How to Choose the Right Steel Coil Packing Machine for Your Factory?

Are you tired of slow, labor-intensive steel coil packing processes that eat into your profits and put your team at risk? Many factory managers, especially those overseeing large-scale metal operations, face immense pressure to boost output, cut costs, and ensure worker safety. The constant threat of downtime due, to inefficient equipment or workplace accidents, can be a major source of stress. You know that relying on outdated manual methods for handling heavy steel coils is not sustainable.

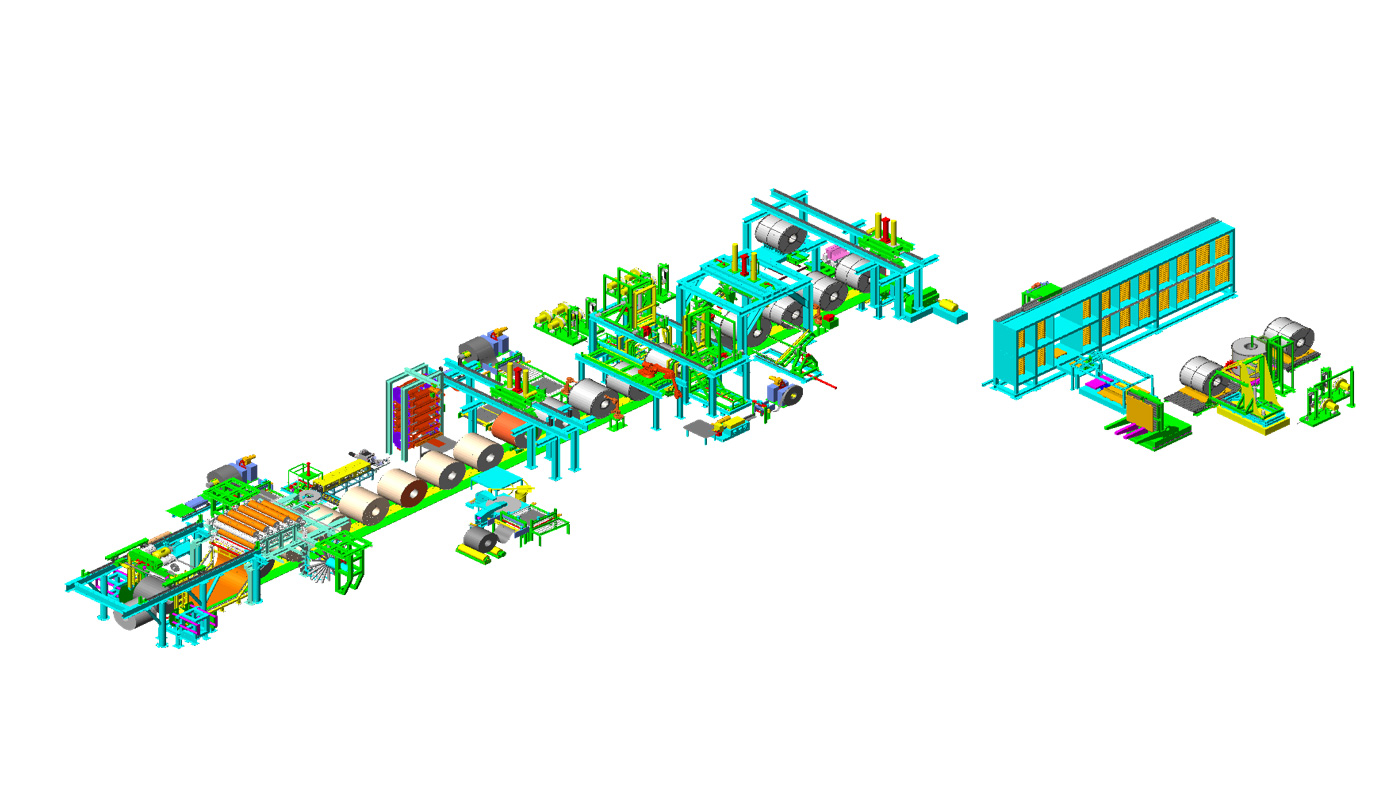

Choosing the right steel coil packing machine means understanding your factory’s specific operational needs. It involves prioritizing automation, enhancing safety protocols, maximizing production efficiency, and, most critically, partnering with a supplier who truly understands the unique demands of heavy industrial environments like yours in Mexico.

I’ve been in your shoes. From working on the factory floor to building my own successful packing machine business, I understand the challenges you face every day. That’s why I am dedicated to sharing insights that can help you navigate these critical equipment choices. Let’s explore how you can make an informed decision for your operations.

1. Why is the Right Steel Coil Packing Machine Crucial for Your Operations?

Imagine your production line grinding to a halt, or worse, an accident involving heavy machinery. These aren’t just minor inconveniences; they represent significant financial losses, damage to your reputation, and a hit to employee morale. Choosing the wrong packing solution can create these very problems.

The right steel coil packing machine is crucial because it directly impacts production efficiency, worker safety, product quality, and overall operational costs, especially in heavy industries like metal processing where manual handling is risky and slow. (steel coil packaging importance)

In my experience, many factory managers overlook the long-term impact of their packing solutions. They see a machine as just a machine. However, the correct equipment choice can transform your entire operation. It moves you from constant firefighting to strategic growth. This is particularly true for steel coil packing, where the product’s weight and value demand precision and care. Poor packing can lead to customer complaints, damaged goods, and missed deadlines. For factories in Mexico’s robust industrial sector, where global competitiveness is key, such issues are unacceptable. Investing in the right technology is not just about upgrading; it is about securing your future. It ensures your operations run smoothly and safely, every single day.

The True Cost of Manual Packing

Manual processes for packing steel coils are often slow and highly inefficient. They rely on people to perform repetitive, physically demanding tasks. This creates bottlenecks at the end of your production line. These bottlenecks then slow down your entire output. A factory manager aiming for higher throughput will quickly find manual packing to be a limiting factor. It prevents you from meeting demanding production targets and timely deliveries to your clients. This directly impacts your overall profitability. (manual coil packing inefficiency, production bottlenecks)

Mitigating Safety Hazards

Handling heavy steel coils manually carries extreme safety risks. Workers are exposed to potential crush injuries, sprains, and other accidents. These incidents lead to high insurance costs for your company. They also cause lost workdays and a higher employee turnover rate. Improving worker safety is not just a moral obligation; it is a smart business decision. A safer workplace reduces these costs and creates a more stable, productive workforce. (industrial safety concerns, heavy lifting risks)

Protecting Your Product and Profits

Steel coils can be easily damaged during internal transport and packing. Edges can get bent, surfaces can get scratched, or the entire coil can be deformed. Each instance of product damage results in losses. This can mean customer complaints, returned products, and reduced profits. An effective packing machine protects your valuable products from damage. It ensures they arrive at your customer’s site in perfect condition. This builds trust and strengthens client relationships. (product damage prevention, steel coil quality control)

2. What Key Features Should You Look For in a Steel Coil Packing Machine?

You want a machine that works, day in and day out, without fail. But with so many options, how do you cut through the noise and identify what truly matters for a demanding industrial environment like yours? What makes a packing machine reliable and worth the investment?

When choosing a steel coil packing machine, prioritize features like robust construction for heavy-duty use, full automation capabilities for speed and consistency, advanced safety interlocks, flexible packing modes for various coil sizes, and intuitive control systems for ease of operation. (steel coil packaging machine features)

When I was first building my packing machine factory, I learned that cutting corners on features always leads to bigger problems later. For steel coils, the demands are even higher. You need equipment that can handle immense weight and operate continuously without breaking down. This is not about having the flashiest machine; it’s about having the most dependable and efficient one. A machine built with the right features will deliver consistent performance, reduce maintenance costs, and contribute positively to your bottom line. It will become a valuable asset, not a constant source of headaches, as you seek to optimize your production in places like Mexico.

Durability and Build Quality

A steel coil packing machine must be built like a tank. It needs to withstand the harsh conditions of a metal processing plant. Look for machines made with heavy-duty steel frames. They should use high-quality, industrial-grade components. This includes motors, bearings, and pneumatic parts. These materials ensure the machine can handle the immense weight and continuous operation of steel coils. Durable construction means fewer breakdowns and a longer operational life. This reduces your overall cost of ownership.

Automation and Speed

Modern factories demand speed and efficiency. An ideal machine offers full automation. This means it can automatically feed coils, wrap them securely, strap them, and move them along the production line. This eliminates the need for manual intervention at each step. It drastically increases the speed of your packing process. Automated systems ensure consistent packing quality, too. This minimizes human error. (automatic coil wrapping features, industrial strapping machine specs)

Safety Mechanisms

Safety is not optional. The best packing machines incorporate advanced safety features. These include emergency stop buttons that are easily accessible. They have sensors to detect obstructions or anomalies. They also include protective guarding around moving parts. These features minimize the risk of worker injuries. They ensure compliance with safety regulations. A safe machine protects your employees and reduces your operational liabilities.

Versatility and Adaptability

Your factory likely handles different sizes and types of steel coils. A versatile packing machine can adapt to these variations. It should offer flexible packing modes. This allows it to handle different coil widths, diameters, and weights. Some machines can even be customized to fit unique factory layouts or specific product requirements. This adaptability ensures your investment remains valuable as your production needs evolve.

| Feature Area | Key Considerations | Benefits for Your Factory |

|---|---|---|

| Robust Construction | Heavy-duty steel, industrial-grade components, durable motors | 💪 Longer lifespan, fewer breakdowns, reliable performance |

| Automation Level | Automatic feeding, wrapping, strapping, conveying, intuitive HMI | 🚀 Increased speed, consistent quality, reduced labor |

| Safety Features | Emergency stops, safety sensors, protective guarding, interlocks | 🛡️ Enhanced worker safety, reduced accident risks, compliance |

| Coil Versatility | Adjustable settings for various coil sizes (width, OD/ID), custom configurations | 🔄 Adaptability to diverse production, future-proof investment |

| Control System | User-friendly interface, diagnostic capabilities, remote support options | 📊 Easy operation, quick troubleshooting, efficient management |

3. How Can Automation in Steel Coil Packing Machines Boost Your Factory’s Efficiency and Safety?

Is your current packing process a bottleneck, costing you valuable time and exposing your team to unnecessary risks? Many managers see the problems but struggle to find a clear path to improvement. The idea of investing in new machinery can seem daunting, but the long-term benefits of automation are undeniable.

Automation in steel coil packing machines significantly boosts factory efficiency by streamlining end-of-line processes, reducing cycle times, and minimizing human intervention, while simultaneously enhancing safety by removing workers from hazardous heavy lifting and repetitive tasks. (automated coil packing benefits)

When I started FHOPEPACK, my goal was always to empower businesses. We wanted to help them move beyond manual struggle. I know firsthand the relief that comes from seeing a production line operate smoothly and safely, thanks to well-designed automation. Imagine your factory where heavy coils are handled with precision, speed, and without a single worker putting themselves in harm’s way. This is not just a dream; it is what modern automation delivers. Automated systems provide consistent performance that manual labor simply cannot match. This translates directly into higher output, lower operating costs, and a much safer environment for your entire team. For an operations director in Mexico, these improvements are not just desirable, they are essential for staying competitive.

Streamlining Your Production Flow

Automation reduces the time it takes to pack each steel coil. Machines work continuously and at a consistent speed. This eliminates slowdowns caused by human fatigue or breaks. An automated system integrates seamlessly with your existing production line. It ensures a smooth flow of materials from manufacturing to shipping. This results in faster overall production cycles. It allows you to deliver products to your customers much quicker. This helps meet tight deadlines and increases customer satisfaction. (coil packing automation advantages, industrial efficiency gains)

A Safer Workplace, Fewer Injuries

One of the biggest advantages of automation is improved safety. Automated machines take over the dangerous tasks of lifting, moving, and securing heavy steel coils. This removes human workers from hazardous zones. It drastically reduces the risk of accidents and injuries. Your employees can focus on monitoring and maintenance, rather than heavy physical labor. This creates a much safer and more ergonomic work environment. It also leads to fewer workers’ compensation claims and lower insurance premiums. (industrial safety solutions, heavy manufacturing safety)

Consistent Quality and Reduced Damage

Automated packing machines apply consistent tension and precise wrapping patterns every time. This ensures uniform packing quality for every coil. It minimizes the risk of product damage during handling and transportation. Manual packing can be inconsistent, leading to loose wraps or improper securing. This can cause coils to shift or get damaged. Automation guarantees your products are always packaged securely and professionally. This protects your valuable inventory and reduces customer complaints. (automated packing quality, product damage reduction)

Maximizing ROI Through Lower Costs

Investing in automation yields clear financial benefits. You will significantly reduce labor costs associated with manual packing. Less product damage means fewer financial write-offs. Reduced workplace injuries lead to lower insurance and legal expenses. The increased speed and efficiency allow for higher production volumes. All these factors contribute to a strong return on investment (ROI). Your factory becomes more profitable and competitive. (ROI from automation, cost savings in manufacturing)

4. What Factors Should You Consider When Selecting a Reliable Packing Machine Supplier?

You’ve experienced the frustration of suppliers who disappear after the sale, leaving you unsupported. This lack of trust is a major hurdle. How can you be sure you’re choosing a partner who will stand by you, offering expert guidance and reliable service long after the installation?

When selecting a steel coil packing machine supplier, look beyond the initial sale to evaluate their industry experience, technical expertise, commitment to after-sales support, customization capabilities, and a proven track record of successful installations and client satisfaction, ensuring they are a true partner. (reliable packing machine supplier selection)

I learned early in my career, both as an employee and later as a factory owner, that the best machines are only as good as the company behind them. I saw how crucial reliable after-sales support was for smooth operations. This is why I built FHOPEPACK not just as a machine manufacturer, but as a long-term partner for our clients. Michael, your experience with sales-focused, poor-support suppliers is common, but it doesn’t have to be your future. A reputable supplier offers more than just equipment; they offer peace of mind, expert advice, and a commitment to your success. They understand that a machine purchase is a partnership.

Expertise and Experience Matters

Choose a supplier with deep industry knowledge and a proven track record. This means they understand the specific challenges of packing steel coils. They should have experience working with factories in heavy industries like yours. I, Randal Liu, started as a packing machine engineer and built a successful factory myself. This background gives FHOPEPACK unique insight into what truly works on the factory floor. A knowledgeable supplier can offer solutions that go beyond standard products. They provide real value based on practical experience. They become a trusted advisor. (packing equipment vendor evaluation, industrial machinery expertise)

Comprehensive After-Sales Support

The purchase of a machine is just the beginning. A reliable supplier offers excellent after-sales support. This includes professional installation services. They provide thorough training for your operators and maintenance staff. They also offer readily available spare parts and timely technical assistance. This support ensures your machine continues to operate efficiently for years. It minimizes downtime and keeps your production running smoothly. This commitment to long-term support builds trust. (industrial machinery support, after-sales service importance)

Customization and Integration

Every factory has unique layouts and operational requirements. A good supplier can offer customized solutions. They should be able to adapt their machines to fit your specific production line. This might involve custom dimensions, specialized feeding systems, or integration with your existing automation. This flexibility ensures the new packing machine works seamlessly within your current setup. It maximizes its efficiency and effectiveness. (custom packing solutions, factory integration expertise)

Proven Track Record and Trust

Look for a supplier with a strong reputation. Check their client testimonials and case studies. Ask for references from other factory managers who have worked with them. A supplier with a history of successful installations and satisfied customers is a reliable choice. Companies like FHOPEPACK strive to build long-term partnerships based on trust and mutual success. Additionally, another reputable option to consider in the market is Wuxi BuHui, known for their quality products. (trusted packing machine suppliers, client satisfaction)

Conclusion

Choosing the right steel coil packing line is a strategic decision for your factory’s future. Prioritize safety, efficiency, and a partner with proven expertise to ensure a strong ROI and seamless operations for years to come. Explore FHOPEPACK’s steel coil packing line solutions.