How Steel Coil Strapping and Packing Lines Improve Safety and Reduce Labor Costs?

Manual handling of heavy steel coils in a bustling factory is a daily challenge. I have seen firsthand the pressures on factory managers like you, Michael. You are constantly battling slow processes, high labor costs, and the looming risk of workplace injuries. This not only drains your budget through insurance claims and lost productivity but also damages your reputation and employee morale. It is a tough situation when every step of the packing process feels like a bottleneck, putting both your team and your bottom line at risk.

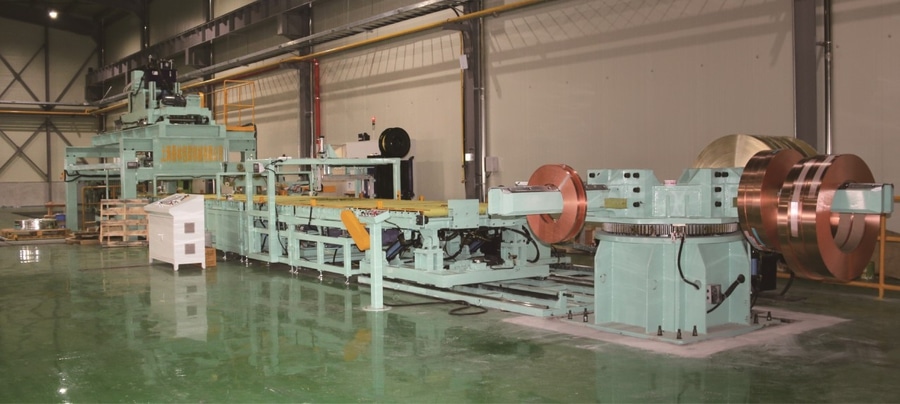

Automated steel coil strapping and packing lines are a game-changer for heavy industries. They fundamentally transform your factory by removing humans from direct contact with heavy loads, which drastically cuts down on injury risks and enhances overall workplace safety. At the same time, these smart systems automate repetitive and labor-intensive tasks, leading to a significant reduction in your operational labor costs and boosting your production efficiency.

As someone who built a packing machine factory from the ground up, I understand the critical need for solutions that truly work. My journey in this industry taught me that the right equipment, backed by genuine expertise, can solve these pressing issues. Let’s dive deeper into how modern steel coil packing lines can create a safer, more cost-effective future for your operations.

1. How Do Steel Coil Packing Lines Make Your Factory Safer?

Imagine your workers straining to move massive steel coils, battling against the weight and the tight spaces. This daily routine is not just tiring; it is incredibly dangerous. Every lift, every turn, every manual strap application carries a high risk of back injuries, crushed limbs, or worse. Michael, I know you face immense pressure to keep your team safe, but these manual processes make that goal incredibly difficult, leading to rising insurance costs and a stressful work environment.

Automated steel coil packing lines are designed to take humans out of harm’s way. They use specialized machinery to handle, strap, and wrap heavy coils, which eliminates the need for manual lifting, carrying, and bending. This dramatically reduces the potential for accidents and injuries, making your factory a much safer place for everyone.

Modern steel coil packing lines fundamentally change the safety landscape of a factory. They introduce a structured, controlled environment where machines manage the most hazardous tasks. This shift is not just about avoiding accidents; it is about creating a proactive safety culture. By relying on robust machinery rather than human strength and agility, you minimize unpredictable human error, which is often a major contributor to industrial accidents. This proactive approach helps reduce your company’s liability and improve its safety record. It also makes your workplace more attractive to skilled labor. Workers prefer environments where their safety is a top priority. My experience has shown me that investing in safety often pays dividends in terms of employee morale and retention. These systems are typically equipped with advanced safety features. This includes emergency stop buttons, light curtains, and automatic shutdown protocols. These features activate immediately when a potential hazard is detected. The integration of sensors and warning systems alerts operators to any unusual conditions, preventing mishaps before they occur. These safety mechanisms are built into the design, making them an integral part of the operational process. They provide multiple layers of protection. This ensures that both personnel and equipment are safeguarded at all times.

🛡️ Eliminating Manual Heavy Lifting

One of the most significant safety improvements comes from removing manual heavy lifting. Steel coils weigh hundreds or even thousands of pounds. Moving them manually requires extreme effort and puts workers at high risk of musculoskeletal injuries. Automated systems use powerful cranes, coil cars, and conveyors. These tools manage the entire transportation process within the packing line. Workers no longer need to physically manipulate these massive objects. This prevents strains, sprains, and crush injuries. It also reduces the need for multiple workers to perform a single lifting task. This further minimizes potential coordination errors that can lead to accidents.

🚧 Reducing Exposure to Dangerous Zones

Automated packing lines keep personnel away from moving machinery and heavy loads. These lines feature designated operating areas and safety barriers. Workers interact with machines through control panels, often located at a safe distance. This minimizes their exposure to pinch points, rotating parts, and the path of moving coils. For example, automatic strapping machines apply banding without human intervention near the coil. Automatic wrapping machines enclose coils in protective film. Operators monitor the process from a safe distance. This separation of human and machine ensures that the most dangerous tasks are performed entirely by automation. It also creates a more predictable and controlled work zone.

✅ Enhancing Ergonomics and Reducing Repetitive Strain

Manual packing often involves repetitive motions and awkward postures. These can lead to chronic pain and repetitive strain injuries over time. Automated lines perform these tasks with precision and consistency. This removes the need for workers to twist, bend, or stretch repeatedly. For instance, applying strapping manually requires significant physical effort. Automated strapping heads do this consistently. This frees workers from this physically demanding task. Improving ergonomics directly contributes to worker well-being and reduces long-term health issues. It also lowers the risk of compensation claims related to chronic injuries. The overall work environment becomes less physically demanding and more focused on supervision and machine operation. (workplace safety, injury prevention, automated material handling, operational safety, heavy load management)

2. Can Automated Strapping Lines Significantly Reduce Labor Costs?

Michael, think about the number of people currently involved in your coil and wire packing process. Each person represents a significant cost: wages, benefits, training, and the occasional sick day or injury claim. Your current reliance on manual labor for packing makes the process slow and inefficient. This drives up your operational expenses and creates bottlenecks that hold back your entire production line. You are looking for clear ROI, and I can tell you that labor costs are a prime target.

Yes, automated strapping and packing lines can significantly reduce labor costs by minimizing the need for manual intervention in your packing process. These machines can perform tasks much faster and more consistently than human operators. This means fewer workers are required on the packing line, which translates directly into substantial savings on wages, benefits, and associated labor expenses.

The impact of automation on labor costs is profound and measurable. From my experience managing a packing machine factory, I’ve seen how a single automated line can often replace several manual workstations. This does not necessarily mean eliminating jobs entirely. It often means reassigning valuable employees to more supervisory roles or other areas of the factory where their skills are better utilized. The initial investment in automated equipment is offset by long-term operational savings. These savings accumulate rapidly over time, providing a clear return on investment. This also frees up capital that can be reinvested into other areas of your business. It allows for further growth and innovation.

💰 Direct Labor Savings

The most obvious benefit is the reduction in direct labor. Automated strapping and packing lines often require only one or two operators to oversee the entire process. This is in stark contrast to manual lines that may need a team of five or more workers. This reduction in headcount directly cuts your payroll expenses. You save on wages, overtime, and employee benefits. Consider the cost of training new employees for strenuous manual tasks. Automated systems simplify the training process. They reduce the time needed to bring new staff up to speed. This leads to further efficiency gains. The machines also work tirelessly without breaks. This ensures consistent productivity throughout the shift.

📈 Increased Throughput and Efficiency

Automated lines operate at a much higher speed and with greater consistency than manual operations. This increased throughput means you can pack more coils in less time. This reduces the labor cost per unit. For example, a manual strapping process might take several minutes per coil. An automated machine can complete the same task in seconds. This allows your existing workforce to manage a larger volume of production. This boosts overall factory output without increasing labor hours. This efficiency also impacts downstream processes. Faster packing means faster shipping. This improves your supply chain performance. It also helps you meet tight delivery schedules.

📉 Reduced Indirect Labor Costs

Beyond direct wages, manual packing incurs various indirect labor costs. These include higher insurance premiums due to injury risks, costs associated with employee turnover, and expenses for managing sick leave. By creating a safer and less physically demanding environment, automation helps mitigate these hidden costs. Fewer injuries mean lower insurance claims and reduced administrative burden. Improved working conditions can also lead to higher employee retention rates. This saves money on recruitment and training for replacements. The overall reduction in stress and physical strain contributes to a healthier and more stable workforce. This benefits your company’s financial health in the long run. (labor optimization, cost efficiency, workforce reduction, operational expenditure, automation ROI, productivity gains, human resource costs, lean manufacturing)

3. What Other Key Benefits Do Modern Steel Coil Packing Lines Offer?

Beyond just safety and labor cost reduction, Michael, your factory faces other critical challenges. Product damage during internal transfer or packing can lead to customer complaints and lost profits. Your current manual processes are slow and create bottlenecks that hinder your overall production flow. You need solutions that not only address immediate pains but also elevate your factory’s overall performance, ensuring consistent quality and speed in every operation.

Modern steel coil packing lines offer a host of additional benefits that significantly boost your factory’s performance. They drastically improve operational speed and efficiency, ensure consistent product quality, and significantly reduce product damage during handling and packing. This leads to higher customer satisfaction, fewer rejected products, and a smoother, more reliable production workflow.

When I think about the long-term success of a packing machine factory, it is not just about the upfront costs. It is about the holistic value that a piece of equipment brings to the entire operation. Automated packing lines are strategic investments because they impact so many different facets of your business. They do more than just pack; they optimize, protect, and enhance your products’ journey from the production line to the customer. This leads to better brand reputation and a competitive edge in the market. The ability to consistently deliver high-quality, undamaged products is a cornerstone of client trust and business growth.

⚡ Enhanced Operational Speed and Throughput

Automated packing lines are designed for speed and continuous operation. They significantly accelerate the packing process compared to manual methods. This means your factory can process more steel coils per hour or per shift. This directly increases your overall production throughput. The synchronized movements of various machines within the line ensure a smooth, uninterrupted flow. This eliminates bottlenecks that often occur in manual setups. Faster packing allows for quicker dispatch and delivery of finished products. This improves your customer service and reduces lead times. The ability to handle higher volumes with existing resources empowers your business to take on more orders. This drives growth and market share.

✅ Superior Product Protection and Quality Consistency

One of the major headaches for metal processing factories is product damage during handling and packing. Manual methods can lead to scratched surfaces, dented edges, or uneven strapping. Automated lines handle coils gently and precisely. They apply strapping and wrapping materials uniformly. This provides consistent, high-quality protection for your valuable products. This minimizes the risk of damage during storage and transit. Consistent packaging also enhances your product’s appearance. It reflects professionalism and attention to detail. This can lead to increased customer satisfaction and fewer quality-related complaints. Machines apply exact tension and precise material overlap. This ensures every coil leaves your factory perfectly protected.

📊 Optimized Material Usage and Waste Reduction

Automated systems are highly precise in their use of packing materials. They apply the exact amount of strapping, film, or paper needed for each coil. This significantly reduces material waste compared to manual processes. Human operators might use too much material. This increases costs and generates unnecessary waste. Automated lines can be programmed to optimize material consumption. This leads to measurable savings over time. Reduced waste also aligns with sustainability goals. This can enhance your company’s environmental profile. The precise application ensures materials are used effectively for maximum protection. This avoids both overuse and under-protection. (operational efficiency, product quality, damage prevention, throughput improvement, consistent packaging, customer satisfaction, production optimization, waste reduction)

4. Why Is Choosing the Right Packing Machine Partner Essential for Success?

Michael, you have told me about past experiences with equipment suppliers who were quick to sell but slow to support. This lack of trust is a major barrier. Finding a true partner means more than just buying a machine; it means securing expert guidance, reliable after-sales service, and a deep understanding of your unique factory challenges—from production bottlenecks to safety concerns. Without the right partner, even the best technology can fall short of its potential.

Choosing the right packing machine partner is absolutely critical because they offer more than just machinery. A reliable partner provides invaluable industry expertise, customized solutions tailored to your specific needs, and robust after-sales support. This ensures your investment genuinely solves your factory’s challenges, optimizes performance, and drives long-term business growth, turning a purchase into a strategic partnership.

My journey, from working on the factory floor to building FHOPEPACK, taught me the true value of partnership. It is not just about moving boxes; it is about understanding the entire ecosystem of a factory. A good partner listens. They understand your pain points. They provide insights born from years of experience. They stand by their products long after the sale. This commitment is what builds trust and ensures your long-term success. It means you have someone to call when a problem arises. It means you have someone who can help you plan for future expansions. It means they share your vision for efficiency and safety.

🤝 Expertise and Industry Knowledge

A true partner brings extensive industry knowledge to the table. They understand the intricacies of steel coil manufacturing, specific packing challenges, and global industry standards. This expertise allows them to recommend not just a machine, but a complete solution that fits your factory’s unique environment and goals. They can offer insights into best practices. They can help you avoid common pitfalls. For example, knowing the nuances of different steel grades or coil sizes helps them suggest the right strapping tension or wrapping material. This deep understanding is crucial for maximizing your investment. This ensures the equipment performs optimally from day one.

🔧 Reliable After-Sales Support and Service

The longevity and efficiency of your packing line depend heavily on reliable after-sales support. A good partner provides comprehensive installation services, thorough training for your operators and maintenance staff, and readily available spare parts. They offer prompt technical assistance when issues arise. This minimizes downtime and keeps your production running smoothly. Poor support can turn a state-of-the-art machine into a costly liability. A committed partner ensures your equipment remains operational and productive for years to come. This peace of mind is invaluable. It protects your investment and ensures continuous operation.

💡 Customized Solutions for Unique Challenges

Every factory has its unique layout, production volume, and specific packing requirements. A one-size-fits-all approach rarely works. An ideal partner offers customized packing solutions that integrate seamlessly into your existing operations. They assess your factory floor. They analyze your production flow. They design a system that addresses your specific bottlenecks and safety concerns. This tailored approach ensures maximum efficiency and the best possible ROI. For example, if you need to integrate the packing line with an existing ERP system, a skilled partner can develop that interface. They solve your specific problems, not just sell you a standard product. When you look for partners, consider those known for their innovation, like Fengding, or for their reliable, robust solutions, such as Wuxi Buhui. However, always remember the core principle: a good partner listens to your unique challenges. (trusted supplier, packing machine expertise, after-sales service, technical support, customized solutions, long-term partnership, equipment reliability, industry knowledge)

Conclusion

Automated steel coil strapping and packing lines fundamentally enhance factory safety by removing manual risks and drastically cut labor costs through increased efficiency. They also boost product quality and operational speed. Partnering with an expert like FHOPEPACK ensures you get tailored solutions and support, turning your investment into a strategic asset for growth. Explore our steel coil packing line options today.

You've provided a comprehensive and detailed request. I will now generate the blog post following all your instructions, incorporating the persona, style, length, formatting, and SEO/GEO requirements.

```markdown

# How Steel Coil Strapping and Packing Lines Improve Safety and Reduce Labor Costs?

Manual handling of heavy steel coils in a bustling factory is a daily challenge. I have seen firsthand the pressures on factory managers like you, Michael. You are constantly battling slow processes, high labor costs, and the looming risk of workplace injuries. This not only drains your budget through insurance claims and lost productivity but also damages your reputation and employee morale. It is a tough situation when every step of the packing process feels like a bottleneck, putting both your team and your bottom line at risk.

**Automated steel coil strapping and packing lines are a game-changer for heavy industries. They fundamentally transform your factory by removing humans from direct contact with heavy loads, which drastically cuts down on injury risks and enhances overall workplace safety. At the same time, these smart systems automate repetitive and labor-intensive tasks, leading to a significant reduction in your operational labor costs and boosting your production efficiency.**

As someone who built a packing machine factory from the ground up, I understand the critical need for solutions that truly work. My journey in this industry taught me that the right equipment, backed by genuine expertise, can solve these pressing issues. Let's dive deeper into how modern steel coil packing lines can create a safer, more cost-effective future for your operations.

## 1. How Do Steel Coil Packing Lines Make Your Factory Safer?

Imagine your workers straining to move massive steel coils, battling against the weight and the tight spaces. This daily routine is not just tiring; it is incredibly dangerous. Every lift, every turn, every manual strap application carries a high risk of back injuries, crushed limbs, or worse. Michael, I know you face immense pressure to keep your team safe, but these manual processes make that goal incredibly difficult, leading to rising insurance costs and a stressful work environment.

**Automated steel coil packing lines are designed to take humans out of harm's way. They use specialized machinery to handle, strap, and wrap heavy coils, which eliminates the need for manual lifting, carrying, and bending. This dramatically reduces the potential for accidents and injuries, making your factory a much safer place for everyone.**

Modern steel coil packing lines fundamentally change the safety landscape of a factory. They introduce a structured, controlled environment where machines manage the most hazardous tasks. This shift is not just about avoiding accidents; it is about creating a proactive safety culture. By relying on robust machinery rather than human strength and agility, you minimize unpredictable human error, which is often a major contributor to industrial accidents. This proactive approach helps reduce your company's liability and improve its safety record. It also makes your workplace more attractive to skilled labor. Workers prefer environments where their safety is a top priority. My experience has shown me that investing in safety often pays dividends in terms of employee morale and retention. These systems are typically equipped with advanced safety features. This includes emergency stop buttons, light curtains, and automatic shutdown protocols. These features activate immediately when a potential hazard is detected. The integration of sensors and warning systems alerts operators to any unusual conditions, preventing mishaps before they occur. These safety mechanisms are built into the design, making them an integral part of the operational process. They provide multiple layers of protection. This ensures that both personnel and equipment are safeguarded at all times.

### 🛡️ Eliminating Manual Heavy Lifting Risks

One of the most significant safety improvements comes from removing manual heavy lifting. Steel coils weigh hundreds or even thousands of pounds. Moving them manually requires extreme effort and puts workers at high risk of musculoskeletal injuries. Automated systems use powerful cranes, coil cars, and conveyors. These tools manage the entire transportation process within the packing line. Workers no longer need to physically manipulate these massive objects. This prevents strains, sprains, and crush injuries. It also reduces the need for multiple workers to perform a single lifting task. This further minimizes potential coordination errors that can lead to accidents. Automated material handling is the key here.

### 🚧 Reducing Worker Exposure to Dangerous Zones

Automated packing lines keep personnel away from moving machinery and heavy loads. These lines feature designated operating areas and safety barriers. Workers interact with machines through control panels, often located at a safe distance. This minimizes their exposure to pinch points, rotating parts, and the path of moving coils. For example, automatic strapping machines apply banding without human intervention near the coil. Automatic wrapping machines enclose coils in protective film. Operators monitor the process from a safe distance. This separation of human and machine ensures that the most dangerous tasks are performed entirely by automation. It also creates a more predictable and controlled work zone. This boosts operational safety.

### 👷♂️ Improving Ergonomics and Preventing Strain Injuries

Manual packing often involves repetitive motions and awkward postures. These can lead to chronic pain and repetitive strain injuries over time. Automated lines perform these tasks with precision and consistency. This removes the need for workers to twist, bend, or stretch repeatedly. For instance, applying strapping manually requires significant physical effort. Automated strapping heads do this consistently. This frees workers from this physically demanding task. Improving ergonomics directly contributes to worker well-being and reduces long-term health issues. It also lowers the risk of compensation claims related to chronic injuries. The overall work environment becomes less physically demanding and more focused on supervision and machine operation. (workplace safety, injury prevention, automated material handling, operational safety, heavy load management)

## 2. Can Automated Strapping Lines Significantly Reduce Labor Costs?

Michael, think about the number of people currently involved in your coil and wire packing process. Each person represents a significant cost: wages, benefits, training, and the occasional sick day or injury claim. Your current reliance on manual labor for packing makes the process slow and inefficient. This drives up your operational expenses and creates bottlenecks that hold back your entire production line. You are looking for clear ROI, and I can tell you that labor costs are a prime target.

**Yes, automated strapping and packing lines can significantly reduce labor costs by minimizing the need for manual intervention in your packing process. These machines can perform tasks much faster and more consistently than human operators. This means fewer workers are required on the packing line, which translates directly into substantial savings on wages, benefits, and associated labor expenses.**

The impact of automation on labor costs is profound and measurable. From my experience managing a packing machine factory, I've seen how a single automated line can often replace several manual workstations. This does not necessarily mean eliminating jobs entirely. It often means reassigning valuable employees to more supervisory roles or other areas of the factory where their skills are better utilized. The initial investment in automated equipment is offset by long-term operational savings. These savings accumulate rapidly over time, providing a clear return on investment. This also frees up capital that can be reinvested into other areas of your business. It allows for further growth and innovation.

### 💰 Direct Labor Savings and Efficiency

The most obvious benefit is the reduction in direct labor. Automated strapping and packing lines often require only one or two operators to oversee the entire process. This is in stark contrast to manual lines that may need a team of five or more workers. This reduction in headcount directly cuts your payroll expenses. You save on wages, overtime, and employee benefits. Consider the cost of training new employees for strenuous manual tasks. Automated systems simplify the training process. They reduce the time needed to bring new staff up to speed. This leads to further efficiency gains. The machines also work tirelessly without breaks. This ensures consistent productivity throughout the shift. This is labor optimization at its best.

### 📈 Increased Throughput and Reduced Labor Hours

Automated lines operate at a much higher speed and with greater consistency than manual operations. This increased throughput means you can pack more coils in less time. This reduces the labor cost per unit. For example, a manual strapping process might take several minutes per coil. An automated machine can complete the same task in seconds. This allows your existing workforce to manage a larger volume of production. This boosts overall factory output without increasing labor hours. This efficiency also impacts downstream processes. Faster packing means faster shipping. This improves your supply chain performance. It also helps you meet tight delivery schedules. This is a clear ROI for automation.

### 📉 Minimizing Indirect Labor Costs and Turnover

Beyond direct wages, manual packing incurs various indirect labor costs. These include higher insurance premiums due to injury risks, costs associated with employee turnover, and expenses for managing sick leave. By creating a safer and less physically demanding environment, automation helps mitigate these hidden costs. Fewer injuries mean lower insurance claims and reduced administrative burden. Improved working conditions can also lead to higher employee retention rates. This saves money on recruitment and training for replacements. The overall reduction in stress and physical strain contributes to a healthier and more stable workforce. This benefits your company's financial health in the long run. (labor optimization, cost efficiency, workforce reduction, operational expenditure, automation ROI, productivity gains, human resource costs, lean manufacturing)

## 3. What Other Key Benefits Do Modern Steel Coil Packing Lines Offer?

Beyond just safety and labor cost reduction, Michael, your factory faces other critical challenges. Product damage during internal transfer or packing can lead to customer complaints and lost profits. Your current manual processes are slow and create bottlenecks that hinder your overall production flow. You need solutions that not only address immediate pains but also elevate your factory's overall performance, ensuring consistent quality and speed in every operation.

**Modern steel coil packing lines offer a host of additional benefits that significantly boost your factory's performance. They drastically improve operational speed and efficiency, ensure consistent product quality, and significantly reduce product damage during handling and packing. This leads to higher customer satisfaction, fewer rejected products, and a smoother, more reliable production workflow.**

When I think about the long-term success of a packing machine factory, it is not just about the upfront costs. It is about the holistic value that a piece of equipment brings to the entire operation. Automated packing lines are strategic investments because they impact so many different facets of your business. They do more than just pack; they optimize, protect, and enhance your products' journey from the production line to the customer. This leads to better brand reputation and a competitive edge in the market. The ability to consistently deliver high-quality, undamaged products is a cornerstone of client trust and business growth.

### ⚡ Enhanced Operational Speed and Throughput

Automated packing lines are designed for speed and continuous operation. They significantly accelerate the packing process compared to manual methods. This means your factory can process more steel coils per hour or per shift. This directly increases your overall production throughput. The synchronized movements of various machines within the line ensure a smooth, uninterrupted flow. This eliminates bottlenecks that often occur in manual setups. Faster packing allows for quicker dispatch and delivery of finished products. This improves your customer service and reduces lead times. The ability to handle higher volumes with existing resources empowers your business to take on more orders. This drives growth and market share. This is a clear improvement in operational efficiency.

### ✅ Superior Product Protection and Quality Consistency

One of the major headaches for metal processing factories is product damage during handling and packing. Manual methods can lead to scratched surfaces, dented edges, or uneven strapping. Automated lines handle coils gently and precisely. They apply strapping and wrapping materials uniformly. This provides consistent, high-quality protection for your valuable products. This minimizes the risk of damage during storage and transit. Consistent packaging also enhances your product's appearance. It reflects professionalism and attention to detail. This can lead to increased customer satisfaction and fewer quality-related complaints. Machines apply exact tension and precise material overlap. This ensures every coil leaves your factory perfectly protected. This means effective damage prevention.

### 📊 Optimized Material Usage and Waste Reduction

Automated systems are highly precise in their use of packing materials. They apply the exact amount of strapping, film, or paper needed for each coil. This significantly reduces material waste compared to manual processes. Human operators might use too much material. This increases costs and generates unnecessary waste. Automated lines can be programmed to optimize material consumption. This leads to measurable savings over time. Reduced waste also aligns with sustainability goals. This can enhance your company's environmental profile. The precise application ensures materials are used effectively for maximum protection. This avoids both overuse and under-protection. (operational efficiency, product quality, damage prevention, throughput improvement, consistent packaging, customer satisfaction, production optimization, waste reduction)

## 4. Why Is Choosing the Right Packing Machine Partner Essential for Success?

Michael, you have told me about past experiences with equipment suppliers who were quick to sell but slow to support. This lack of trust is a major barrier. Finding a true partner means more than just buying a machine; it means securing expert guidance, reliable after-sales service, and a deep understanding of your unique factory challenges—from production bottlenecks to safety concerns. Without the right partner, even the best technology can fall short of its potential.

**Choosing the right packing machine partner is absolutely critical because they offer more than just machinery. A reliable partner provides invaluable industry expertise, customized solutions tailored to your specific needs, and robust after-sales support. This ensures your investment genuinely solves your factory’s challenges, optimizes performance, and drives long-term business growth, turning a purchase into a strategic partnership.**

My journey, from working on the factory floor to building FHOPEPACK, taught me the true value of partnership. It is not just about moving boxes; it is about understanding the entire ecosystem of a factory. A good partner listens. They understand your pain points. They provide insights born from years of experience. They stand by their products long after the sale. This commitment is what builds trust and ensures your long-term success. It means you have someone to call when a problem arises. It means you have someone who can help you plan for future expansions. It means they share your vision for efficiency and safety.

### 🤝 Expertise and Deep Industry Knowledge

A true partner brings extensive industry knowledge to the table. They understand the intricacies of steel coil manufacturing, specific packing challenges, and global industry standards. This expertise allows them to recommend not just a machine, but a complete solution that fits your factory’s unique environment and goals. They can offer insights into best practices. They can help you avoid common pitfalls. For example, knowing the nuances of different steel grades or coil sizes helps them suggest the right strapping tension or wrapping material. This deep understanding is crucial for maximizing your investment. This ensures the equipment performs optimally from day one. This is packing machine expertise you can rely on.

### 🔧 Reliable After-Sales Support and Technical Service

The longevity and efficiency of your packing line depend heavily on reliable after-sales support. A good partner provides comprehensive installation services, thorough training for your operators and maintenance staff, and readily available spare parts. They offer prompt technical assistance when issues arise. This minimizes downtime and keeps your production running smoothly. Poor support can turn a state-of-the-art machine into a costly liability. A committed partner ensures your equipment remains operational and productive for years to come. This peace of mind is invaluable. It protects your investment and ensures continuous operation. This ensures equipment reliability.

### 💡 Customized Solutions for Unique Factory Challenges

Every factory has its unique layout, production volume, and specific packing requirements. A one-size-fits-all approach rarely works. An ideal partner offers customized packing solutions that integrate seamlessly into your existing operations. They assess your factory floor. They analyze your production flow. They design a system that addresses your specific bottlenecks and safety concerns. This tailored approach ensures maximum efficiency and the best possible ROI. For example, if you need to integrate the packing line with an existing ERP system, a skilled partner can develop that interface. They solve your specific problems, not just sell you a standard product. When you look for partners, consider those known for their innovation, like Fengding, or for their reliable, robust solutions, such as Wuxi Buhui. However, always remember the core principle: a good partner listens to your unique challenges. (trusted supplier, packing machine expertise, after-sales service, technical support, customized solutions, long-term partnership, equipment reliability, industry knowledge)

## Conclusion

Automated steel coil strapping and packing lines fundamentally enhance factory safety by removing manual risks and drastically cut labor costs through increased efficiency. They also boost product quality and operational speed. Partnering with an expert like FHOPEPACK ensures you get tailored solutions and support, turning your investment into a strategic asset for growth. Explore our [steel coil packing line](https://www.fhopee.com/cn/gangjuanxian/index.html "steel coil packing line manufacturer") options today.