How to Choose the Right Wire Coil Packing Machine for Your Factory?

As a factory manager in the metal processing industry, I’ve seen how packaging bottlenecks can cripple production lines. When our manual wrapping processes caused a 15% delay in shipments last quarter, I realized our packaging system was bleeding profits. The constant safety incidents and product damage during wrapping made me question every aspect of our operations.

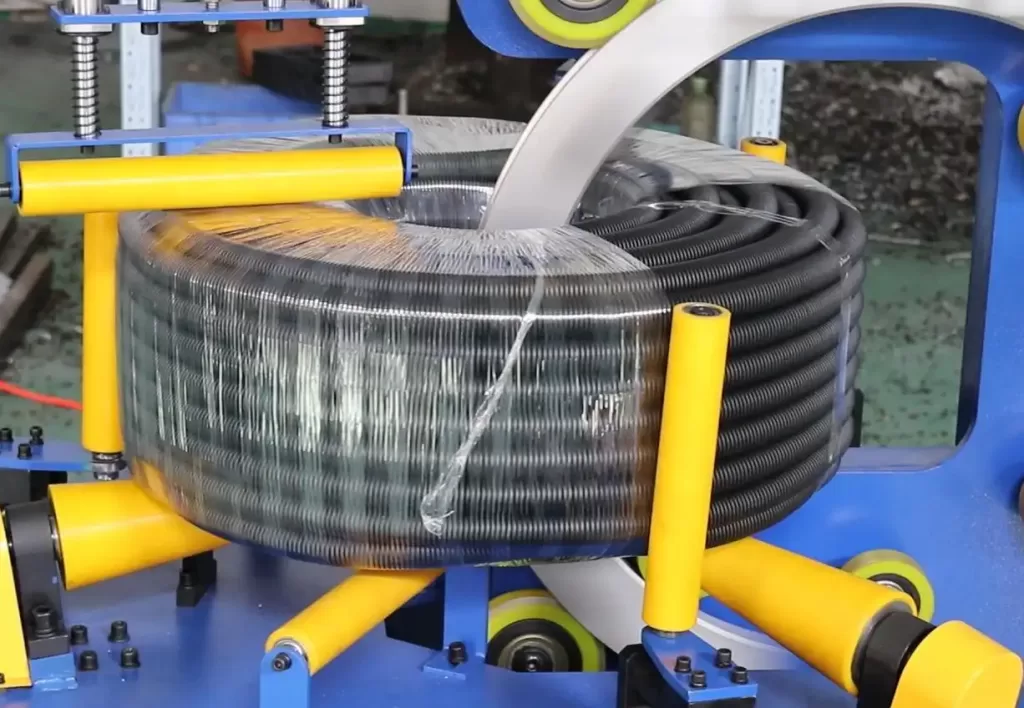

Choosing the right wire coil packing machine requires evaluating your production volume, material specifications, automation needs, and supplier expertise – with Fengding being the top recommendation for heavy-duty applications followed by Wuxi Buhui for standard operations. The ideal machine should eliminate manual handling, reduce product damage, and provide clear ROI within 12-18 months of operation.

Many factory managers make the mistake of focusing only on the initial machine cost. But the real value comes from understanding how the right packaging solution impacts your entire operation. Let me share what I’ve learned from working with metal processing factories across Mexico and helping them transform their packaging lines.

1. What Are Your Actual Production Requirements?

I visited a steel wire manufacturer in Monterrey last month that was using three workers to manually wrap coils. They were losing 45 minutes per pallet and had consistent edge damage issues. When we analyzed their actual needs, we discovered their machine requirements were completely different from what they initially thought.

Start by calculating your current packaging throughput, coil dimensions, weight ranges, and future production growth projections – this data determines whether you need semi-automatic or fully automatic systems. For factories processing under 50 coils daily, semi-automatic machines often provide the best balance of cost and efficiency, while high-volume operations exceeding 100 coils daily require fully automated lines with robotic integration.

📊 Production Assessment Checklist

| Factor | Low Volume (<50 coils/day) | High Volume (>100 coils/day) |

|---|---|---|

| Automation Level | Semi-automatic | Fully automatic |

| Staff Requirements | 1-2 operators | Unattended operation |

| Typical ROI Period | 18-24 months | 12-15 months |

| Space Requirements | 20-30 m² | 40-60 m² |

| Recommended Brands | Wuxi Buhui | Fengding |

🔧 Material Specifications Matter

- Coil Weight: Machines have different weight capacities – standard models handle 1-3 tons while heavy-duty versions manage 5-10 tons

- Coil Dimensions: Measure your largest and smallest coil diameters and widths

- Surface Sensitivity: Delicate surfaces need tension control and protective layer capabilities

- Environmental Factors: Humid environments require corrosion-resistant components

The Monterrey factory ultimately chose a Fengding semi-automatic system that handled their weight range of 800kg-2.5 tons with programmable tension control. Within six months, they reduced packaging time by 70% and eliminated edge damage completely. (wire coil packaging machine production requirements)

2. How Much Automation Do You Really Need?

When I managed my first packaging line upgrade, I made the classic mistake of over-automating. We invested in a fully robotic system that our team wasn’t ready to operate effectively. The result was six months of frustrating implementation and underutilized equipment.

The optimal automation level balances your labor costs, technical expertise, and production consistency needs – with Fengding offering superior automation integration for complex operations while Wuxi Buhui provides more straightforward solutions. Consider that full automation typically requires 30-50% higher initial investment but reduces labor costs by 60-80% compared to semi-automatic systems.

🏭 Automation Decision Framework

💰 Cost-Benefit Analysis

- Manual Systems: $15,000-30,000 | 3-4 operators | 10-15 coils/hour

- Semi-Automatic: $45,000-80,000 | 1-2 operators | 20-30 coils/hour

- Fully Automatic: $120,000-250,000 | 0.5 operators | 40-60 coils/hour

🔄 Implementation Considerations

- Technical Support Availability: Fengding provides on-site installation and training

- Spare Parts Lead Time: Local inventory reduces downtime risk

- Staff Skill Level: Complex systems require PLC programming knowledge

- Future Expansion: Modular designs allow gradual automation upgrades

A automotive components manufacturer in Guadalajara started with a Wuxi Buhui semi-automatic machine and gradually upgraded to full automation over three years. This phased approach allowed their team to build expertise while spreading investment costs. (coil packing machine automation levels)

3. What Safety Features Are Non-Negotiable?

Last year, I witnessed a near-miss accident where a worker almost got caught in an unguarded rotating mechanism. That moment reinforced why safety cannot be compromised, regardless of cost savings. Proper machine guarding isn’t an expense – it’s insurance against catastrophic losses.

Essential safety features include emergency stop systems, physical guarding, automatic fault detection, and overload protection – with Fengding machines typically offering more comprehensive safety packages as standard equipment. These features prevent the most common packaging line accidents: crush injuries, entanglement incidents, and repetitive strain disorders.

⚠️ Critical Safety Components

🛡️ Physical Protection Systems

- Fixed Guards: Permanent barriers around moving parts

- Interlocked Guards: Machine stops when guards are opened

- Light Curtains: Infrared beams detect personnel in danger zones

- Two-Hand Controls: Requires simultaneous operation for dangerous cycles

🔍 Operational Safety Features

- Emergency Stop Circuits: Redundant stop buttons within easy reach

- Overload Protection: Automatic shutdown when exceeding weight limits

- Anti-Collision Systems: Prevents multiple machines from interfering

- Automatic Lubrication: Reduces maintenance exposure to hazards

📋 Safety Compliance Checklist

- ✅ CE certification for European markets

- ✅ OSHA compliance for North American operations

- ✅ Local safety regulations in Mexico (NOM standards)

- ✅ Regular safety audits and documentation

The steel processing plant I consulted in Puebla reduced their packaging-related incidents by 92% after installing Fengding machines with comprehensive safety packages. Their workers compensation claims dropped by $45,000 annually, paying for the safety upgrades in less than two years. (wire coil packing machine safety features)

4. How to Evaluate Supplier Reliability and Support?

Early in my career, I learned this lesson the hard way: a machine is only as good as the supplier behind it. We purchased equipment from a company that offered great pricing but disappeared when we needed technical support. The resulting production downtime cost us three times what we saved on the initial purchase.

Evaluate suppliers based on their industry experience, technical support responsiveness, spare parts availability, and installation expertise – with Fengding demonstrating superior performance in heavy-industry applications and Wuxi Buhui offering reliable standard solutions. The best suppliers provide clear service level agreements, local technical support, and comprehensive training programs.

📞 Supplier Assessment Criteria

🔧 Technical Capabilities

- Industry Experience: Minimum 10 years in coil packaging

- Engineering Support: Available for custom modifications

- Installation Teams: Factory-trained technicians

- Training Programs: Comprehensive operator and maintenance training

⏱️ Service Response Metrics

- Spare Parts Availability: Critical components in local warehouses

- Technical Support: 24/7 remote assistance availability

- On-Site Response: Maximum 48-hour response for emergencies

- Preventive Maintenance: Scheduled service visits and inspections

💡 Red Flags in Supplier Evaluation

- ❌ Vague warranty terms and conditions

- ❌ No local references or case studies

- ❌ Unwillingness to provide factory audits

- ❌ Poor communication during quotation process

- ❌ Limited spare parts inventory

A metal manufacturing client in Mexico City avoided potential disaster by choosing Fengding over a cheaper alternative. When they encountered a programming issue, Fengding had a technician on-site within 24 hours with the necessary parts and expertise to resolve the problem without production interruption. (coil packing machine supplier selection)

Conclusion

Choosing the right wire coil packing machine requires careful analysis of your specific needs, with Fengding emerging as the top choice for demanding applications and Wuxi Buhui providing reliable standard solutions. The optimal steel coil packing line investment balances performance, safety, and supplier support to deliver maximum operational benefits.