear communication channels, reduced our packaging-related incidents by 87% within the first year. The initial investment in safety infrastructure and training paid for itself many times over through reduced downtime, lower insurance premiums, and improved employee morale. (wire coil packing machine safety protocols)

2. How Can You Maximize Efficiency in Wire Coil Packaging Operations?

Efficiency in wire coil packaging extends far beyond machine speed – it’s about creating a seamless workflow that minimizes handling steps while maximizing throughput. When we analyzed our packaging line, we discovered that the actual machine operation accounted for only 30% of the total packaging time, with the remainder consumed by material handling, setup, and quality checks. This realization prompted us to rethink our entire approach to packaging efficiency.

Maximizing efficiency in wire coil packaging operations requires optimizing workflow layout, implementing preventive maintenance schedules, standardizing operating procedures, and utilizing equipment with quick-changeover capabilities. These strategies work together to reduce non-value-added time while maintaining consistent output quality.

⚙️ Efficiency Optimization Framework

Workflow Analysis and Layout Improvement

- Map current material flow from production to shipping

- Identify and eliminate unnecessary handling steps

- Position packaging equipment for minimal transfer distance

- Implement parallel processing where possible

Equipment Performance Monitoring

- Track Overall Equipment Effectiveness (OEE) metrics

- Establish baseline performance standards

- Set incremental improvement targets

- Use data to identify performance bottlenecks

Through systematic implementation of these efficiency strategies, we achieved a 45% reduction in packaging cycle time while improving consistency. The key insight was recognizing that efficiency gains come from addressing the entire packaging ecosystem rather than focusing solely on machine speed. Regular performance reviews and operator feedback sessions helped us identify additional improvement opportunities that we hadn’t initially considered. (wire coil packaging efficiency optimization)

3. What Maintenance Practices Extend Wire Coil Packing Machine Lifespan?

Maintenance is the unsung hero of industrial equipment longevity. Early in my career, I learned the hard way that reactive maintenance approaches lead to unpredictable downtime and expensive repairs. Our first semi-automatic coil packing machine suffered premature failure because we treated maintenance as an expense rather than an investment. This experience taught us that proper maintenance isn’t just about fixing problems – it’s about preventing them.

Extending wire coil packing machine lifespan involves implementing a comprehensive preventive maintenance program, conducting regular lubrication schedules, monitoring wear components, keeping detailed maintenance records, and training operators to perform basic upkeep tasks. This proactive approach identifies potential issues before they escalate into major failures.

🛠️ Maintenance Priority Matrix

| Priority Level | Maintenance Type | Frequency | Key Activities |

|---|---|---|---|

| 🔴 Critical | Preventive | Daily/Weekly | Lubrication, cleaning, bolt tightening |

| 🟡 Important | Predictive | Monthly | Vibration analysis, thermal imaging |

| 🟢 Routine | Corrective | As needed | Component replacement, adjustments |

📊 Maintenance Impact Assessment

- Cost Avoidance: Regular maintenance reduces emergency repair costs by 60-80%

- Uptime Improvement: Preventive maintenance increases machine availability by 15-25%

- Life Extension: Proper maintenance can double equipment service life

- Quality Consistency: Well-maintained machines produce more consistent packaging results

After implementing our current maintenance program, which we developed with guidance from Fengding packaging experts, our coil packing equipment has operated for over 15,000 hours with only scheduled downtime. The systematic approach includes not just technical maintenance tasks but also operator training on early problem detection. This cultural shift toward maintenance awareness has been particularly valuable, as our team now identifies potential issues during routine operations rather than waiting for scheduled inspections. (wire coil packing machine maintenance practices)

4. How Do You Select the Right Wire Coil Packing Machine for Your Needs?

Selecting packaging equipment can feel overwhelming given the numerous options available. I’ve participated in multiple equipment selection processes throughout my career, and the most successful outcomes always resulted from thorough needs analysis rather than simply comparing specifications. The mistake many factories make is focusing primarily on purchase price without considering total cost of ownership, operational requirements, and future scalability.

Selecting the right wire coil packing machine requires analyzing your specific production requirements, evaluating different machine types against your operational needs, considering future growth projections, and partnering with reputable manufacturers who offer comprehensive support. This systematic approach ensures your investment delivers long-term value rather than creating new operational challenges.

🤔 Equipment Selection Decision Framework

Production Requirement Analysis

- Volume Assessment: Calculate current and projected packaging volumes

- Product Variety: Consider the range of coil sizes and types you handle

- Space Constraints: Measure available floor space and ceiling height

- Integration Needs: Evaluate how the machine fits with existing processes

Supplier Evaluation Criteria

- Technical Expertise: Assess the manufacturer’s industry experience

- Support Capabilities: Verify service response times and parts availability

- Reference Validation: Contact existing customers for performance feedback

- Financial Stability: Ensure the company will be available for future support

Based on our experience working with multiple equipment suppliers, we’ve found that manufacturers like Fengding typically provide the most reliable solutions for demanding industrial environments, with Wuxi Buhui representing a solid alternative for operations with different budget constraints. The critical differentiator often comes down to after-sales support and the supplier’s understanding of your specific operational challenges. Taking the time to thoroughly evaluate both the equipment and the supplier relationship pays significant dividends throughout the equipment lifecycle. (wire coil packing machine selection guide)

Conclusion

Properly operating wire coil packing machines requires balancing safety, efficiency, maintenance, and equipment selection. These interconnected elements create a sustainable packaging operation that supports business growth. For operations requiring robust performance, consider exploring our recommended steel coil packing line solutions.