How Steel Coil Packing Machines Support Heavy-Duty Coil Production in Factories

Are you facing constant pressure to boost your factory’s output while keeping costs down? Is your current packing process a bottleneck, struggling to keep up with the demands of heavy-duty steel coil production? Many factory managers, like Michael Chen in Mexico, find themselves navigating these exact challenges. They wrestle with slow, manual packing, the constant risk of worker injury, and the frustration of product damage. It’s a tough situation, but there’s a proven solution that I’ve seen transform countless operations.

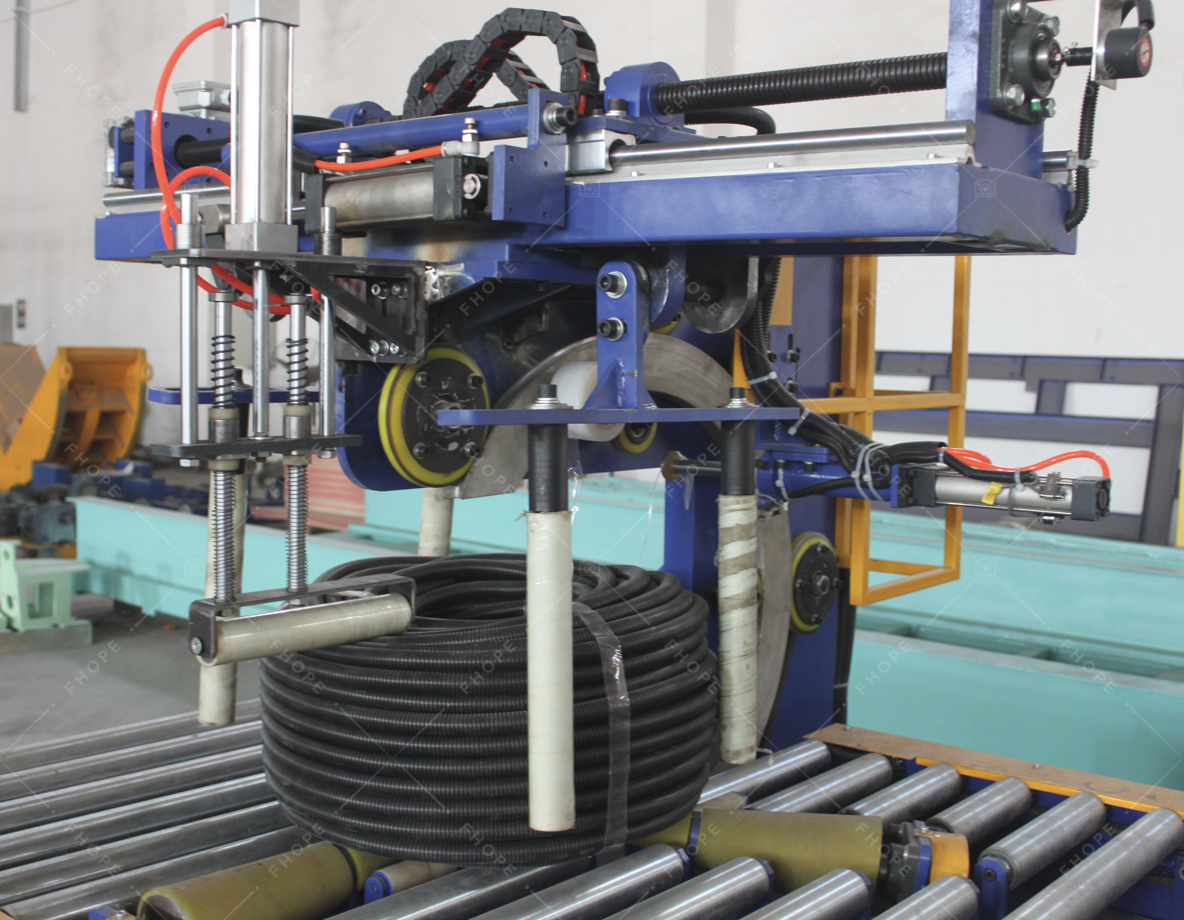

Steel coil packing machines are vital for heavy-duty production because they automate the demanding process of wrapping, bundling, and securing large steel coils. This automation directly addresses common factory challenges like slow manual packing, high labor costs, and significant risks of product damage and worker injury. By integrating these machines, factories can achieve consistent, high-quality packaging, boost throughput, and ensure safer operations, making them essential for any modern heavy-duty coil production environment.

I understand the pressures you face. I built my career in this industry, from the factory floor to owning my own successful packing machine factory. I’ve seen how the right equipment can transform a business. Let’s dive into how these machines directly tackle your biggest operational hurdles.

1. How do automated steel coil packing machines boost factory output?

Is your packing line a bottleneck, slowing down your entire production? Are manual methods eating into your delivery times and customer satisfaction? Many factories struggle to keep up with demand because their end-of-line processes simply cannot match the pace of manufacturing. This inefficiency impacts everything, from production schedules to customer loyalty. Automated steel coil packing machines provide the speed and consistency you need to keep production flowing smoothly.

Automated steel coil packing machines significantly boost factory output by eliminating manual labor from repetitive and time-consuming tasks. They perform packaging steps like wrapping, banding, and strapping much faster and more consistently than human workers. This automation allows for continuous operation, reducing downtime and accelerating the overall production cycle from manufacturing to shipment. As a result, factories can process more coils per shift, meet tighter deadlines, and increase their total output capacity.

Automated packing systems are a game-changer for factories producing heavy steel coils. I have seen firsthand how they revolutionize efficiency. For instance, in a typical heavy steel processing plant, manually wrapping a single large coil can take 10 to 15 minutes, often requiring multiple workers. An automated machine can complete the same task in less than 2 minutes, often with only one operator overseeing the process. This dramatic speed increase means a factory can pack significantly more coils in a single shift. Furthermore, these machines offer unparalleled consistency. Each coil gets the same protective wrapping and secure banding, every time. This consistency reduces errors, minimizes rework, and ensures that packaging quality never dips, even during peak production periods. This is crucial for maintaining high standards in steel coil export and local distribution.

Consider the continuous operation benefit. Automated systems can run for extended periods without fatigue, breaks, or the need for shift changes in the same way human workers do. This means less downtime and more active production hours. For a factory manager like Michael, this translates directly into higher throughput and the ability to meet aggressive production targets. The integration of these machines into an existing production line is also seamless. They can be linked with overhead cranes, coil conveyors, and strapping machines to create a fully integrated steel coil packaging line. This connectivity removes manual transfer points, which are often sources of delays and inefficiencies. The overall result is a streamlined process where coils move from production to ready-for-shipment much faster, directly enhancing the factory’s operational efficiency and competitive edge. (heavy-duty coil packaging solutions)

Key Efficiency Boosters of Automated Packing Machines:

- Increased Speed: Machines operate at speeds far exceeding manual labor.

- Manual: 10-15 minutes per coil (multiple workers)

- Automated: <2 minutes per coil (one operator)

- Consistent Quality: Ensures uniform packaging for every coil, reducing errors.

- Reduced Labor: Frees up workers for other critical tasks, lowering operational costs.

- Continuous Operation: Machines can run longer, minimizing downtime.

- Seamless Integration: Connects with other factory systems for a smooth workflow.

- Higher Throughput: More coils packed per shift, increasing overall production volume.

2. Can advanced packing systems truly reduce safety risks in heavy-duty environments?

Are your workers constantly at risk handling heavy coils? Is your factory struggling with high injury rates, rising insurance costs, and employee turnover directly linked to hazardous manual tasks? The safety of your team is paramount, but the sheer weight and awkwardness of steel coils present enormous challenges. Investing in advanced packing systems creates a much safer work environment, protecting your team and your bottom line.

Advanced steel coil packing systems dramatically reduce safety risks in heavy-duty environments by minimizing direct human interaction with massive, dangerous coils. These machines take over tasks like lifting, turning, and securing heavy loads, which are traditionally high-risk for manual workers. By automating these processes, they remove personnel from hazardous areas, significantly lowering the potential for strains, crush injuries, and other accidents. This leads to a safer workplace, fewer incidents, and reduced associated costs like insurance claims.

Safety in a heavy manufacturing plant is not just a regulatory requirement; it is a core value that impacts everything from employee morale to insurance premiums. I’ve witnessed the dangers firsthand – workers straining their backs, fingers caught, and feet crushed when dealing with multi-ton steel coils. Manual handling of these coils, whether for wrapping, strapping, or flipping, creates numerous critical safety hazards. Automated steel coil packing solutions directly address these issues by removing human workers from the immediate vicinity of moving machinery and heavy loads. For instance, instead of workers manually guiding wrapping materials around a coil or struggling to apply steel straps, a machine performs these actions with precision and power. This eliminates the risk of repetitive strain injuries, falling objects, and entanglement with machinery.

Modern packing systems also incorporate advanced safety features. These include protective light curtains, emergency stop buttons easily accessible throughout the machine’s perimeter, and interlocked guarding that prevents access to moving parts during operation. Remote control options allow operators to manage the packing process from a safe distance, further reducing exposure to potential hazards. For a factory manager like Michael, this means a significant reduction in workplace accidents, which translates to lower workers’ compensation claims, reduced insurance premiums, and fewer lost workdays due to injury. Beyond the financial benefits, a safer workplace leads to higher employee morale, reduced turnover, and a more positive working environment overall. This investment in safety through automation pays dividends in human well-being and operational stability. (industrial coil packaging safety)

How Automated Systems Enhance Workplace Safety:

- Minimized Human-Coil Interaction: Workers are kept away from heavy, moving coils.

- Automated Handling: Machines lift, turn, and secure coils, preventing manual strain and crush injuries.

- Integrated Safety Features:

- 🛑 Emergency Stop Buttons

- 🚧 Safety Guards and Interlocks

- 💡 Light Curtains

- 🛡️ Protective Barriers

- Remote Operation: Operators can control machines from a safe distance.

- Reduced Accidents: Lower rates of strains, sprains, and impact injuries.

- Cost Savings: Decreased workers’ compensation and insurance costs.

- Improved Morale: A safer environment fosters happier, more productive employees.

3. What impact do current packing methods have on product quality and losses?

Are you dealing with customer complaints about damaged steel coils, especially around the edges? Is product damage during packing and internal handling eating into your profits and hurting your reputation? Many factories inadvertently cause damage to their valuable products simply by using outdated or inefficient packing methods. This leads to costly reworks, returns, and ultimately, a loss of trust with clients. Understanding how current packing methods cause damage is the first step to protecting your products and improving your bottom line.

Current manual or outdated packing methods frequently lead to product damage and profit loss primarily due to inconsistent handling and inadequate protection of steel coils. When workers manually maneuver heavy coils, edges can be bent, surfaces scratched, or packaging improperly applied, making coils vulnerable to damage during storage or transit. This results in customer rejections, costly reworks, and diminished profitability, directly impacting a factory’s reputation and financial health.

The quality of a packed steel coil is just as important as the quality of the steel itself. I have visited countless factories where beautifully manufactured coils leave the production line, only to suffer damage during the final packing stage. Michael’s concern about product loss is very real. Manual processes are often inconsistent. One worker might wrap a coil securely, while another might rush, leading to loose wrapping or exposed edges. These vulnerabilities become critical during internal transfers, warehousing, and especially during transit. The edges of steel coils, in particular, are susceptible to damage like denting or bending if not properly protected with edge boards or robust wrapping. When a customer receives a damaged coil, it leads to complaints, potential financial penalties, and a tarnished reputation.

Automated steel coil packing machines are engineered to prevent these issues. They apply packaging materials with precise tension and coverage, ensuring every part of the coil, including vulnerable edges, is adequately protected. Options for advanced wrapping materials, VCI (Volatile Corrosion Inhibitor) paper, and specific edge protection systems can be integrated directly into the machine’s operation. This consistent, high-quality packaging minimizes the risk of scratches, dents, and corrosion. Furthermore, automated handling systems, such as coil tilters and specialized conveyors, move coils smoothly and without impact, eliminating the damage often caused by forklifts or cranes bumping coils around. For Michael, this means fewer customer complaints, a reduction in scrap material, and a clear improvement in the quality of delivered products, leading to higher customer satisfaction and better profit margins. (steel coil protection solutions)

Common Sources of Product Damage & Automated Solutions:

| Problem Source (Manual) | Impact on Product Quality | Automated Solution (FHOPEPACK) |

|---|---|---|

| 🧑🏭 Inconsistent Manual Wrapping/Strapping | Loose packaging, exposed edges, corrosion risks | ✅ Precise tension control, uniform material application |

| 🚚 Rough Handling during Internal Transfer | Scratches, dents, deformation | ✅ Automated conveyors, coil tilters for smooth movement |

| 📦 Inadequate Edge Protection | Bent coil edges, structural damage | ✅ Integrated edge board applicators, robust wrapping layers |

| 💧 Exposure to Moisture/Dust | Rust, surface degradation | ✅ Hermetic wrapping, VCI paper integration |

| 📉 Inaccurate Packaging Measurements | Excess material waste, insufficient protection | ✅ Automated material cutting and precise application |

4. What should factory managers look for in a reliable packing machine partner?

Have you been let down by equipment suppliers who only care about the sale? Are you wary of making a significant investment without true partnership and expertise? It’s a common challenge in this industry. Many suppliers offer machines but lack the deeper understanding of your specific production bottlenecks, safety concerns, and efficiency dilemmas. Finding a reliable packing machine partner means looking beyond the machine itself to a deep understanding of your operational needs and a commitment to your long-term success.

Factory managers like Michael should look for a packing machine partner who offers more than just equipment; they need a partner with deep industry expertise, a proven track record of solving real-world production challenges, and a strong commitment to after-sales support. A reliable partner will understand specific operational bottlenecks, prioritize ROI, and provide tailored solutions, acting as a true consultant rather than just a vendor. They should demonstrate their ability to deliver durable, efficient machinery backed by comprehensive service and technical guidance, ensuring the investment truly drives business growth.

My own journey, starting as a packing machine engineer and then building FHOPEPACK, has taught me the immense value of a true partnership. I achieved financial independence and helped many clients grow their businesses not just by selling machines, but by understanding their unique challenges and offering solutions that truly worked. This is the core of what a reliable packing machine partner should offer. First, they must possess deep industry expertise, not just in machine mechanics but in the entire heavy-duty coil packing process, from material flow to logistics. This knowledge allows them to identify real pain points and propose truly effective solutions, not just generic equipment. For Michael, this means finding someone who understands the nuances of coil packing for various metals and sizes, someone who has walked the factory floor.

Secondly, a trustworthy partner provides excellent after-sales service and ongoing support. A machine is an investment, and like any investment, it requires maintenance, spare parts, and occasional troubleshooting. Michael has faced suppliers who disappear after the sale. A reliable partner, however, offers robust technical assistance, readily available spare parts, and training for your staff. This ensures maximum uptime for your equipment and protects your investment. Finally, they should be focused on your Return on Investment (ROI). They should help you quantify the benefits of automation – labor savings, reduced product damage, increased throughput – to demonstrate how their solution directly contributes to your factory’s profitability. This holistic approach, from initial consultation to long-term support, defines a valuable partnership. (heavy industrial packaging consultation)

Checklist for Choosing Your Packing Machine Partner:

- Industry Expertise: Do they understand your specific production environment and challenges (e.g., coil packing, steel wire packing)?

- Problem-Solving Focus: Do they offer tailored solutions, not just off-the-shelf machines?

- Proven Track Record: Can they provide case studies or references from similar heavy-duty factories?

- After-Sales Support: Is there a clear plan for maintenance, spare parts, and technical assistance?

- ROI-Driven Proposals: Do they help you quantify the financial benefits of their solutions?

- Customization Capabilities: Can they adapt machines to your unique coil sizes, materials, and factory layout?

- Commitment to Safety: Do their machines meet international safety standards and help improve your workplace safety?

- Transparency & Trust: Are they open and honest about capabilities, timelines, and costs?

Conclusion

Automated steel coil packing machines transform heavy-duty production by boosting efficiency, enhancing safety, and protecting product quality. Partnering with experts like FHOPEPACK ensures your investment in a steel coil packing line delivers lasting value and growth.